Patents

Literature

57results about How to "Realize one-time processing and molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

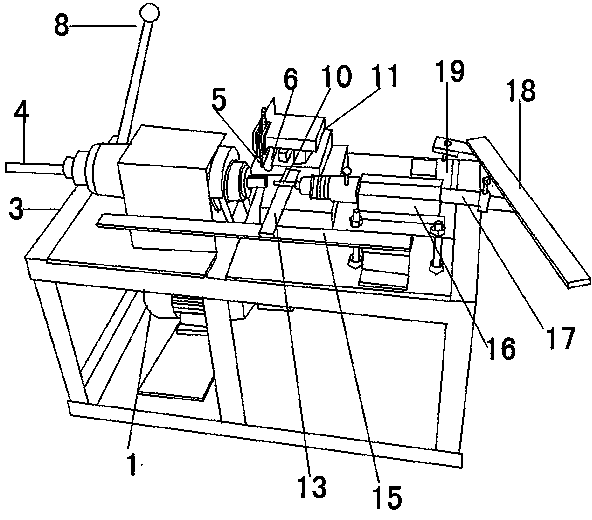

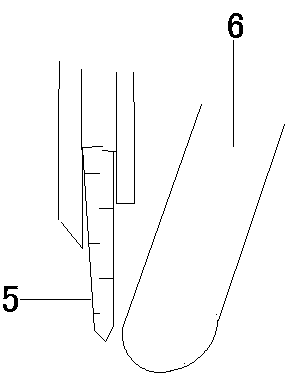

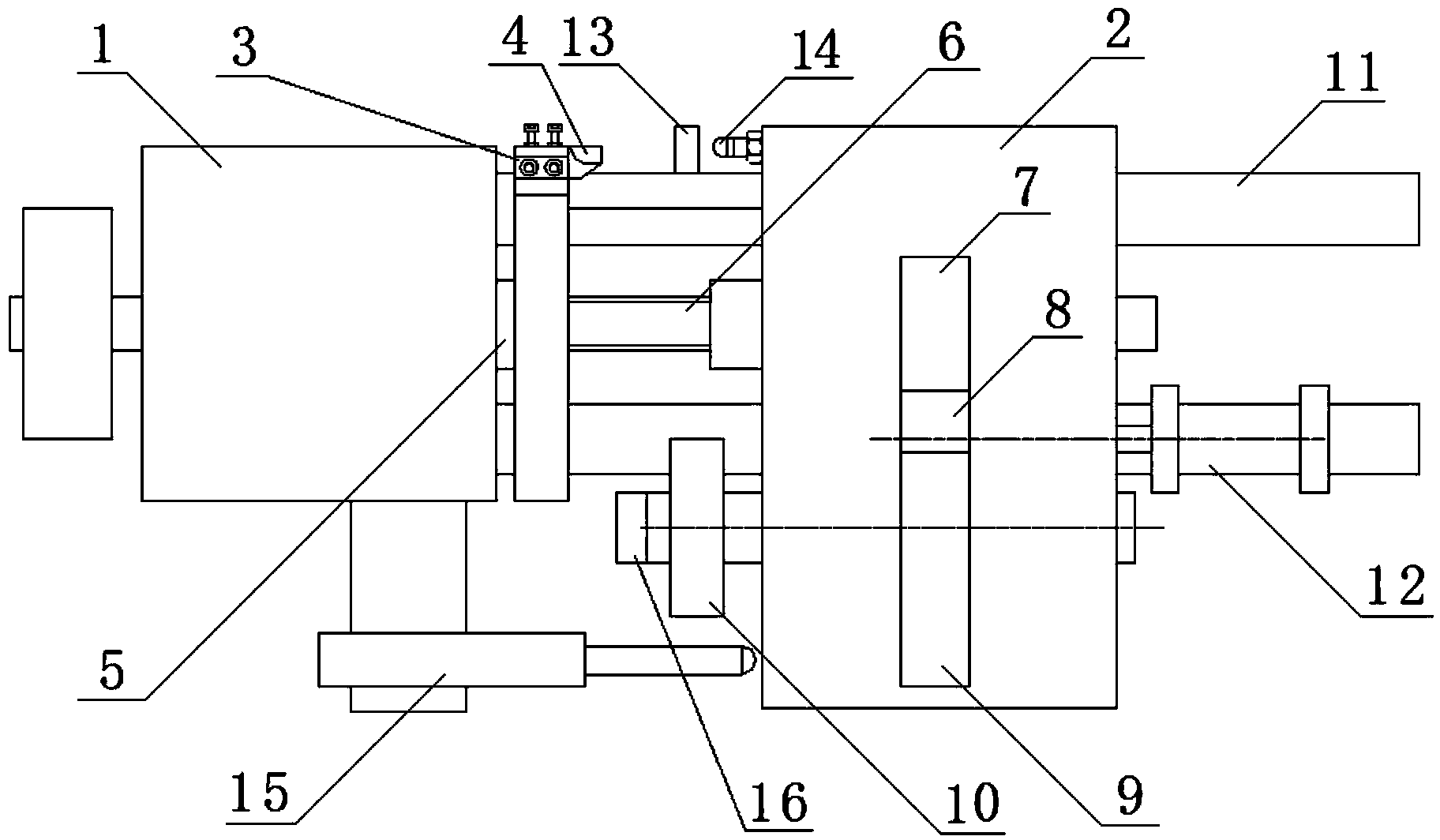

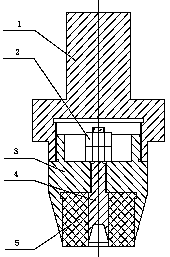

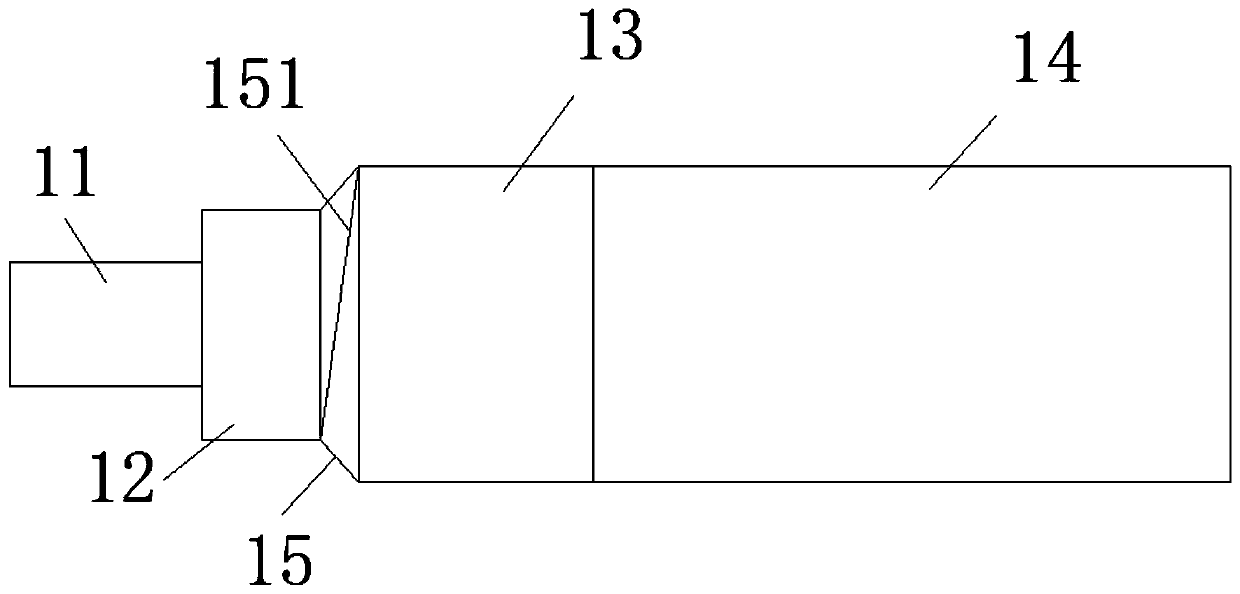

Buddha-bead forming drilling machine

ActiveCN104042004AEasy to useRealize one-time processing and moldingMulti-purpose machinesJewelleryEngineeringTime processing

The invention relates to a buddha-bead forming drilling machine. The Buddha-bead forming drilling machine comprises a motor; the motor is connected with a clutch structure on a frame, and a wood material penetrates the clutch structure; and the frame also is provided with a drilling apparatus for drilling the wood material, and a cut-off knife and a forming knife both capable of making fore and aft movement. By employing the Buddha-bead forming drilling machine, the wood material can be rotated under the driving of the motor; the wood material is firstly drilled by utilizing the drilling apparatus, so that the disadvantages are avoided that drilling is not convenient and drilling is easily off-centered when a conventional Buddha bead is firstly formed and then drilled; and after the wood material is drilled, the cut-off knife and the forming knife are used to polish the wood material for forming a Buddha bead and cut off the Buddha bead from the wood material, so that one-time processing forming is realized, operation is simple and usage is convenient.

Owner:滨州市虎森数控机械研究所

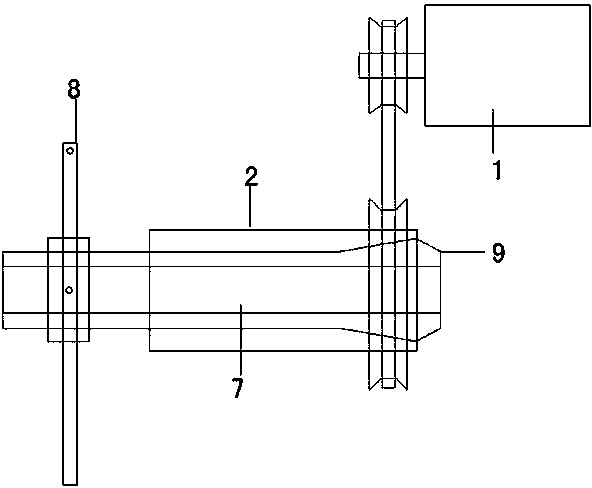

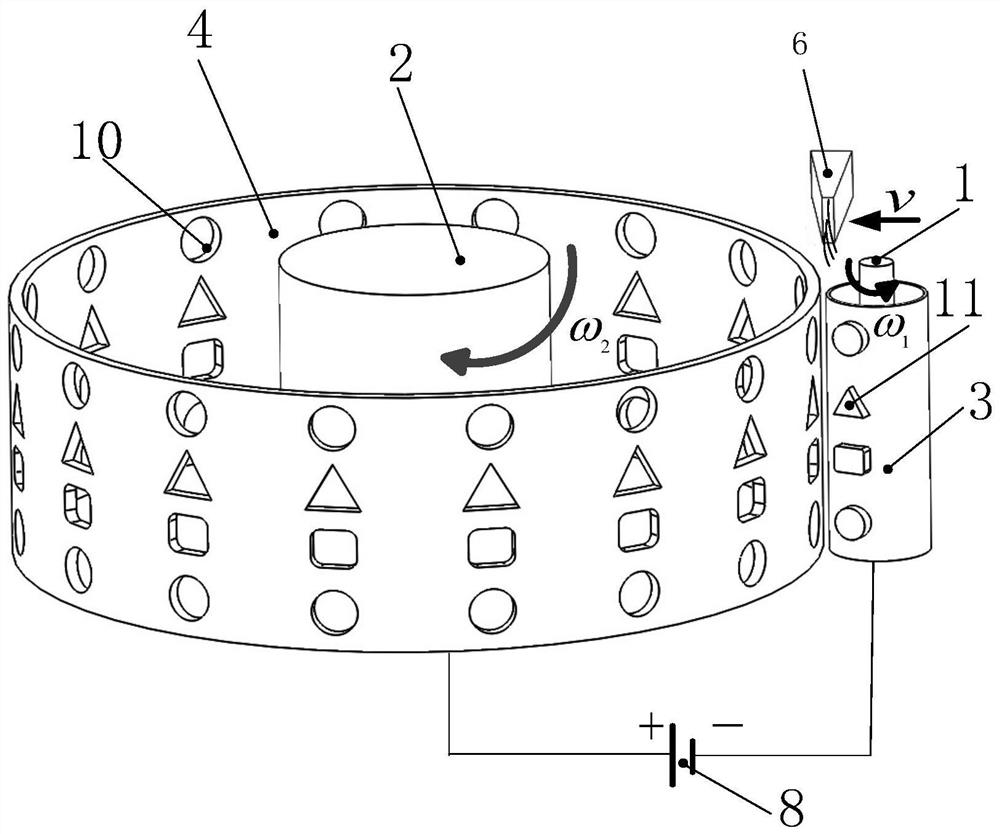

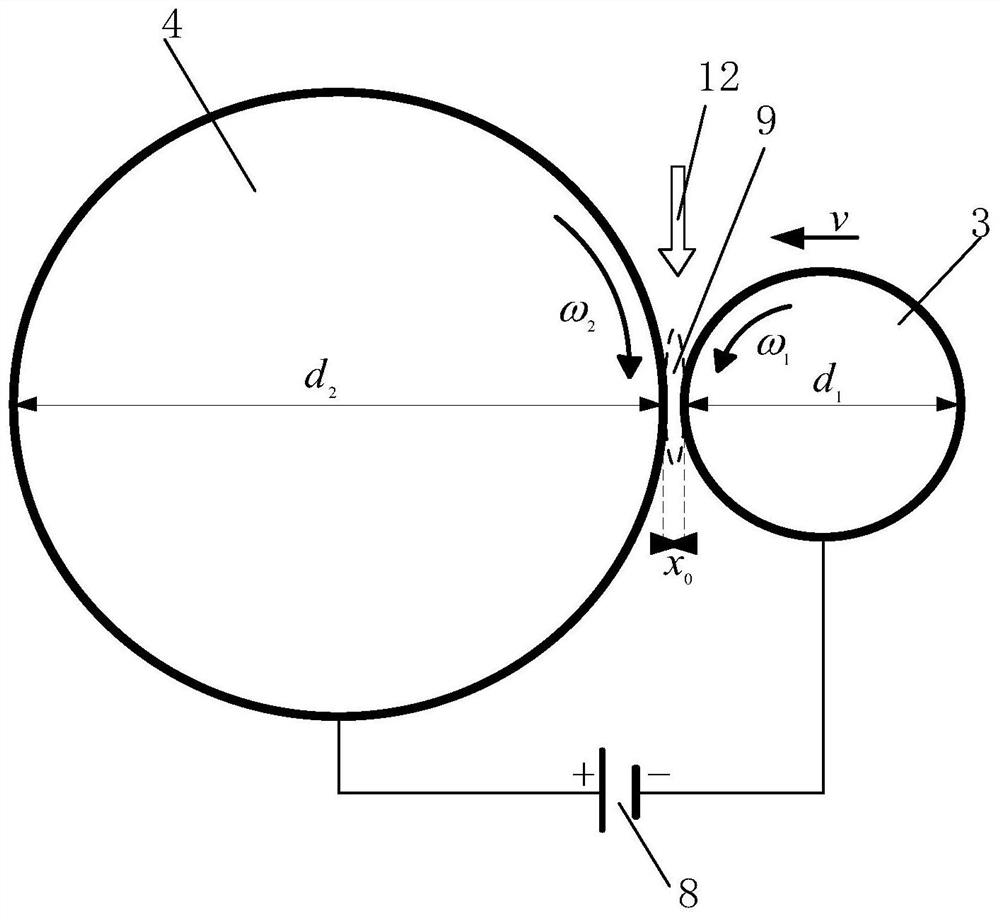

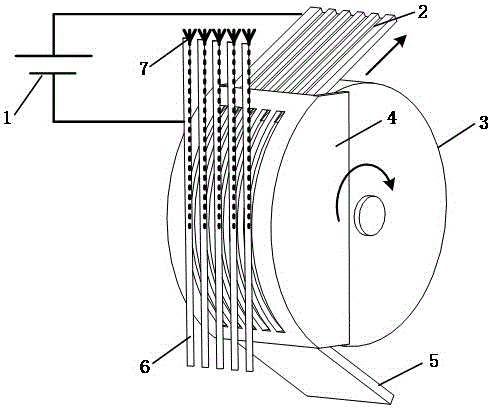

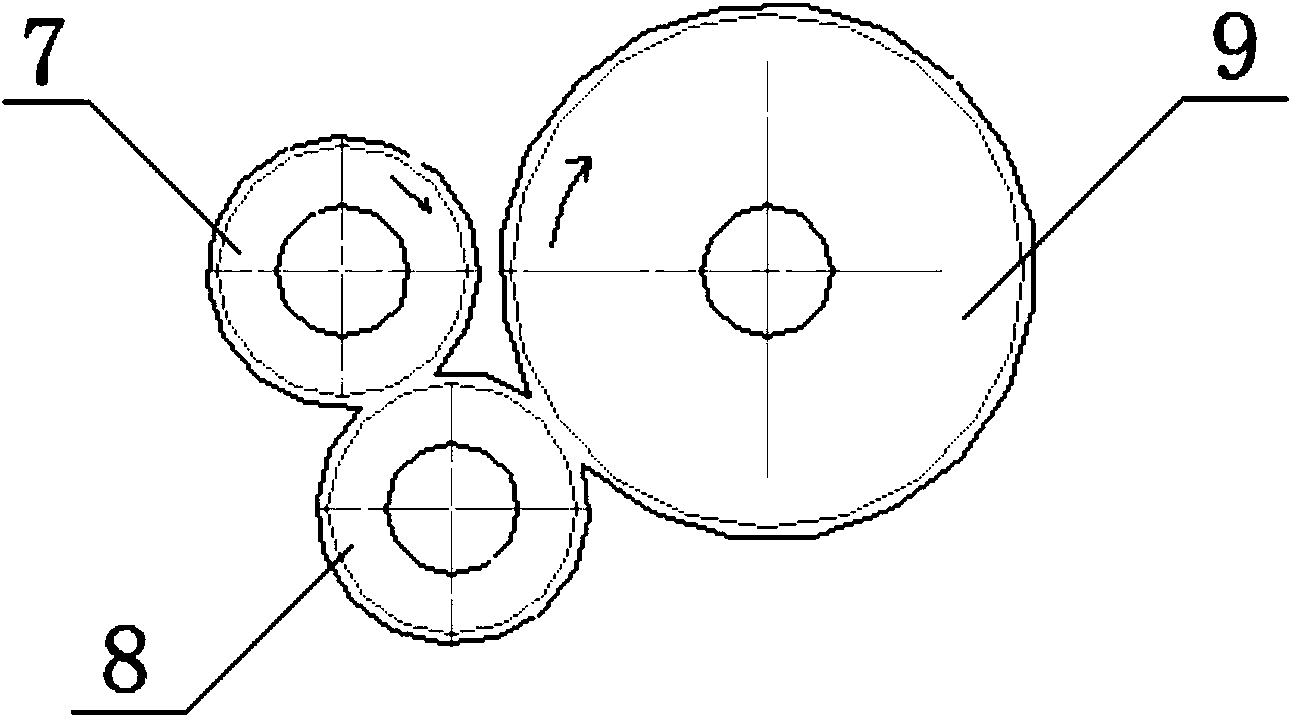

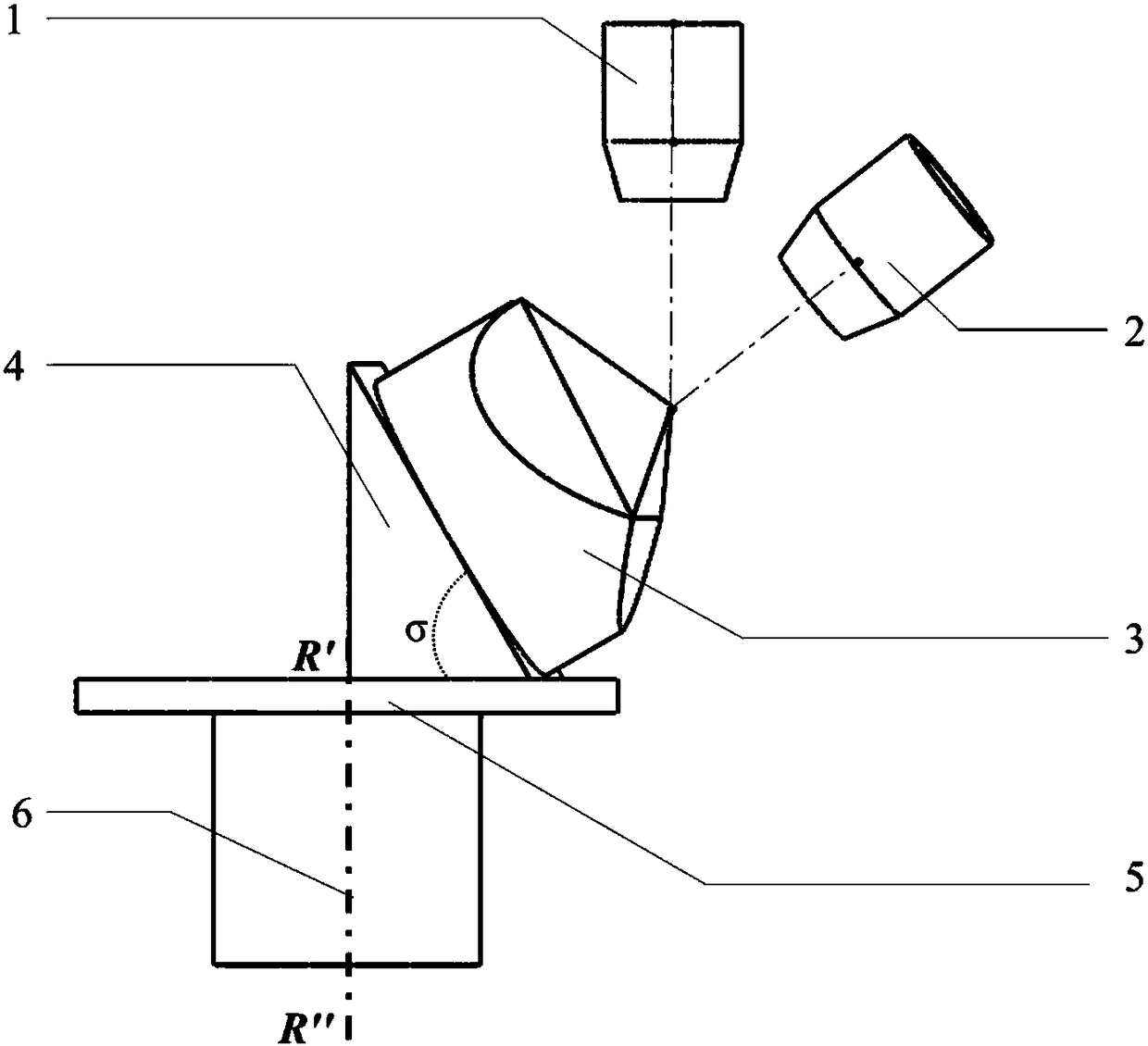

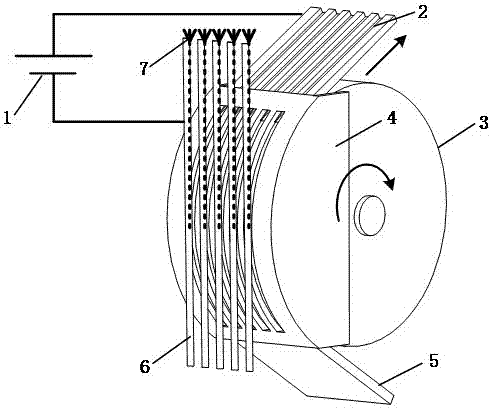

Rotary body surface concave-convex array structure double-rotation-speed rotary printing electrolysis system and method

InactiveCN112676658ASimple structureRealize one-time processing and moldingElectrochemical machining apparatusElectrolysisEngineering

The invention discloses a rotary body surface concave-convex array structure double-rotation-speed rotary printing electrolysis system and method, and belongs to the technical field of electrolytic machining. The machining method is mainly used for machining the concave-convex array structure on the surface of a rotary body part and is characterized in that a tool cathode is of a rotary body structure with the diameter approximate to 1 / n times that of a rotary body workpiece to be machined, and array boss structures or window structures with the number 1 / n times that of concave cavities or boss structures on the surface of the rotary body workpiece are arranged on the surface of the tool cathode. In a machining process, a workpiece anode rotates at a certain angular speed, the tool cathode rotates in a reverse opposite at an angular speed n times that of the workpiece anode, meanwhile, feeding is conducted in a radial direction of the rotary body workpiece, and therefore boss or cavity arrays with the number n times that of window or boss structures on the surface of a workpiece cathode are machined on the surface of the workpiece anode. According to the method, the small-size tool cathode of a simple structure is adopted, and one-time efficient machining of the concave-convex rotary body part with complex arrays can be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

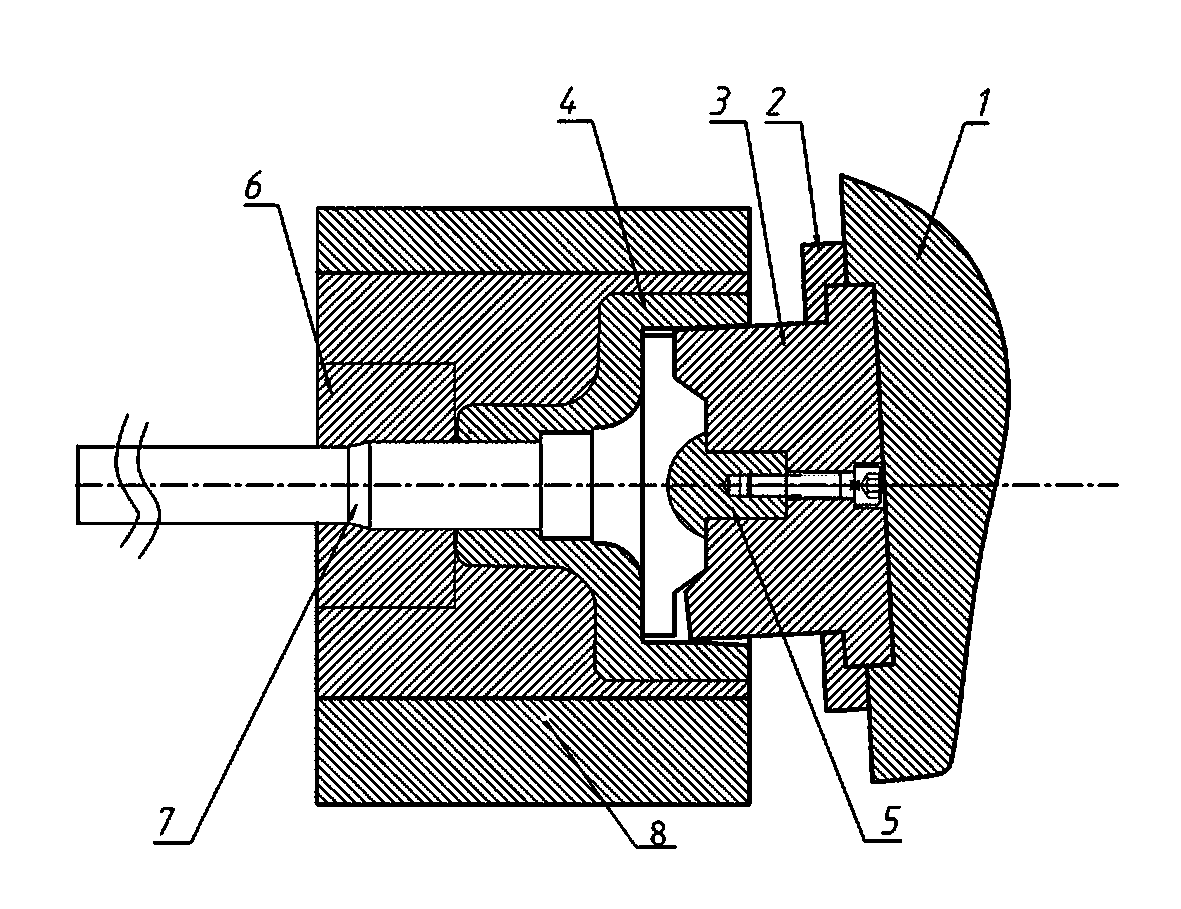

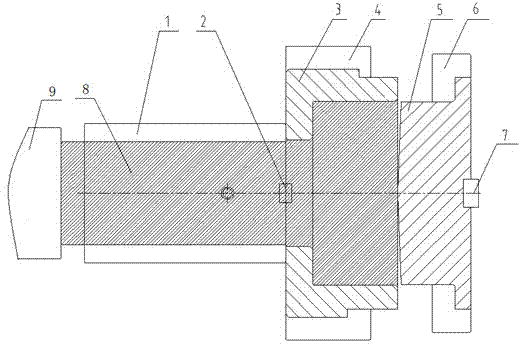

Punching and swing grinding die of half axle with flange disc

InactiveCN103736825ASave man hoursSave materialPerforating toolsForging/hammering/pressing machinesEngineeringMachining time

The invention discloses a punching and swing grinding die of a half axle with a flange disc. The punching and the swing grinding die of the half axle with the flange disc comprises a die sleeve, a terrace die, a connecting die, a terrace die outer bushing and a pressing board. The terrace die is arranged on the flange disc of a half axle forging and ejecting the flange disc, the terrace die and the terrace die outer bushing are in clearance fit and connected through screws, the connecting die is arranged on the axle body section of the half axle forging and fixedly connected with the die sleeve, and the terrace die outer bushing is connected with a swing head through the pressing board. The punching and swing grinding die of the half axle with the flange disc achieves one-step forming of the half axle with the flange disc, saves working hours and materials, facilitates subsequent processes, shortens the overall machining time and improves the machining efficiency.

