One-time molding method of large-angle regular triangular pyramid-shaped indenter based on fib

A forming method, technology of regular triangular pyramids, applied in the field of processing regular triangular pyramid-shaped indenters by using focused ion beam milling technology, to achieve the effects of high repeatability, small surface roughness, and high cone angle precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

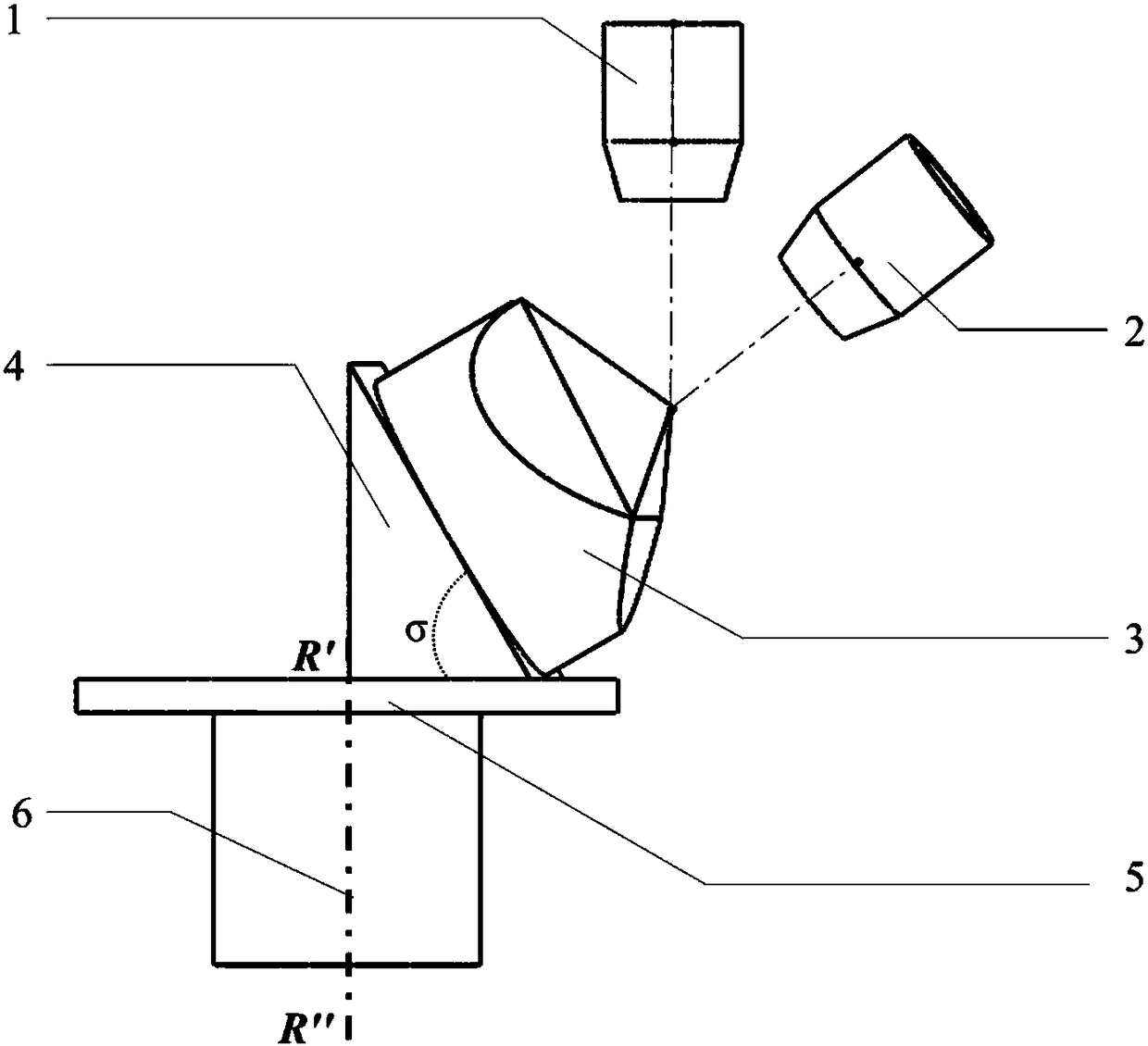

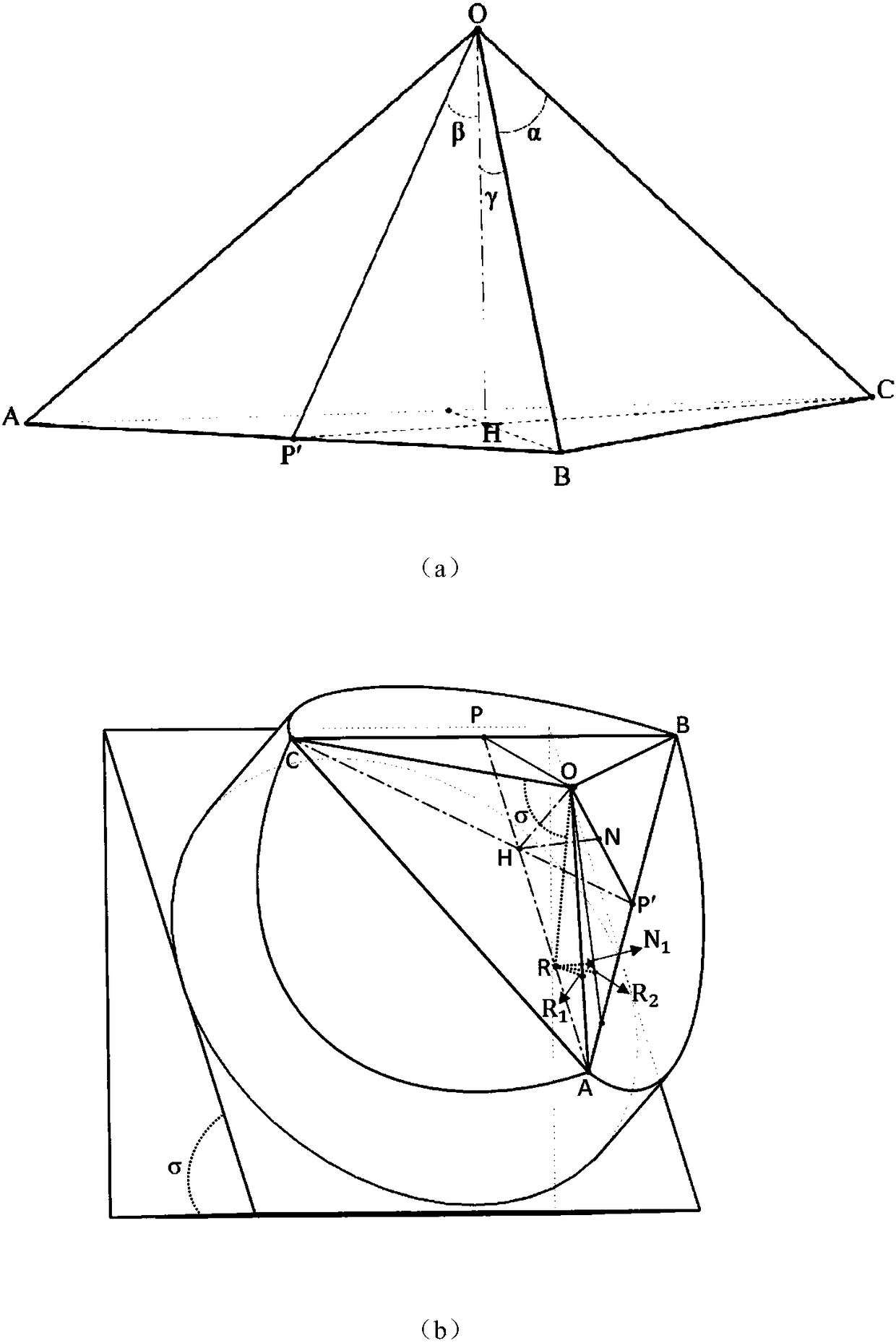

