A flat copper wire processing device

A processing device, copper wire technology, applied to wire processing, household appliances, other household appliances, etc., can solve the problem of low efficiency of flat copper wire rolling processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, various specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. However, it is obvious to those skilled in the art that the described embodiments can be practiced without some or all of these specific details. In other cases, well-known processing steps are not specifically described.

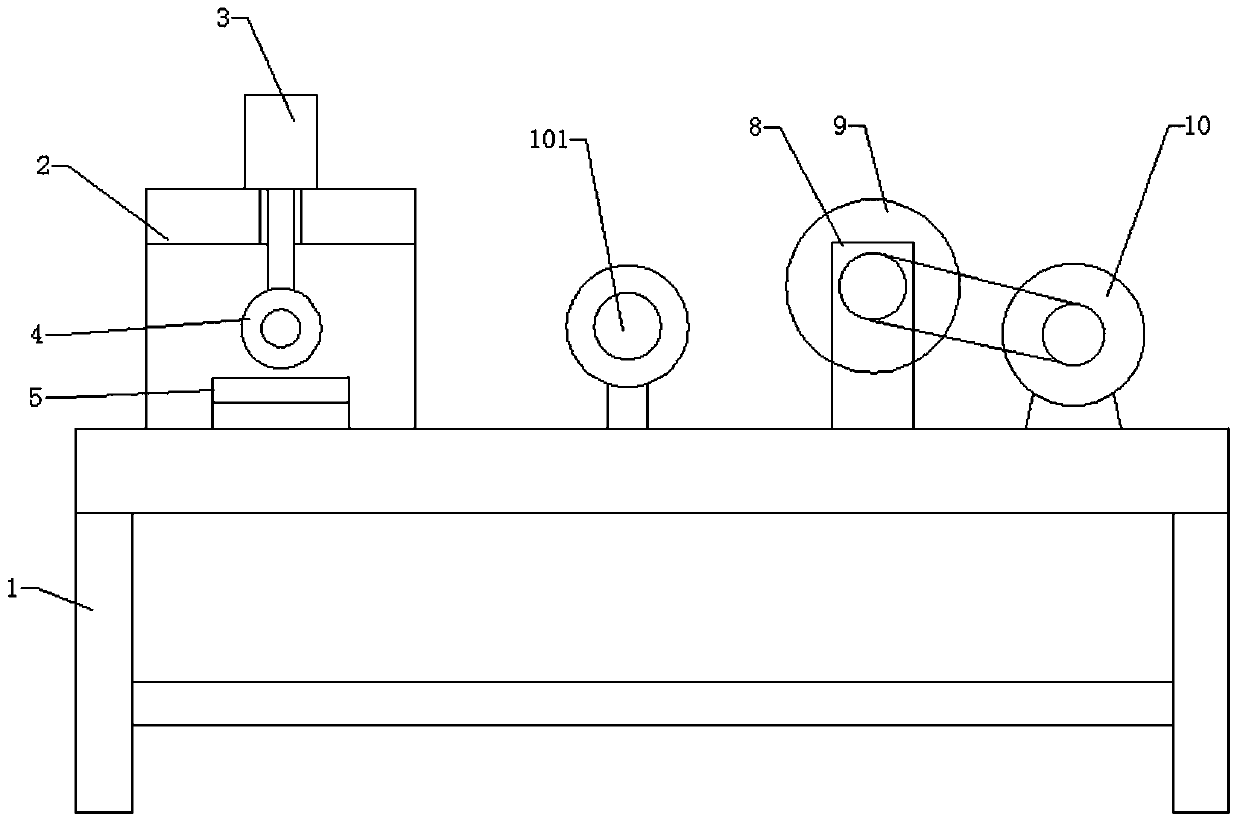

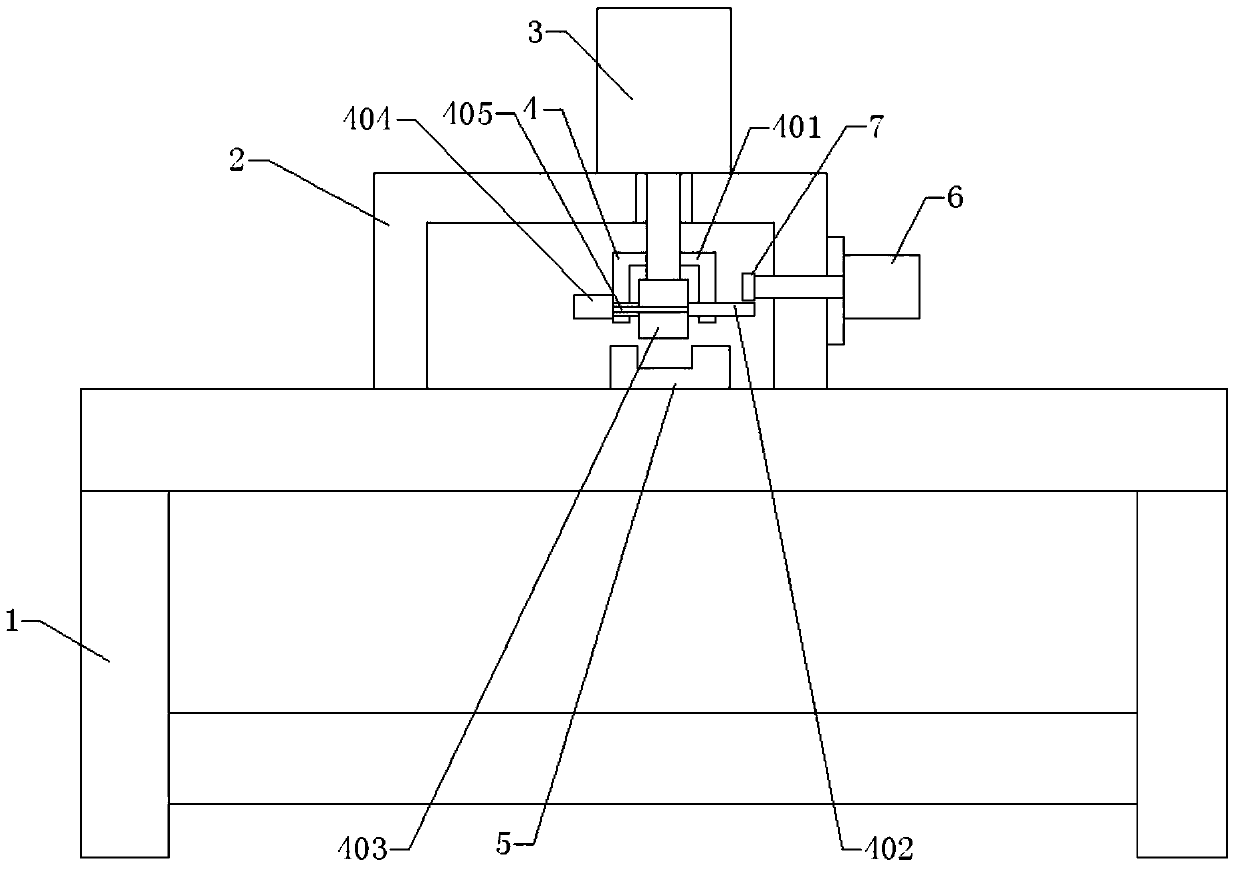

