Machining device for machining polygon and machining method thereof

A processing device and polygon technology, applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as poor accuracy, low efficiency, and inability to meet the needs of small and medium-sized enterprises, and achieve the effect of ensuring verticality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

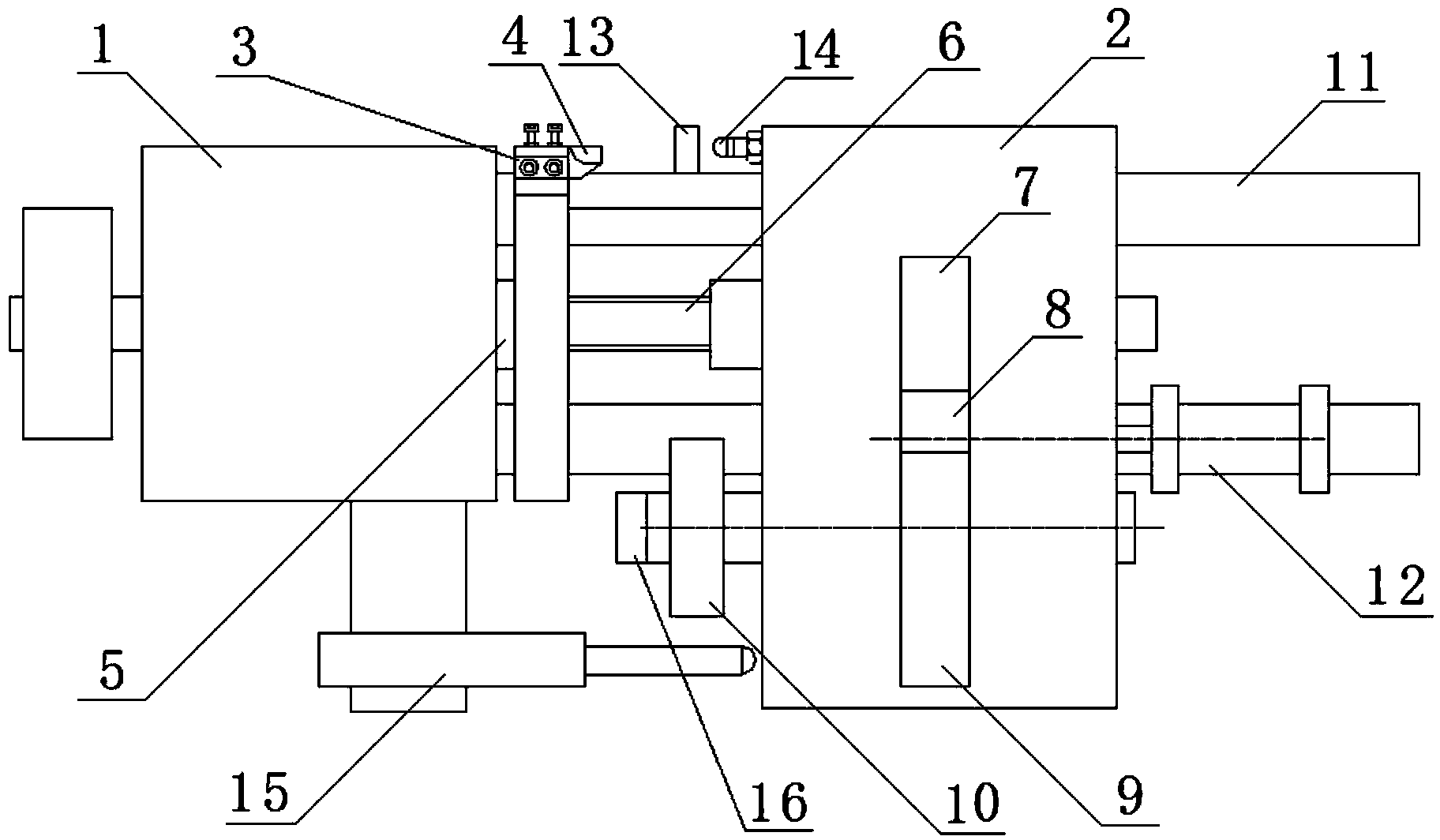

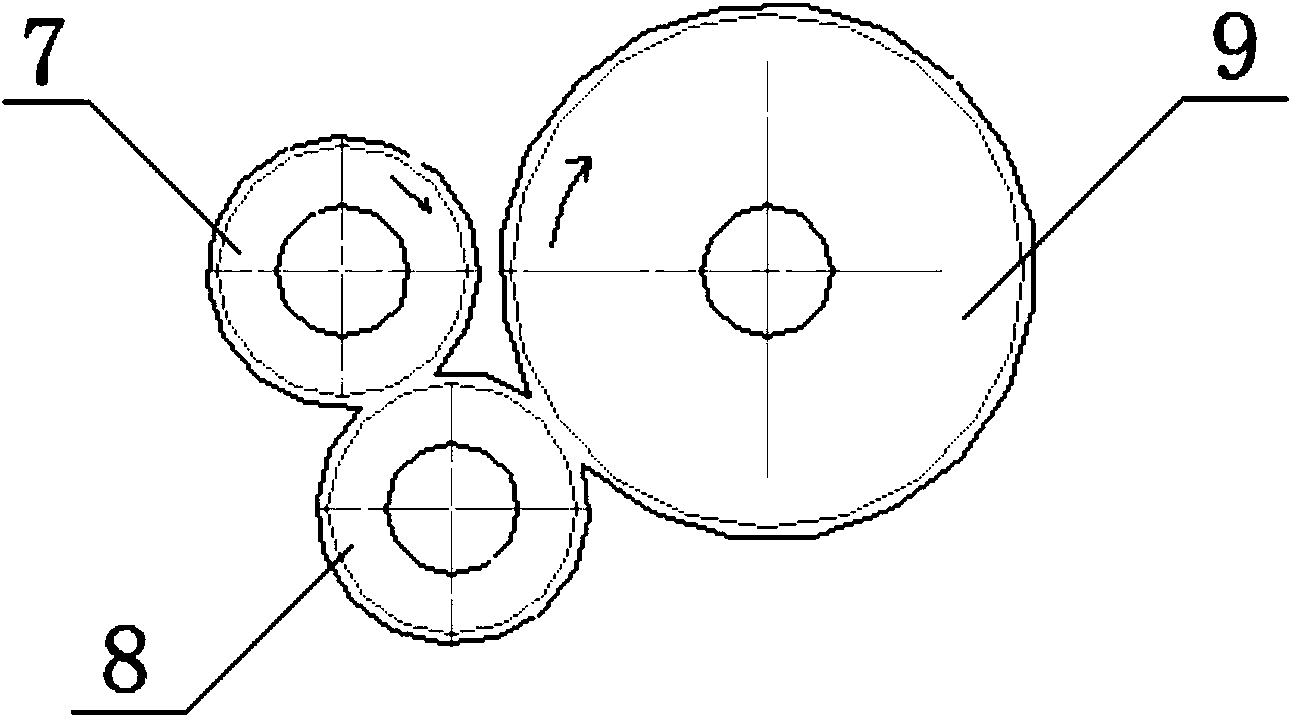

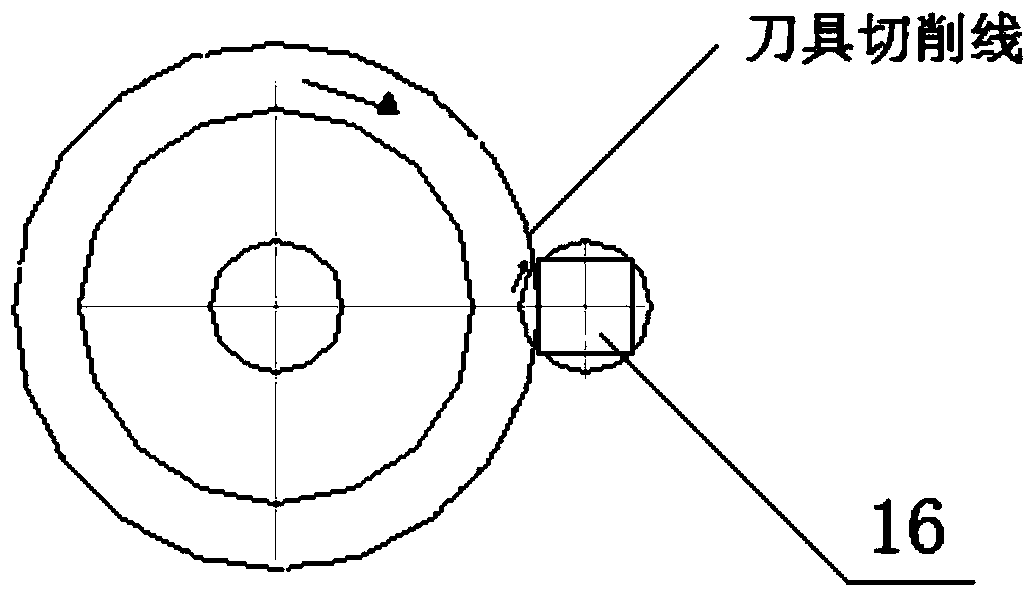

[0022] figure 1 It is a structural schematic diagram of a processing device for processing polygons according to the present invention, figure 2 It is the transmission schematic diagram of the present invention, image 3 It is the cutting schematic diagram of the present invention. Depend on Figure 1-3 Combining the shown structures, it can be seen that this kind of processing device for processing polygons includes a main box 1 and a sub-box 2 arranged side by side. The main box 1 is equipped with a first shaft, and the first shaft is close to the sub-box. One end of the box body 2 is provided with a cutterhead 3, and a cutting tool 4 is installed on the cutterhead 3, which is located on the main box body 1 and is close to one end of the auxiliary box body 2, and is provided with a hydraulic pressure that limits the amount of cutting tool 4. Buffer deceleration cylinder 15; one end of the cutterhead 3 on the first shaft is also provided with a spline groove cover 5; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com