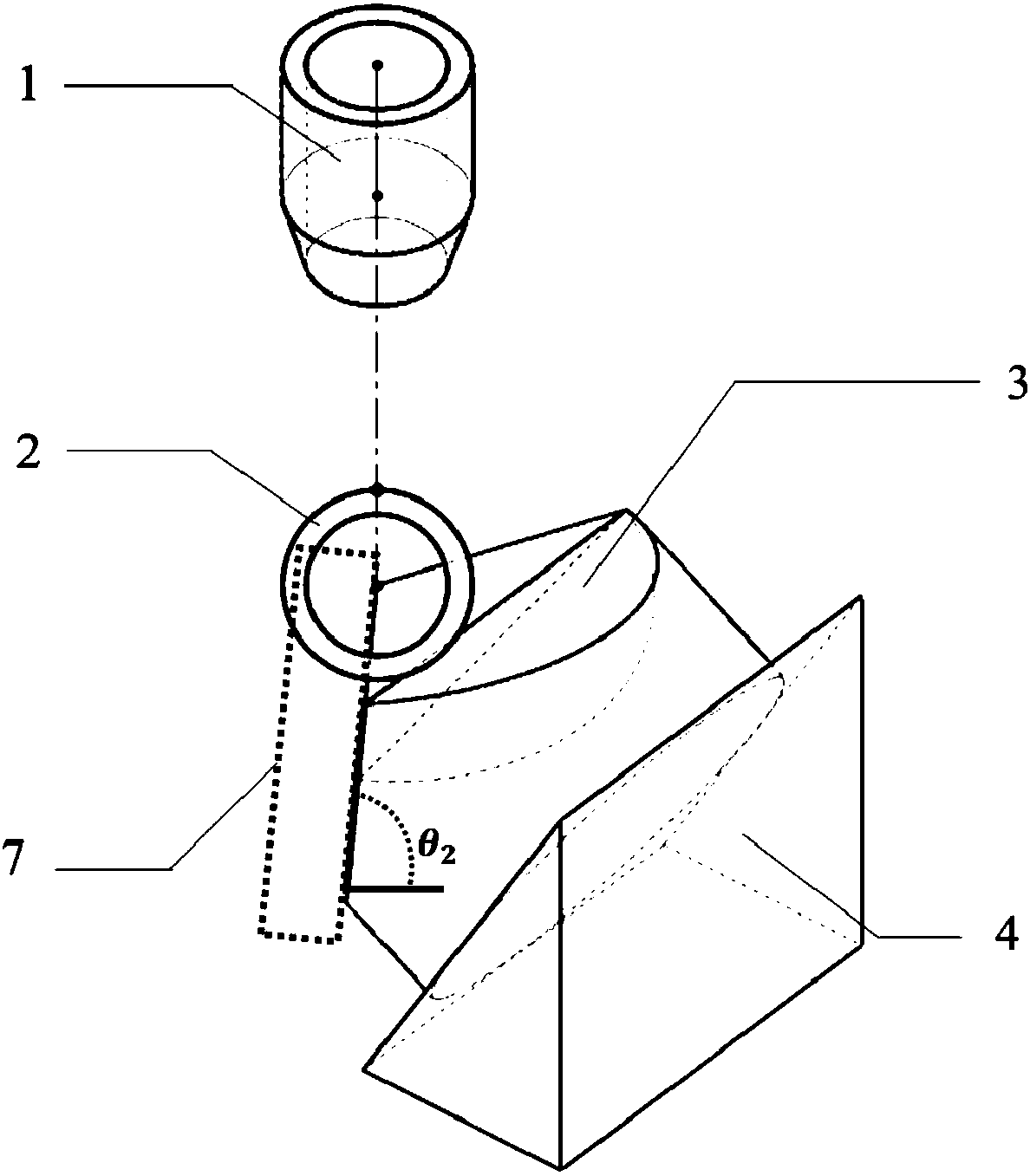

[0040] Referring to the accompanying drawings, where, figure 2 (a) is the schematic diagram of the regular triangular pyramid on the platform surface, O, A, B, C are the four vertices of the regular triangular pyramid, OAB, OAC, OBC are the faces to be processed, OH is the height of the regular triangular pyramid, β is the height of OH and the surface The formed line angle, γ is the angle formed by the high OH and the edge, and α is the angle formed between the edge and the edge; figure 2 (b) is a schematic diagram of a regular triangular prism on an inclined table, OR is parallel or coincident with the rotation axis R′R″ of the test bench, RN 1 Perpendicular to face OAB, OR to face RR 1 R 2 Vertical, ∠RON 1 is the line-surface angle β between OR and surface OAB Ra , ∠ROP″ is the line-surface angle β between OR and surface OBC Rc ,∠R 1 RR 2 Compensation angle determined for the lower base of the ramp. In the machining of the inclined table, firstly, the plane OPC (th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com