Owner:LIUZHOU ZHENGLING GROUP

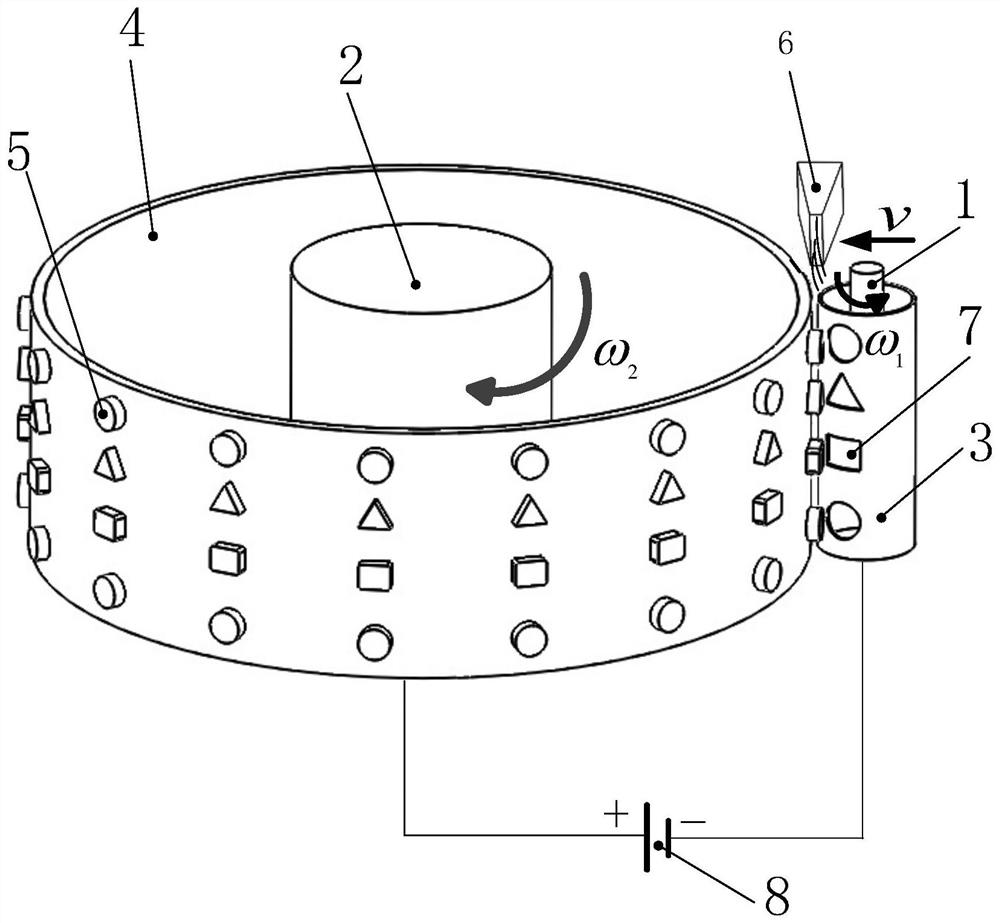

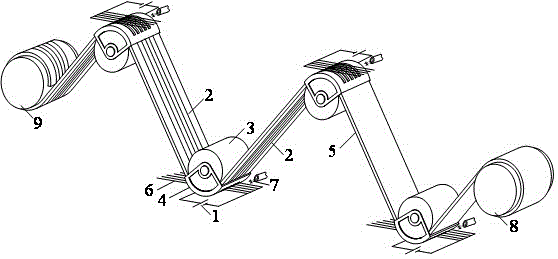

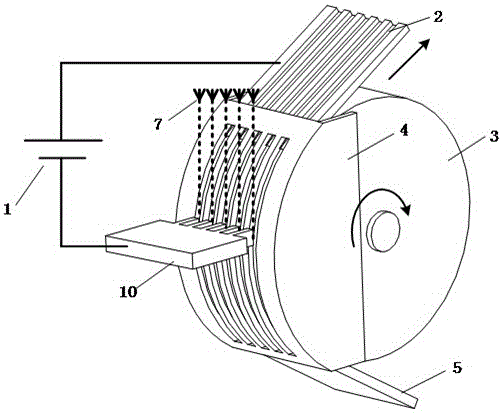

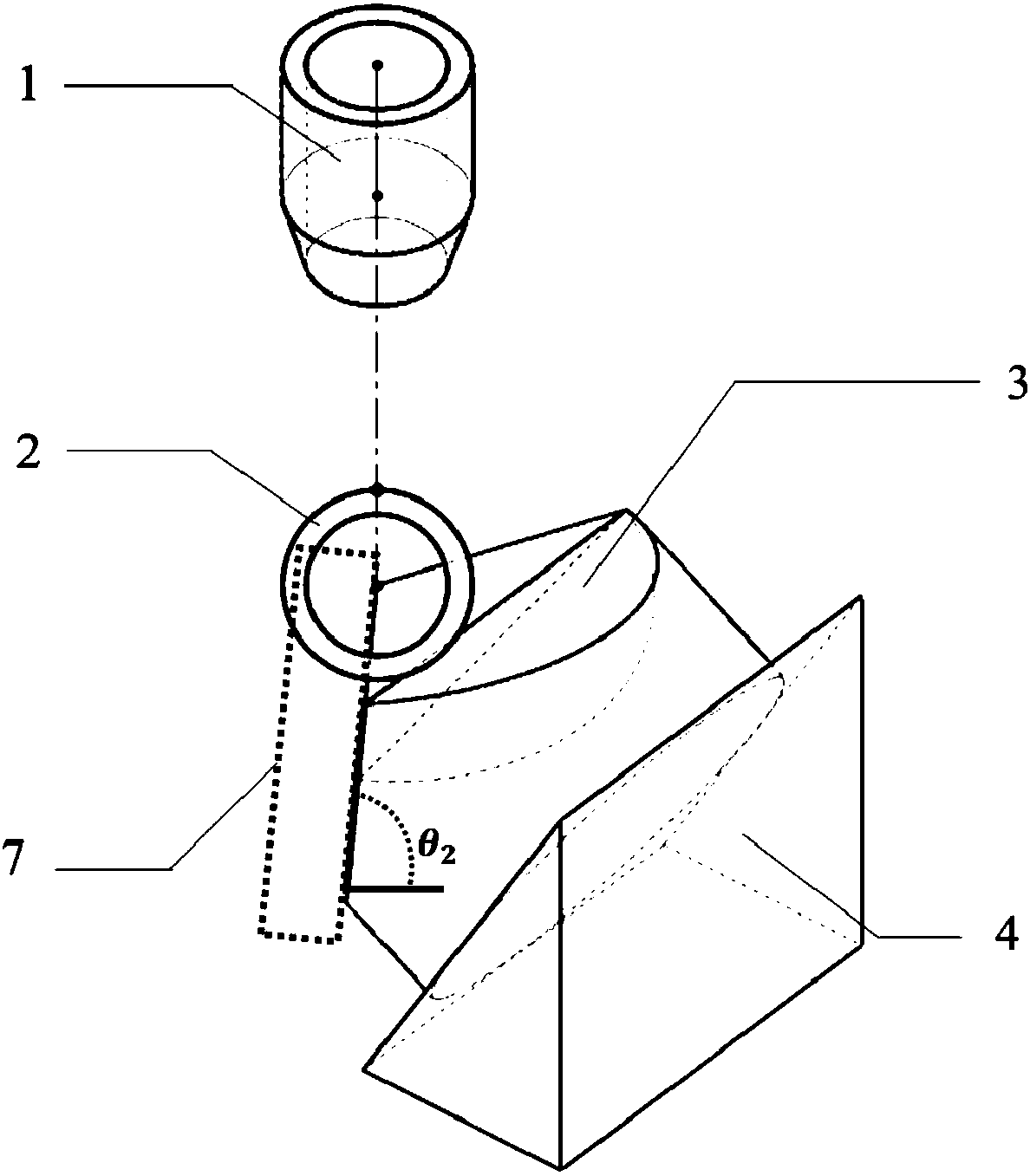

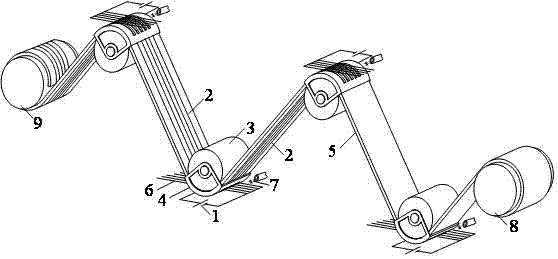

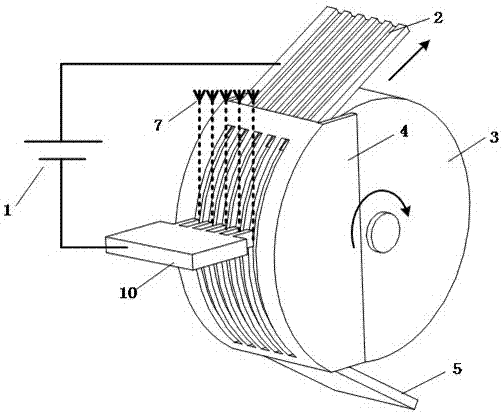

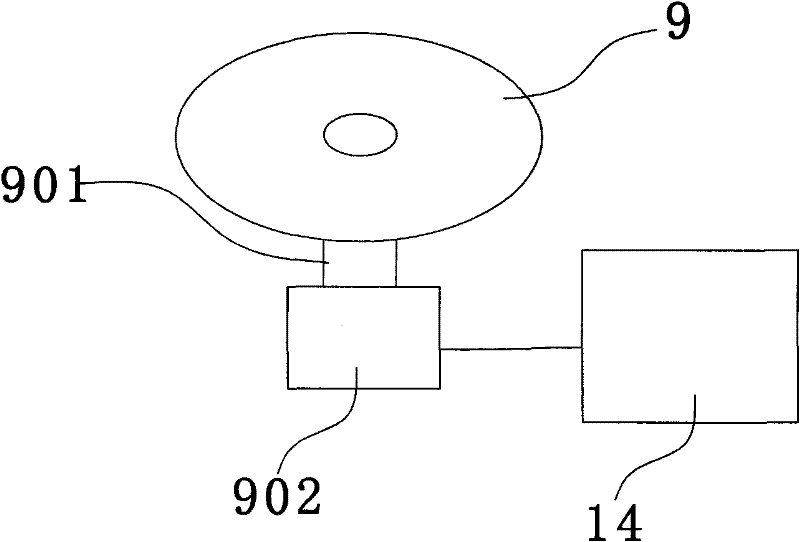

System and method for continuous electrolysis processing of microgroove groups of flexible metal sheet

ActiveCN106270841AImprove processing efficiencyRealize one-time processing and moldingElectrochemical machining apparatusElectricityElectrolysis

The invention relates to a system and a method for continuous electrolysis processing of microgroove groups of a flexible metal sheet, and belongs to the technical field of electrolysis processing. The system comprises a flexible metal sheet workpiece conveying system, an electrolysis processing tool electrode system, a processing power source, an electrolyte circulating system, and an electrolysis processing machine tool. The method comprises the following steps of during processing, firstly, clamping the flexible metal sheet, enabling the flexible metal sheet to penetrate between a plurality of support rollers and an arc-shaped masking plate, and enabling the inner and outer surfaces to tightly attach with the corresponding support rollers and the arc-shaped masking plate; according to the structure and size of each microgroove group, selecting a tool electrode, and completing the clamping; flushing electrolyte, feeding each tool electrode along the radial direction of the corresponding support roller, and processing a groove structure in the surface of the flexile metal sheet; processing to the specified depth, enabling a driving wheel to continuously rotate, and driving the flexible metal sheet to slowly slide along the tangential direction of each roller, so as to complete the continuous processing of the microgroove groups of the flexible metal sheet. The system and the method have the advantages that the tool electrodes can be synchronously performed with auxiliary movement, and the updating of electrolyte and the discharging of electrolysis products are promoted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

