Ultrasonic pipe end machining device

A processing device and ultrasonic technology, applied in the field of metal pipe processing, can solve the problems of low processing efficiency, high scrap rate, fast tool wear, etc., and achieve the effects of high processing accuracy, high yield and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

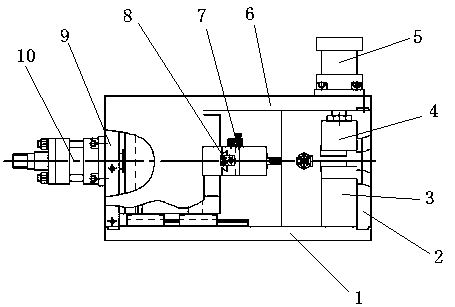

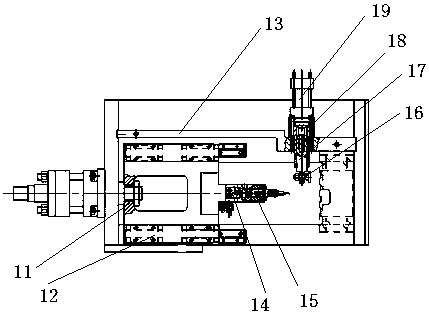

[0010] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as figure 1 , figure 2 , in this example, steel plates are selected to make it into the bottom plate 1, and the bottom plate 1 is installed on the lower ends of the left side plate 9 and the right side plate 2, and the two ends of the bottom plate 1 are respectively connected with the lower ends of the left side plate 9 and the right side plate 2 Select steel plate as the material of right side plate 2, it is installed on the right end of base plate 1 and top plate 6 and is connected with the right end of base plate 1 and top plate 6 respectively, offers feed inlet on the right side plate 2 simultaneously, can make to be processed The pipe enters between the lower clamping die 3 and the upper clamping die 4 from the feed port; the lower clamping die processed by the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com