Patents

Literature

62results about How to "Meet the positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel functional flexible clamp and application method thereof

ActiveCN107322347AVersatileEnergy savingPositioning apparatusMaintainance and safety accessoriesPhysicsMagneto

Owner:HEBEI UNIV OF TECH

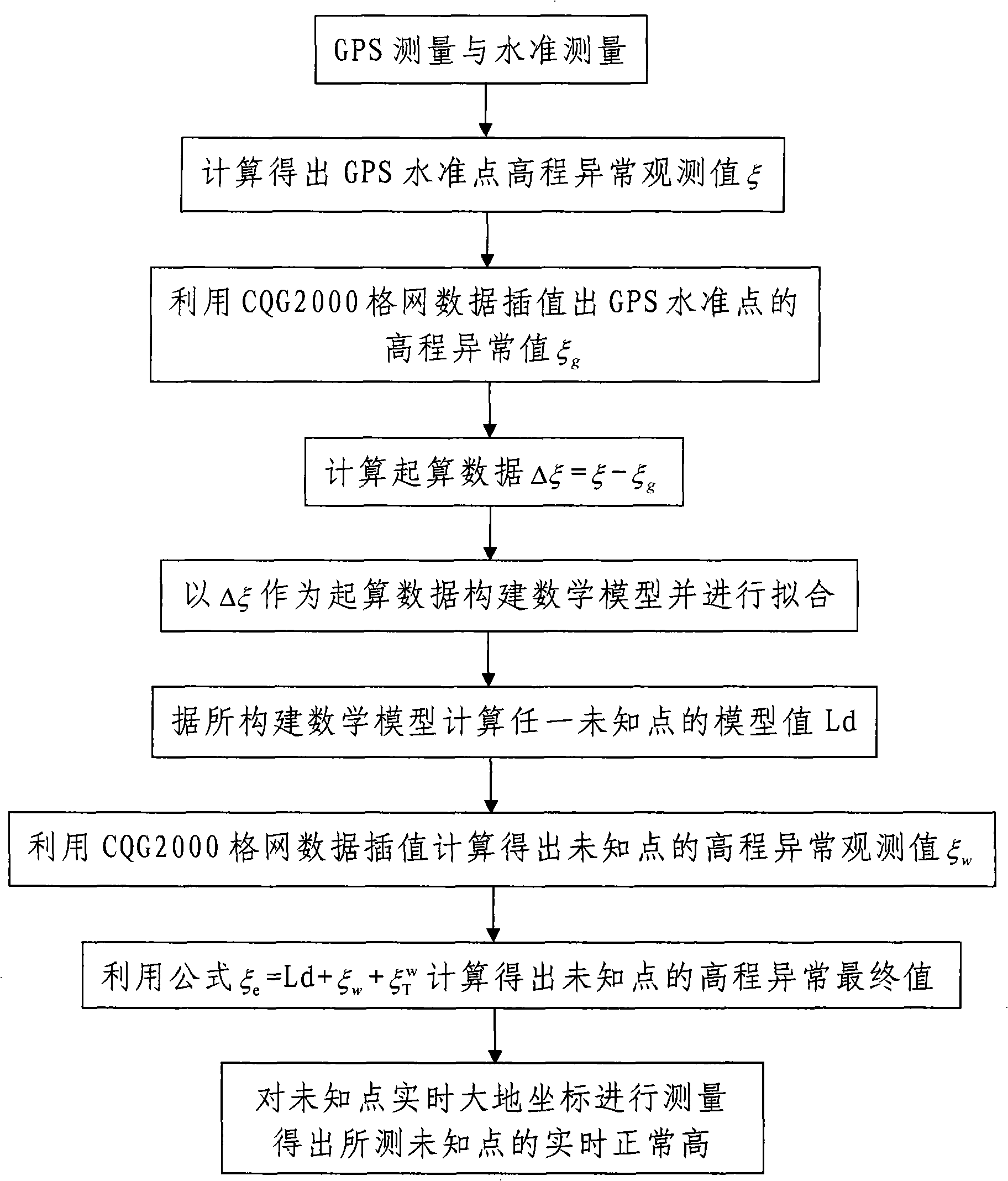

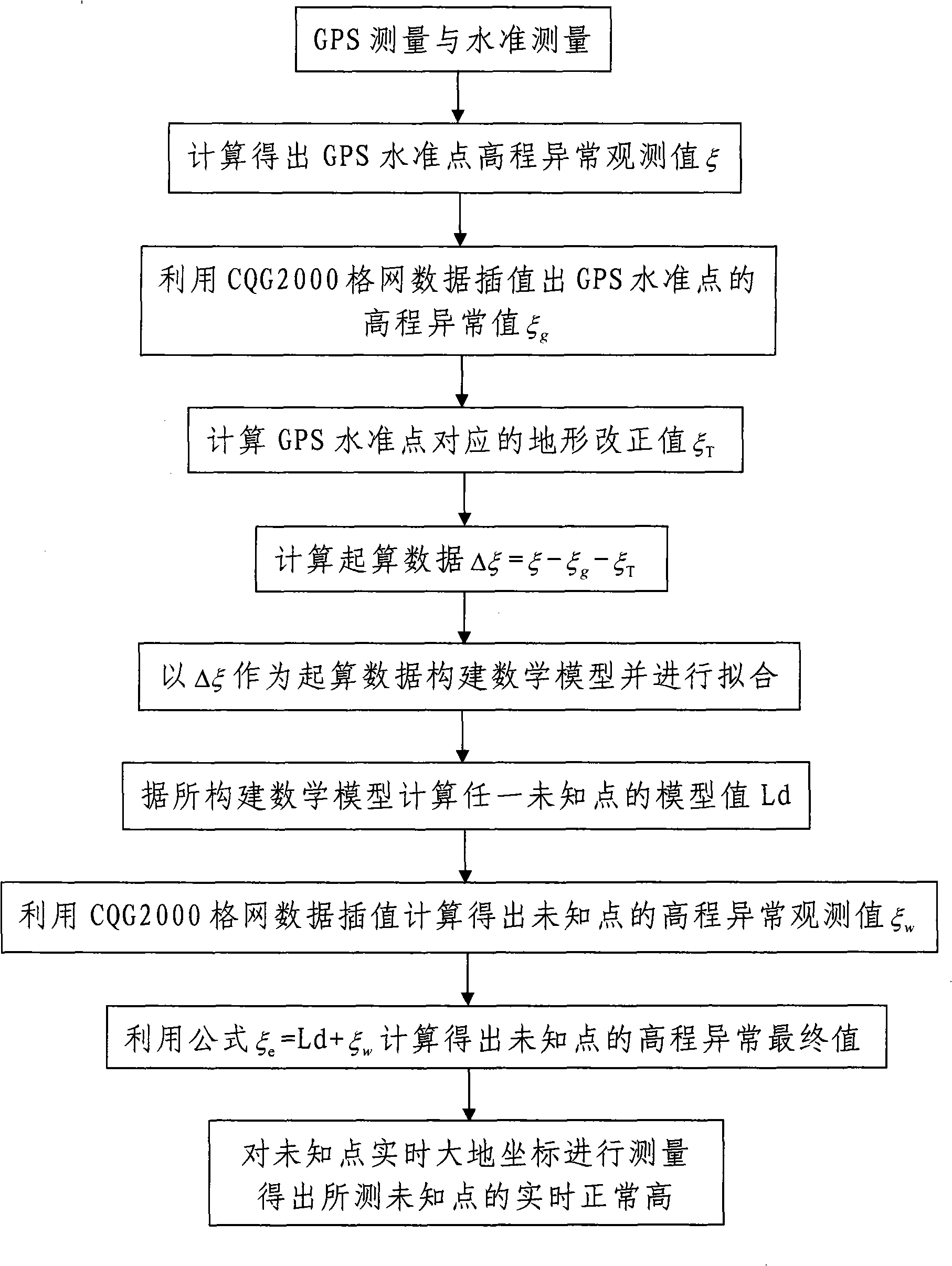

Region quasi-geoid refining method based on CQG2000

InactiveCN101493324AReduce budget expensesEasy accessHeight/levelling measurementImage resolutionNormal height

The invention discloses a region quasi-geoid refining method based on CQG2000, including the followings: step one, the CQG2000 is used as a platform, and GPS leveling data is used for determining the quasi-geoid model of the region to be measured according to remove-fit-restore method; step two, GPS system is used for obtaining the real-time geodetical coordinates of any unknown point in the region to be measured, and measured data are transmitted to an arithmetic and control unit that uses the constructed region quasi-geoid model to convert the measured GPS geodetic height of the known point into normal height, i.e., leveling height, in real time. The method is simple and convenient to be carried out, the measured data are accurate and reliable, and the measurement speed is quick, thereby being capable of efficiently solving the problem of geoid fitting defect caused by no gravity data obtained when the quasi-geoid is refined and the problems of complicated measuring processes and big measuring cost when gravity data is used for refining, greatly improving the precision and resolution factor of quasi-geoid and having very high use value.