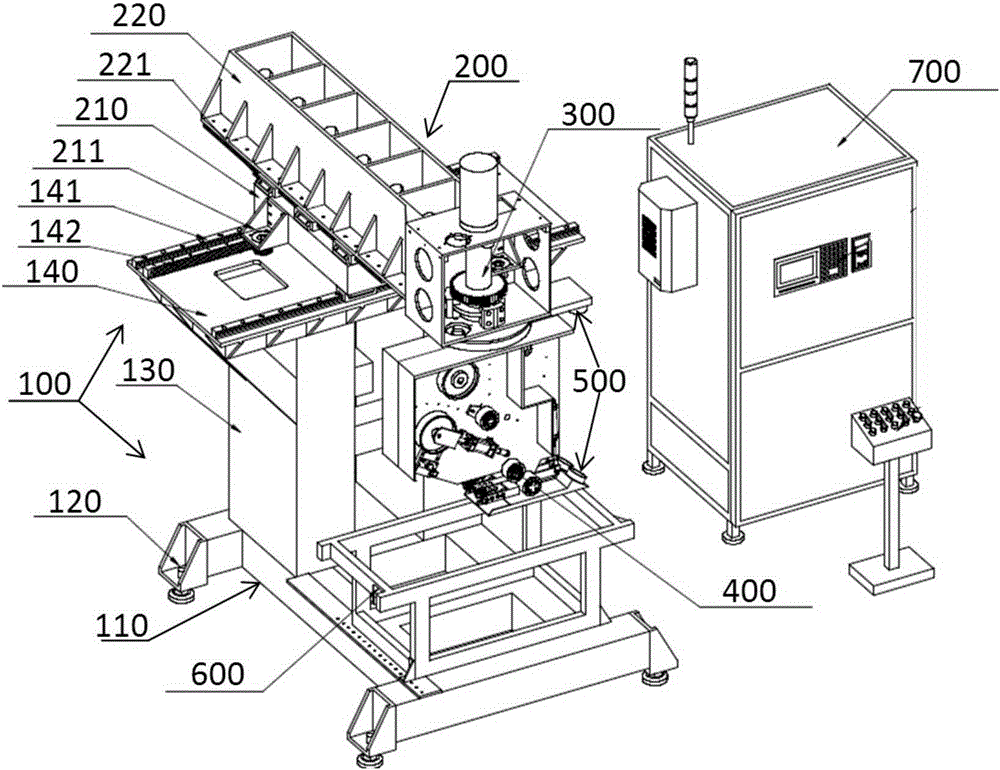

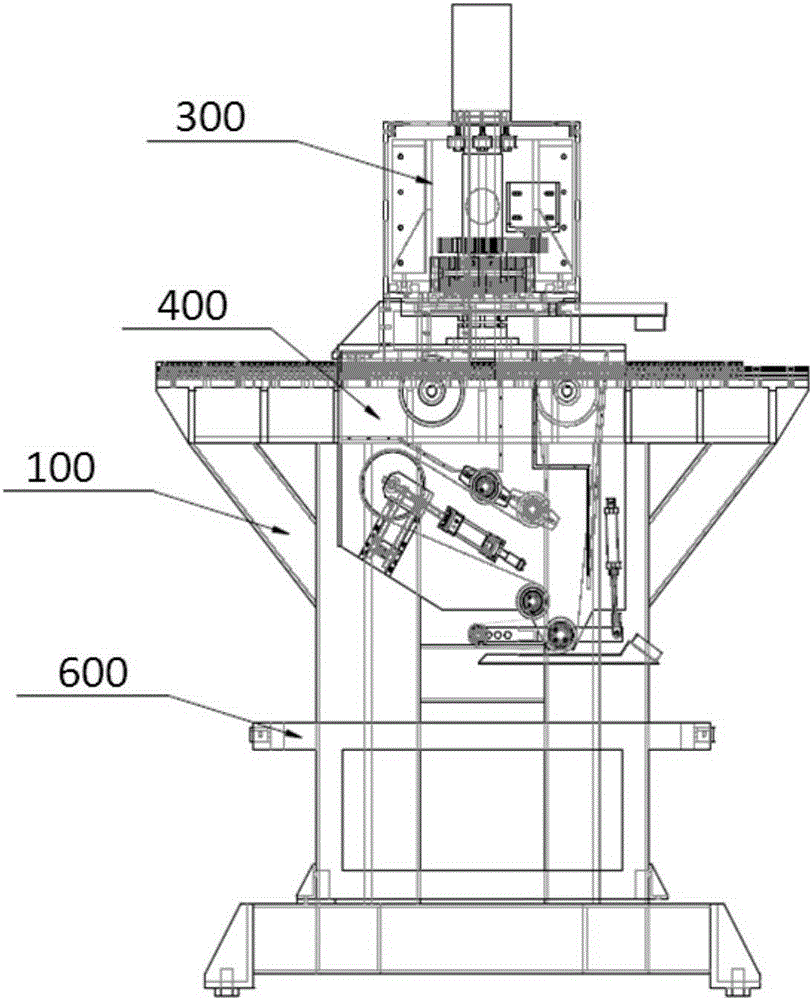

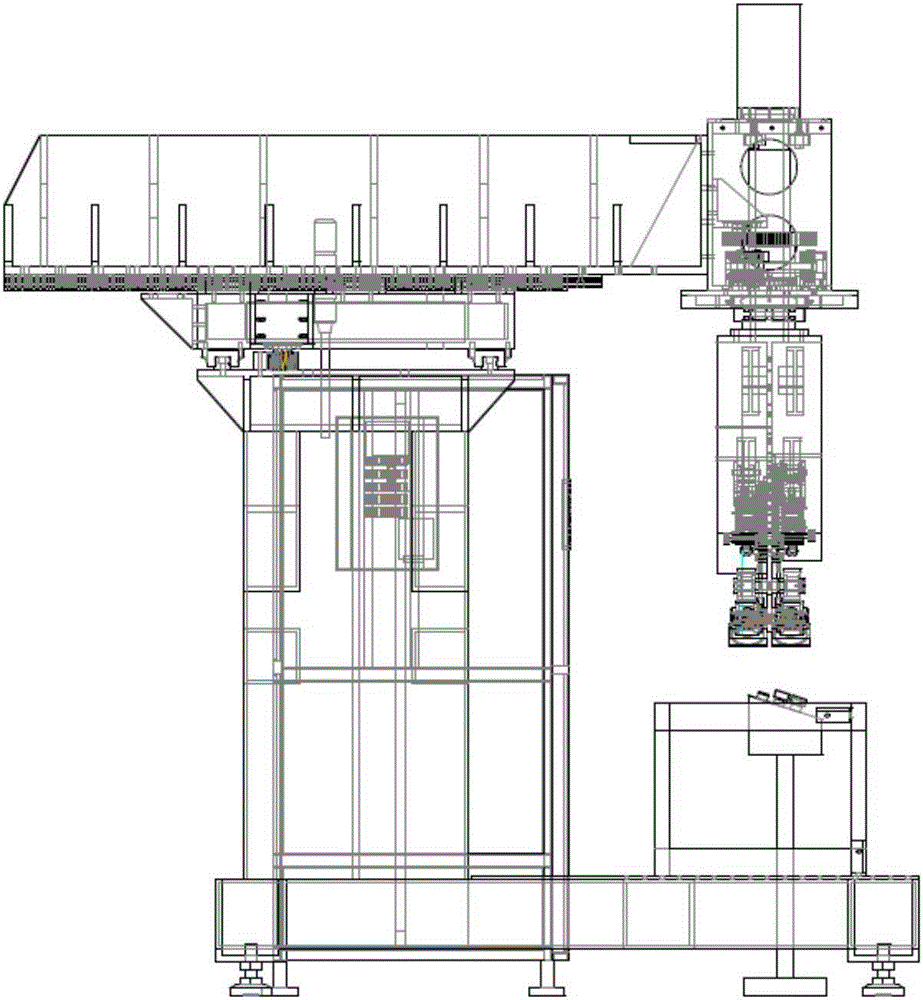

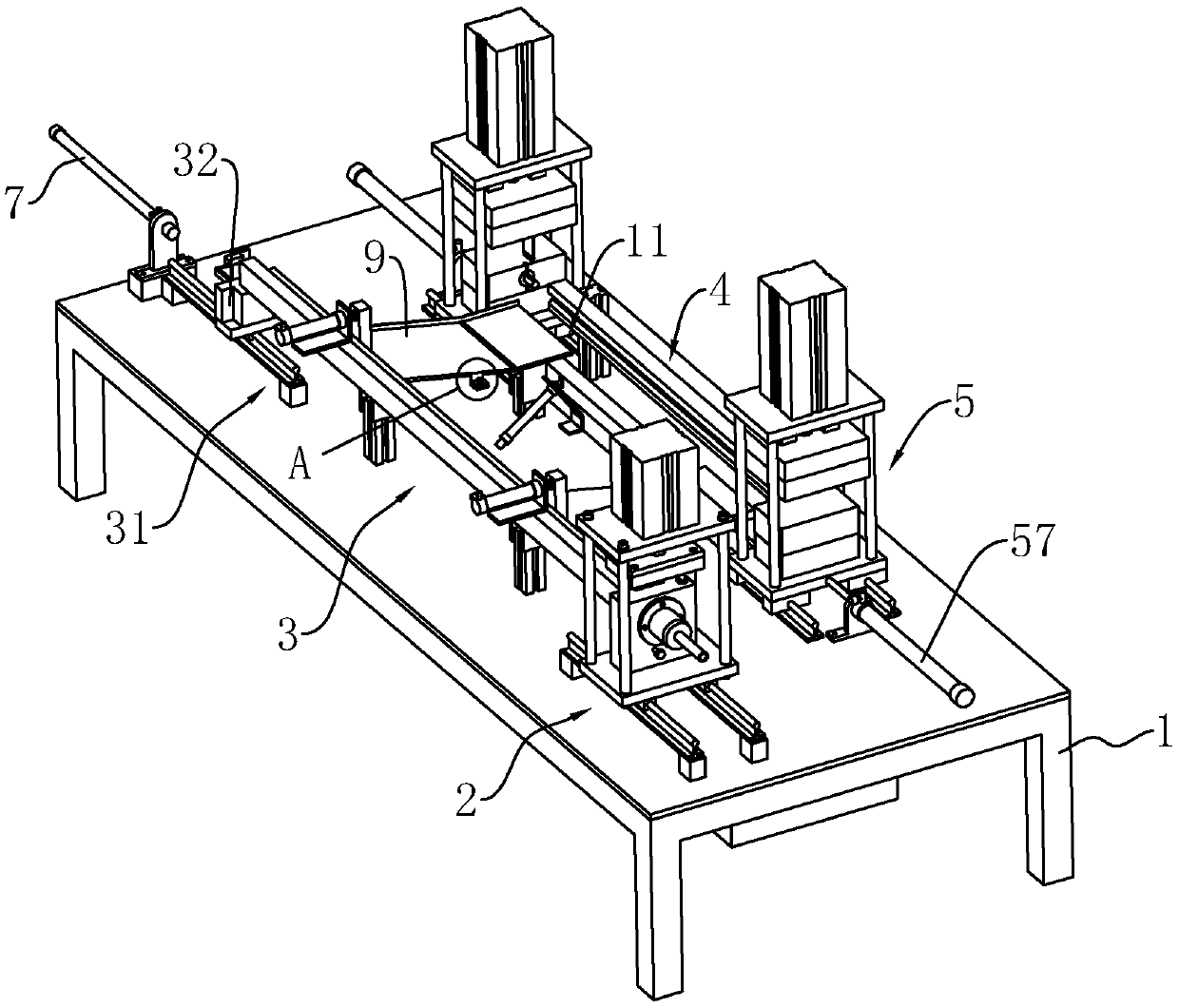

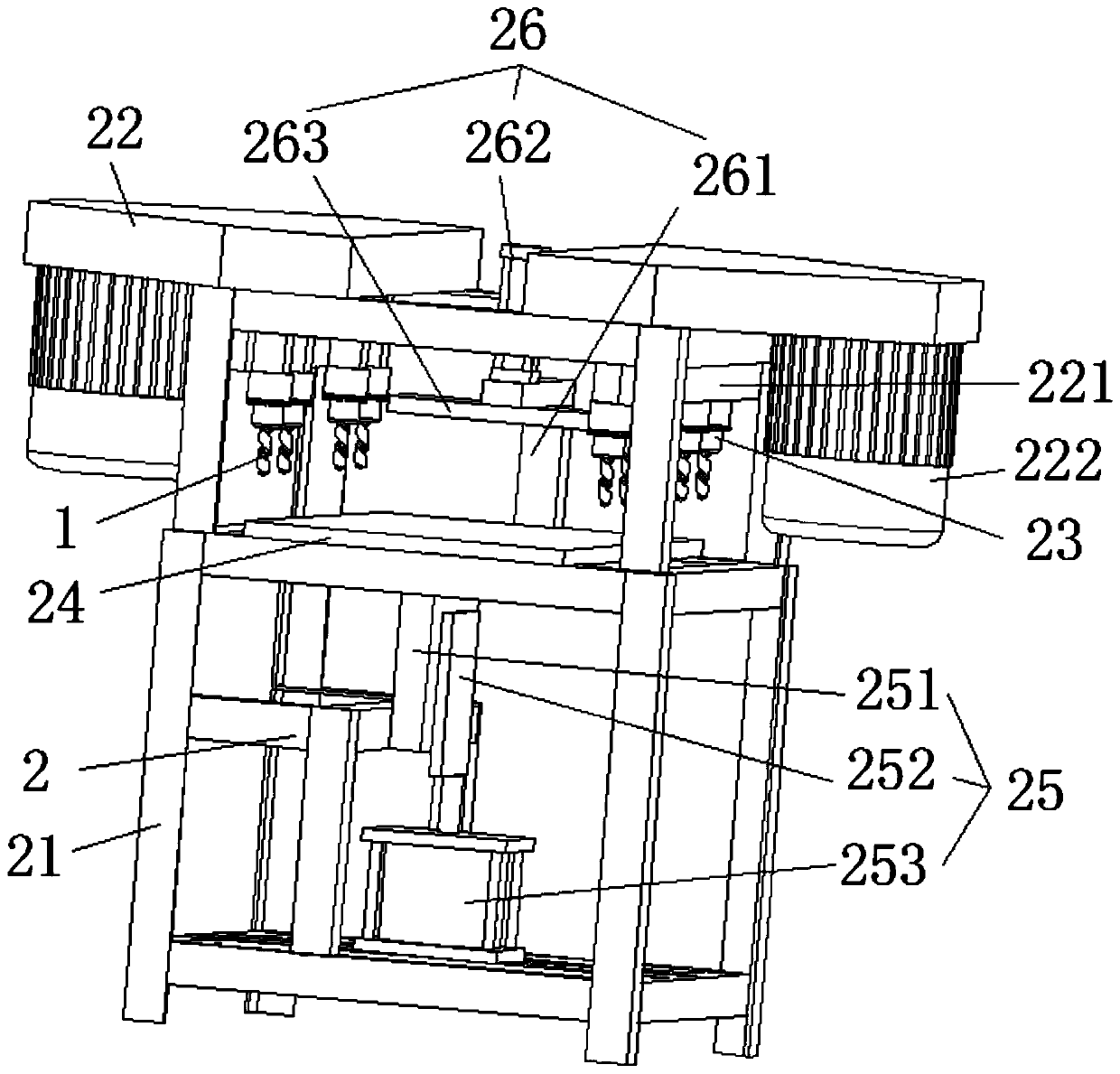

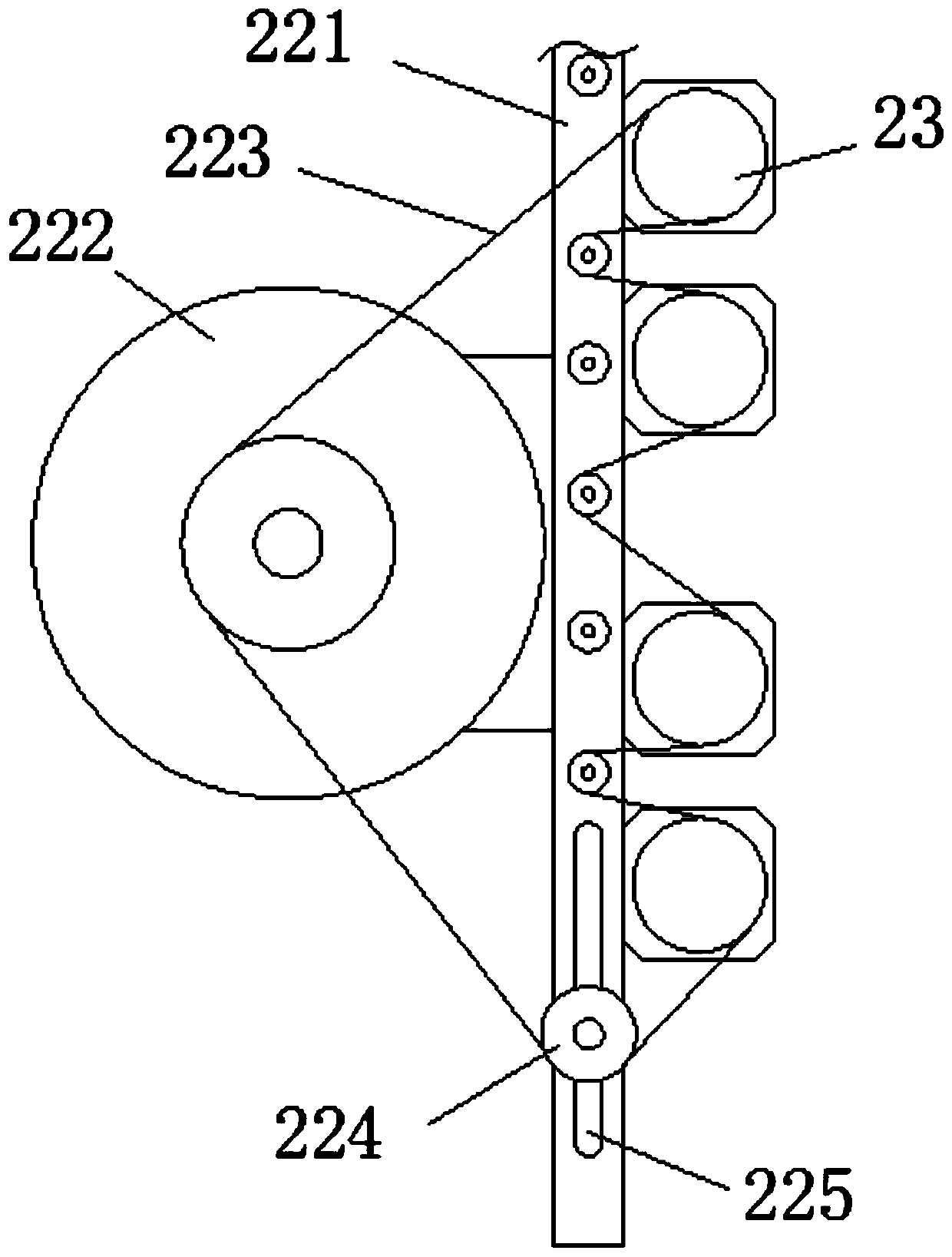

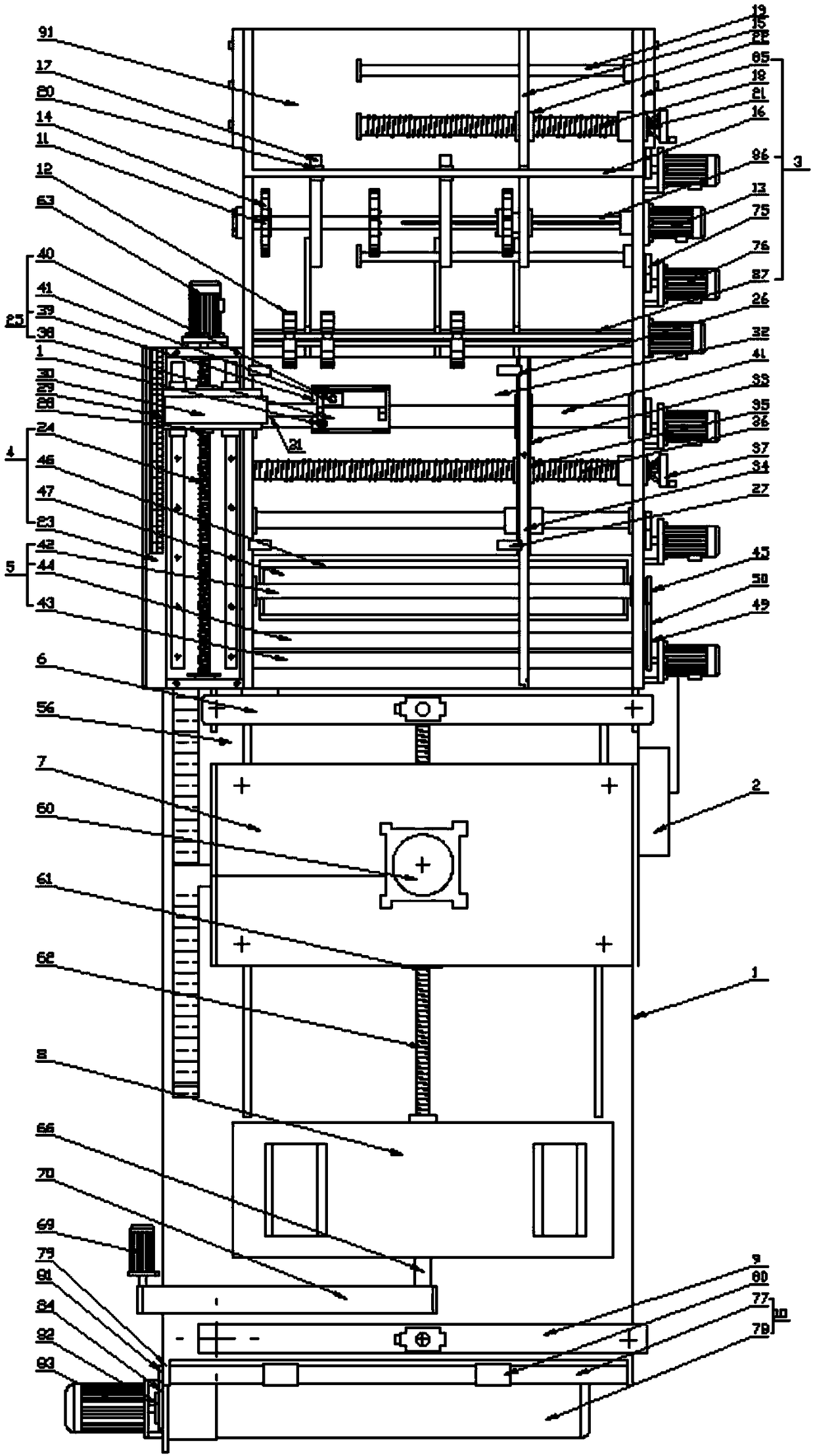

Full-automatic grinding and polishing device

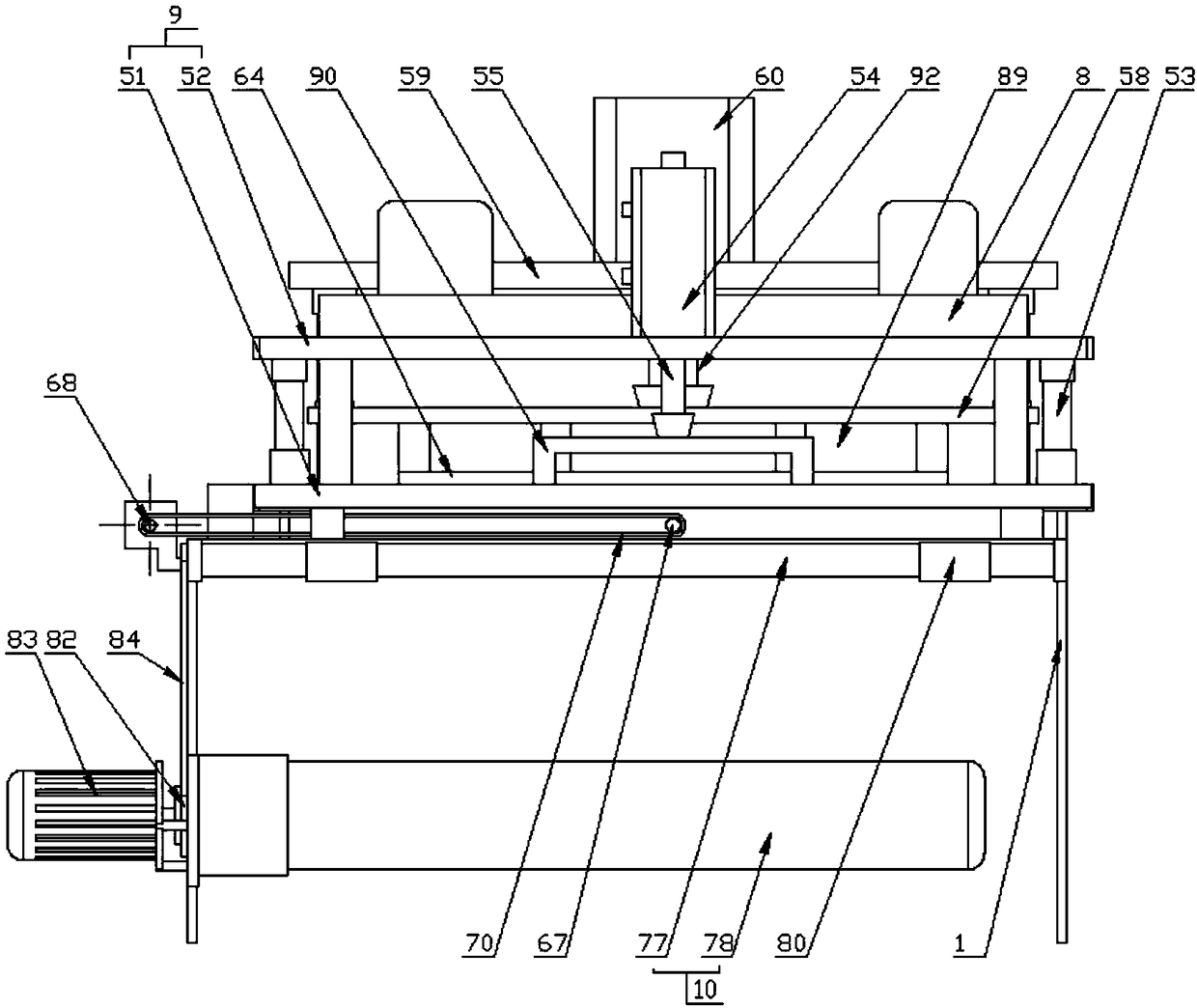

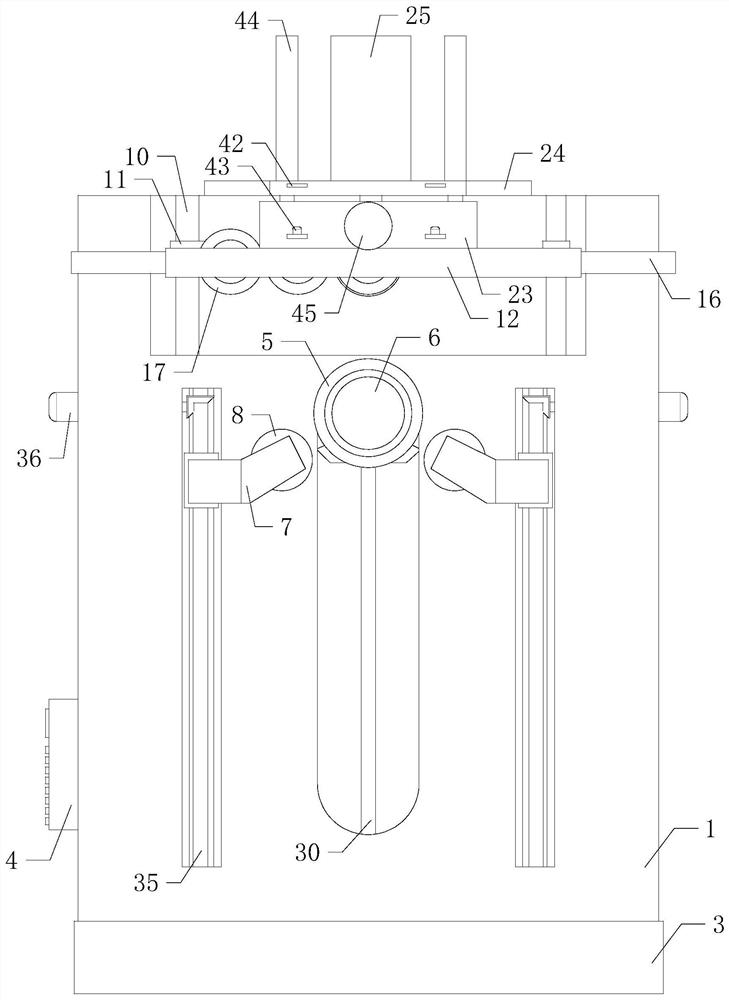

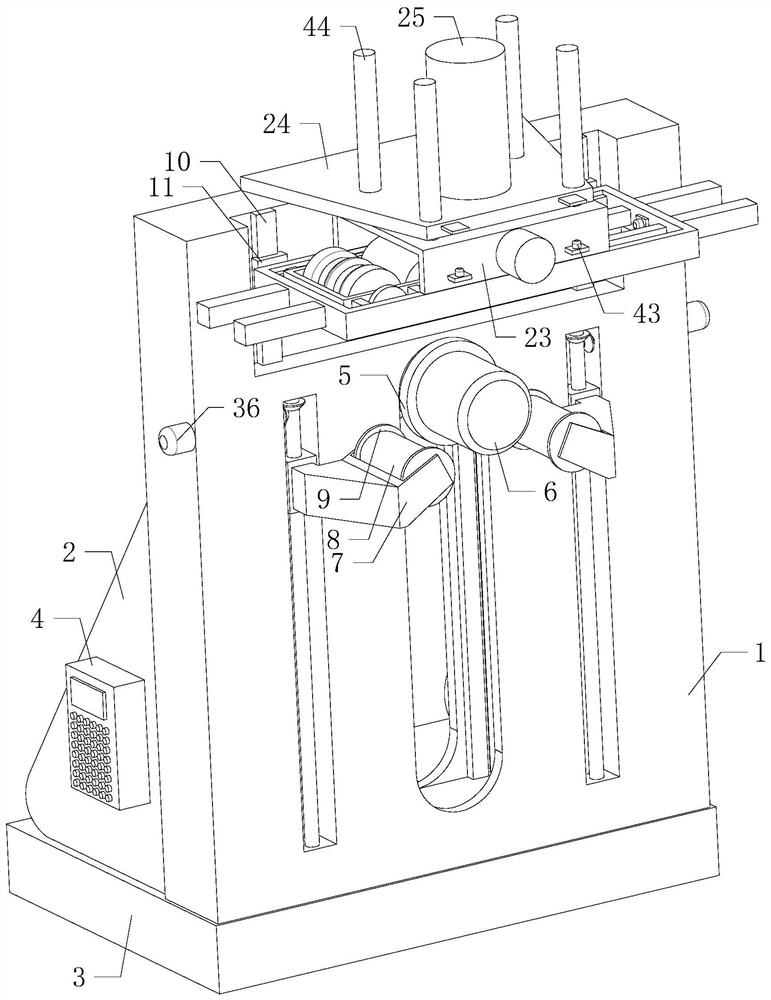

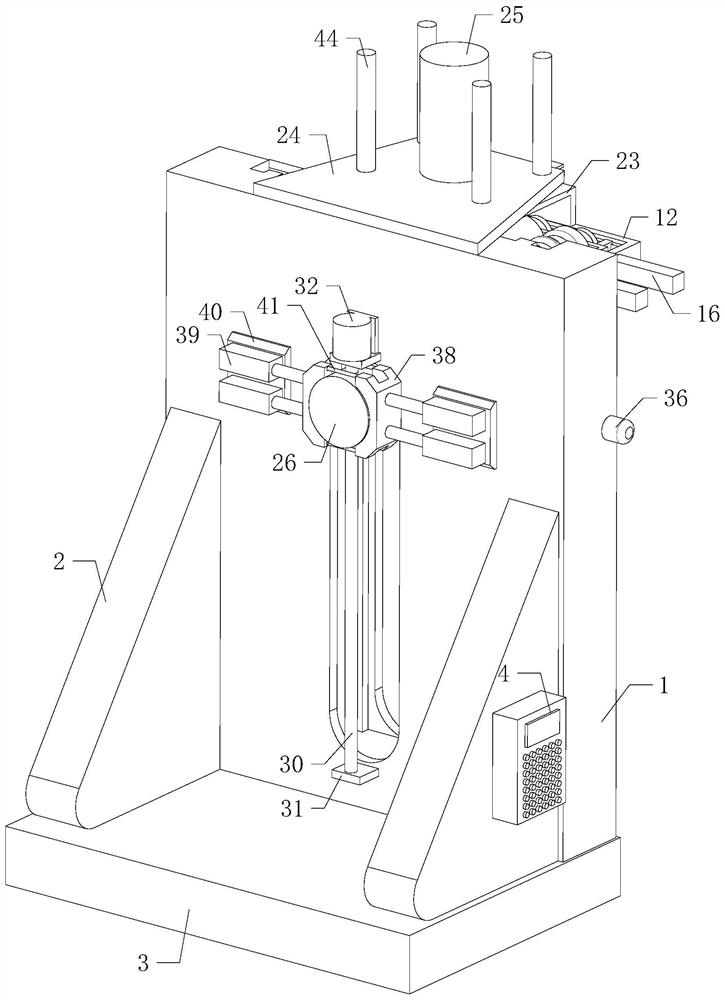

ActiveCN105196127APrecise working position adjustmentRealize one-time processing and moldingEdge grinding machinesGrinding carriagesAutomatic controlEngineering

The invention provides a full-automatic grinding and polishing device. The full-automatic grinding and polishing device comprises a grinding rack, a grinding material rest, a translation mechanism, a rotating mechanism, a grinding and polishing mechanism, an air pumping mechanism and a control cabinet, the grinding material rest is arranged on the grinding rack, the translation mechanism is installed on the grinding rack, the rotating mechanism is installed on the translation mechanism, the grinding and polishing mechanism is installed on the rotating mechanism, the air pumping mechanism is connected with the grinding mechanism, and the control cabinet is connected with and controls the translation mechanism, the rotating mechanism, the grinding and polishing mechanism and the air pumping mechanism. According to the full-automatic grinding and polishing device, accurate control over the grinding and polishing position is achieved by means of the innovation of combining the translation mechanism and the rotating mechanism which can be controlled automatically, one-time-process molding of the workpiece surface is achieved by means of the innovation of combining the grinding mechanism and a polishing mechanism, the grinding and polishing efficiency and quality are improved in an automated mode, and the full-automatic grinding and polishing device can be widely used for treatment of the surfaces of various workpieces and has wide market use prospect.

Owner:GUANGDONG HWASHI TECH INC

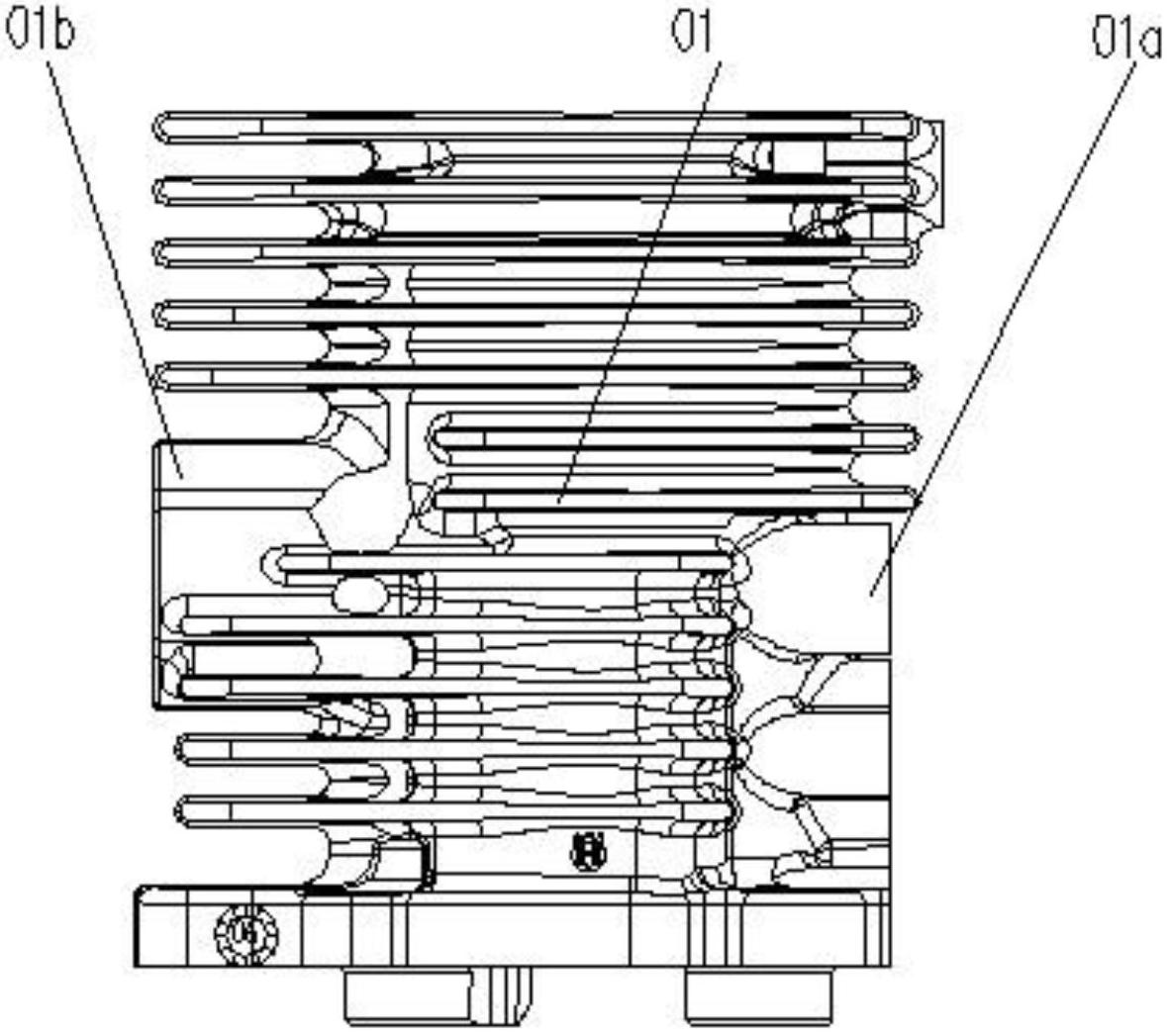

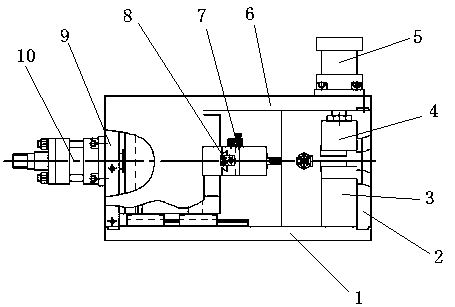

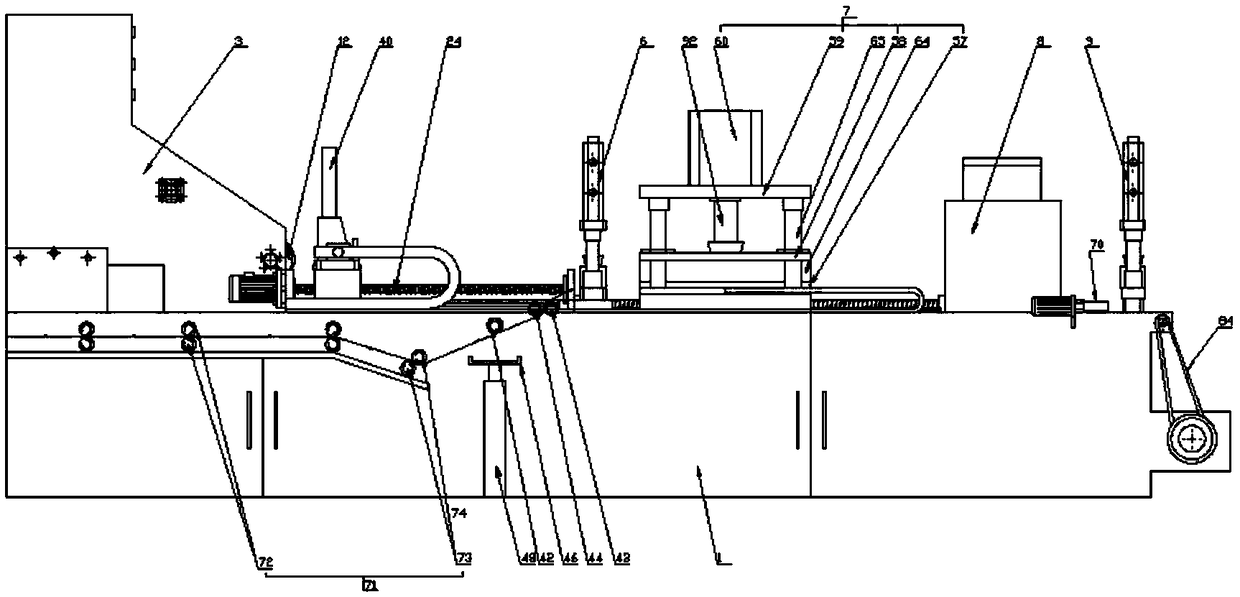

Machine tool for simultaneously machining threaded holes on air inlet side and air outlet side of cylinder

InactiveCN102689184AIncrease productivityRealize one-time processing and moldingOther manufacturing equipments/toolsEngineeringScrew thread

The invention discloses a machine tool for simultaneously machining threaded holes on an air inlet side and an air outlet side of a cylinder. The machine tool comprises a machine tool body, a worktable, an air inlet side drilling mechanism, an air outlet side drilling mechanism, an air inlet side tapping mechanism, an air outlet side tapping mechanism, a positioning clamp, a sliding table and a sliding rail, wherein the worktable is arranged on the machine tool body; the sliding rail is arranged on the worktable; the sliding table is arranged on the sliding rail in a sliding mode; the positioning clamp is fixedly arranged on the sliding table; a cylinder to be machined is fixed on the positioning clamp; the air inlet side drilling mechanism and the air inlet side tapping mechanism are sequentially arranged on the worktable on one side of the sliding rail in a mode of being opposite to an air inlet side of the cylinder to be machined; and the air outlet side drilling mechanism and the air outlet side tapping mechanism are sequentially arranged on the worktable on the other side of the sliding rail in a mode of being opposite to an air outlet side of the cylinder to be machined. According to the machine tool, the threaded holes on the air inlet side and the air outlet side of the cylinder are machined and molded by one time, the machining precision of the threaded holes of the cylinder is improved, and the production efficiency of the cylinder is greatly improved.

