An automatic transformer insulation piece adhesive processing device

A technology for processing devices and insulating parts, applied in the manufacture of inductors/transformers/magnets, electrical components, coils, etc., can solve the problems of high labor cost and site cost, lack of automatic processing machinery, low processing efficiency, etc., to reduce labor costs. and site cost, novel and compact structure, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

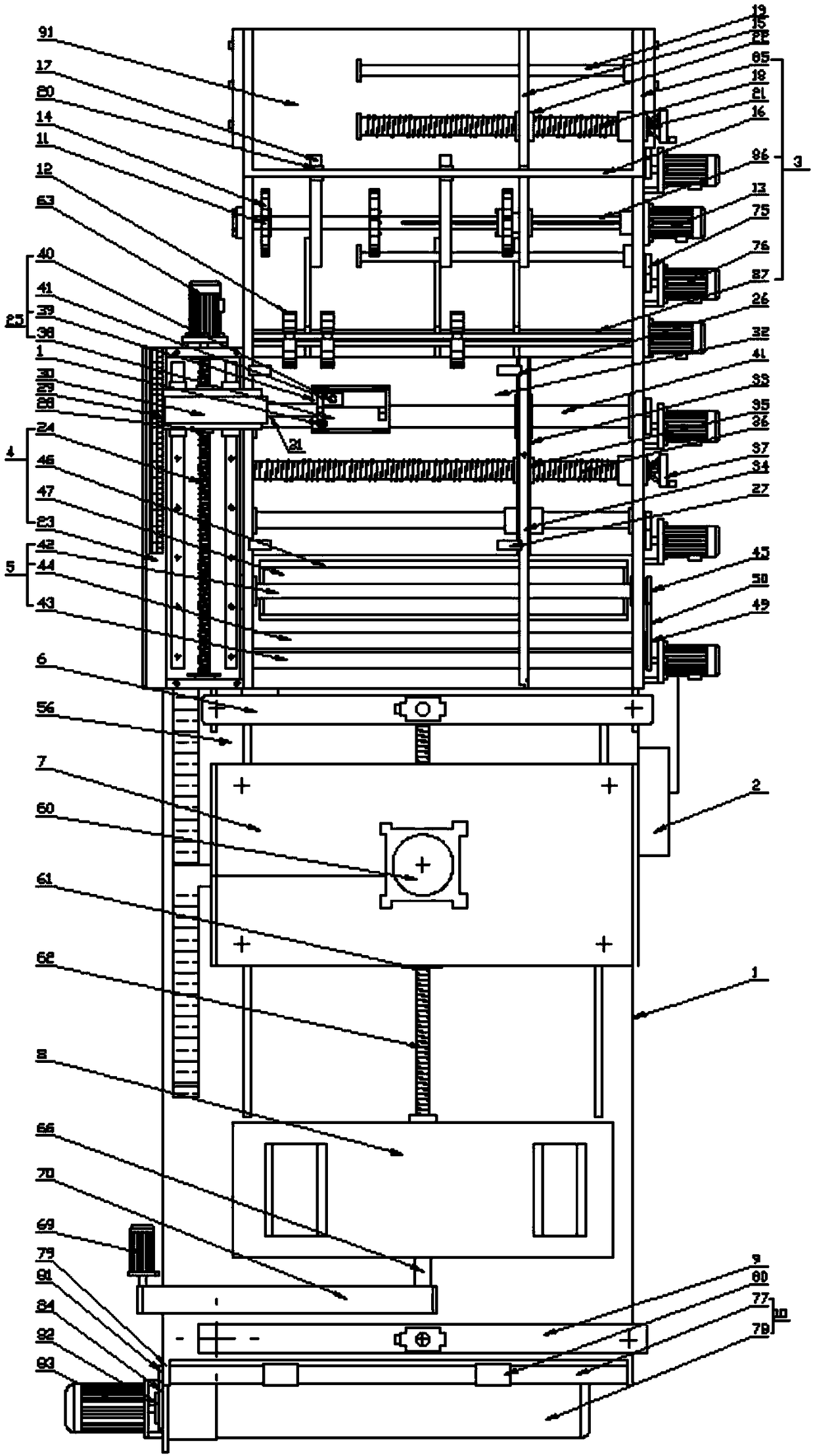

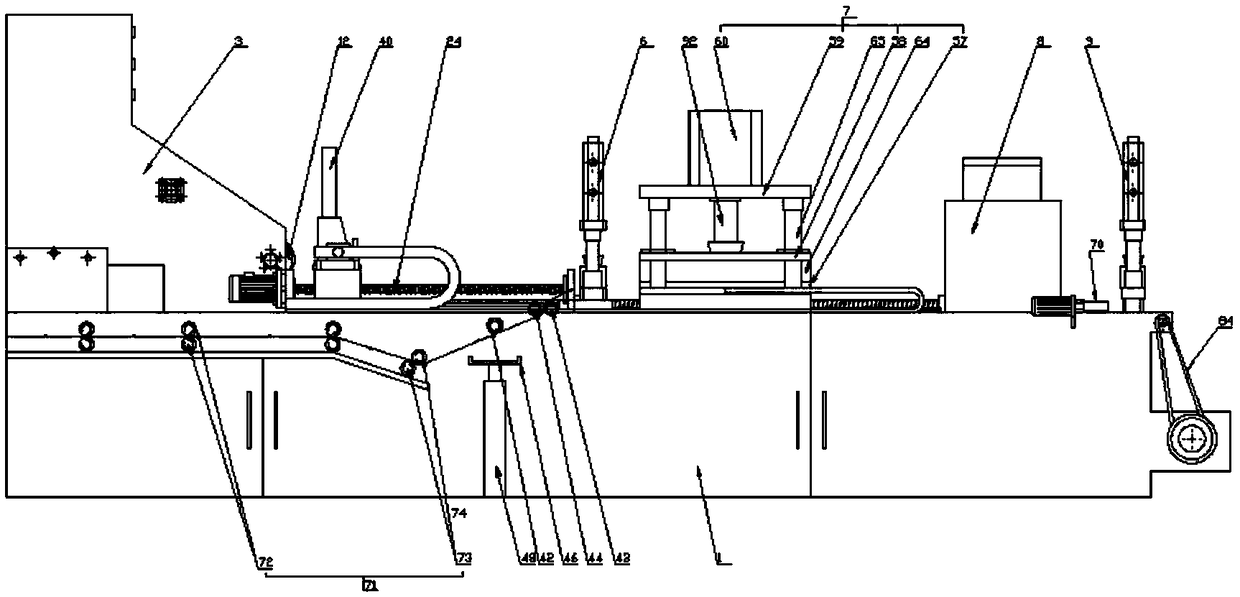

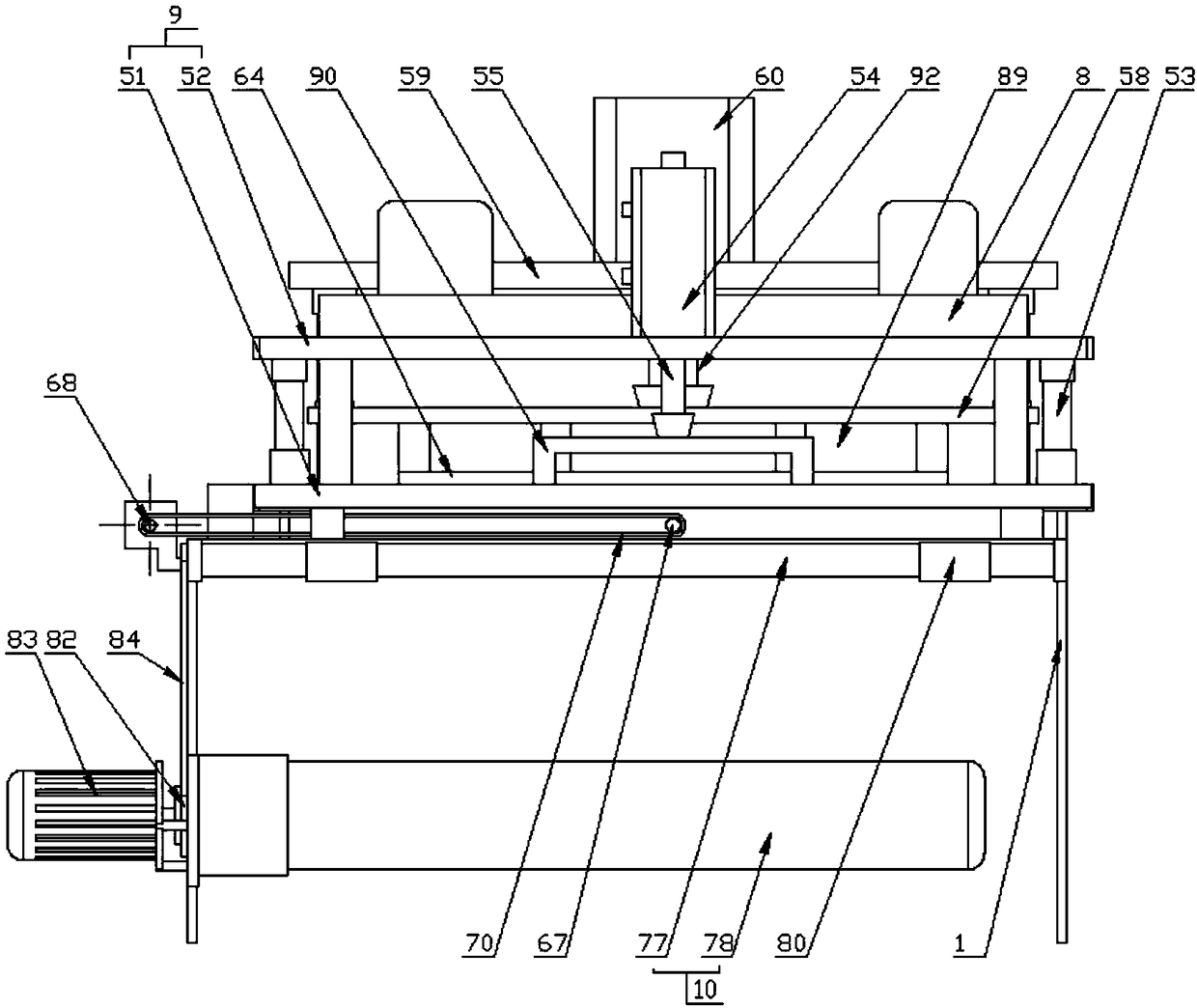

[0024] An automatic transformer insulation gluing processing device, including a machine tool 1, the machine tool 1 is provided with a PLC controller 2, from one end of the machine tool 1 to the other end, and the machine tool 1 is sequentially provided with a material handling mechanism 3 and a transmission mechanism 4 , the rubber rolling mechanism 5, the first pressing mechanism 6, the pressure feeding mechanism 7, the drying box 8, the second pressing mechanism 9 and the winding mechanism 10, and the described material handling mechanism 3 includes the first frame 85, the material handling mechanism Shaft 86 and material dial shaft 87, described first frame 85 is provided with the first platen 91 that is provided with inclination, described material management shaft 86 and material dial shaft 87 are arranged in parallel with the first fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com