Punching and swing grinding die of half axle with flange disc

A flange and mold technology, applied in the field of machining, can solve the problems of long processing time, material waste, and inconvenient processing of other parts, and achieve the effects of shortening machining time, saving man-hours, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

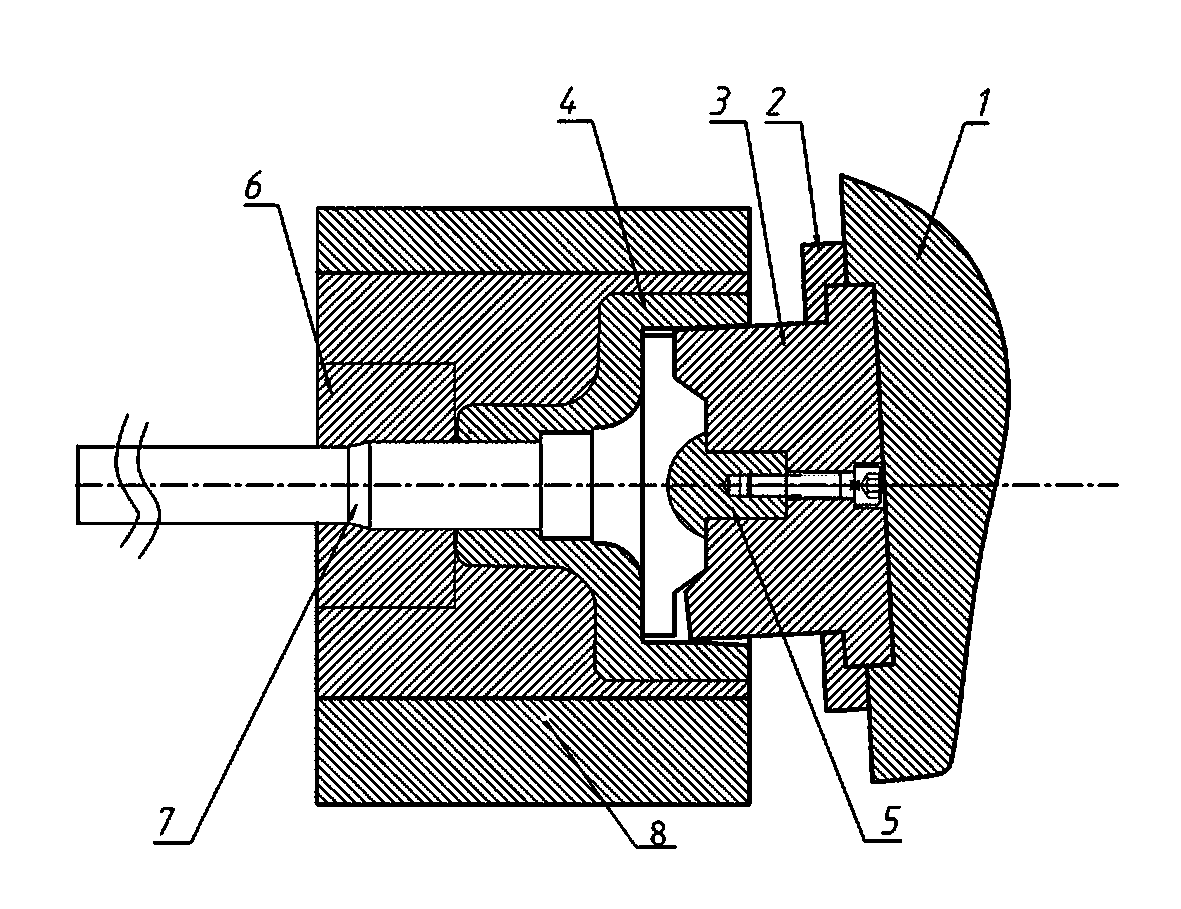

[0009] Referring to the accompanying drawings, a half-axis punching and rolling die with a flange includes a die set 8, a punch 5, a connecting die 6, a punch outer sleeve 3 and a pressing plate 2. The punch The die is set on the 7 flanges of the semi-shaft forging and tightened against the flange. The punch and the outer insert of the punch are fitted with a gap and connected by screws. The die is set on the shaft section of the half-shaft forging and the The die sleeve is fixedly connected, and the outer insert sleeve of the punch is connected with the swing head 1 through the pressing plate.

[0010] Preferably, the half-shaft punching and rolling die with a flange also includes a die pad 4, which is arranged on the flange section and the transition part between the flange and the half-shaft forging to protect the half-shaft forging .

[0011] A semi-shaft punching and rolling mold with a flange proposed by the present invention realizes one-time processing and molding of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com