Owner:福建华威钜全精工科技有限公司

Die for machining thin-walled door-shaped bent part and use method of die

The invention provides a die for machining a thin-walled door-shaped bent part. The die comprises an upper template and a lower template, wherein the upper template is provided with a material pressing plate; the material pressing plate is connected with the upper template by a compression spring; an inclined block is arranged outside the material pressing plate; a female die is arranged on the lower template; the female die is slidably connected with the lower template by a first reset device; a cone block is arranged at the top of an ejector and is slidably connected with the female die; the outside of the female die is provided with a slide seat slidably connected with the lower template by a second reset device; the slide seat is fixedly connected with a punch and is slidably connected with the inclined block. The invention also provides a use method of the die. According to the die for machining the thin-walled door-shaped bent part and the use method of the die, the die is compact in structure and convenient to operate, and the production efficiency is greatly improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

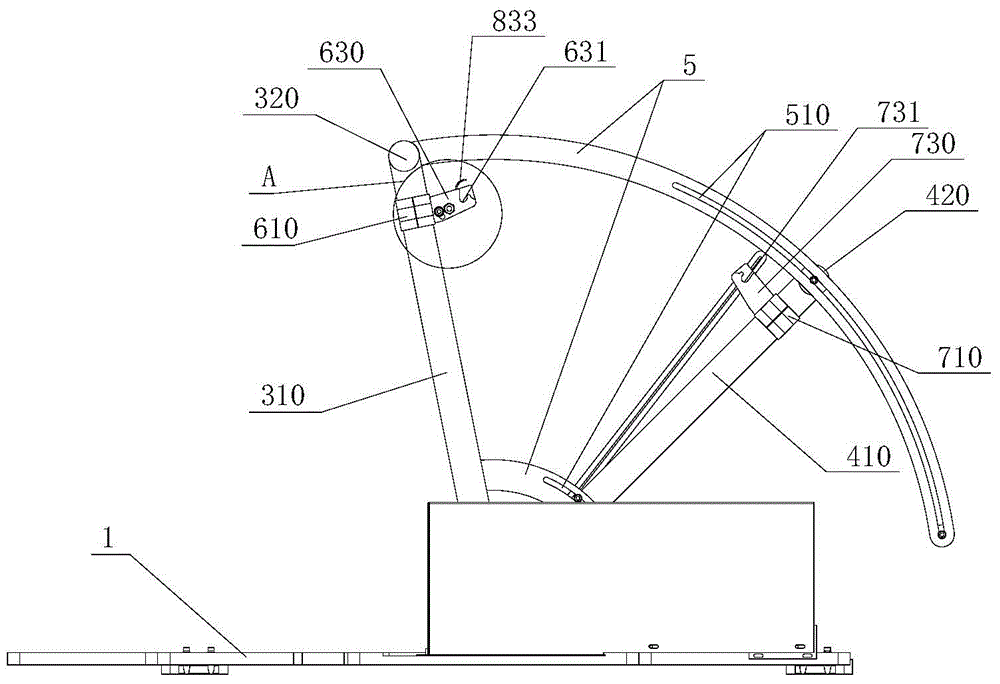

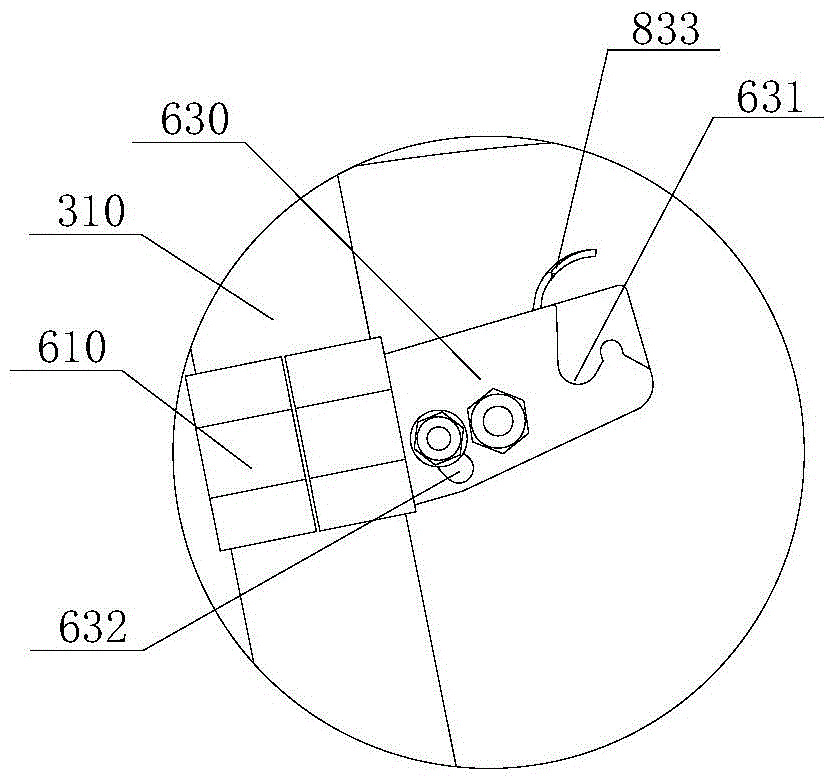

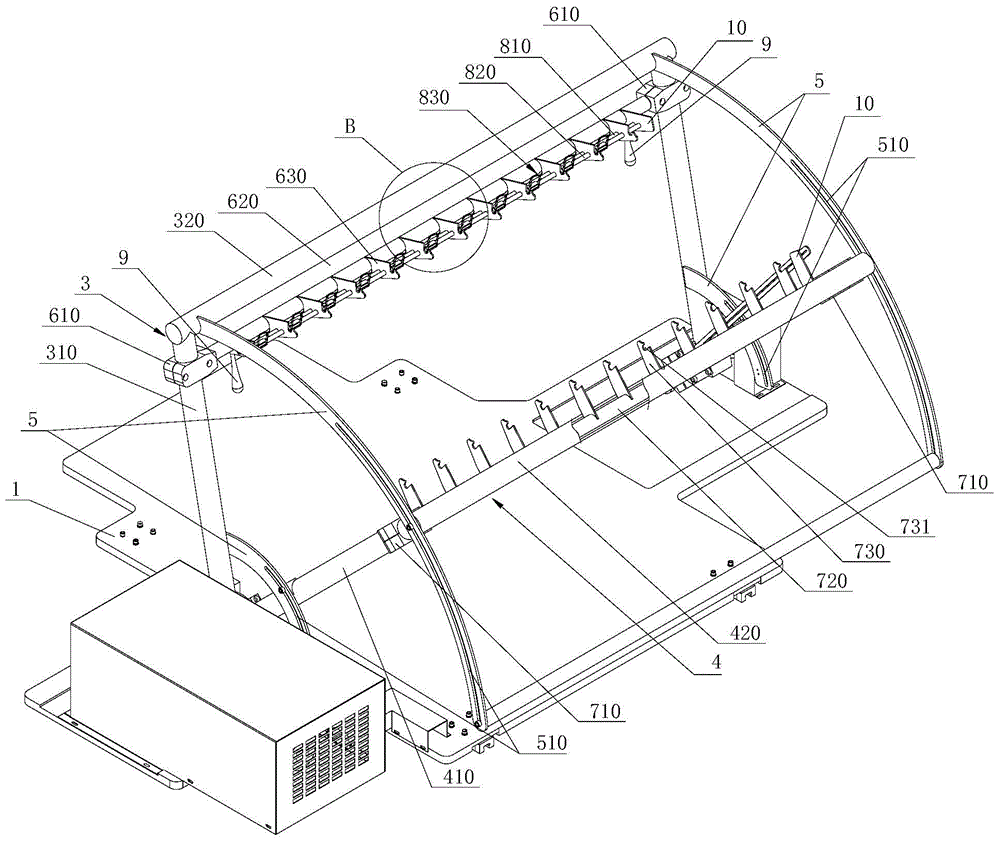

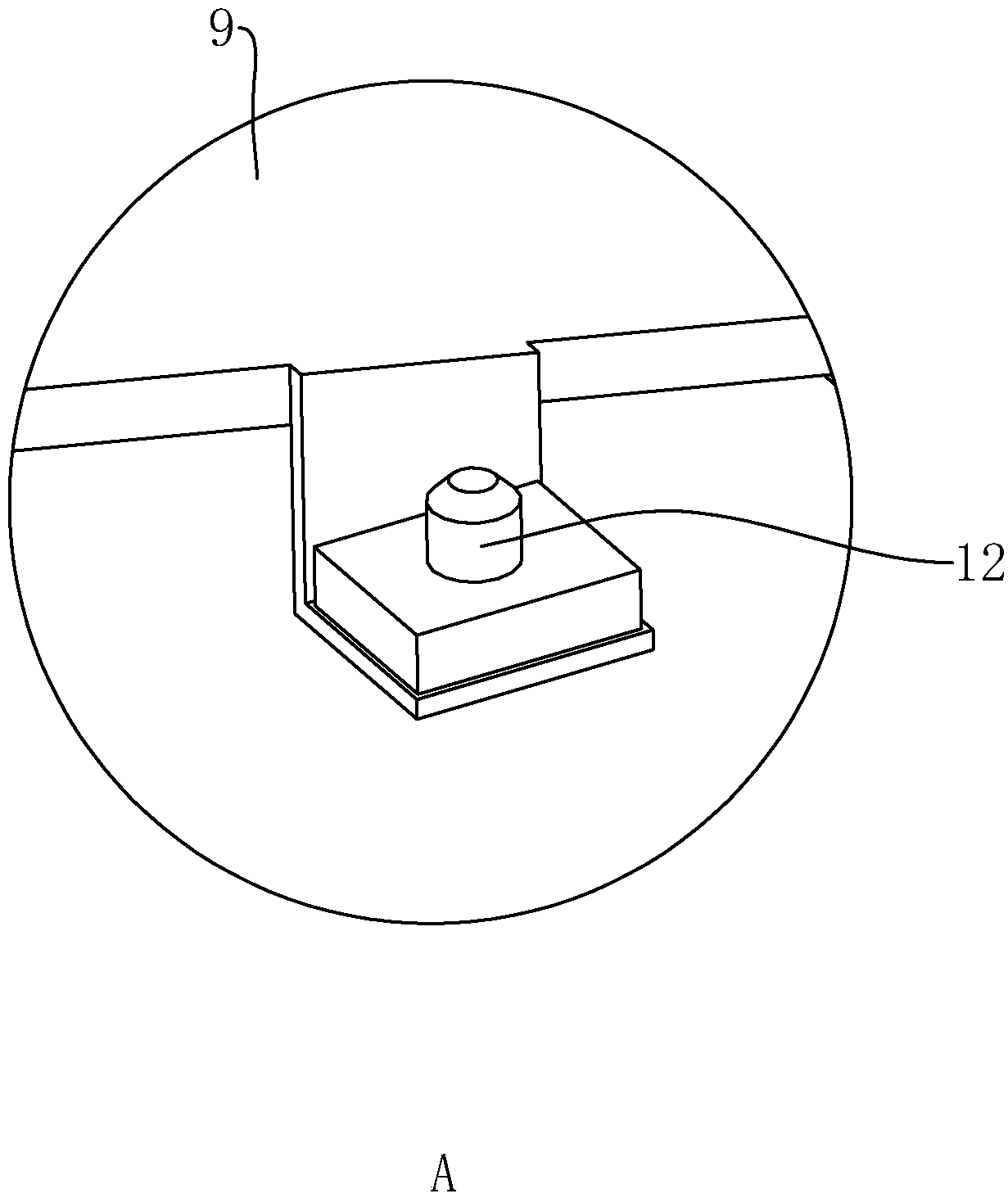

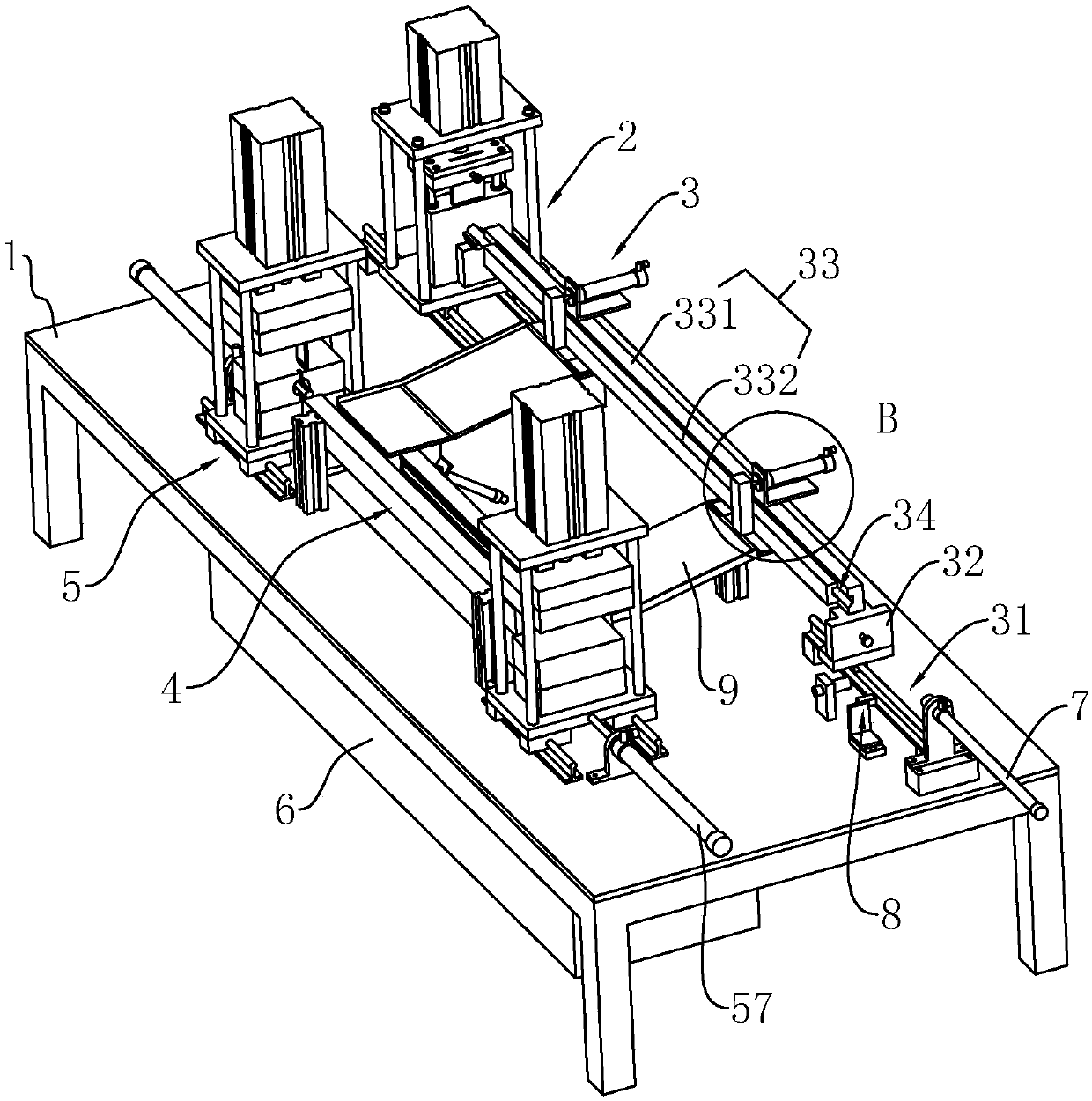

Rotary mounting and clamping device arranged on wood board laser cutting machine and used for arc-shaped board processing

ActiveCN104827229AMeet the positioningRealize one-time processing and moldingWelding/cutting auxillary devicesAuxillary welding devicesLaserReducer

A rotary mounting and clamping device arranged on a wood board laser cutting machine and used for arc-shaped board processing comprises a bottom platform, an adjusting shaft supported in the bottom platform, a speed reducer, a motor, a left inclined support, a right inclined support and multiple arc-shaped connection plates, wherein the speed reducer and the motor are installed on the bottom platform, the left inclined support and the right inclined support are supported on the adjusting shaft, and the arc-shaped connection plates are connected with the two inclined supports. The left inclined support comprises two fixed supporting arms and a fixing supporting beam, and the lower ends of the two fixed supporting arms are fixedly connected with the two ends of the adjusting shaft respectively. The right inclined support comprises two rotary supporting arms and a rotary supporting beam, and the lower ends of the two rotary supporting arms are rotationally connected with the two ends of the adjusting shaft respectively. One end of each arc-shaped connection plate is fixedly connected with the left inclined support, and the arc-shaped connection plates are detachably and fixedly connected with the right inclined support through screws penetrating through arc-shaped long connection holes. The device comprises a left side supporting plate assembly and a right side supporting plate assembly, the left side supporting plate assembly is supported on the two fixed supporting arms in a cross mode, the right side supporting plate assembly is supported on the two rotary supporting arms in a cross mode, and at least one side supporting plate assembly is provided with a pressing plate structure. The rotary mounting and clamping device achieves hollowed-out one-time machining and processing in the normal direction of the arc-shaped plates.

Owner:美克国际家私(天津)制造有限公司

Flat-mouth copper wire processing apparatus

ActiveCN104815867AImprove plasticityEliminate internal stressWire articlesHydraulic cylinderMotor drive

The present invention discloses a flat-mouth copper wire processing apparatus, which comprises a bracket, a hydraulic cylinder base, a hydraulic cylinder, a hot rolling pressing wheel, a rolling pressing lower mold, a transmission motor, a belt wheel, a support seat, a wire collection wheel, and a motor. Compared with the apparatus in the prior art, the apparatus of the present invention has the following characteristics that: a round-mouth copper wire passes through the lower rolling pressing mold, hydraulic pressure pushes the hot rolling pressing wheel to move downward so as to press the copper wire, the hot rolling pressing wheel is electrified and heated, the transmission motor is started when achieving a certain temperature, the transmission motor drives the hot rolling pressing wheel to rotate, the round-mouth copper wire is rolled and pressed into the flat-mouth copper wire, and the motor drives the wire collection wheel to rotate so as to collect the rolled and pressed flat-mouth copper wire. According to the present invention, the apparatus adopts the hot rolling pressing technology, such that the plasticity of the copper wire can be increased, and the internal stress of the plastic deformation can be eliminated so as to achieve one-time processing molding and improve processing efficiency.

Owner:江西华业精工有限公司

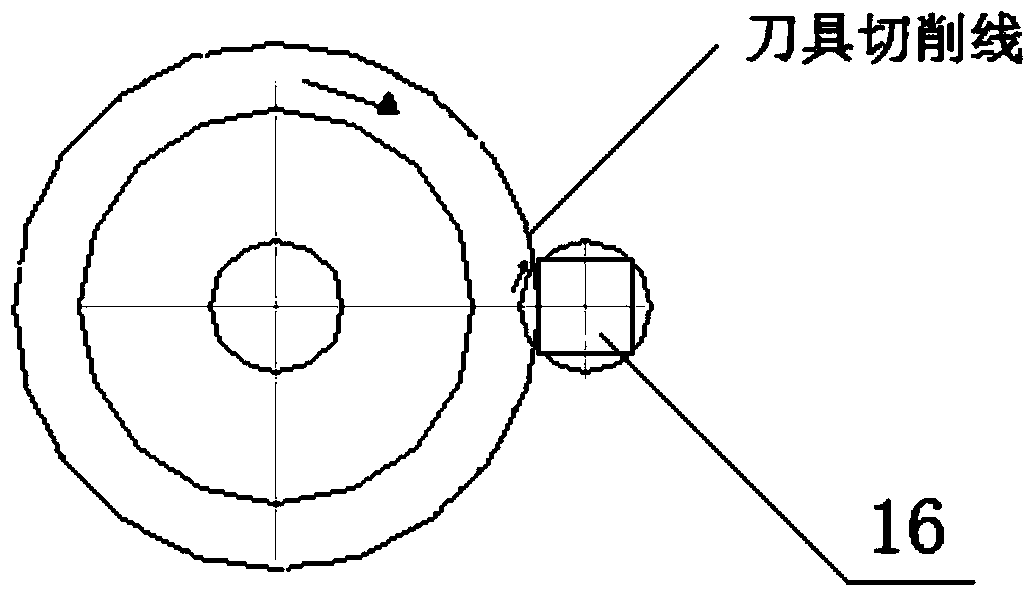

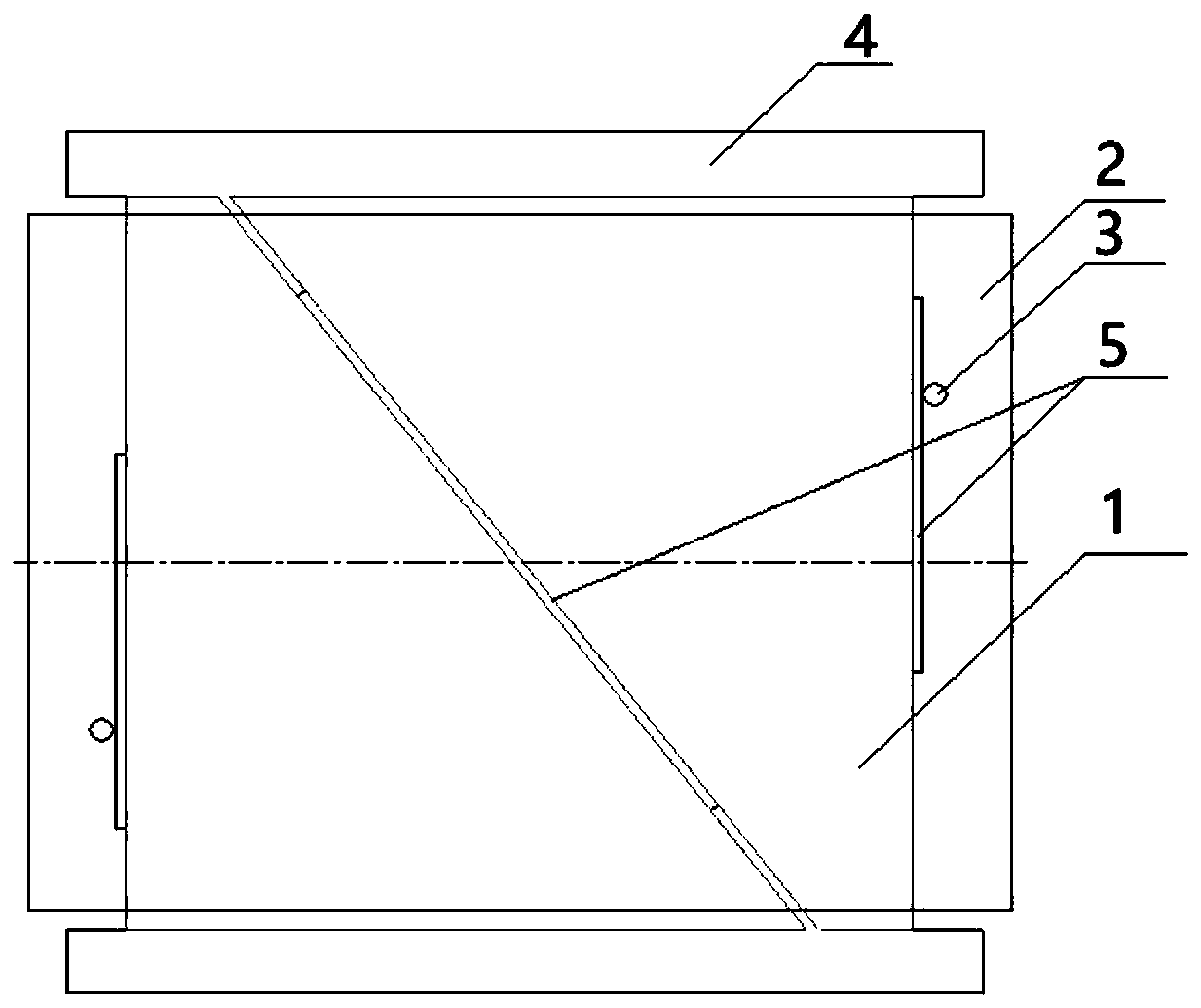

Machining device for machining polygon and machining method thereof

ActiveCN103586638AGuaranteed verticalityEasy feedingMilling equipment detailsTransmitted powerMechanical engineering

The invention discloses a machining device for machining a polygon and a machining method thereof. The machining device comprises a main box body and an auxiliary box body which are arranged side by side, a first shaft is installed on the first main box, a cutter head is arranged at one end, close to the auxiliary box body, of the first shaft, the cutter head is provided with a cutting tool, and the end, where the cutter head is arranged, of the first shaft is further provided with a spline groove sleeve; a second shaft is installed on the auxiliary box body, a spline groove is formed in one end, close to the main box body, of the second shaft, the spline groove is matched with the spline groove sleeve in installation, a driving wheel is installed on a position, located inside the auxiliary box body, of the second shaft, and the common multiple of the ratio of the number of teeth of the driving wheel to the number of teeth of a driven wheel is equal to the number of sides of the polygon to be machined; the driven wheel transmits power to a driven wheel installed on a third shaft through a middle idle gear, and a chuck is installed at the end, close to the main box body, of the third shaft. The machining device can achieve one-time machining forming for polygon components, and compared with working efficiency of an existing milling machine and a planning machine, working efficiency of the machining device can be increased by 2-3 times.

