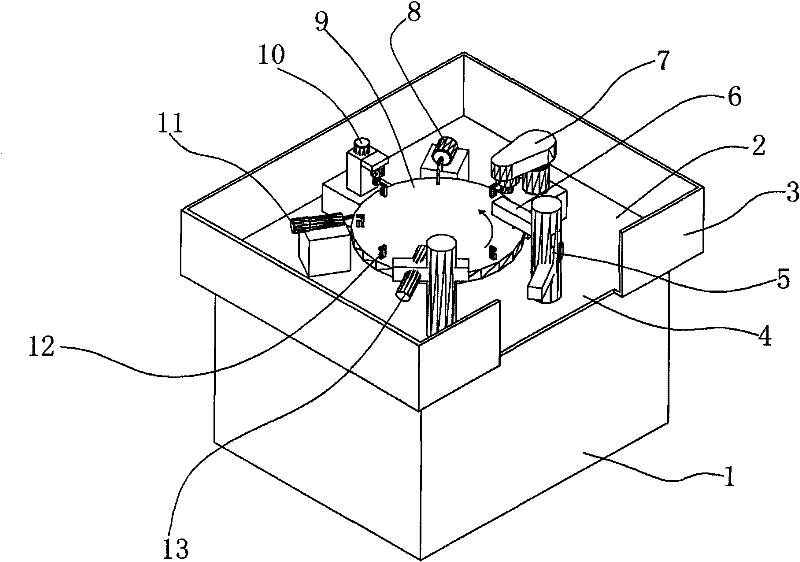

Drilling and milling eight-station combined machine

A combined machine and eight-station technology, used in metal processing machinery parts, positioning devices, manufacturing tools, etc., can solve the problems of long processing cycle and low processing efficiency, and achieve the effect of fast processing time, short cycle and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

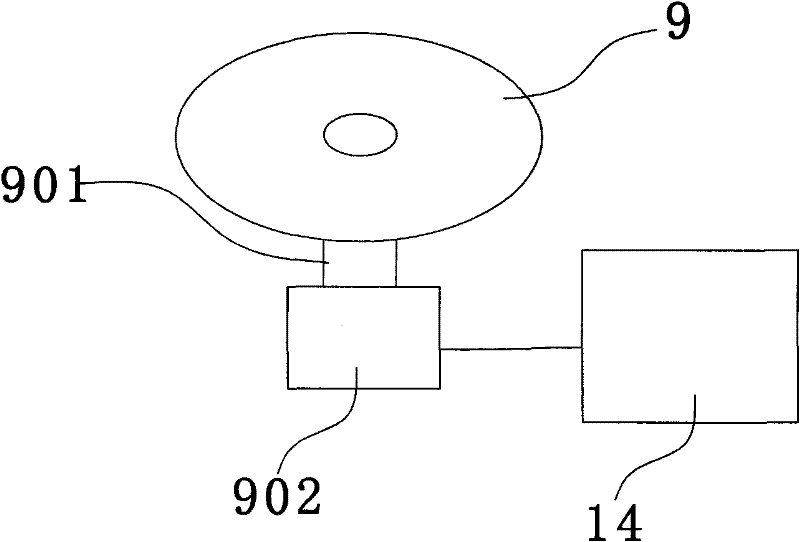

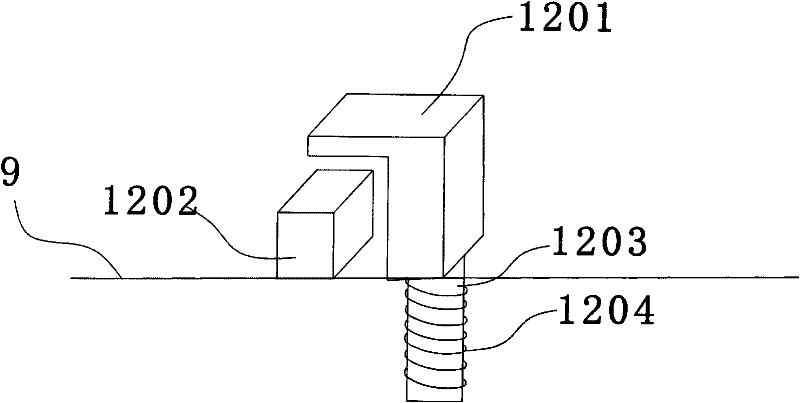

[0019] The core idea of the present invention is: the present invention first feeds the incoming parts into the fixture through the feeding mechanism for clamping and fixing, then turns the turntable to make the fixture reach the positioning mechanism, and positions the parts clamped in the fixture through the positioning mechanism , to make it meet the requirements of processing, and then control the rotation of the turntable, so that the fixture rotates to the first milling mechanism for milling processing; after the processing is completed, turn the turntable to the drilling mechanism to drill the parts; the drilling is completed Finally, turn to the second milling mechanism to perform milling processing on the drilling part; then control the turntable to turn to the reaming mechanism for reaming; after the reaming is completed, control the turntable to turn to the material receiving mechanism, and the clamp is released by the cylinder control. And control the push rod to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com