Pipe processing equipment and technology

A technology for processing equipment and pipes, applied in the field of pipe processing equipment and processing technology, can solve the problems of low production efficiency and high labor costs, and achieve the effect of improving production efficiency and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

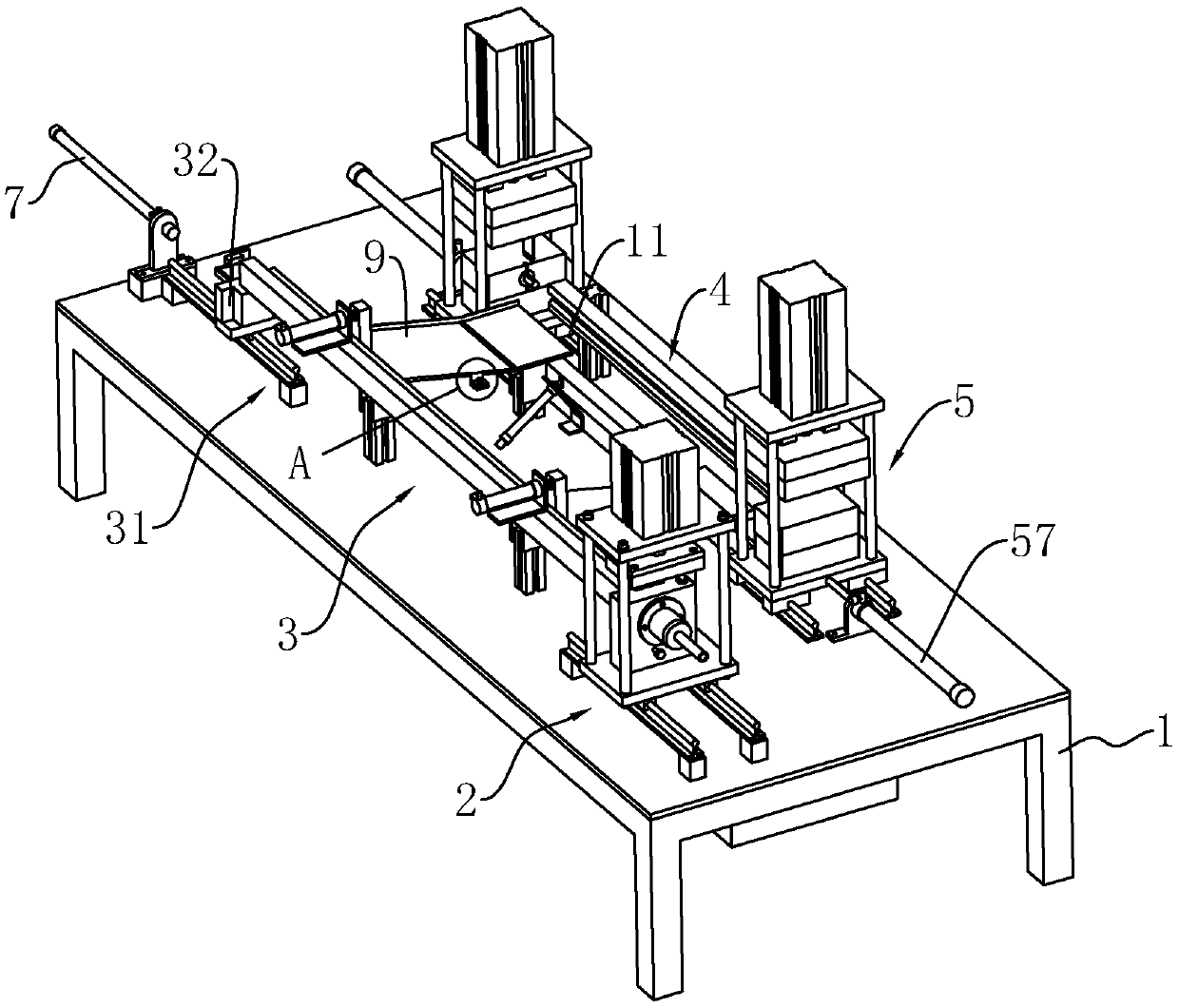

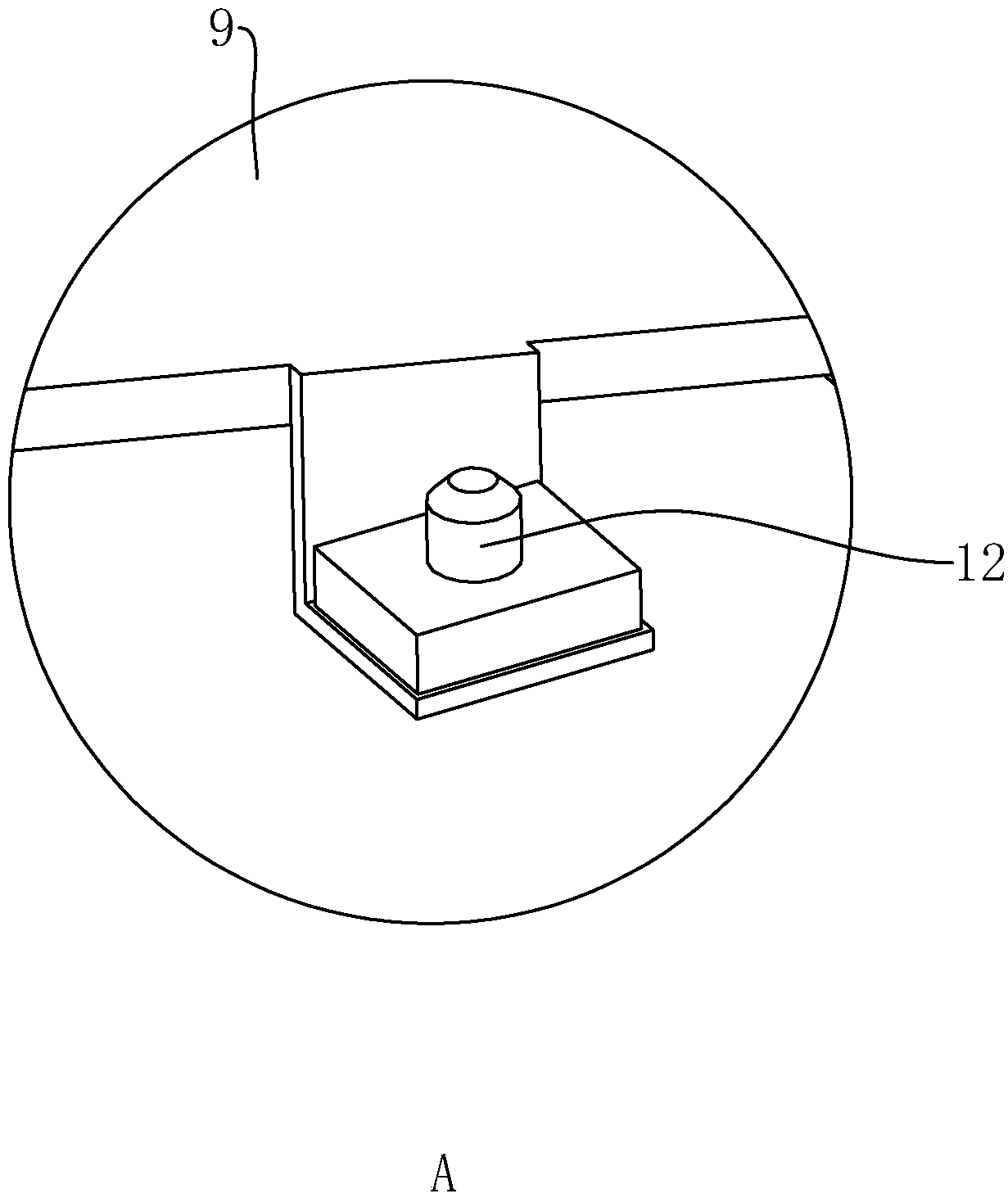

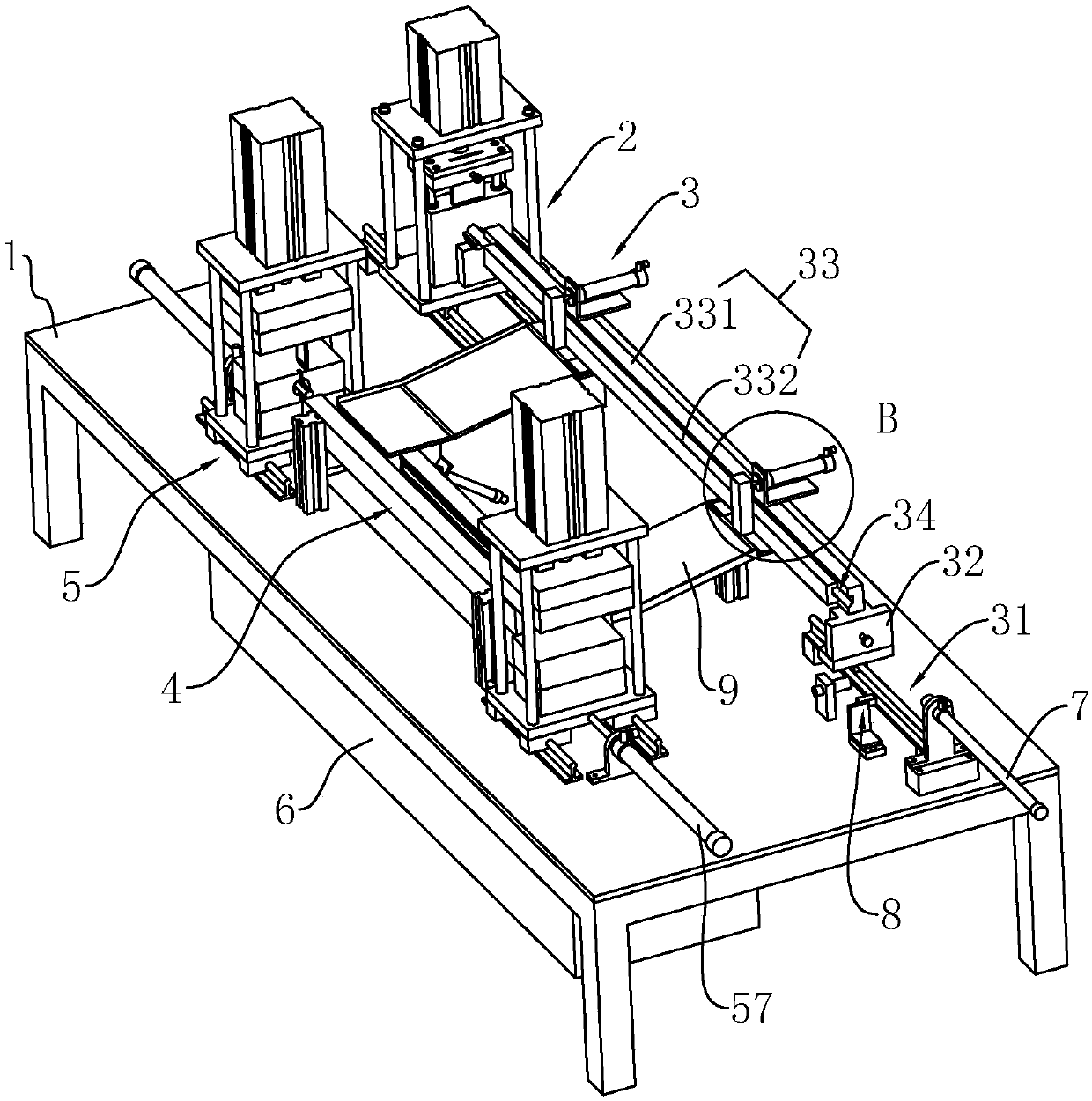

[0059] See attached figure 1 , A pipe processing equipment, which is integrally arranged on the side of the extruder where the pipe is extruded, and includes a frame 1, on which a cutting device is arranged on the side close to the extruder; at the same time, the side of the cutting device is also Equipped with slotting device. The cutting device includes a