Owner:ANHUI HUAXING FIRE EQUIP GRP CO LTD

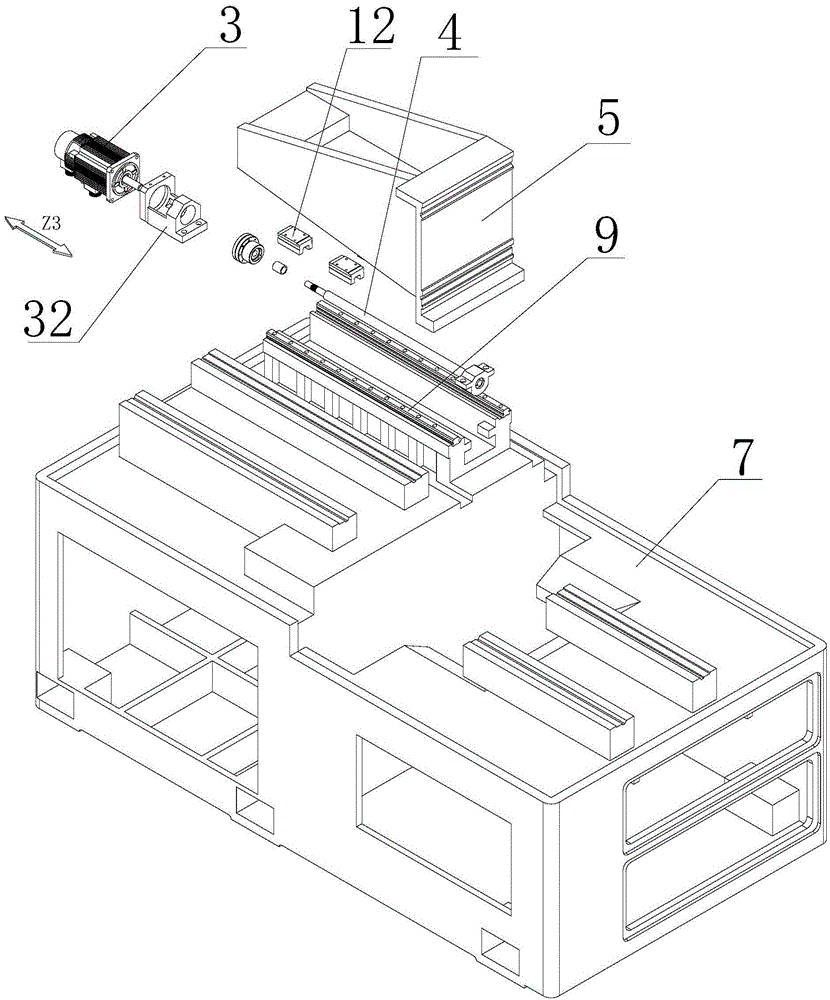

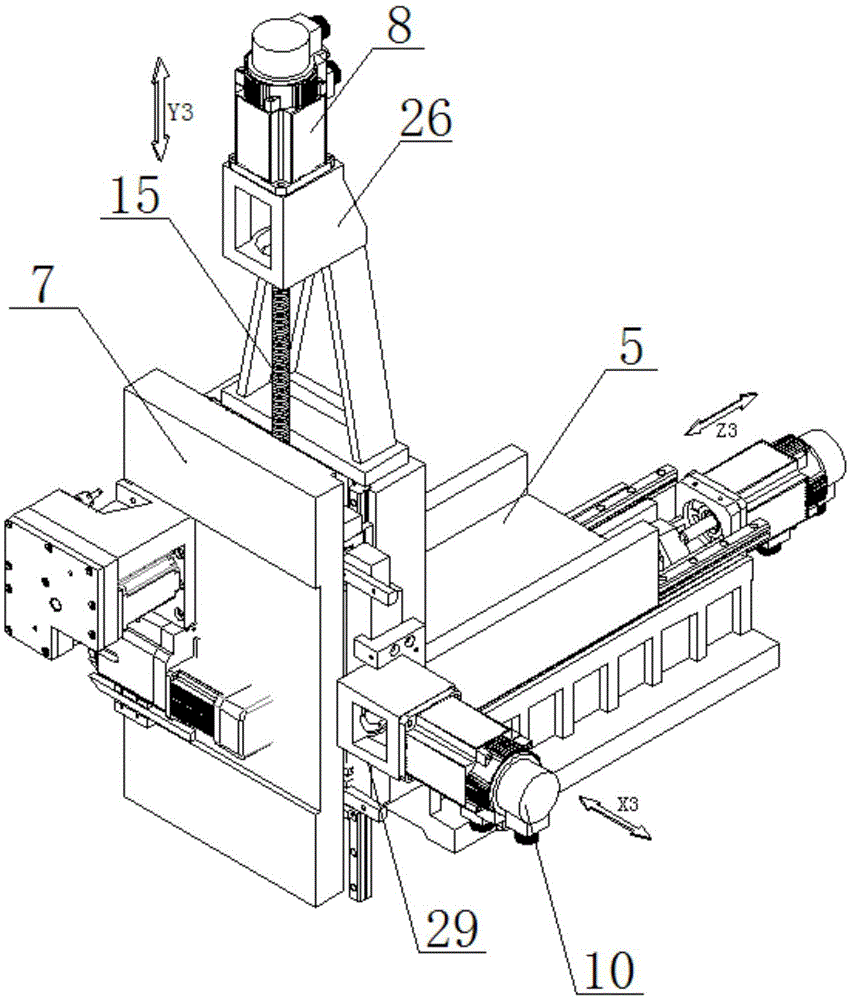

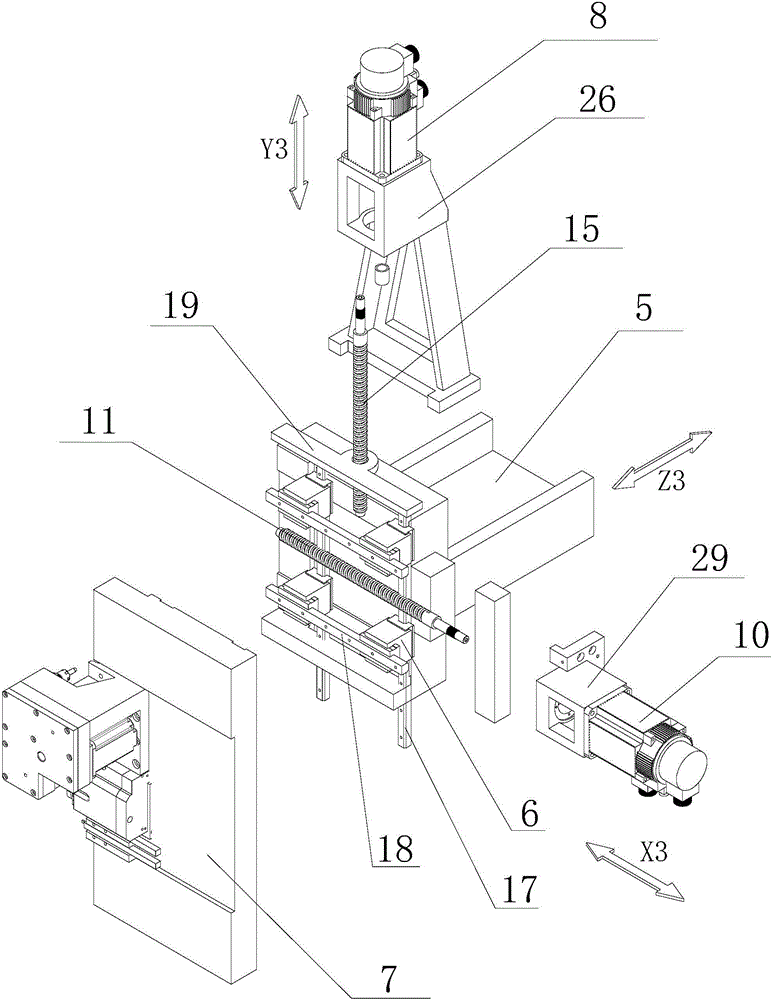

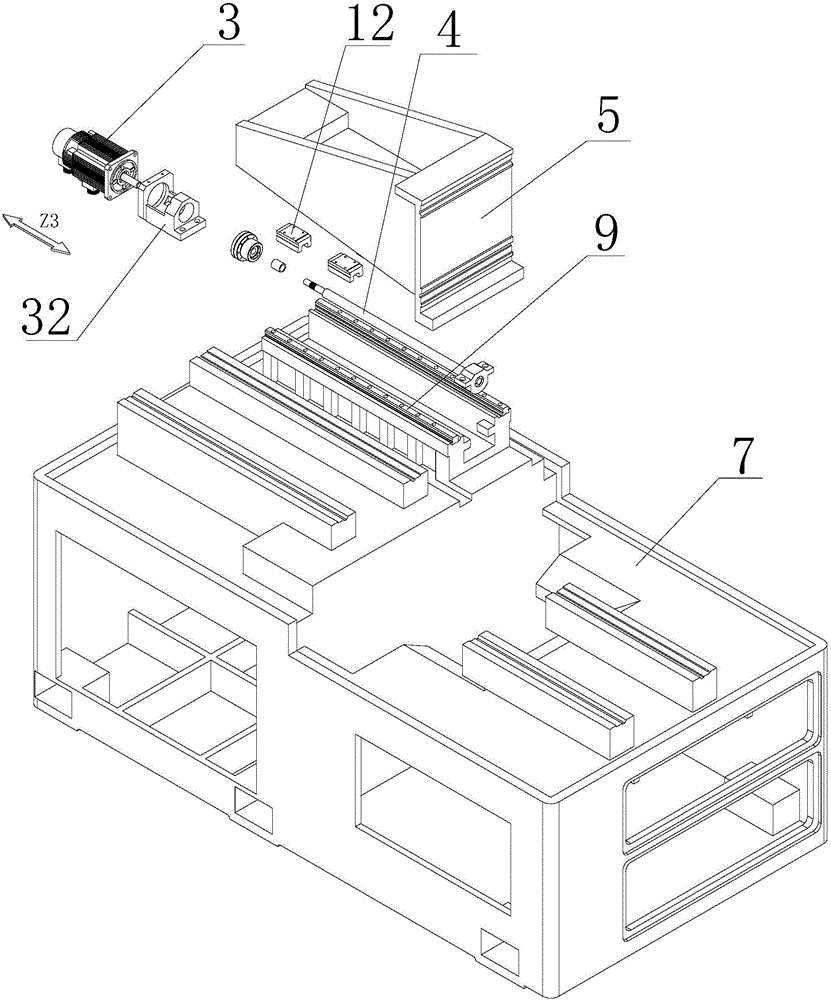

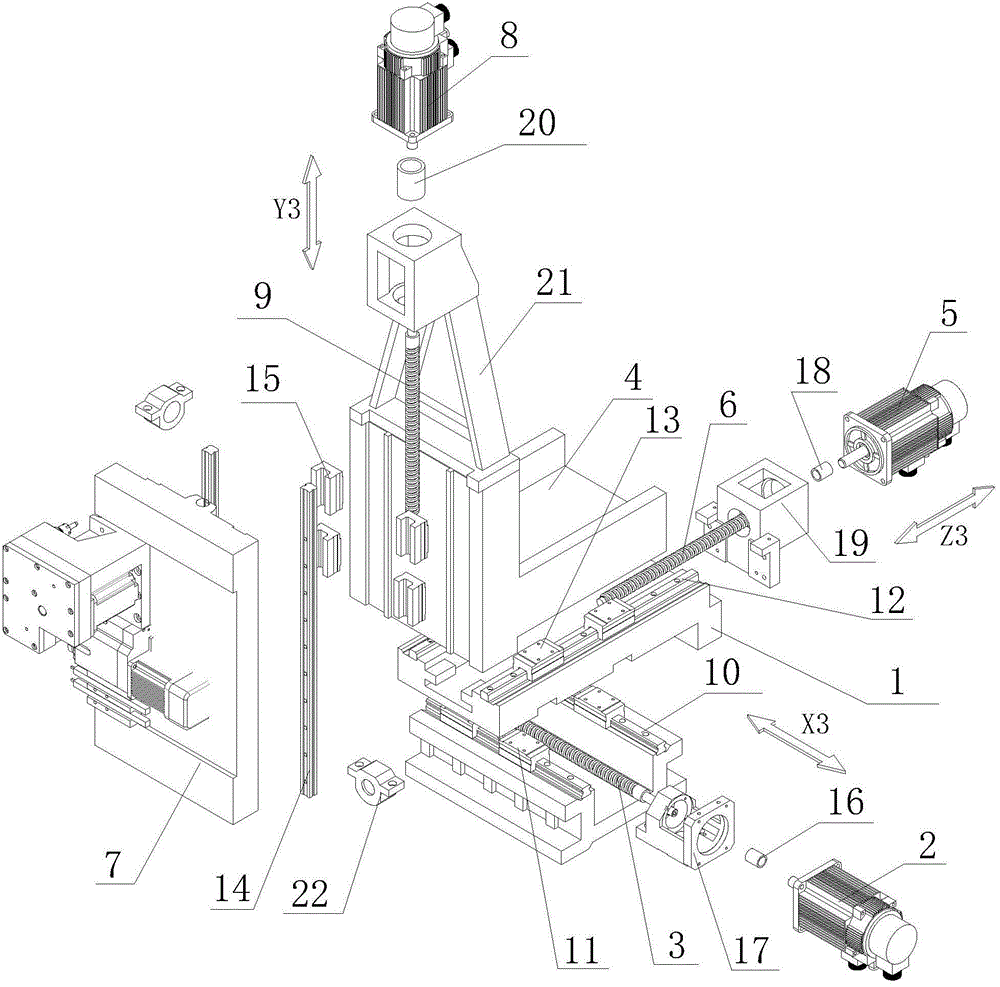

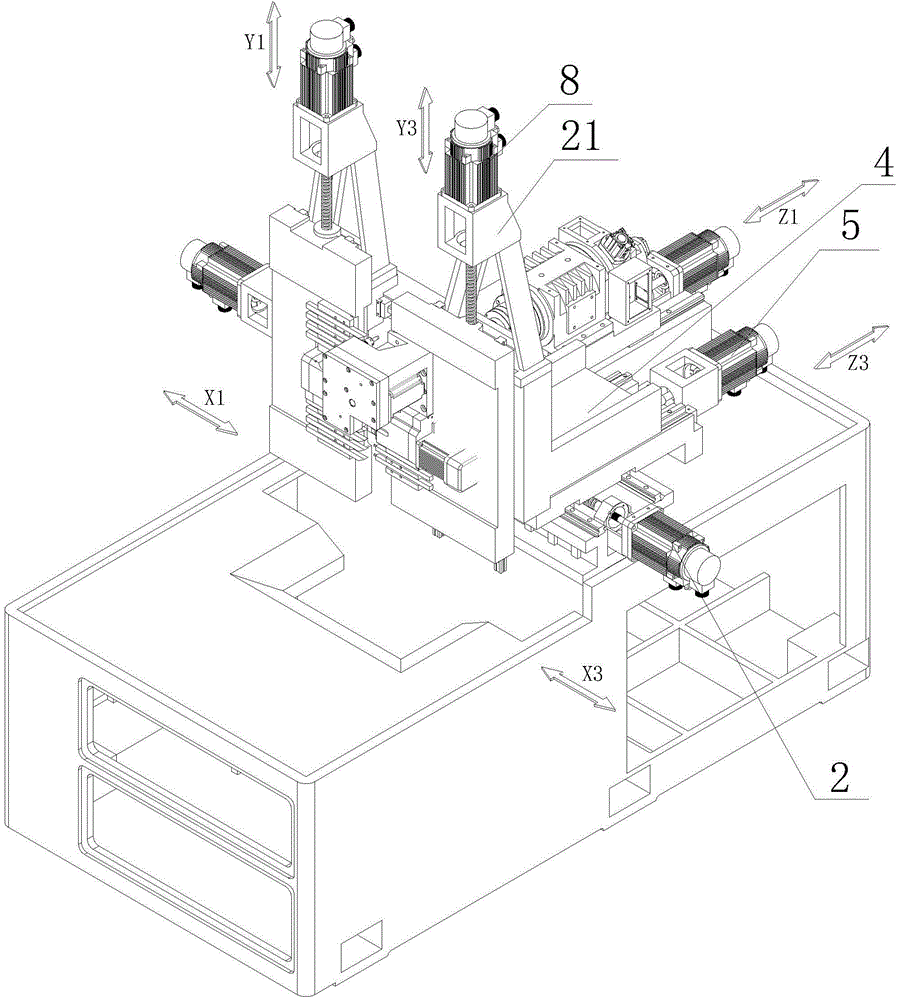

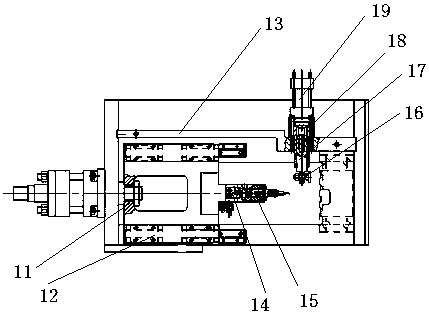

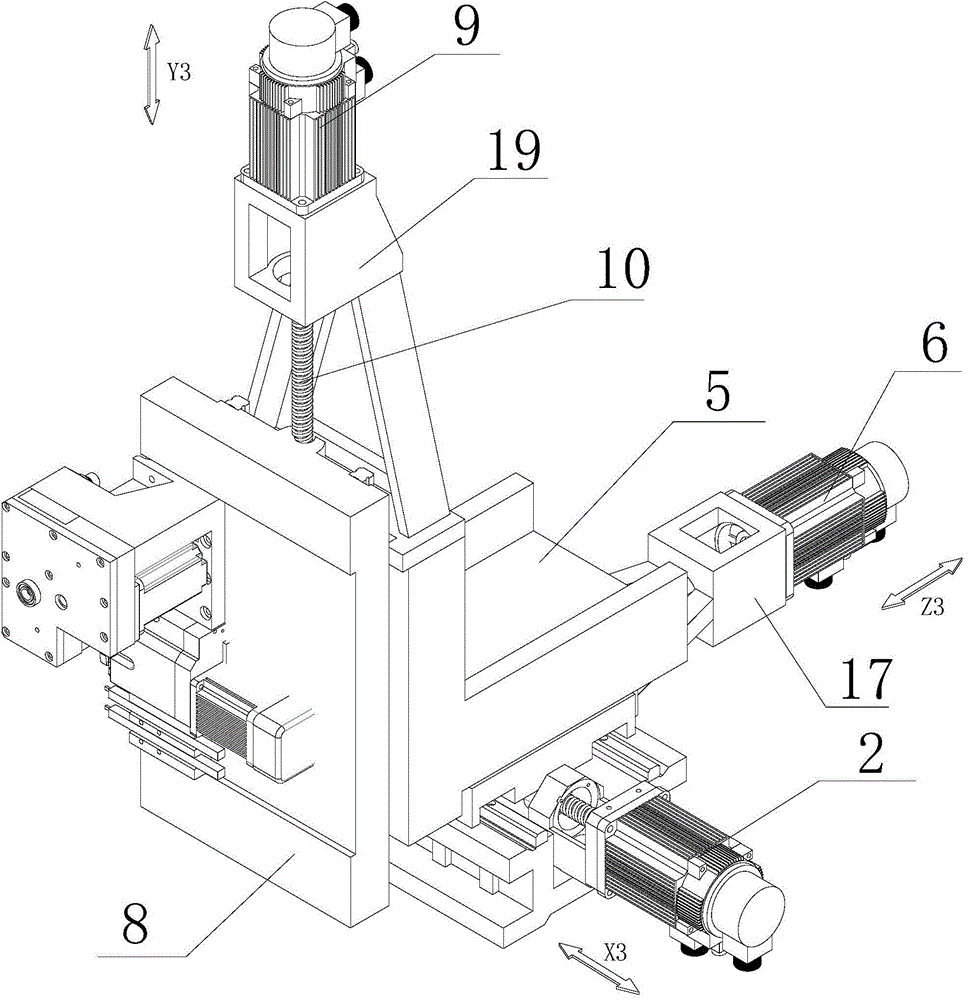

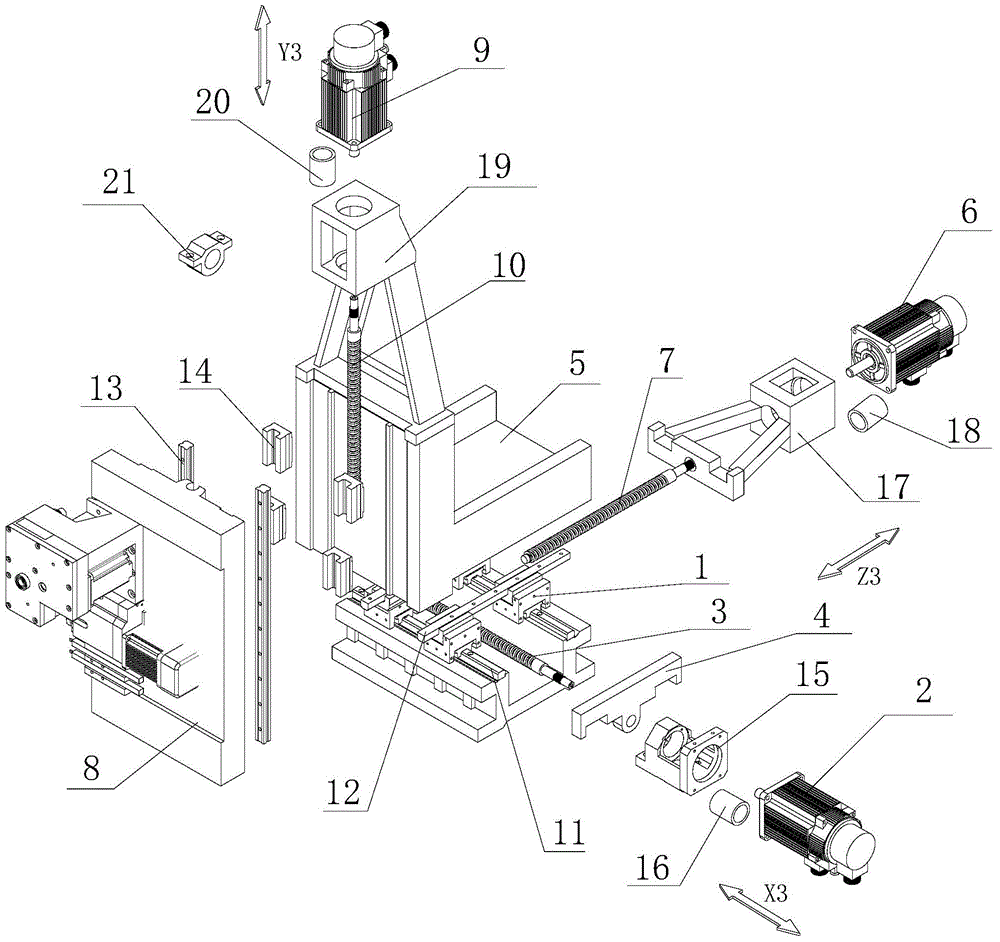

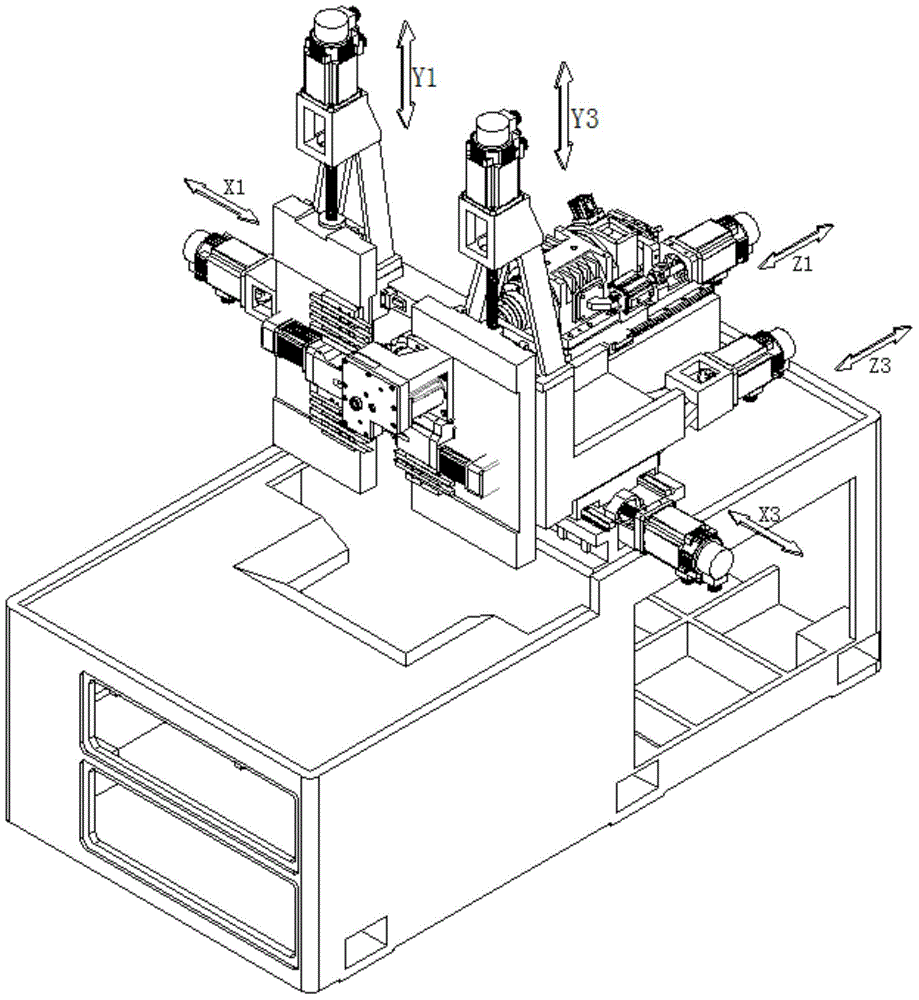

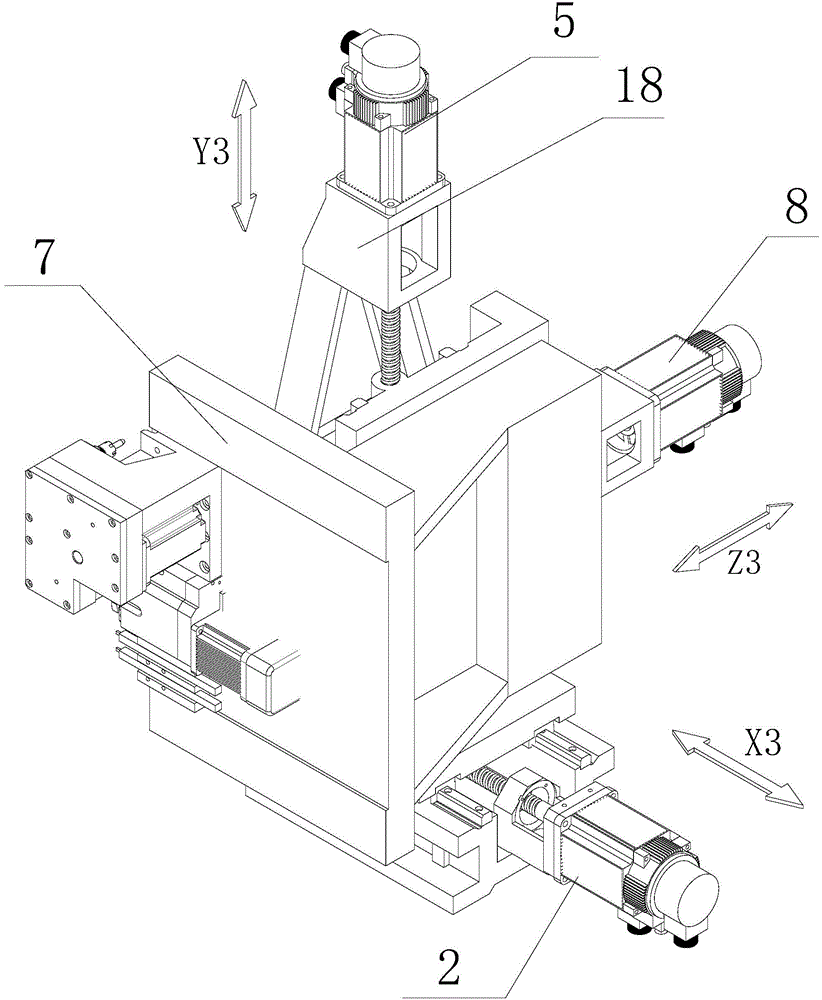

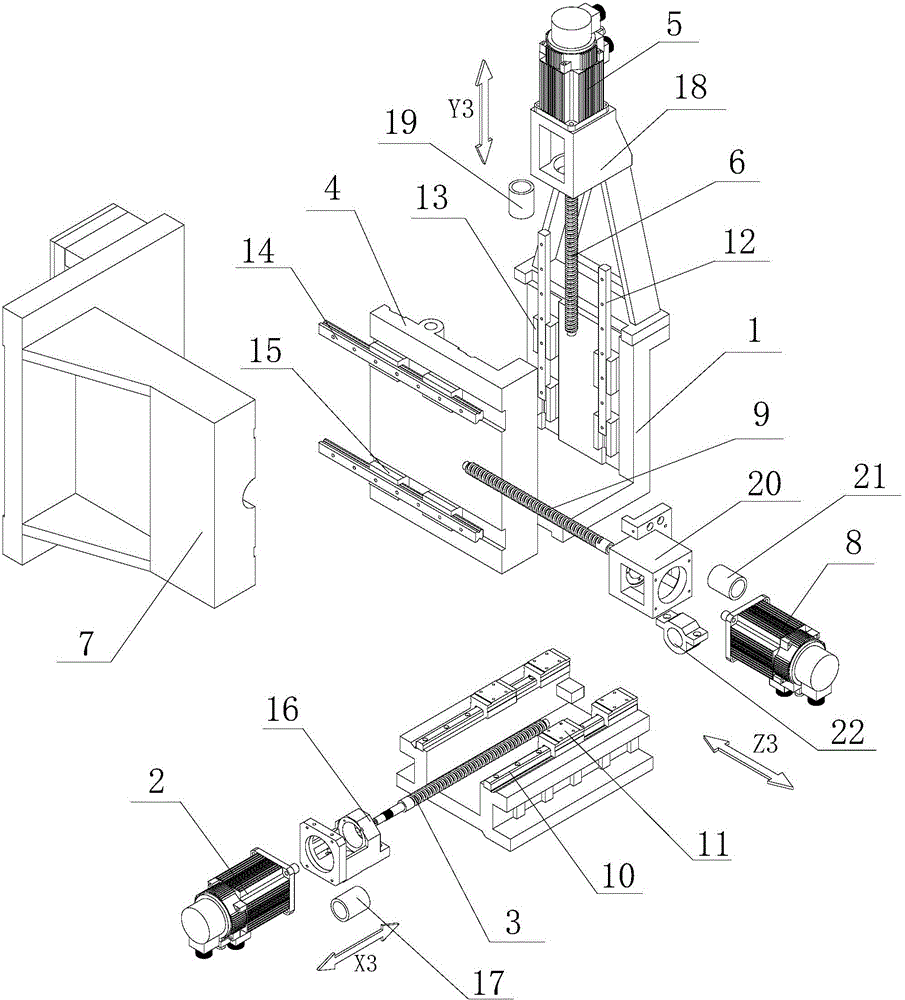

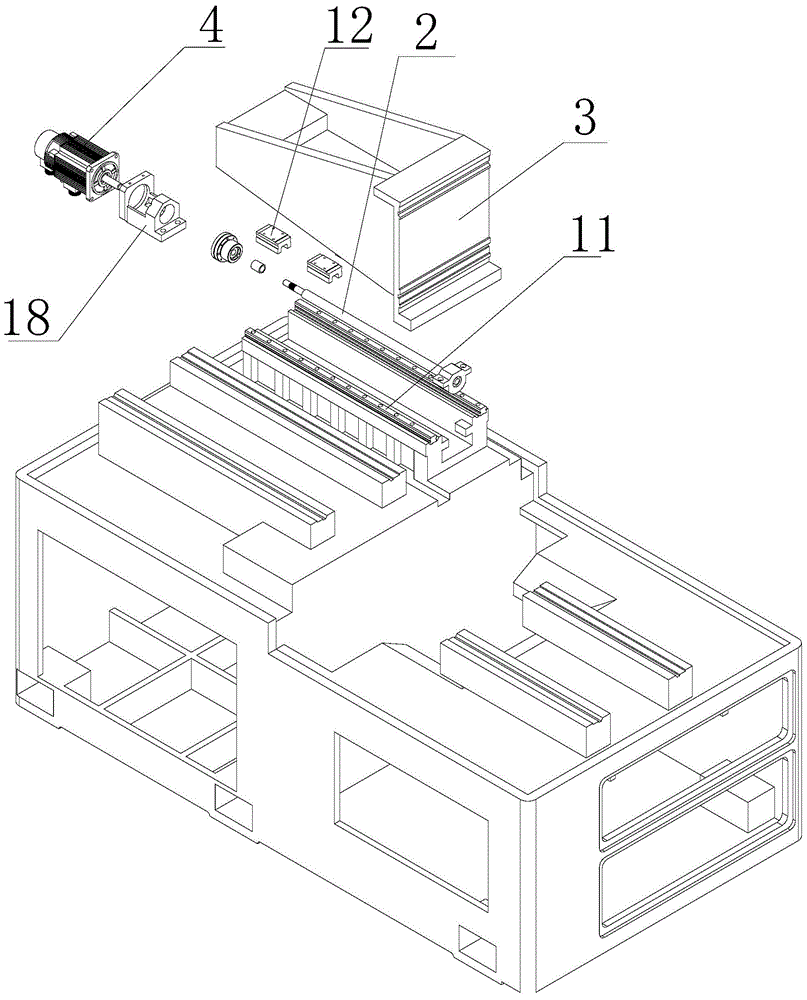

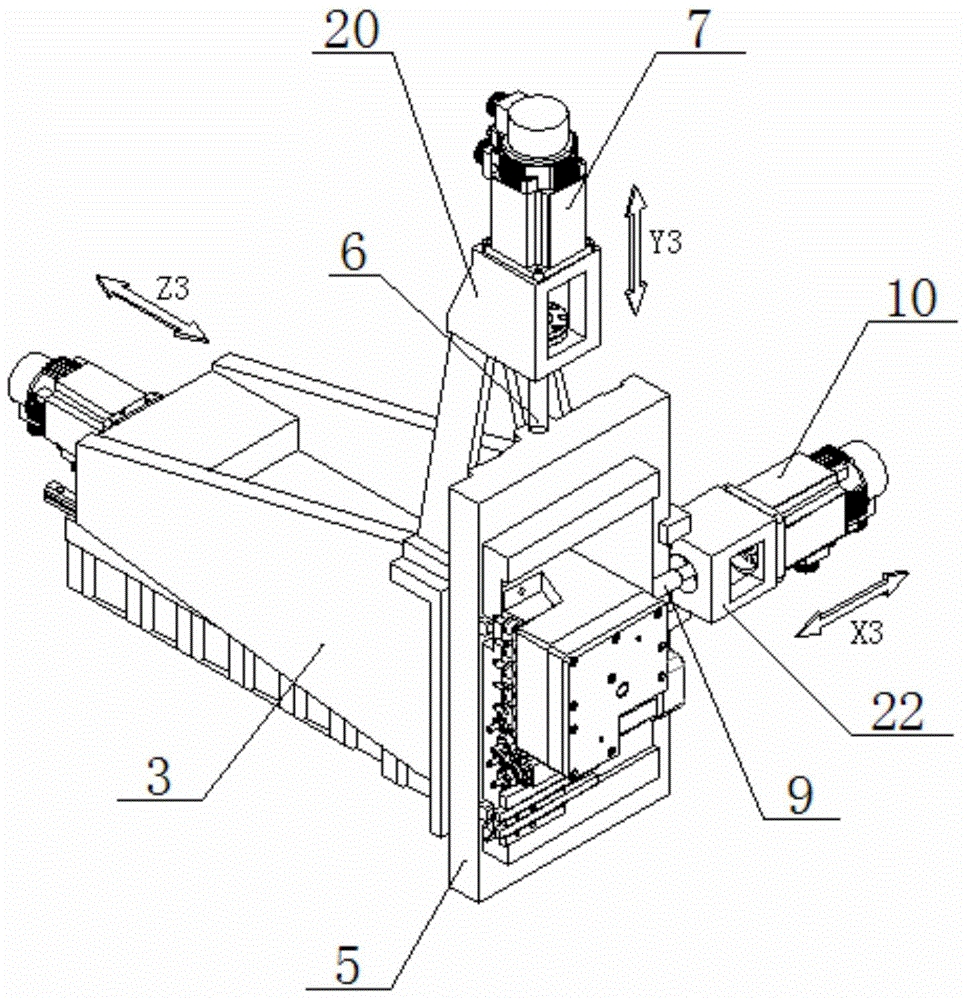

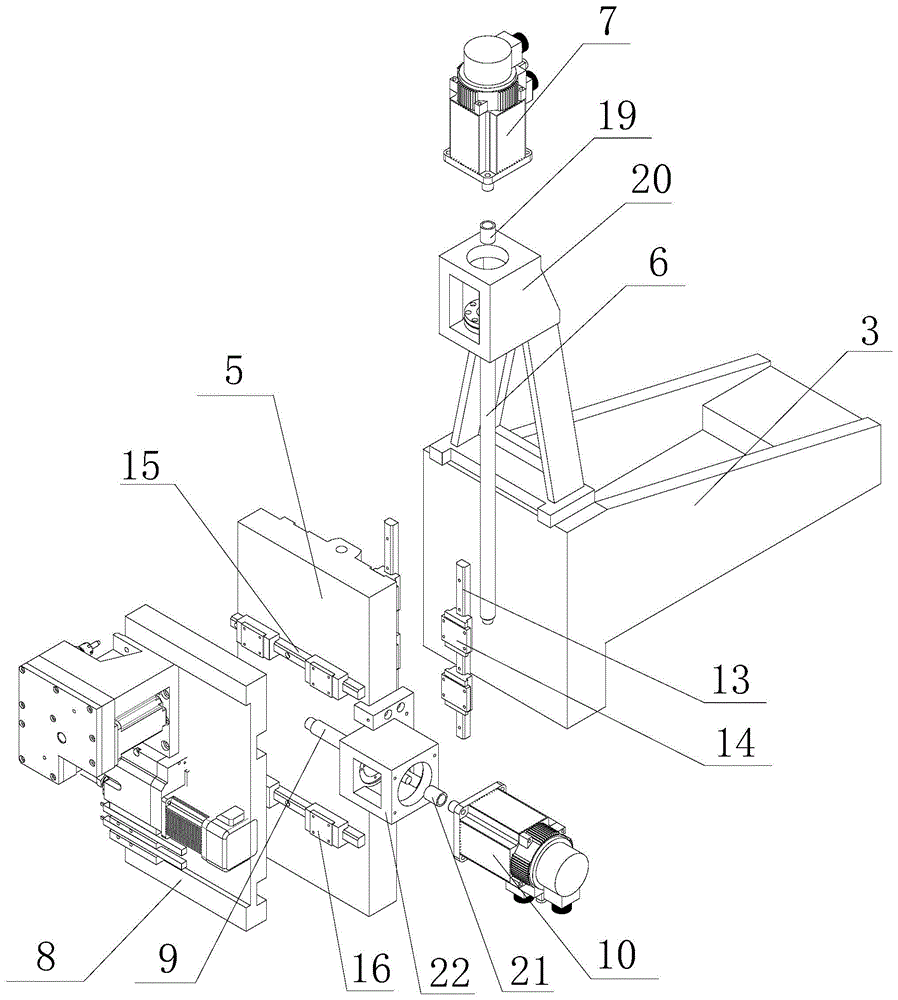

Crosshead shoe third shaft group mechanism of center-moving lathe-milling machine tool

InactiveCN104589079AGuaranteed high precision rotationAvoid the problem of large concentricity deviationFeeding apparatusOther manufacturing equipments/toolsDrive shaftSlide plate

The invention discloses a crosshead shoe third shaft group mechanism of a center-moving lathe-milling machine tool. The crosshead shoe third shaft group mechanism comprises a Z3 shaft group arranged on a lathe bed, a Y3 shaft group and an X3 shaft group, wherein the Z3 shaft group comprises a Z3 shaft servo motor, a Z3 shaft screw rod and a Z3 shaft slide plate; the Z3 shaft slide plate is mounted on the lathe bed; the Z3 shaft screw rod is in thread connection with the Z3 shaft slide plate; one end of the Z3 shaft screw rod is connected with a transmission shaft of the Z3 shaft servo motor; the Y3 shaft group comprises a crosshead shoe which is glidingly arranged on the Z3 shaft slide plate, a Y3 shaft servo motor, a slide seat and a Y3 shaft screw rod; the Y3 shaft screw rod is in thread connection with the slide seat; one end of the Y3 shaft screw rod is connected with a transmission shaft of the Y3 shaft servo motor; the X3 shaft group comprises a tool mounting plate, an X3 shaft servo motor and an X3 shaft screw rod; the X3 shaft screw rod is in thread connection with the tool mounting plate; one end of the X3 shaft screw rod is connected with a transmission shaft of the X3 shaft servo motor. The crosshead shoe third shaft group mechanism has the beneficial effects that the problems that the machining and molding of a complicated part cannot be realized at one step by an existing center-moving lathe-milling machine tool and the efficiency is not high are solved.

Owner:NANJING JIANKE MACHINERY

Output gear shaft rotary forging die

The invention discloses an output gear shaft rotary forging die which comprises a female die, a swinging head male die and a connecting die. The connecting die is arranged on a forging shaft body section of a output gear shaft and is connected with the female die by a fixed key; the female die and the swinging head male die are respectively connected with a compressing plate. According to the output gear shaft rotary forging die disclosed by the invention, one-step processing forming of the output gear shaft is implemented, working hours are saved, materials are saved, convenience is provided for next processing, processing time of an integral machine is shortened, processing efficiency is improved and a length-diameter ratio of a casting reaches 3.1>2.5.

Owner:姚烔涛

Pipe processing equipment and technology

ActiveCN109624257ARealize one-time processing and moldingIncrease productivityMetal working apparatusEngineering

The invention discloses pipe processing equipment and technology, and relates to the technical field of pipe processing. The pipe processing equipment comprises a rack, a cutting-off device and a grooving device, the cutting-off device comprises a bearing assembly and a cutting-off assembly, and the grooving device comprises a clamping assembly and a grooving assembly; a bearing space is formed ina combined bearing component and further internally provided with a positioning piece; the cutting-off device comprises a cutting-off driving piece fixedly erected on the rack, and the cutting-off driving piece is connected with a first cutting knife; the clamping assembly comprises a fixed clamping piece and a movable clamping piece, and the rack is further provided with a clamping driving piece; and the grooving assembly comprises a grooving driving piece connected with a second cutting knife. According to the pipe processing equipment, the production cost is lowered advantageously, the pipe processing quality can be improved greatly, the pipe production efficiency can be greatly improved; and in addition, the invention further provides the pipe processing technology, the recycling property of pipes can be effectively lowered, and the use performance of the pipes is ensured.

