Full-automatic grinding and polishing device

A technology of polishing device and grinding machine, which is applied in the direction of grinding/polishing safety device, grinding automatic control device, grinding drive device, etc. It can solve the problems of difficulty in realizing large-scale industrial production, low processing quality, and poor grinding uniformity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

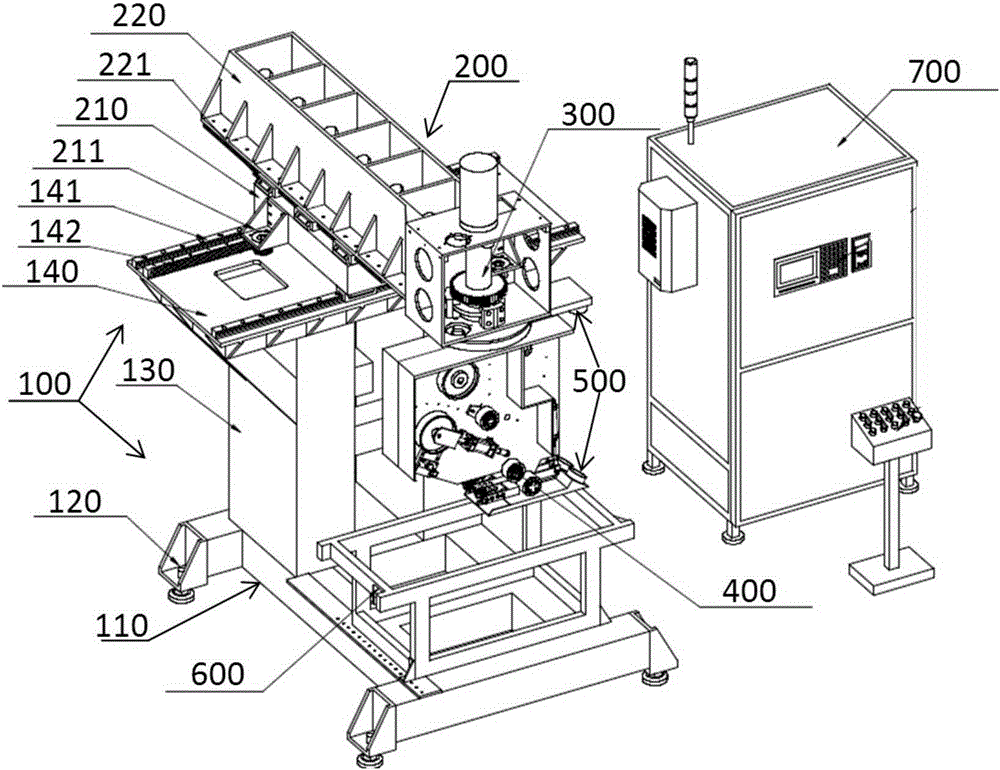

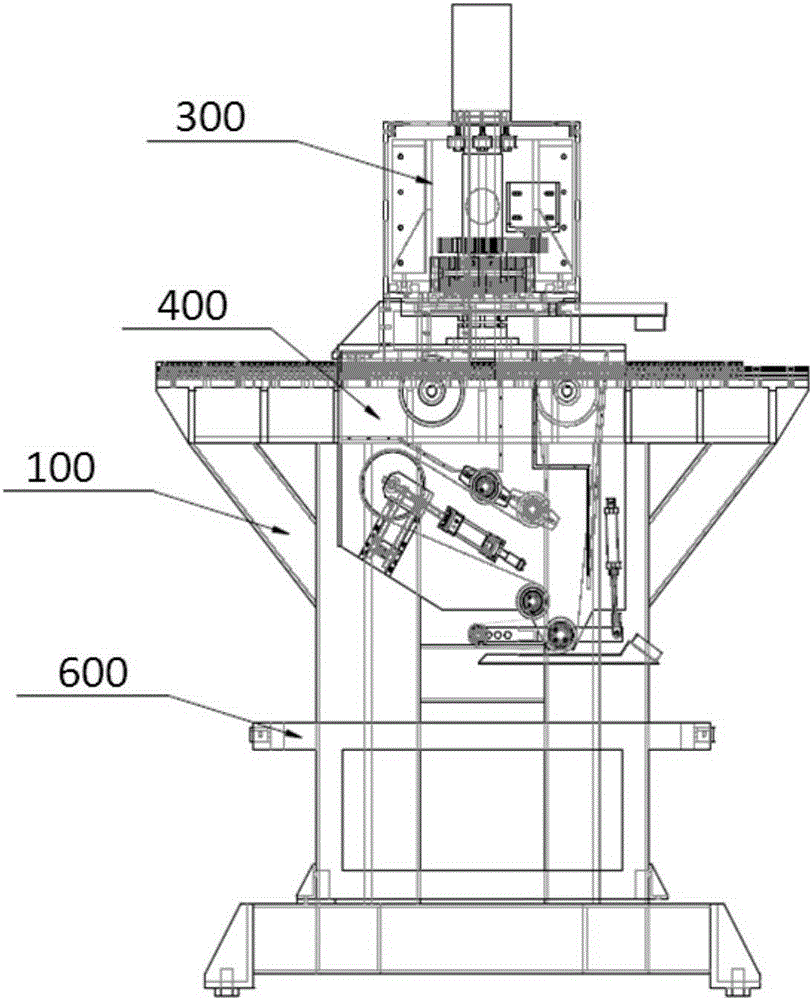

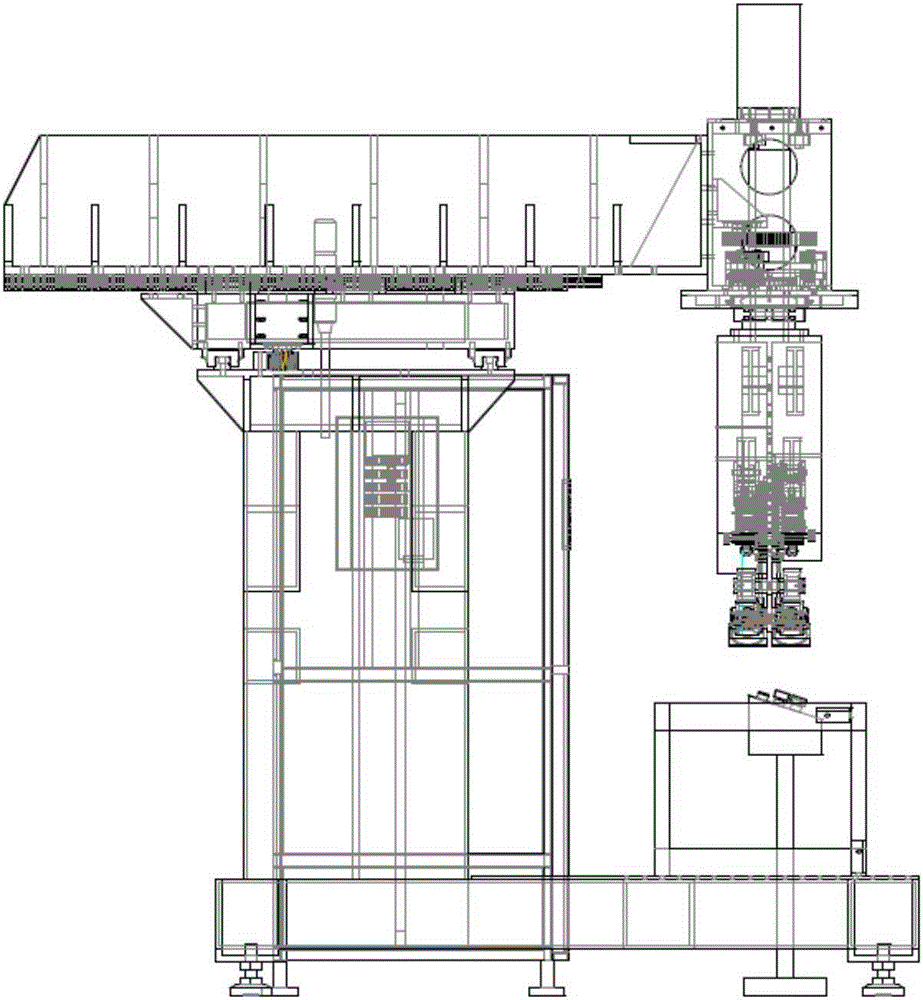

[0042] The overall structure of the sink grinding and polishing device provided by the present invention is as attached figure 1 to attach image 3 As shown, it includes a grinding frame 100, a grinding material rack 600, a translation mechanism 200, a rotating mechanism 300, a grinding and polishing mechanism 400, an air extraction mechanism 500 and a control cabinet 700, and the grinding frame 100 is used as the supporting base of the entire device structure, the grinding rack 600 is fixed on the bottom platform of the grinding frame 100, the workpiece to be polished is placed on the grinding rack 600, and the translation mechanism 200 is arranged on the top of the grinding frame 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com