Machine tool for simultaneously machining threaded holes on air inlet side and air outlet side of cylinder

A technology on the intake side and exhaust side, which is applied in the field of machine tools that simultaneously process the threaded holes on the intake side and exhaust side of the cylinder, which can solve the problems of low production efficiency, low machining accuracy of the threaded holes on the intake side and exhaust side of the cylinder, etc. problems, to achieve the effect of improving production efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

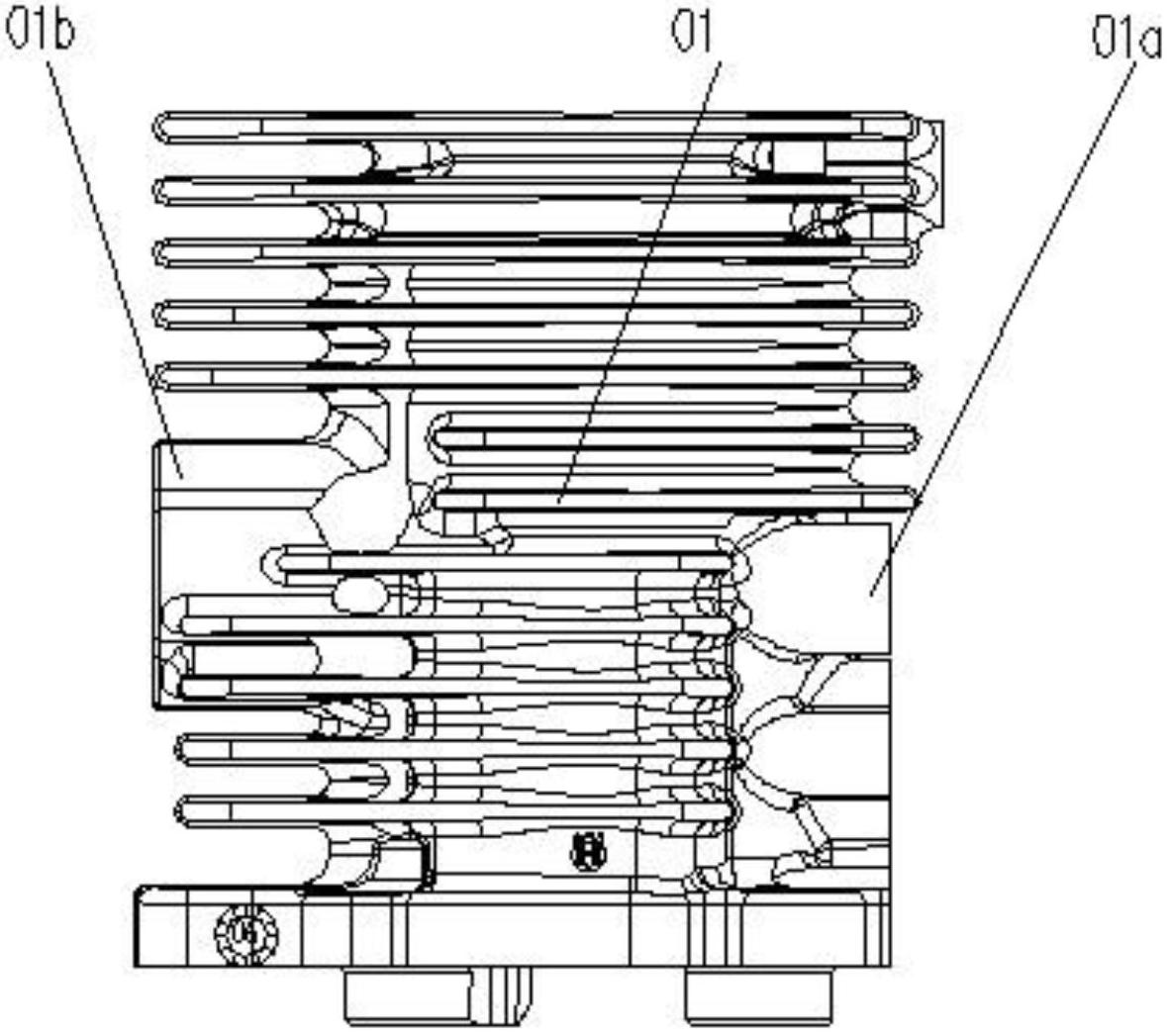

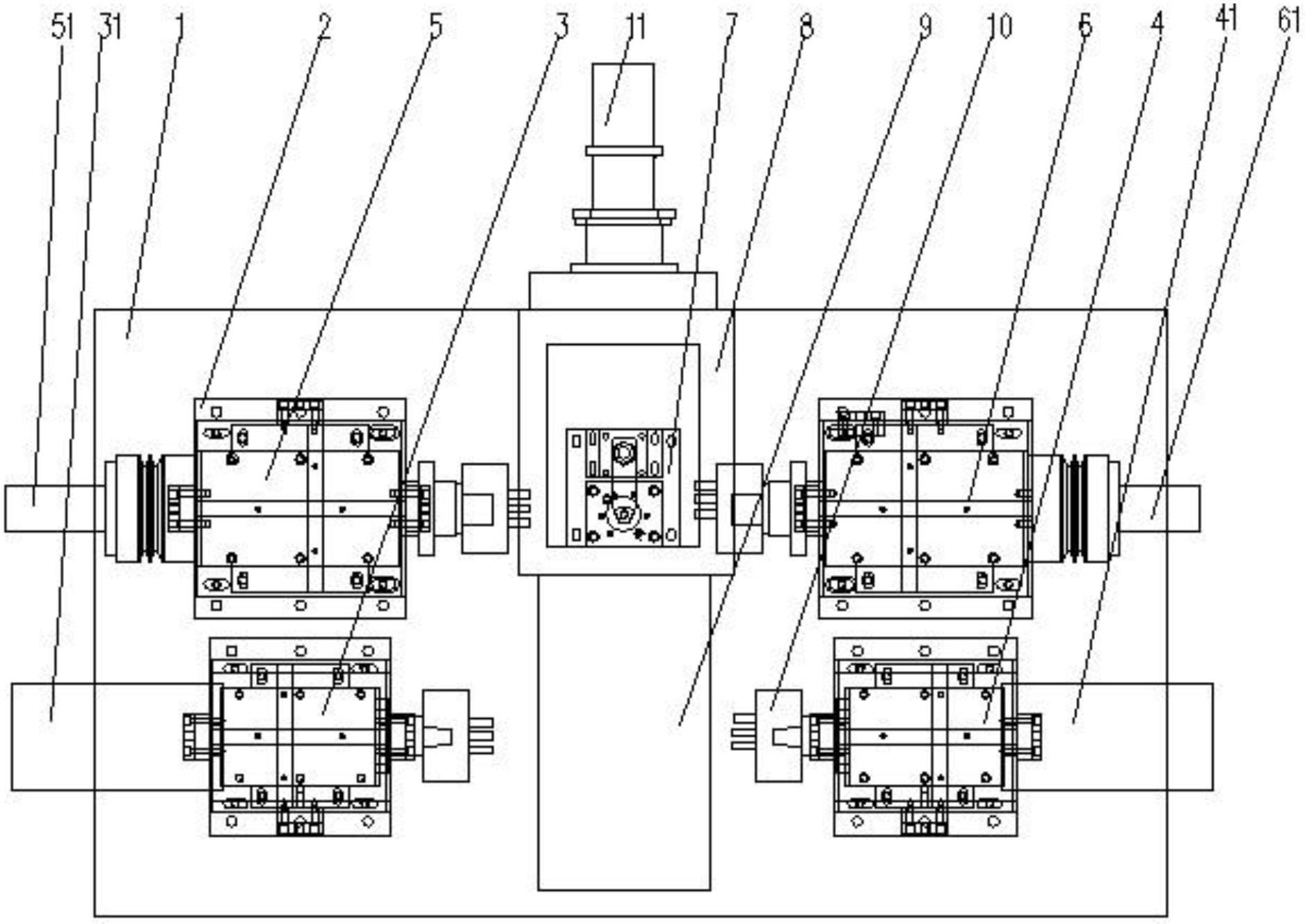

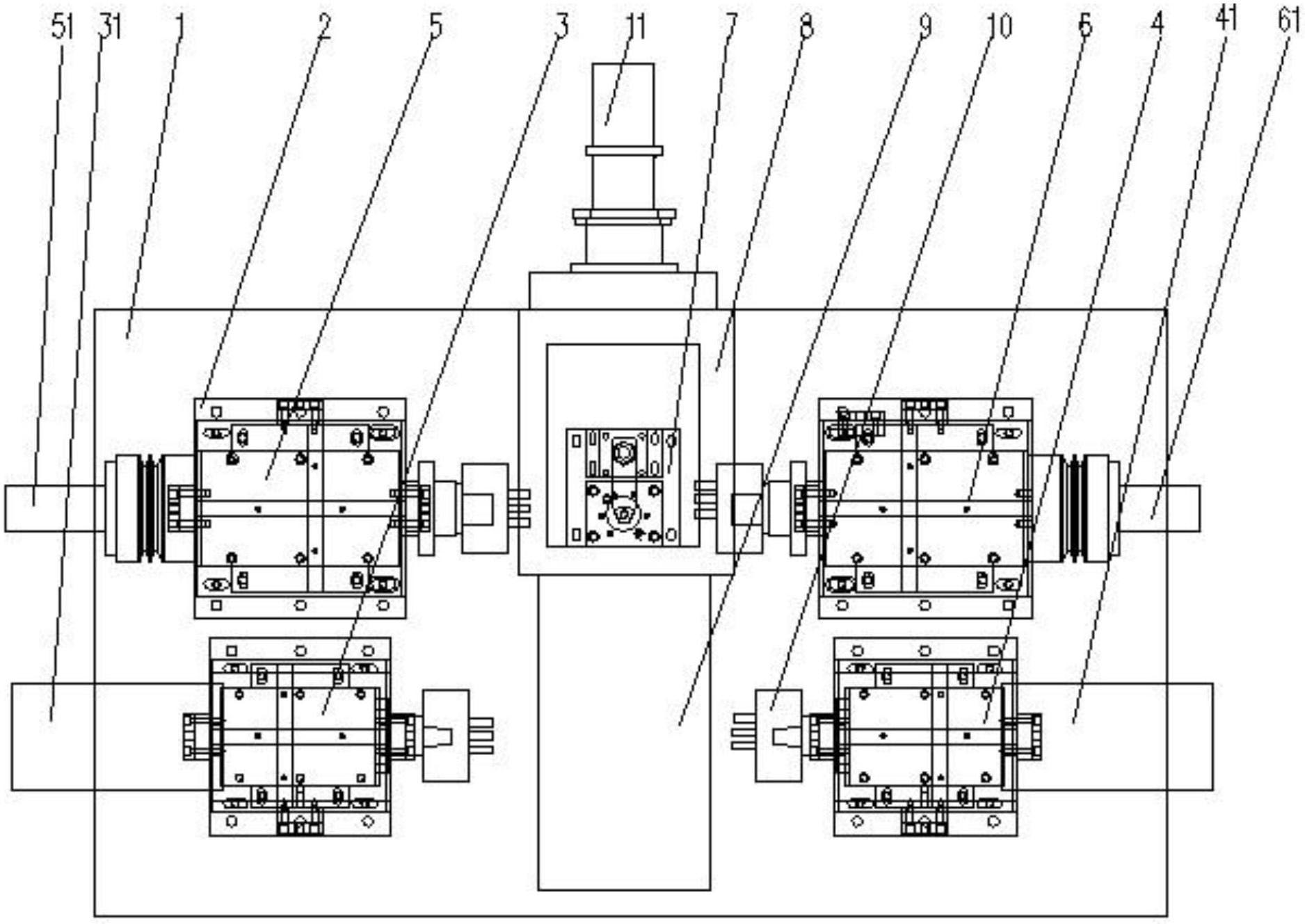

[0012] like figure 1 Or as shown in 2, a machine tool for simultaneously processing threaded holes on the intake side and exhaust side of a cylinder, including a bed body 1, a workbench 2, an intake side drilling mechanism 3, an exhaust side drilling mechanism 4, an intake side Tapping mechanism 5, exhaust side tapping mechanism 6, positioning fixture 7, slide table 8 and slide rail 9, workbench 2 is set on the bed body 1, workbench 2 is provided with slide rail 9, and slide table 8 slides Set on the slide rail 9, the positioning jig 7 is fixed on the slide table 8, the processed cylinder 01 is fixed on the positioning jig 7, the intake side drilling mechanism 3 and the intake side tapping mechanism 5 are corresponding to the processed cylinder 01. The gas side 01a is sequentially arranged on the workbench 2 on one side of the slide rail 9, and the exhaust side drilling mechanism 4 and the exhaust side tapping mechanism 6 are sequentially arranged on the other side of the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com