Owner:上海天原集团胜德塑料有限公司

Lyocell fiber and preparation method thereof

PendingCN114108118AImprove environmental performanceReduce uneven stainingMonocomponent cellulose artificial filamentConjugated cellulose/protein artificial filamentsPolymer scienceSpinning

The invention provides a lyocell fiber and a preparation method thereof, and the preparation method comprises the following steps: pretreating seaweed particles to obtain seaweed fiber particles with the particle size of 0.2-0.5 [mu] m; adding a dispersing agent into deionized water, uniformly stirring, and adding the alginate fiber particles to form suspension liquid of the alginate fiber particles; dissolving cellulose pulp in an N-methylmorpholine-N-oxide aqueous solution containing an antioxidant, then adding the suspension of alginate fiber particles to form a mixed system, and uniformly stirring the mixed system to obtain a spinning solution; carrying out dry-jet wet spinning on the spinning solution, and washing and drying to obtain lyocell fibers; the pretreatment comprises grinding, screening and surface coating treatment. The suspension emulsion of alginate fiber particles is added into the spinning solution, so that the prepared lyocell fiber has a good far infrared function and a good negative ion function. According to the preparation method, the content of alginate fiber particles in the lyocell fibers can be effectively increased, and the functionality of the fibers is improved.

Owner:LUOLAI LIFESTYLE TECH CO LTD +1

Plain-end copper wire machining device

The invention discloses a plain-end copper wire machining device. The plain-end copper wire machining device comprises a bracket, and further comprises a hydraulic cylinder base, a hydraulic cylinder,a hot rolling wheel, a rolling lower mold, a transmission motor, a belt wheel, a support base, a collecting wire wheel and a motor. Compared with the prior art, a circular-end copper wire passes through the lower rolling mold; the hot rolling wheel is hydraulically pushed to downwards move to press the copper wire, and is electrified for heating; after a certain temperature is reached, the transmission motor is started to drive rotation of the hot rolling wheel to roll the circular-end copper wire as a plain-end copper wire; the motor drives the collecting wire wheel to rotate to collect therolled plain-end copper wire; and as the device adopts the hot rolling technology to improve the plasticity of the copper wire and to eliminate the internal stress of plastic deformation, once moldingcan be realized, and the machining efficiency is improved.

Owner:陈锦华

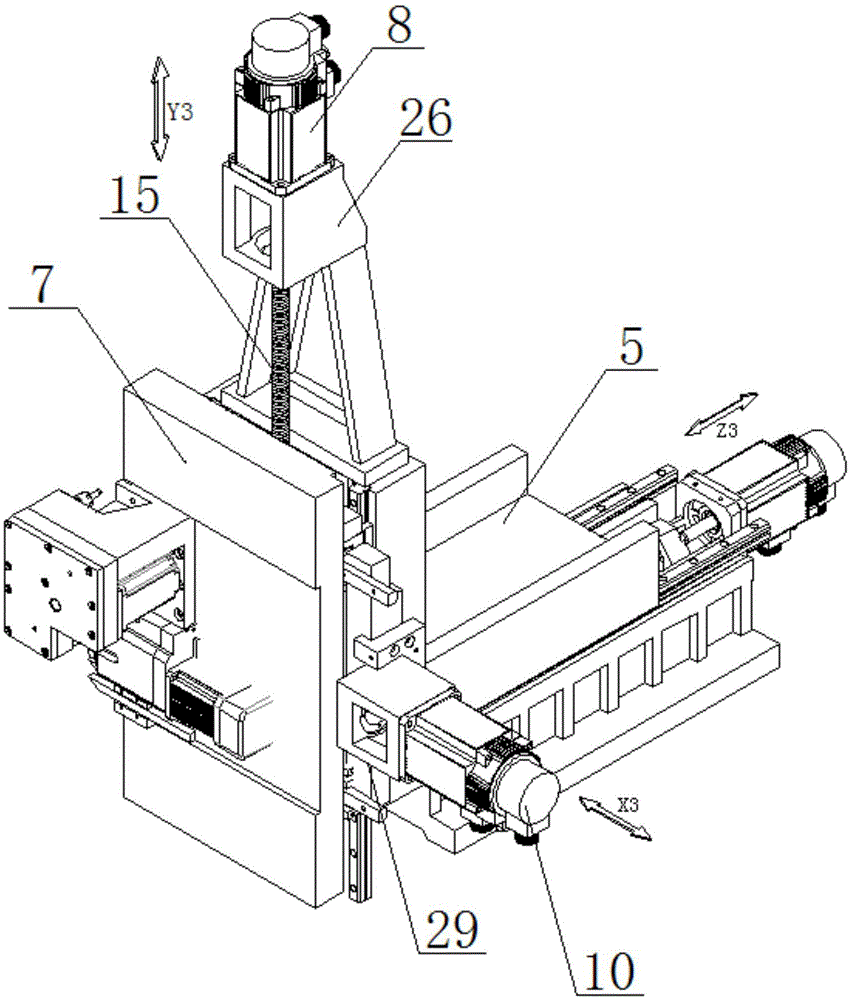

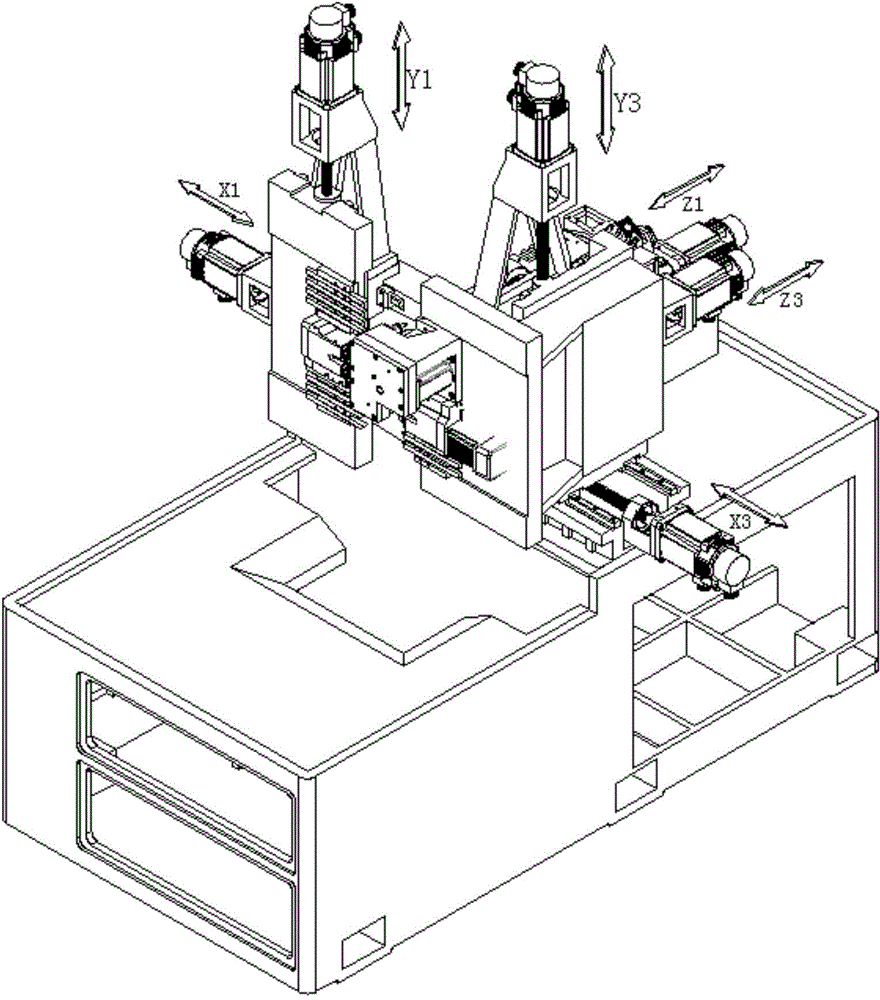

Cross-shaped sliding block third axis group mechanism of Swiss-type turning-milling machine tool

InactiveCN104827332AReduce frictionReduce wearFeeding apparatusMetal working apparatusNumerical controlDrive shaft

The invention discloses a cross-shaped sliding block third axis group mechanism of a Swiss-type turning-milling machine tool. The cross-shaped sliding block third axis group mechanism of the Swiss-type turning-milling machine tool comprises a Z3-axis group arranged on a machine tool bed, a Y3-axis group and an X3-axis group, wherein the Z3-axis group comprises a Z3-axis servo motor, a Z3-axis lead screw and a Z3-axis sliding plate, the Z3-axis sliding plate is installed on the machine tool bed, the Z3-axis lead screw is in threaded connection with the Z3-axis sliding plate, one end of the Z3-axis lead screw is connected with a transmission shaft of the Z3-axis servo motor, the Y3-axis group comprises cross-shaped sliding blocks which are arranged on the Z3-axis sliding plate in a sliding mode, a Y3-axis servo motor, a sliding seat and a Y3-axis lead screw, the Y3-axis lead screw is in threaded connection with the sliding seat, one end of the Y3-axis lead screw is connected with a transmission shaft of the Y3-axis servo motor, the X3-axis group comprises a cutter mounting base, an X3-axis servo motor and an X3-axis lead screw, the X3-axis lead screw is in threaded connection with the cutter mounting seat, and one end of the X3-axis lead screw is connected with a transmission shaft of the X3-axis servo motor. The cross-shaped sliding block third axis group mechanism of the Swiss-type turning-milling machine tool has the advantage of solving the problems that for an existing computer numerical control precision turning-milling machine tool, one-time machining forming of complex parts can not be achieved, and the machining efficiency is not high.