receiving assembly 3 for receiving the pipe and a cutting assembly 2 for cutting the pipe, and the grooving device includes a clamping assembly 4 for clamping the pipe and a grooving assembly 5 for grooving the pipe.

[0060] In actual work, the pipe is extruded by an extruder and enters the receiving assembly 3; after the pipe enters the receiving assembly 3, the pipe can continue to be fed, and then the cutting assembly 2 can cut the pipe. After the pipe is cut, the cut pipe can be clamped and fixed in the clamping assembly 4, and the slotting assembly 5 can punch out the required notches on the pipe according to the product...

Embodiment 2

[0080] See attached Picture 10 , A pipe processing technology, including the following steps:

[0081] S1. Extrusion: Use an extruder to extrude semi-finished pipes.

[0082] S2, primary cooling; a cooling water area is set at the end of the extruder, the semi-finished pipe will enter the cooling water area after the extrusion is completed, and the temperature of the cooling water used in the cooling water area is 50-70°C.

[0083] S3. Sizing; a sizing die is set at the end of the cooling water area, and a sizing area is formed in the sizing die. The internal temperature of the sizing area is 50-70℃; after the semi-finished pipe is extruded through the sizing die, the semi-finished product The diameter of the pipe is finally determined.

[0084] S4. Secondary cooling: A natural water cooling area is provided at the end of the sizing mold, and the temperature of the cooling water used in the natural water cooling area is 10-20°C.

[0085] S5. Cutting: After the pipe is cooled for the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com