System and method for continuous electrolytic machining of flexible metal sheets with micro-group grooves

A flexible metal and processing system technology, applied in metal processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve the problems of poor precision control ability of micro grooves, improve processing efficiency, realize isolation protection, and facilitate rapid tool setting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

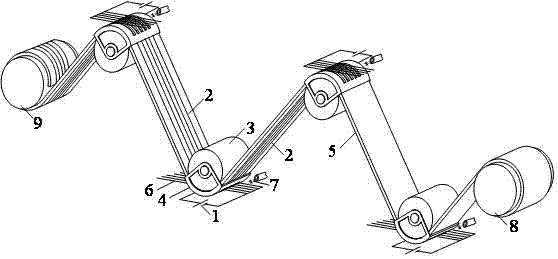

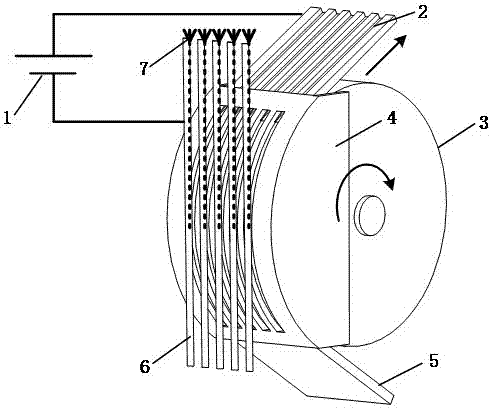

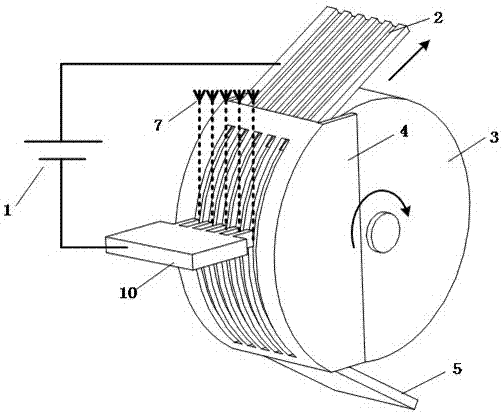

[0026] figure 1 In the schematic diagram of the continuous electrolytic machining of the micro-groove of the flexible metal sheet shown, during processing, firstly, the arc-shaped mask plate 4 is installed and fixed on the roller shaft of the supporting roller 3, and one end of the flexible metal sheet 5 is wound on the conveying wheel 8, the other end of the flexible metal sheet 5 passes between the arc-shaped mask plate 4 and the support roller 3 in turn, and is fixed on the driving wheel 9, and the inner surface and the outer surface of the flexible metal sheet 5 are close to the corresponding support roller wheel 3 and arc-shaped mask plate 4; then select the electrolytic processing tool electrode according to the groove width, groove depth, cross-sectional shape and groove spacing of the micro-group groove 2 to be processed, and complete the installation and fixing of the tool electrode; then, the electrolyte 7 Align the processing area for flushing, the tool electrode is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com