Owner:NANJING JIANKE MACHINERY

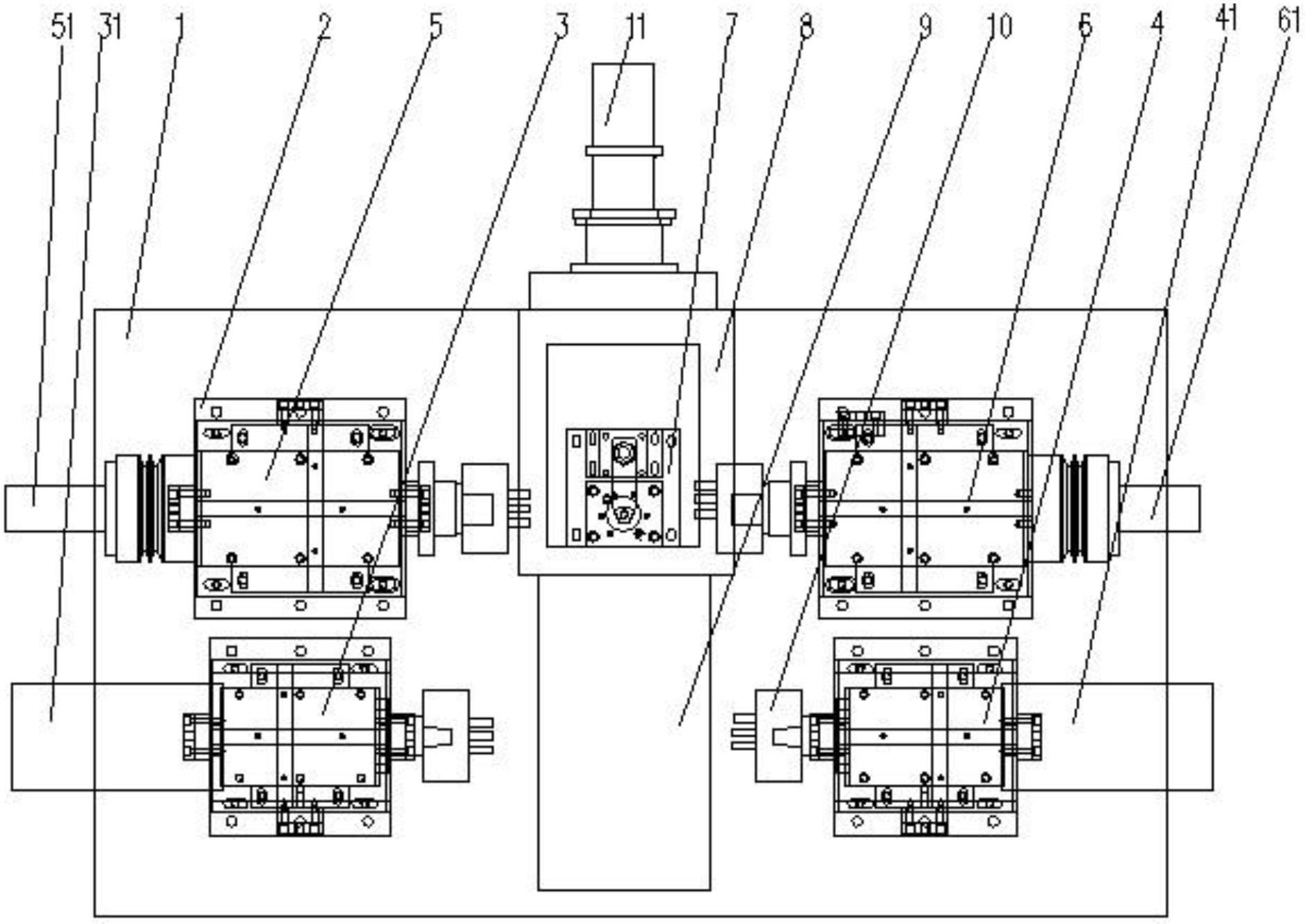

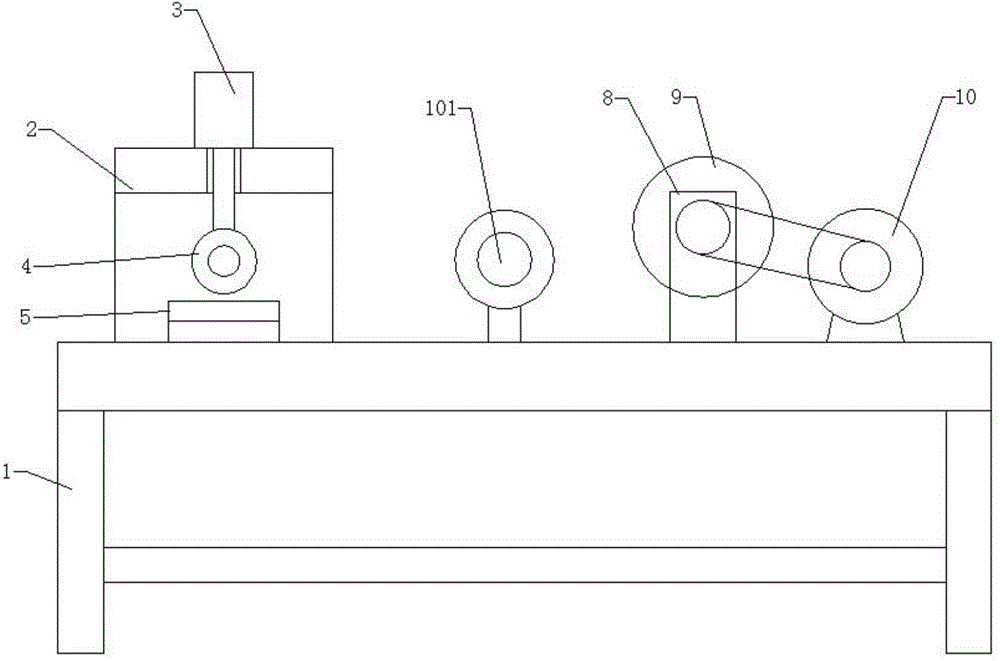

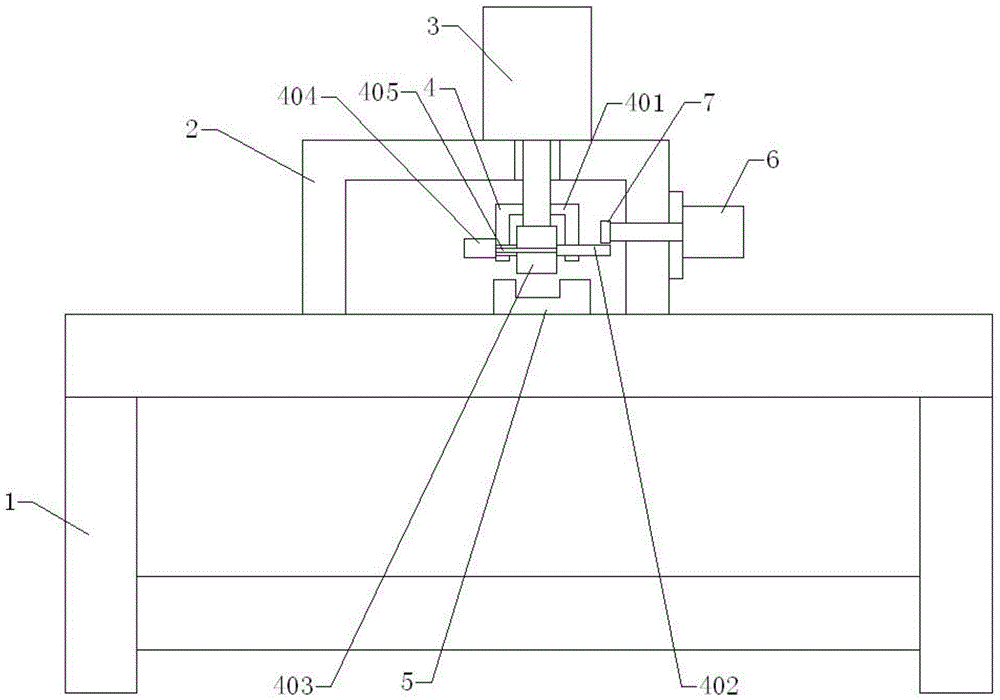

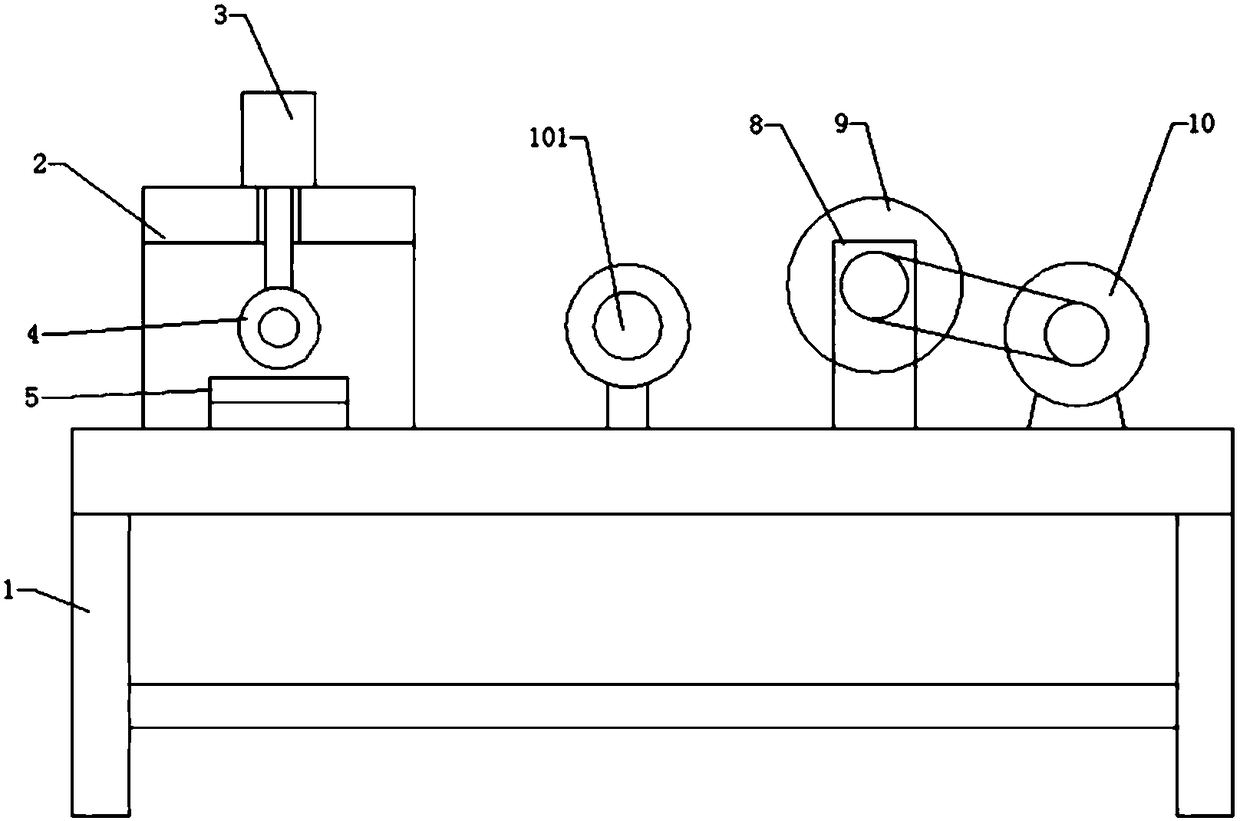

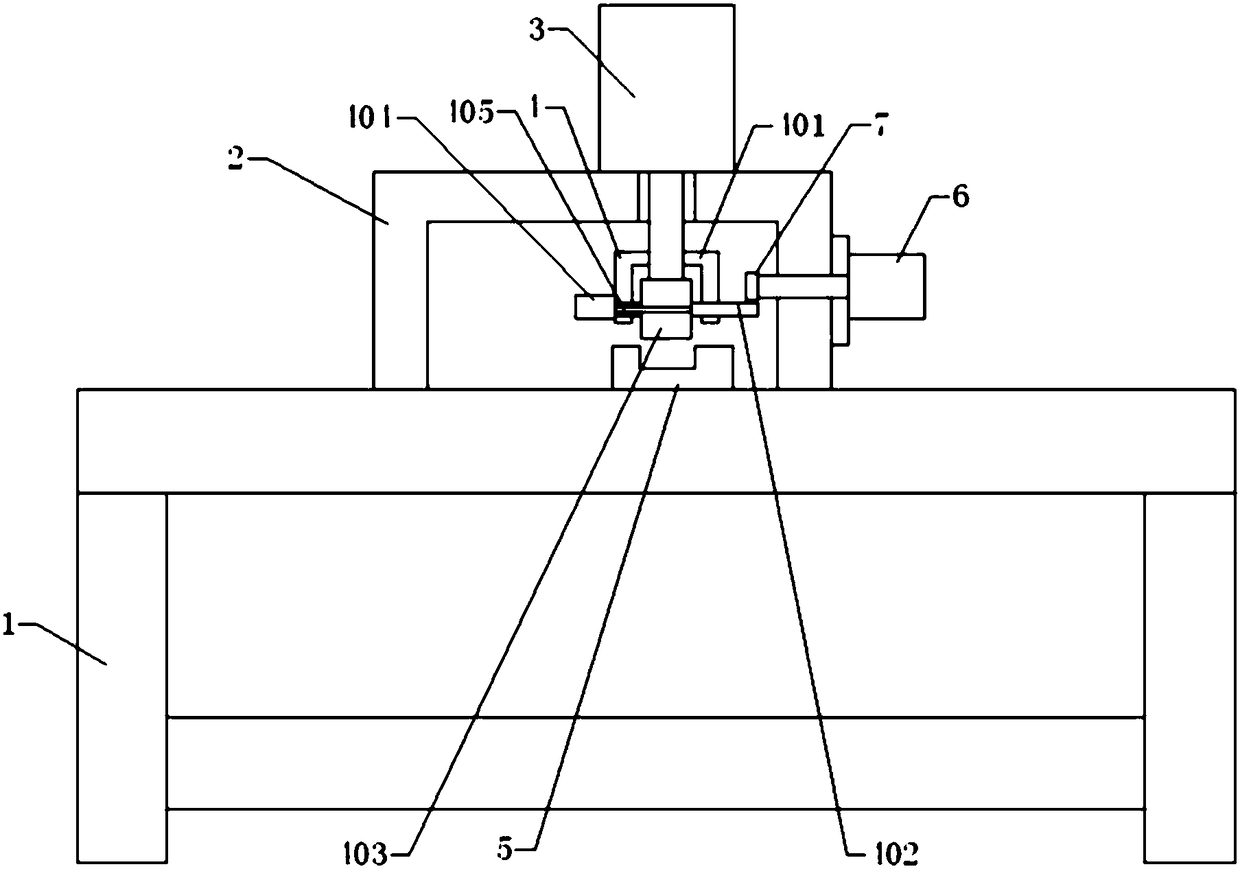

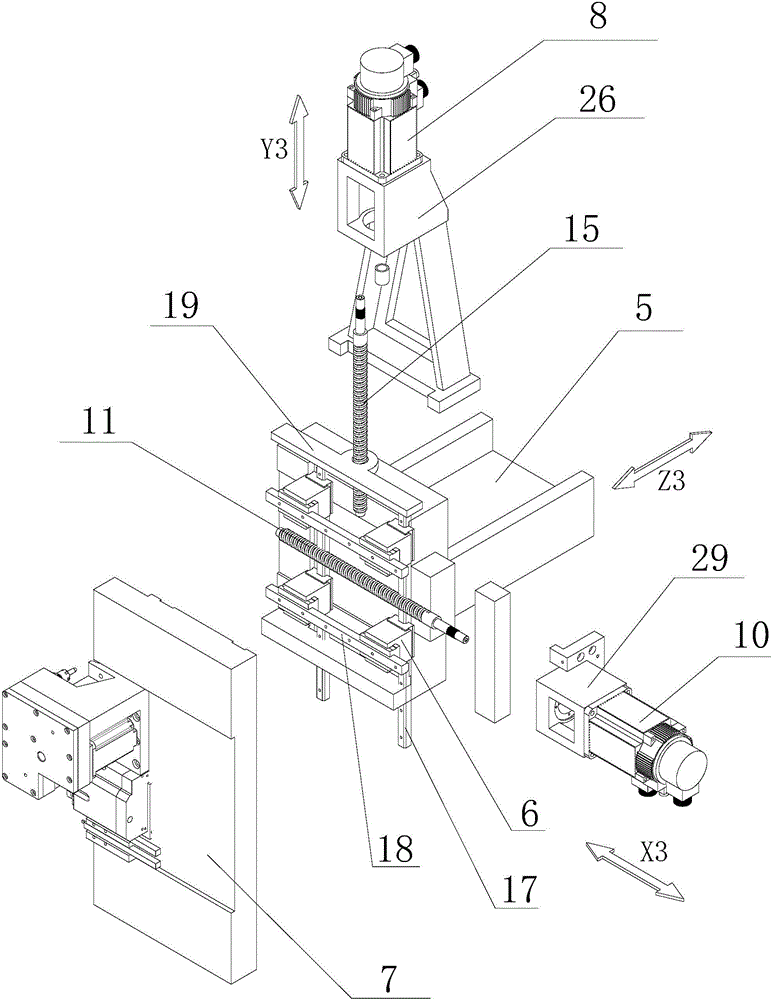

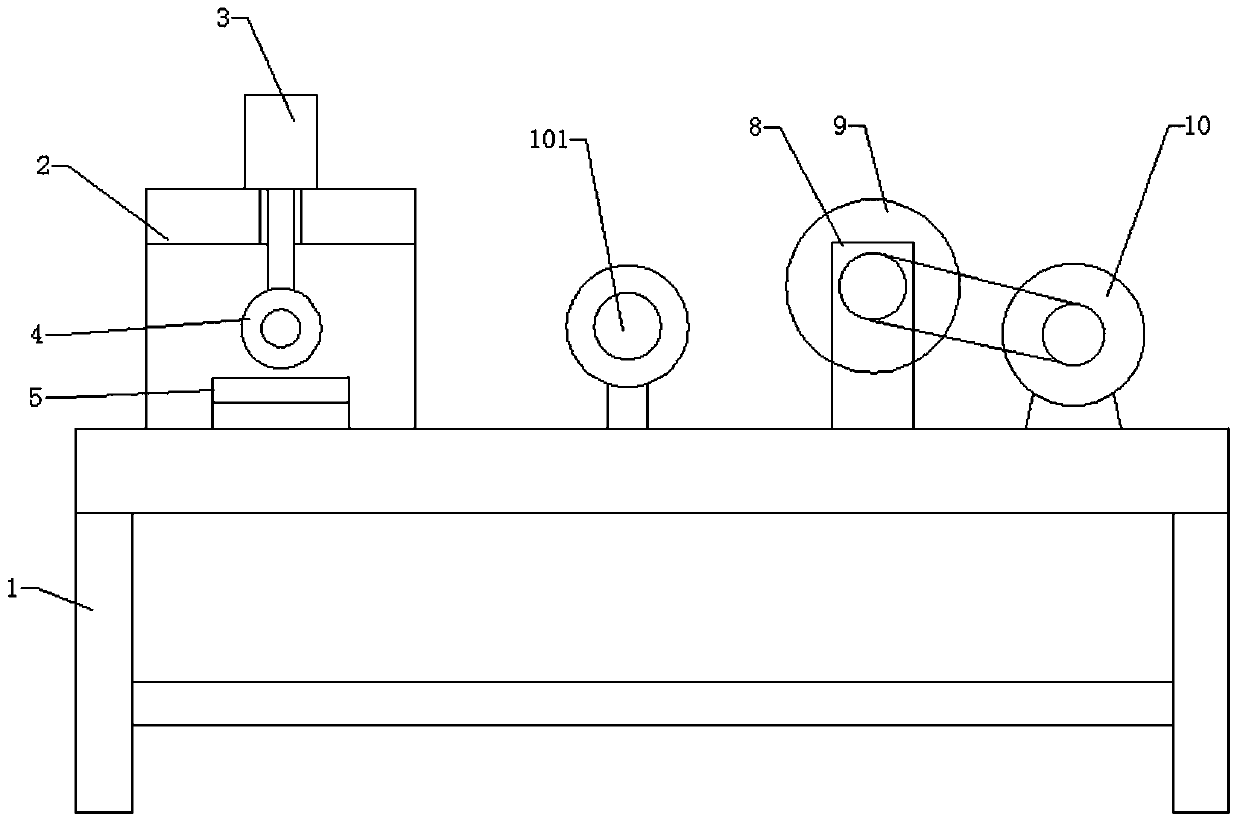

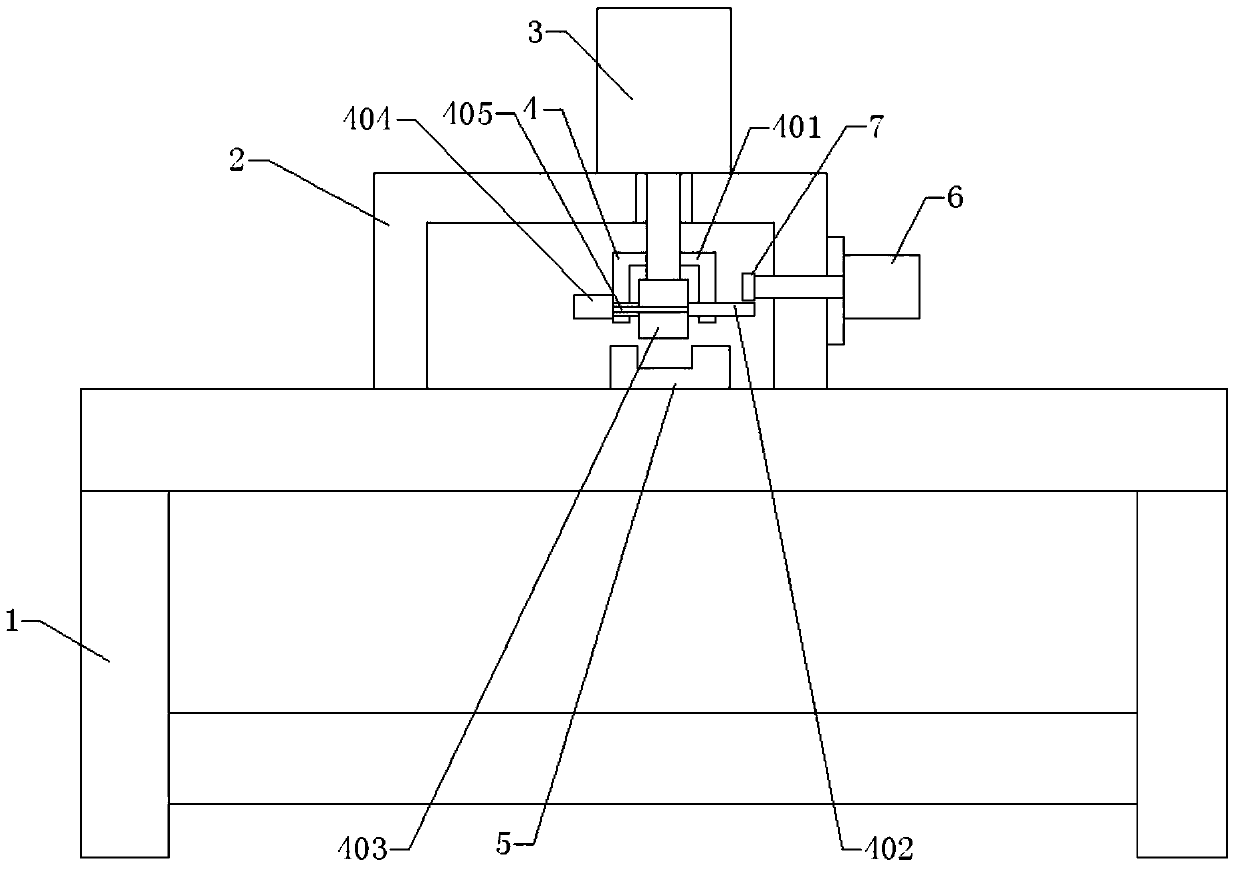

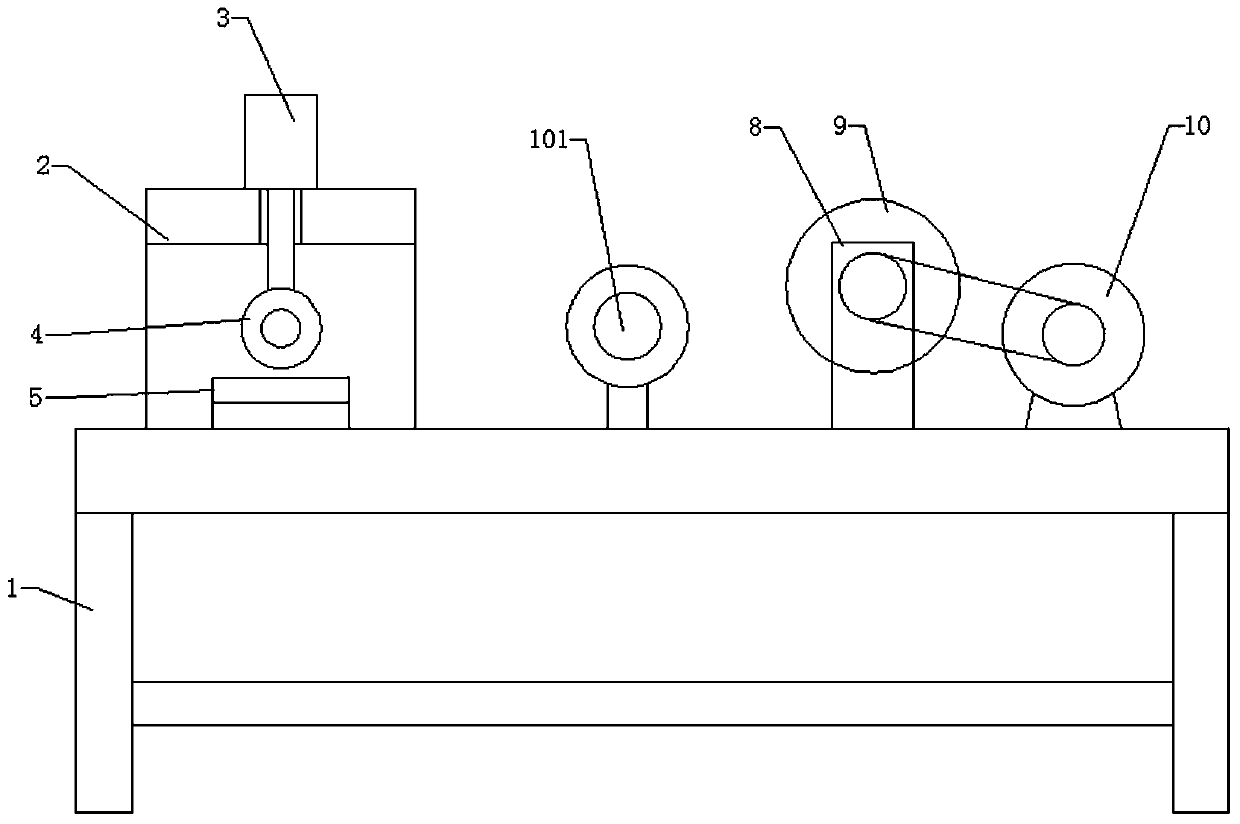

Third axis group mechanism on movable turning-milling machine tool

InactiveCN104889752AFast molding speedAvoid wasting timeFeeding apparatusOther manufacturing equipments/toolsSlide plateEngineering

The invention discloses a third axis group mechanism on a movable turning-milling machine tool. The third axis group mechanism comprises an X3 axis group, a Z3 axis group and a Y3 axis group, the X3 axis group comprises an X3 axis sliding plate (1), an X3 axis servo motor (2) and an X3 axis lead screw (3), the Z3 axis group comprises a Z3 axis sliding plate (4), a Z3 axis servo motor (5) and a Z3 axis lead screw (6), and the Y3 axis group comprises a tool mounting seat (7), a Y3 axis servo motor (8) and a Y3 axis lead screw (9). The third axis group mechanism has the advantages that the third axis group mechanism is matched with an existing movable turning-milling machine tool, complicated parts can be machined and formed once, and production efficiency is high. Both the bottoms of the X3 axis group and the Z3 axis group are supported, and the third axis group mechanism is more stable in structure and better in rigidity.

Owner:NANJING JIANKE MACHINERY

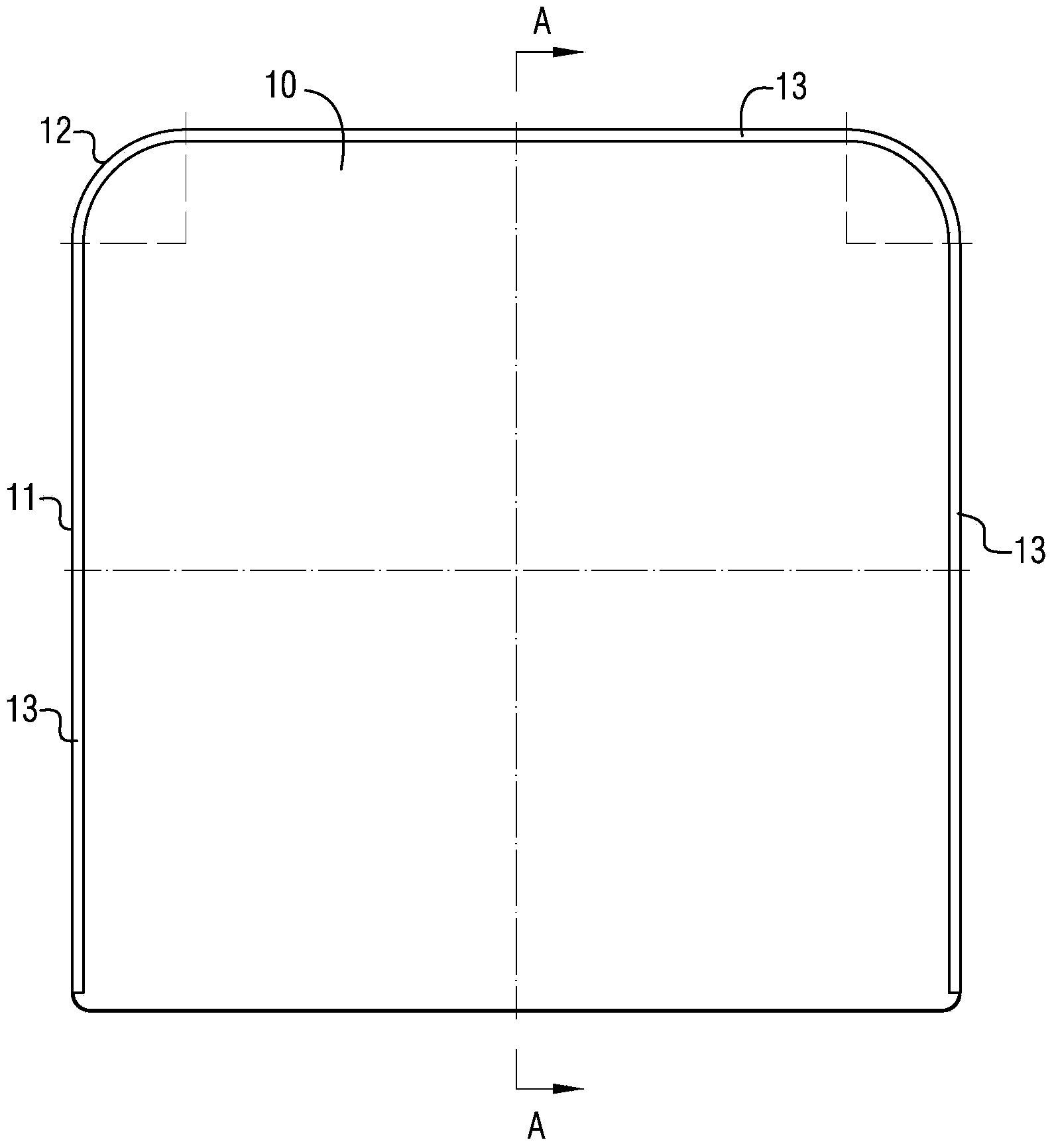

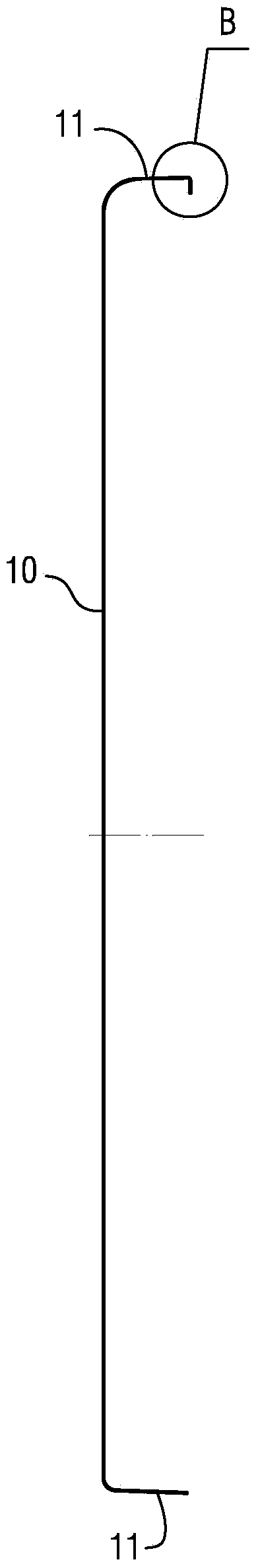

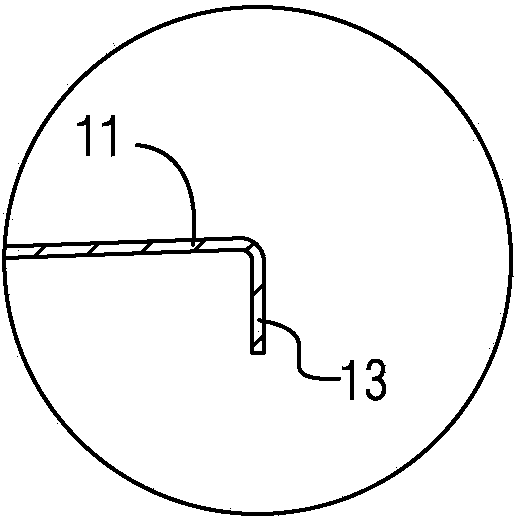

Thin-walled annular aluminum foil forming method and blanking die device

InactiveCN109483647ARealize one-time processing and moldingHigh precisionMetal working apparatusThin walledScratching

The invention relates to a thin-walled annular aluminum foil forming method and a blanking die device. According to the thin-walled annular aluminum foil forming method, a punching machine is adoptedto machine and form thin-walled annular aluminum foil, a fabroil is put on a workbench of the punching machine, the upper part and the lower part of the aluminum foil are covered and protected throughthin powder paper, and after the aluminum foil is protected, the aluminum foil is laid on the fabroil to be blanked; and after blanking is completed, shape correcting is carried out, to avoid scratching and pits during shape correcting, the upper face and the lower face of the annular aluminum foil are covered and protected through the thin powder paper, the thin-walled annular aluminum foil is put on the smooth tempered glass surface and is leveled. The blanking die device comprises a blanking die handle, a large blanking die head, a small blanking die head and an elastic jacking device. Aninner and outer blanking die head combined mode is adopted, the small blanking die head is sleeved with the large blanking die head, and the annular elastic jacking device is arranged in the middle. According to the thin-walled annular aluminum foil forming method and the blanking die device, the problem that as the aluminum foil is very thin, difficulty of annular part machining is very large issolved. The consistency of sizes of inner circles and outer circles of annular aluminum foil in batch machining is guaranteed, the part machining precision is high, edges are very tidy, and no burr exists. The die is low in machining cost, and low-cost popularization can be achieved.

