High-performance ball socket

a ball socket, high-performance technology, applied in the direction of shafts, bearings, pivots, etc., can solve the problems of shortening the service life of the ball socket joint, tribologically well suited in the unreinforced form, and unable to meet the needs of unreinforced form, so as to achieve the effect of increasing the service li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

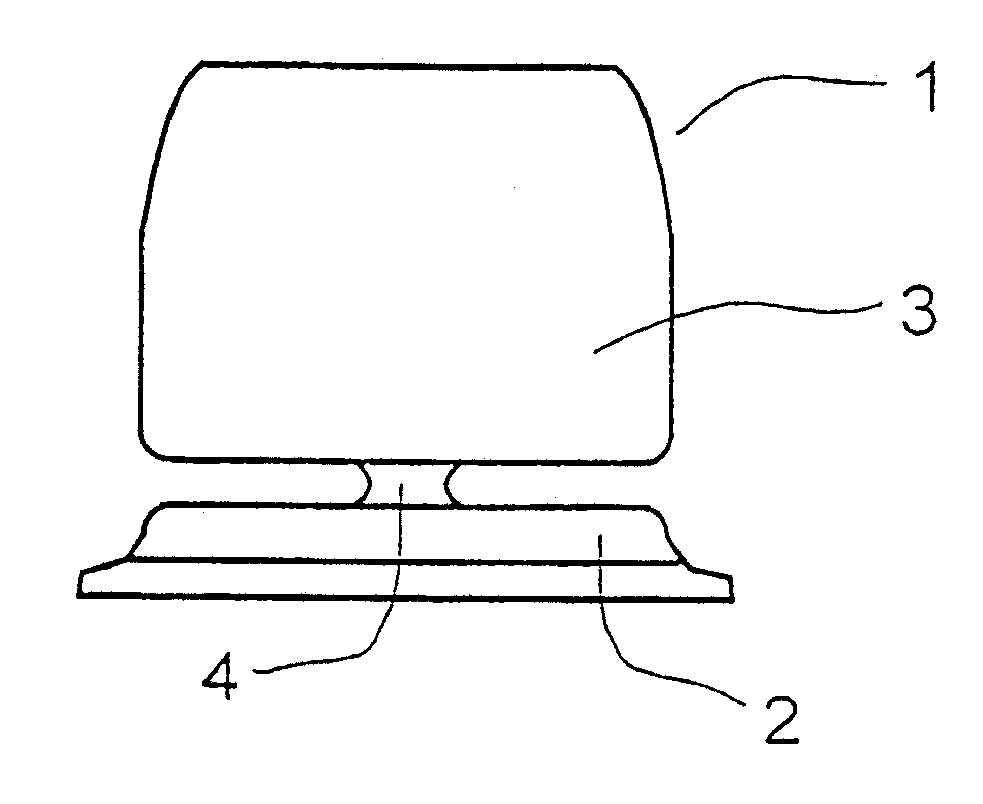

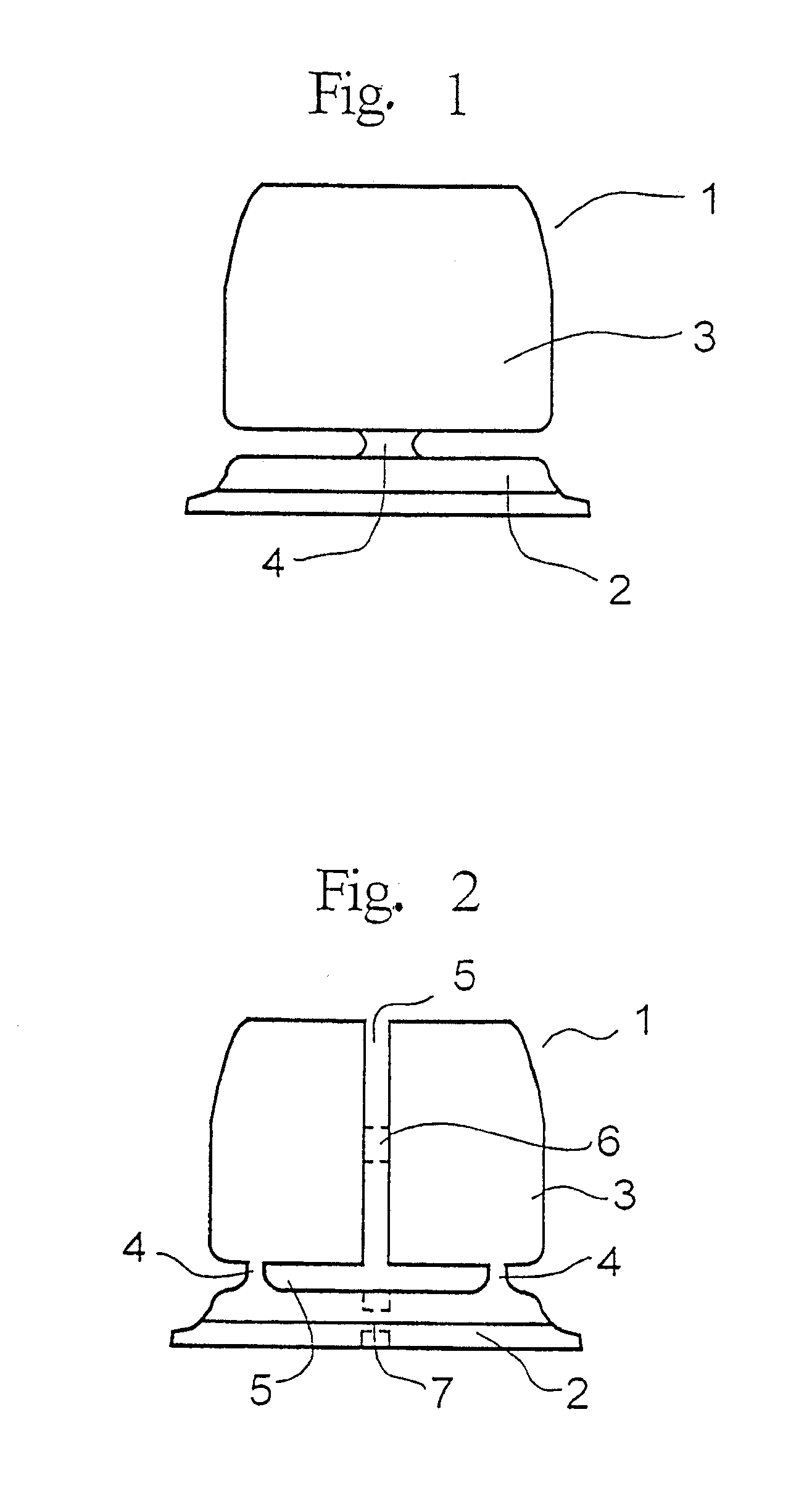

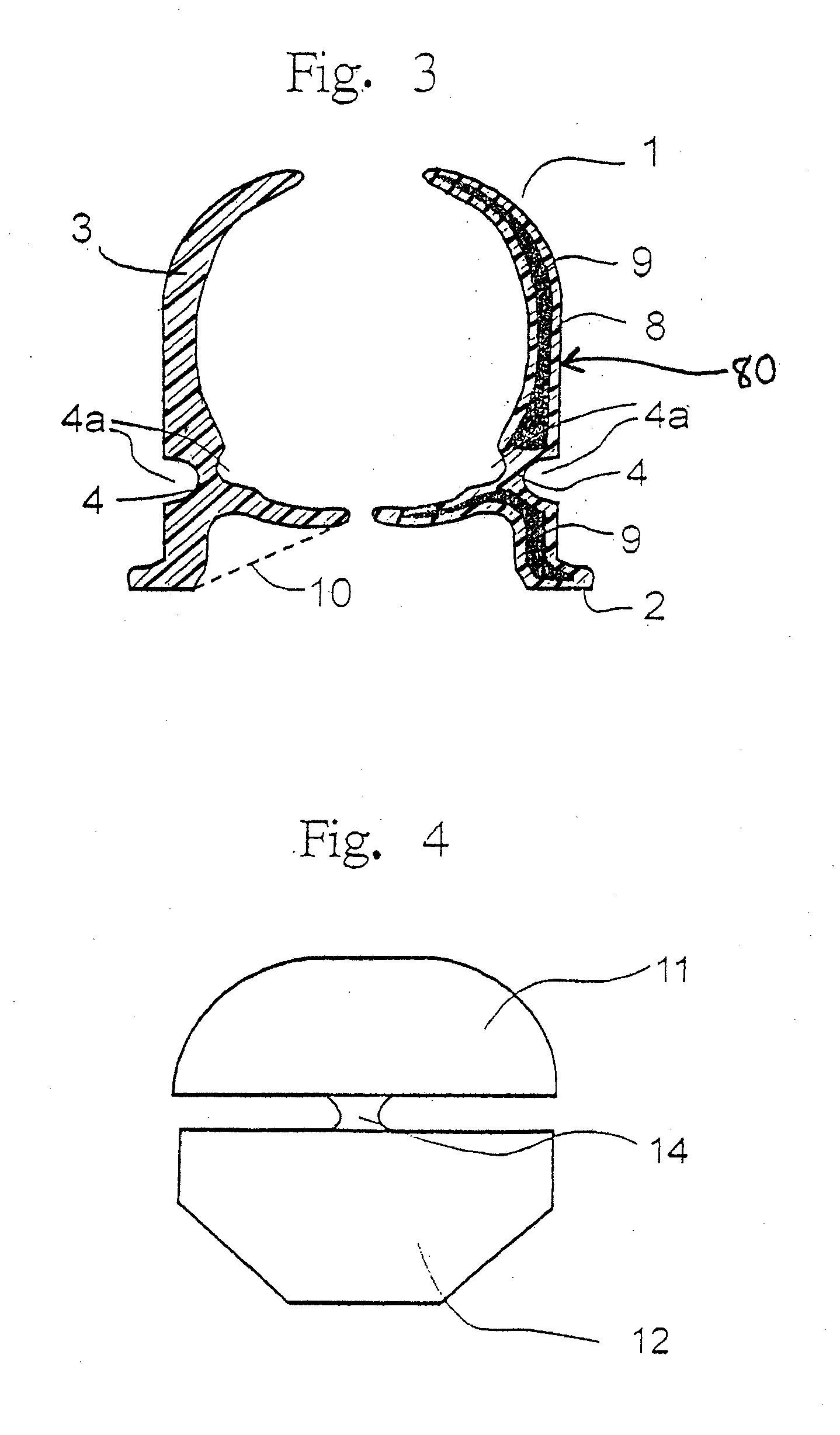

[0023] Referring to the drawings, FIGS. 1 through 3 show a bearing shell 1 of a ball and socket joint loaded mainly radially. The bearing shell has a one-part design and has a basic body 2, with which a bearing shell part 3 comprising a joint ball is made integrally in one piece. To simplify the mounting, the bearing shell 1 is provided with elastic webs 4 and slots 5, which enable the bearing shell 1 to expand elastically during the mounting operation. Weakening of the plastic, which is otherwise common, and which may lead to rupture of the bearing shell due to the strain of the plastic during the mounting operation, is counteracted by the elastic expansion already during the mounting operation.

[0024] The bearing shell according to FIG. 1 is intended mainly for radially loaded ball and socket joints. The elastic web 4 is designed such that, combined with a circular slot 5, the bearing shell can expand elastically without the application of any great force during the mounting (see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com