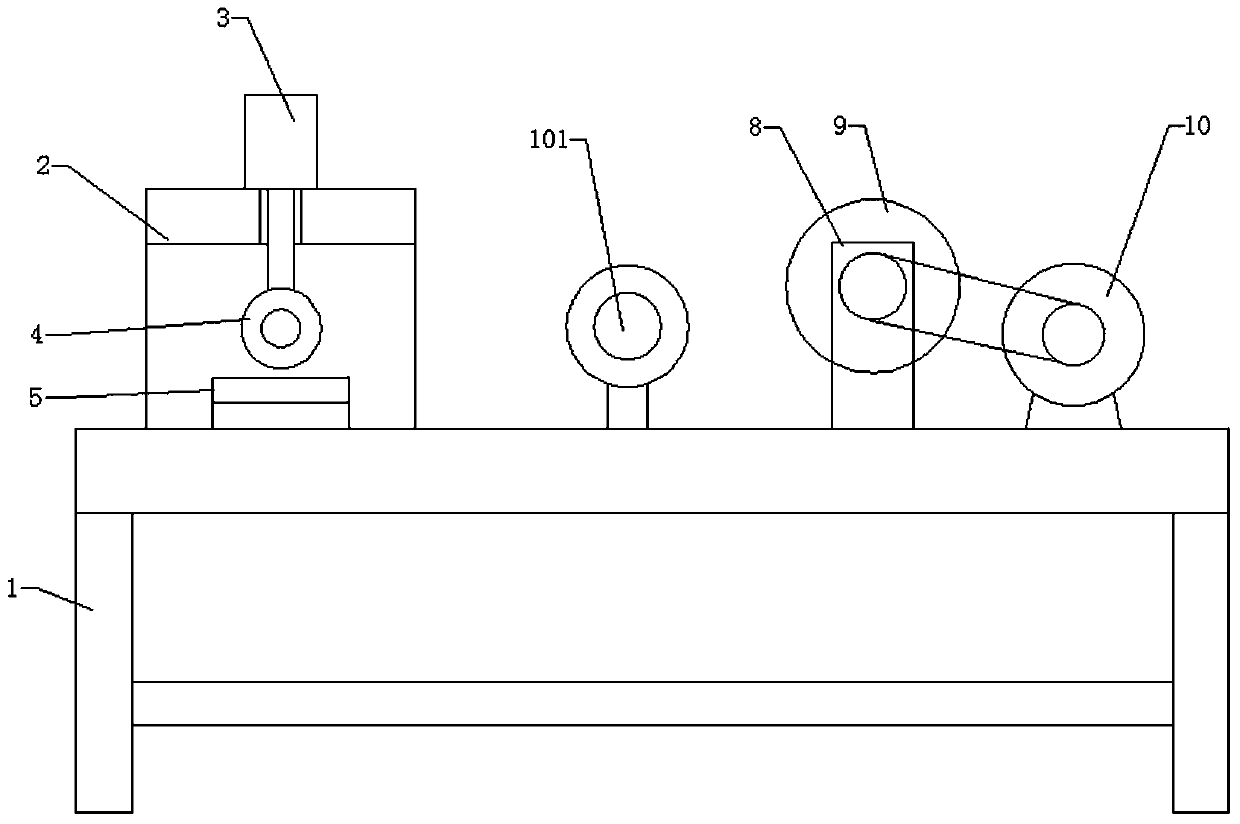

[0025] Such as figure 1 , figure 2 As shown, a flat-cut copper wire processing device includes a support 1, a hydraulic cylinder base 2, a hydraulic cylinder 3, a hot rolling wheel 4, a rolling die 5, a transmission motor 6, a pulley 7, a support seat 8, and a collecting wire wheel 9. The motor 10, the guide wheel 101, the mounting frame 401, the drive shaft 402, the rolling wheel 403, the heating power source 404, and the heating tube 405. The hydraulic cylinder base 2 is located on the left side of the top center of the bracket 1, and the two are connected by threads. The hydraulic cylinder 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com