Owner:INNER MONGOLIA AEROSPACE HONGGANG MACHINERY

Ultrasonic pipe end machining device

InactiveCN108031763ARealize one-time processing and moldingExtended service lifeMetal-working feeding devicesPositioning devicesEngineeringMachining

An ultrasonic pipe end machining device is characterized by comprising a die clamping mechanism, a pipe end positioning mechanism, a transverse ultrasonic flaring mechanism, a top plate, a bottom plate, a front plate, a left plate and a right plate. The die clamping mechanism is arranged between the top plate and the bottom plate, and the pipe end positioning mechanism is installed on the front plate and fixedly connected with the front plate; the transverse ultrasonic flaring mechanism is installed on the left plate; the top plate is arranged between the left plate and the right plate and islocated at the upper ends of the left and right plates; the bottom plate is arranged between the left and right plates and located on the left plate; the front plate is arranged between the top plateand the bottom plate; the left plate is arranged at the left end of the top plate and the left end of the bottom plate and connected with the top plate and the bottom plate; the right plate is arranged between the top plate and the bottom plate and connected with the right ends of the top plate and the right end of the bottom plate. The device has the advantages that the efficiency is high and a die is durable.

Owner:XINXIANG UNIV

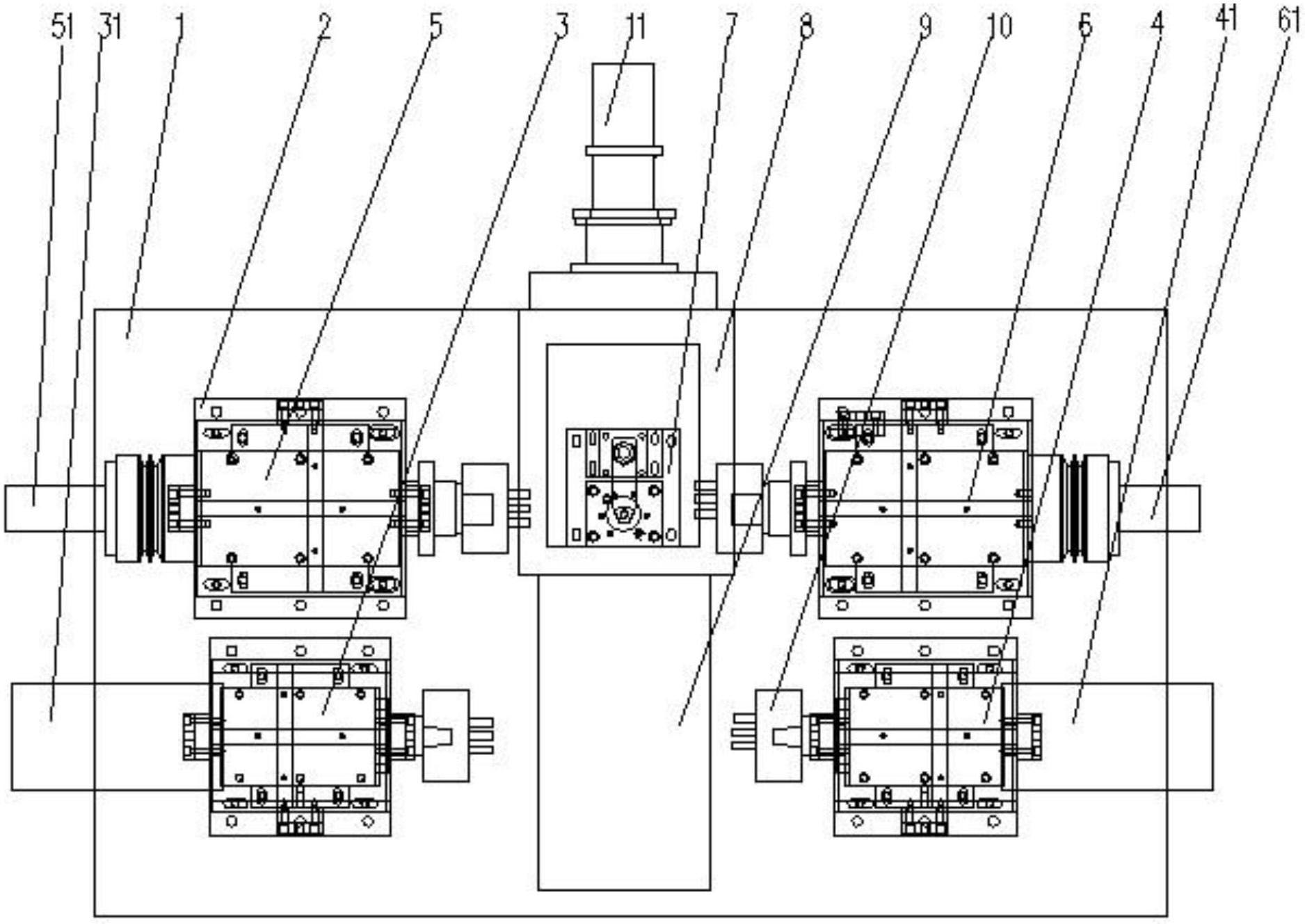

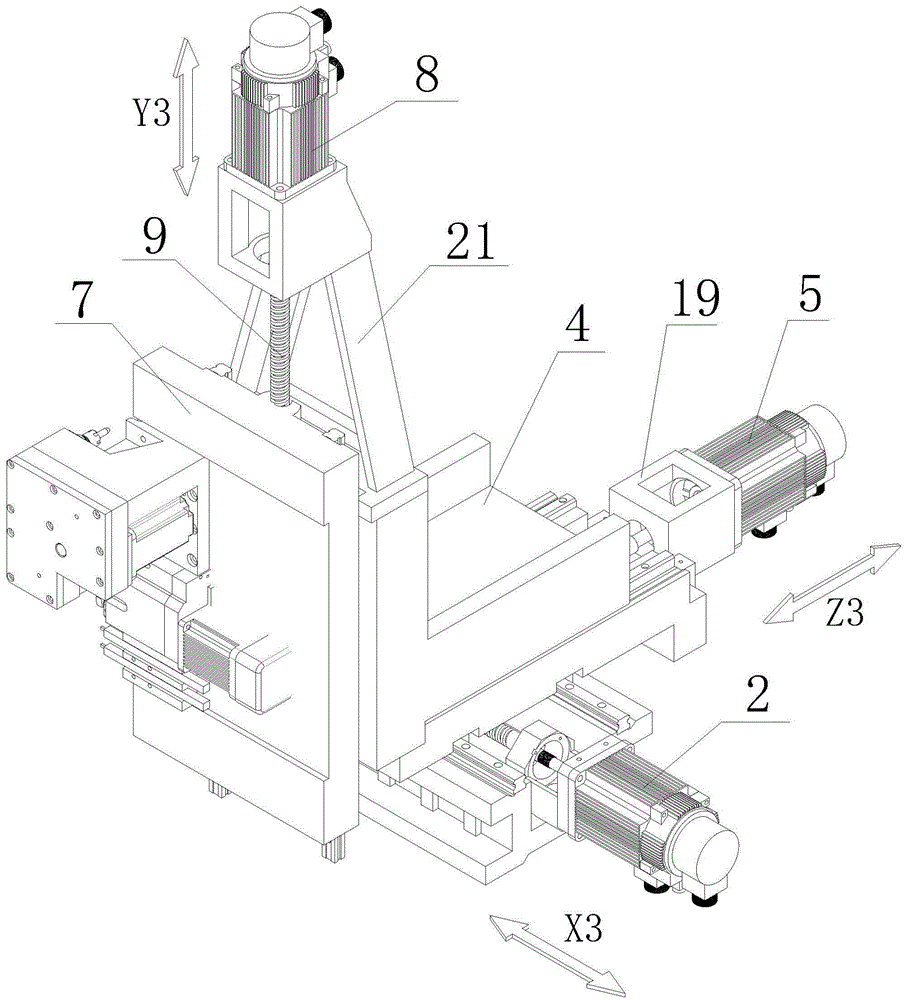

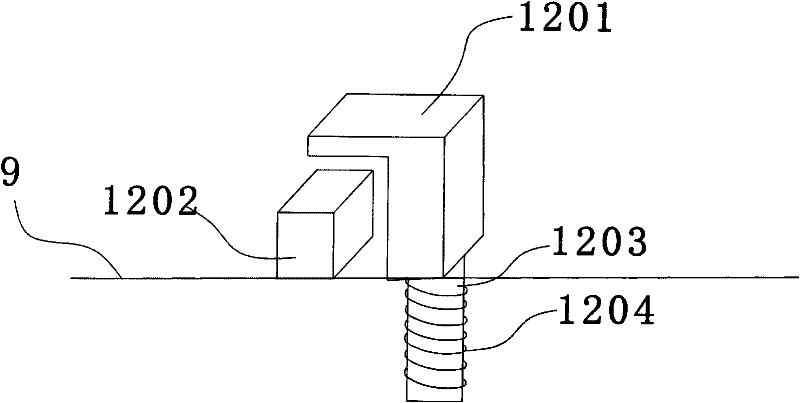

Crossed slider third axis set mechanism matched with positive-axis mechanism on numerical control turn milling main shaft box moving machine

InactiveCN104827306AGuaranteed high precision rotationAvoid the problem of large concentricity deviationFeeding apparatusOther manufacturing equipments/toolsNumerical controlEngineering

The invention discloses a crossed slider third axis set mechanism matched with a positive-axis mechanism on a numerical control turn milling main shaft box moving machine. The crossed slider third axis set mechanism is composed of an X3 axis set, a Z3 axis set and a Y3 axis set. The X3 axis set comprises a crossed slider (1), an X3 servo motor (2) and an X3 axis lead screw (3). The Z3 axis set comprises an L-shaped Z3 axis sliding plate (5), a Z3 servo motor (6) and a Z3 axis lead screw (7). The Y3 axis set comprises a cutter installing base (8), a Y3 axis servo motor (9) and a Y3 axis lead screw (10). The crossed slider third axis set mechanism has the advantage that the problem that complicated parts cannot be machined and formed at a time through an existing main shaft box moving type turn milling machine tool, and efficiency is low is solved.

Owner:NANJING JIANKE MACHINERY

Efficient punching device

InactiveCN111408760AAvoid low processing efficiencyEfficient drillingTransportation and packagingStepped drillsDrill bitStructural engineering

The invention provides an efficient punching device, and belongs to the technical field of automatic punching machining. The efficient punching device comprises a stepped drill bit and a punching assembly, wherein cross-sectional diameters of all sections of the stepped drill bit are sequentially increased or decreased in one direction, transition surfaces with knife edges are arranged between every two adjacent sections, so that one-time machining on a variable cross-sectional hole and orifice chamfering of the variable cross-sectional hole on a workpiece can be realized, the problems of lowmachining efficiency and poor product quality caused by multiple clamping or replacement of the drill bit are avoided, in addition, the punching assembly is arranged for mounting the stepped drill bit, the punching assembly comprises a plurality of detachably connected drill bit mounting heads, so that synchronous movement of drill bits mounted on the plurality of drill bit mounting heads is realized, one-time machining on a workpiece with a plurality of holes in different positions is achieved, the problems that machining efficiency is low and deviation is prone to occur due to multiple clamping is avoided as well, and efficient punching machining is achieved.

Owner:宁波格林工艺玩具有限公司

Third axis group structure on numerical control repeated cutting material moving type lathe

InactiveCN104827331AGuaranteed high precision rotationAvoid the problem of large concentricity deviationFeeding apparatusMetal working apparatusNumerical controlSlide plate

The invention discloses a third axis group structure on a numerical control repeated cutting material moving type lathe. The third axis group structure is composed of an X3-axis group, a Y3-axis group and a Z3-aixs group. The X3-axis group comprises an L-shaped X3-axis sliding plate (1), an X3-axis servo motor (2) and an X3-axis lead screw (3). The Y3-axis group comprises a Y3-axis sliding plate (4), a Y3-axis servo motor (5) and a Y3-axis lead screw (6). The Z3-aixs group comprises a tool mounting seat (7), a Z3-aixs servo motor (8) and a Z3-aixs lead screw (9). The third axis group structure has the advantage that the problems that an existing material moving type turn-milling machine tool cannot achieve one-time machining forming of complex parts and is low in efficiency are solved.

Owner:NANJING JIANKE MACHINERY

An automatic transformer insulation piece adhesive processing device

The invention relates to an automatic transformer insulation piece adhesive processing device, including machine tools, A material adjust mechanism, Transfer mechanism, glue rolling mechanism, first compression mechanism, pressure feed mechanism, a drying oven, a second crimping mechanism and a winding mechanism are arranged on the machine tool in turn, the tailoring mechanism comprises a first frame, a tailoring shaft and a dialing shaft, the transmission mechanism comprises a second frame, a first screw rod and a mechanical fixture, the glue rolling mechanism comprises an upper rubber roller, a first rotating roller and a second rotating roller, the pressing and feeding mechanism comprises a third frame, a second slide plate, a moving plate, a first top plate and a second cylinder, and the machine tool is provided with a PLC controller; The material can be automatically adjusted after the insulating stay is blanked, Automatic feeding under sensor induction, synchronous rolling of insulation paper, pressing and conveying, drying of secondary pressing and winding can realize one-time processing and forming of insulation adhesive blank, which greatly improves the processing efficiency, has high qualified rate of finished products, reduces the labor and site cost, and is widely used in insulation and supporting materials of transformers.

Owner:镇江市鑫泰绝缘材料有限公司

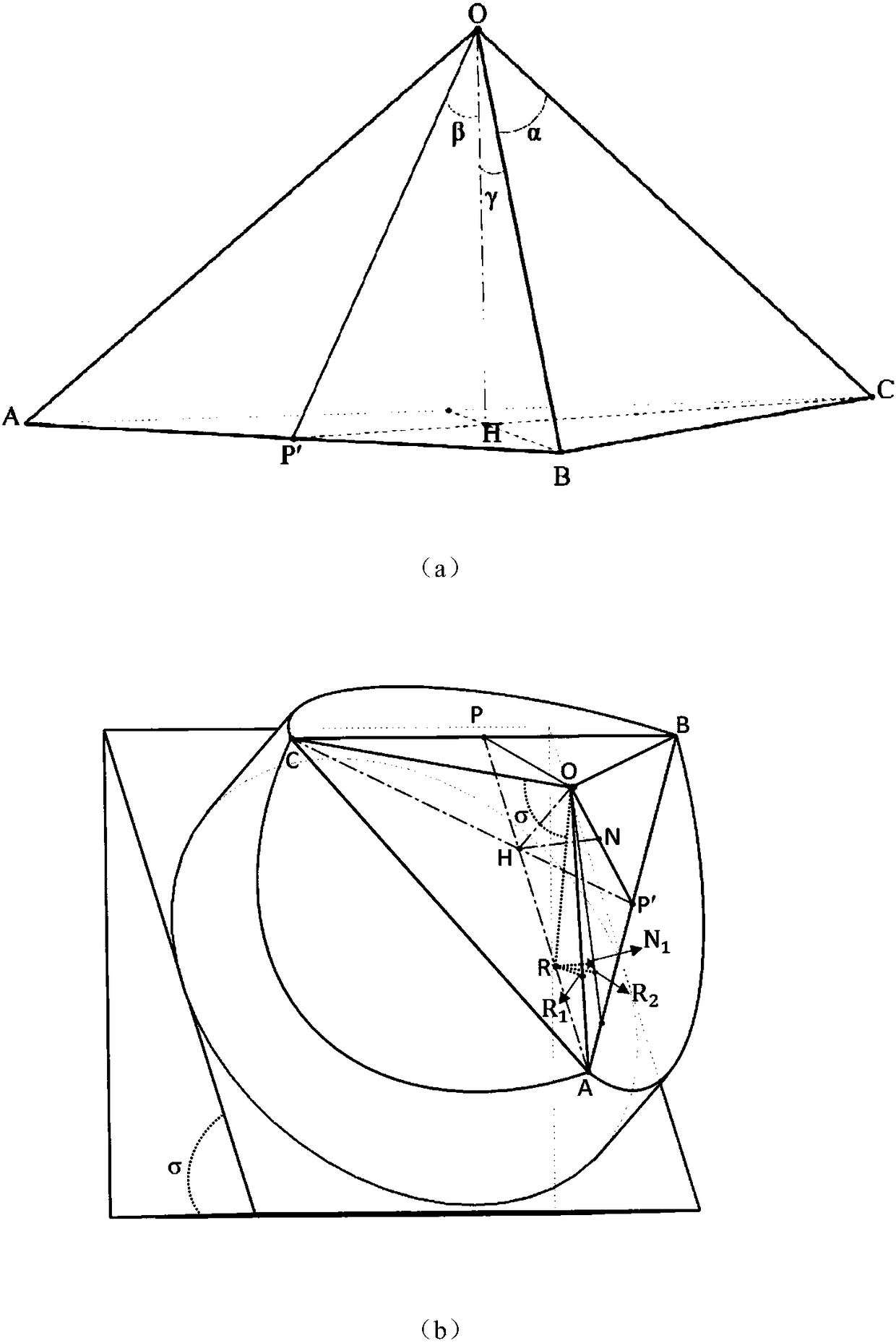

One-time molding method of large-angle regular triangular pyramid-shaped indenter based on fib

Owner:咸阳瞪羚谷新材料科技有限公司

Ring rolling machine with main roller multi-station structure

ActiveCN112059080AReduce wall thicknessAvoid deformationMetal rollingStructural engineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, and in particular to a ring rolling machine with a main roller multi-station structure. The ring rolling machine can be used for conveniently carrying out one-step machining and forming on a workpiece by carrying out multi-station adjustment work on a main roller, saving time for manually replacing the main roller and time for secondarily heating the workpiece, improving working efficiency, and saving manpower. The equipment machining mode is simplified, meanwhile, equipment part abrasion caused by repeated disassembly of the main roller is avoided, the service life of the equipment is prolonged, and practicability and reliability are improved. The ring rolling machine comprises a vertical plate, two sets of reinforcingplates, a base, a center control box and a limiting disc. The front sides of the two sets of reinforcing plates are installed on the rear side of the vertical plate. The bottom of the vertical plate and the bottoms of the two sets of reinforcing plates are fixed to the base. The center control box is installed on the left side of the left side reinforcing plate. A through groove running back and forth is vertically formed in the middle part of the vertical plate. An adjustment device is arranged in the through groove. The front side of the adjusting device extends to the front of the verticalplate.

Owner:ZHUCHENG SHENGYANG MACHINERY

System and method for continuous electrolytic machining of flexible metal sheets with micro-group grooves

ActiveCN106270841BImprove processing efficiencyRealize one-time processing and moldingElectrochemical machining apparatusElectricityDrive wheel

The invention relates to a system and a method for continuous electrolysis processing of microgroove groups of a flexible metal sheet, and belongs to the technical field of electrolysis processing. The system comprises a flexible metal sheet workpiece conveying system, an electrolysis processing tool electrode system, a processing power source, an electrolyte circulating system, and an electrolysis processing machine tool. The method comprises the following steps of during processing, firstly, clamping the flexible metal sheet, enabling the flexible metal sheet to penetrate between a plurality of support rollers and an arc-shaped masking plate, and enabling the inner and outer surfaces to tightly attach with the corresponding support rollers and the arc-shaped masking plate; according to the structure and size of each microgroove group, selecting a tool electrode, and completing the clamping; flushing electrolyte, feeding each tool electrode along the radial direction of the corresponding support roller, and processing a groove structure in the surface of the flexile metal sheet; processing to the specified depth, enabling a driving wheel to continuously rotate, and driving the flexible metal sheet to slowly slide along the tangential direction of each roller, so as to complete the continuous processing of the microgroove groups of the flexible metal sheet. The system and the method have the advantages that the tool electrodes can be synchronously performed with auxiliary movement, and the updating of electrolyte and the discharging of electrolysis products are promoted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Machining method based on simple clamping of triangular parts

InactiveCN110666537AStable positionReduce the number of clampingPositioning apparatusMetal-working holdersMachine toolMachining

The invention provides a machining method based on simple clamping of triangular parts. The machining method includes the steps that the two triangular parts are oppositely clamped between two positioning pins in the length direction of a bottom plate, the triangular parts are clamped through a vice clamp in the width direction of the bottom plate, cushion plates are mounted on the two sides of the positioning pins separately, and therefore it is guaranteed that the clamping relative positions of the two parts are consistent; and during machining, the vice clamp is directly fixed to a simple numerical milling workbench, and the parts are machined after the relative positions of a clamping tool and a machine tool are determined. According to the method, the two parts are simultaneously oppositely clamped and machined through the vice clamp and the clamping tool, simple clamping of the triangular parts is achieved, the clamping frequency and difficulty of the parts are reduced, the machining quality of the parts is guaranteed, one-time machining forming of the two parts is achieved, and the clamping and machining efficiency is improved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Third axis group mechanism matched with positive axis of movable machine

InactiveCN104889753AFast molding speedAvoid wasting timeFeeding apparatusOther manufacturing equipments/toolsNumerical controlClassical mechanics

The invention discloses a third axis group mechanism matched with a positive axis of a movable machine. The third axis group mechanism comprises a Z3 axis group, a Y3 axis group and an X3 axis group, the Z3 axis group comprises a Z3 axis lead screw, a Z3 axis sliding plate and a Z3 axis servo motor, the Y3 axis group comprises a Y3 axis sliding plate, a Y3 axis lead screw and a Y3 axis servo motor, and the X3 axis group comprises a tool mounting seat, an X3 axis lead screw and an X3 axis servo motor. The third axis group mechanism has the advantages that the third axis group mechanism matched with the positive axis of the movable machine is matched with a positive axis structure of a numerical control movable turning-milling machine tool, and the numerical control movable turning-milling machine tool with a positive six-axis structure can be formed to avoid unnecessary time waste due to the fact that tool structures are arranged on the same X axis sliding plate, tool arrays are mutually connected, and independent operation cannot be realized. When the tool arrays on the positive axis structure of the machine tool are used for machining workpieces, an independent tool array on the third axis group can simultaneously machine the workpieces in different working procedures.

Owner:NANJING JIANKE MACHINERY

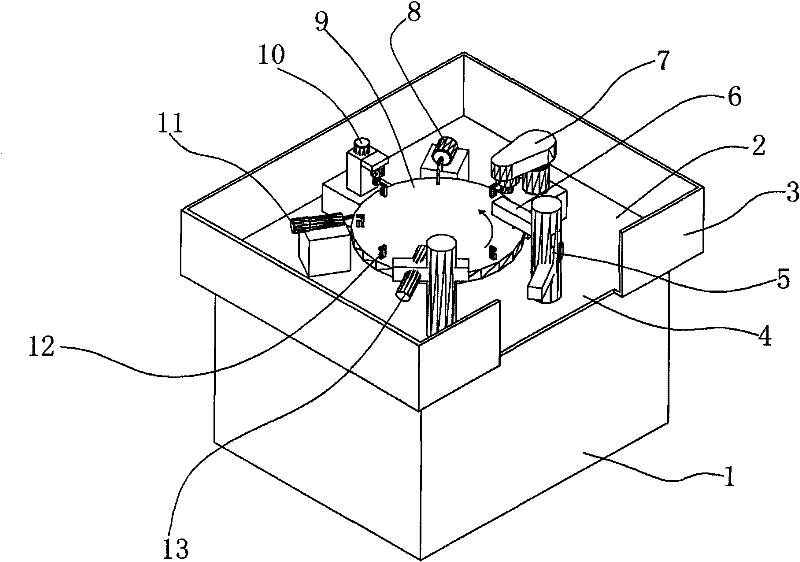

Drilling and milling eight-station combined machine

InactiveCN102000978BRealize one-time processing and moldingShort processing timeOther manufacturing equipments/toolsPositioning apparatusEngineeringMechanical engineering

The invention discloses a drilling and milling eight-station combined machine which comprises a turntable, as well as a feed mechanism, a positioning mechanism, a first milling mechanism, a drilling mechanism, a second milling mechanism, a reaming mechanism and a material catching mechanism which are arranged on the periphery of the turntable in sequence. In the invention, a part to be processed is fixedly arranged on a clamp of the turntable, the turntable is controlled to rotate according to setting requirements; when the turntable rotates to a processing step, the turntable is controlled to stop rotating and performing processing step; after the processing is finished, the turntable continues to rotate to the next processing step to repeat different processing steps for carrying out milling, drilling, reaming and the like on the part in sequence to finish multiple processing steps of the part. Compared with the prior art, the drilling and milling eight-station combined machine finishes milling of all surfaces of a part and drilling and reaming of all positions through once clamping, realizes one-time moulding of precision parts; in addition, the drilling and milling eight-station combined machine has the advantages of short processing time, short period, high efficiency and the like.

Owner:丰兴精密产业(惠州)有限公司

A flat copper wire processing device

ActiveCN104815867BImprove plasticityEliminate internal stressWire articlesHydraulic cylinderMotor drive

Owner:江西华业精工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com