Machining method based on simple clamping of triangular parts

A processing method and triangular technology, applied in the field of parts processing, can solve problems such as difficulty in clamping triangular parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

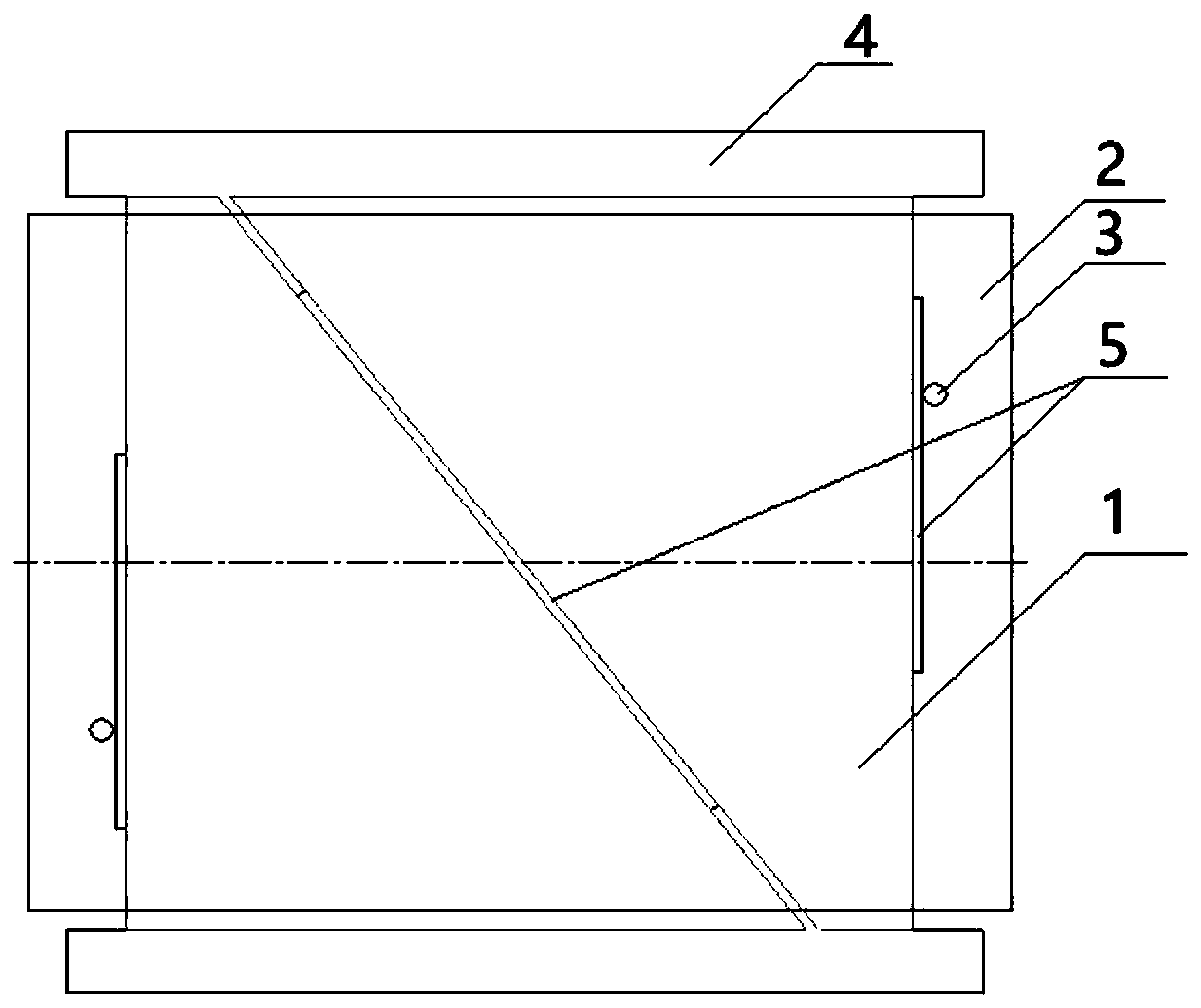

[0012] This embodiment proposes a processing method based on simple clamping of triangular parts, such as figure 1 As shown, the processing method includes relatively clamping two triangular-shaped parts 1 between two positioning pins 3 in the length direction of the bottom plate 2, clamping them in a vise 4 in the width direction of the bottom plate 2, and installing them on both sides of the positioning pins 3. A backing plate 5 to ensure that the relative positions of the two parts 1 are consistent; during processing, directly fix the vise 4 on the simple digital milling workbench, and after determining the relative position of the clamping tool and the machine tool, it can be quickly Complete the simple clamping, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com