Owner:CHANGAN UNIV

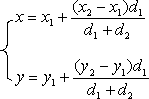

Downhole worker positioning method based on Wi-Fi signal strength

ActiveCN102938874ALong transmission distanceImprove reliabilityLocation information based serviceWi-FiCommunications system

The invention discloses a downhole worker positioning method based on Wi-Fi signal strength. The downhole worker positioning method comprises installing Wi-Fi base stations at intervals of a certain distance in a mine straight line roadway, installing base stations at inflection points and branch points of the roadway, carrying a Wi-Fi wireless network card in a portable device of a mine worker, and enabling the base stations and the network card to form a downhole wireless communication network. The distances between the worker and the two nearest base stations are calculated according to the Wi-Fi signal strength received by the wireless network card, and position information of the worker is obtained according to the proportion of distance. A Wi-Fi wireless network technology is utilized to position the downhole worker in real time, safety guarantee is provided for downhole operation by reasonably arranging the base stations and simplifying positioning algorithms, and possibility is provided for integration with a mine communication system based on Wi-Fi.

Owner:杭州维一科技有限公司

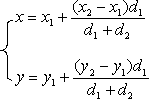

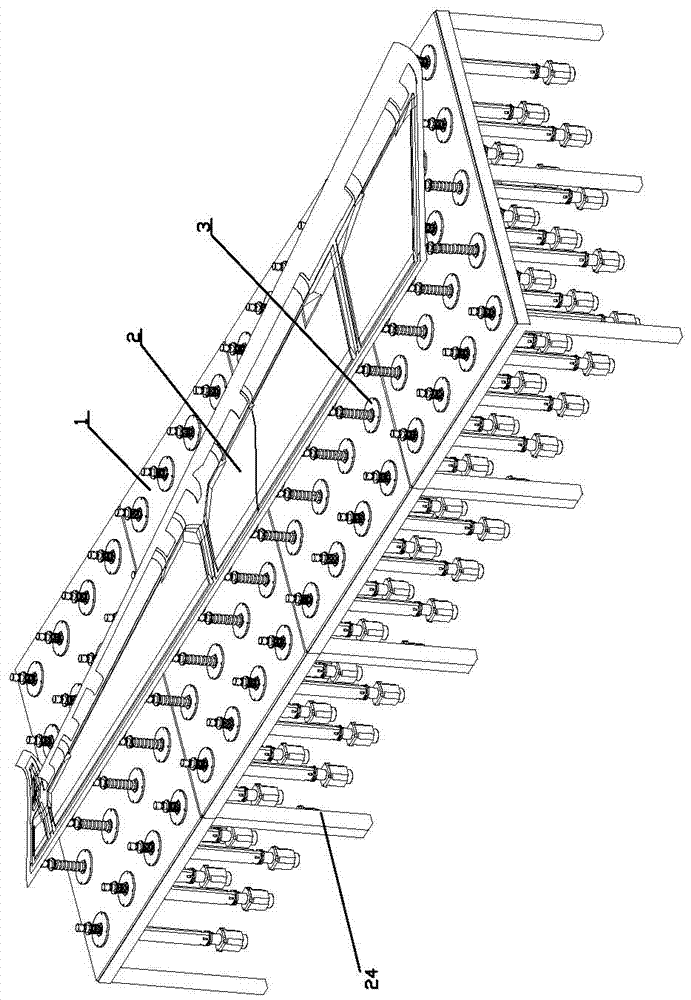

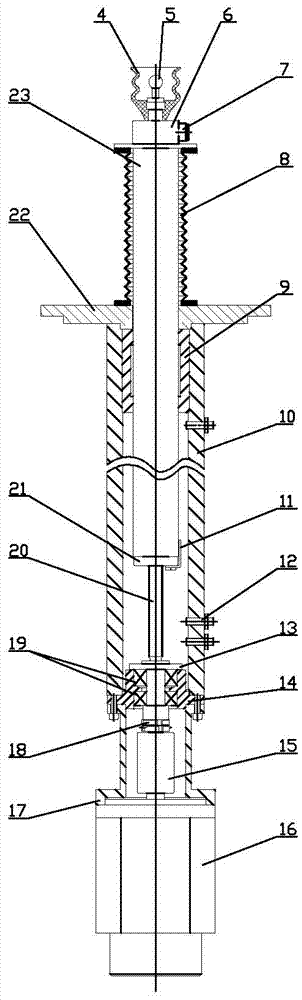

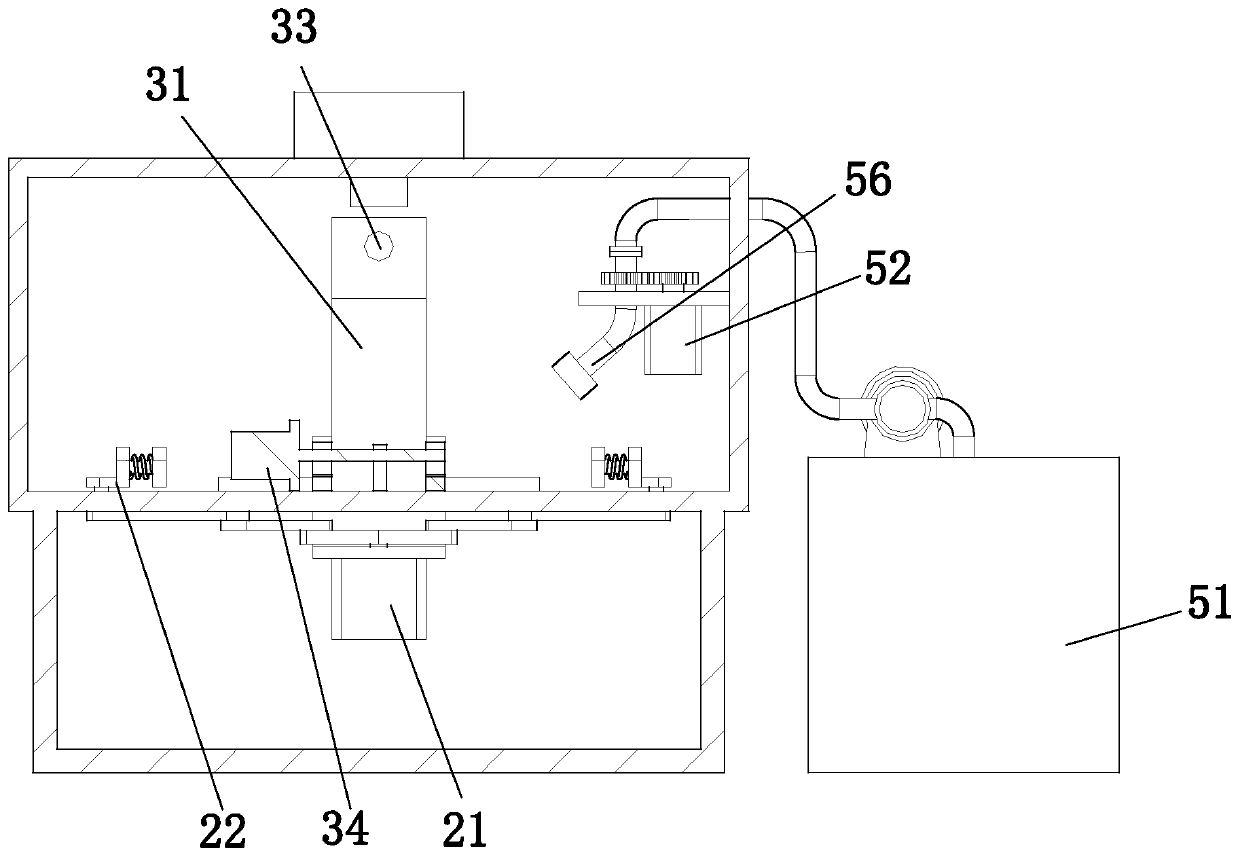

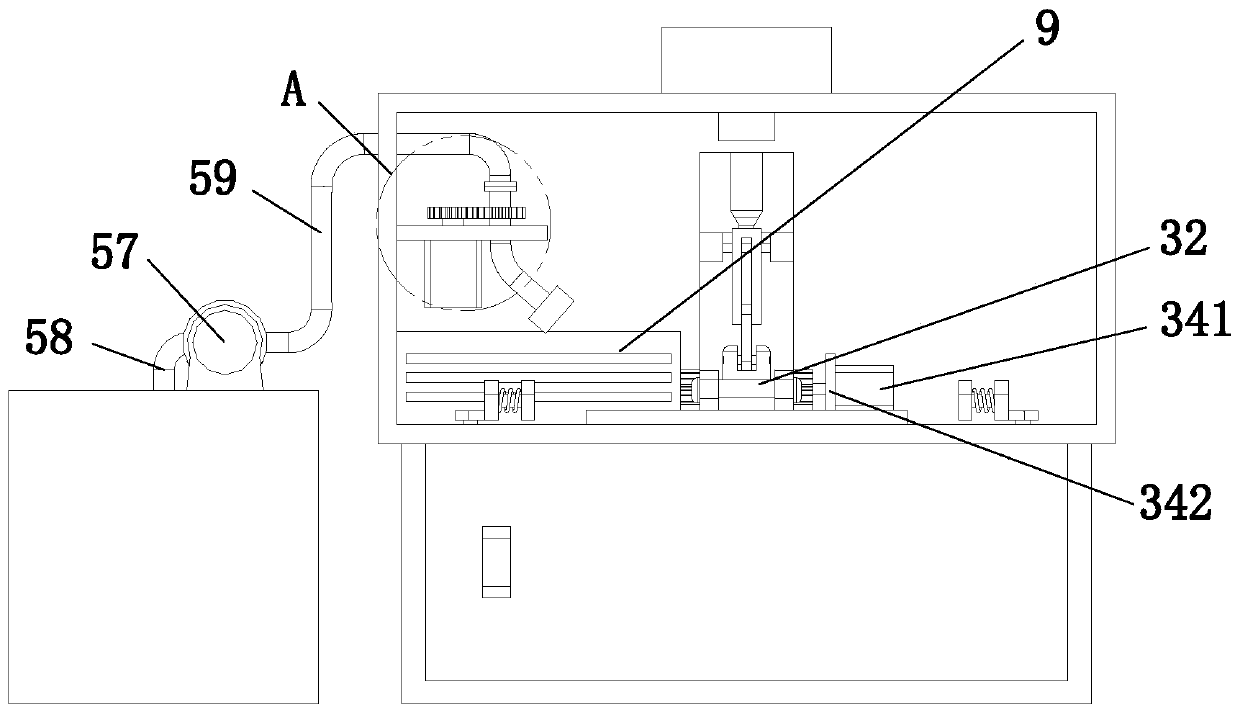

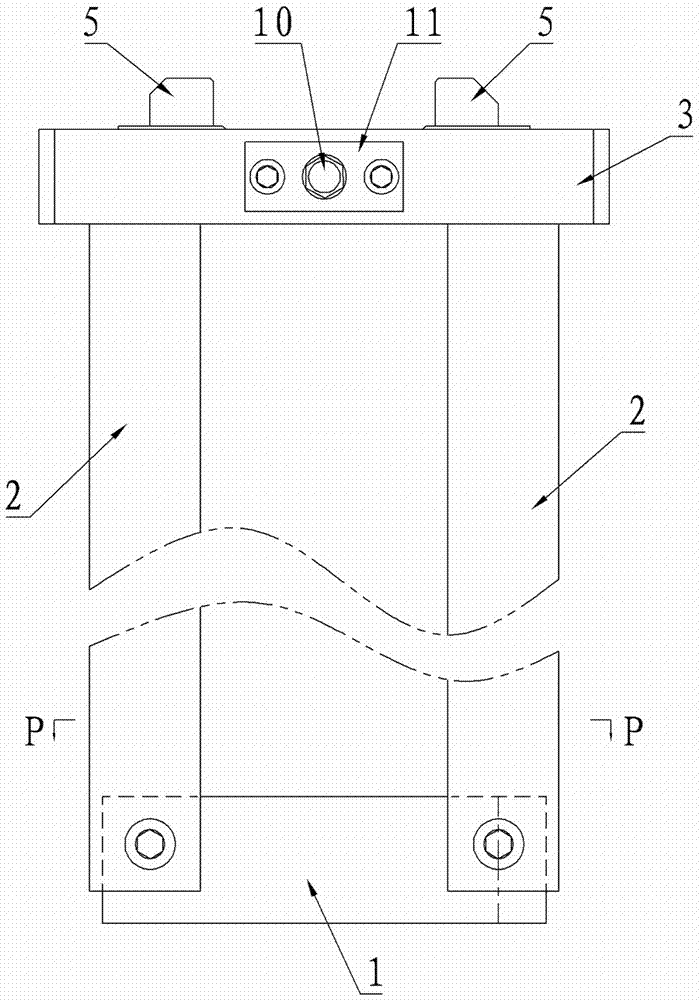

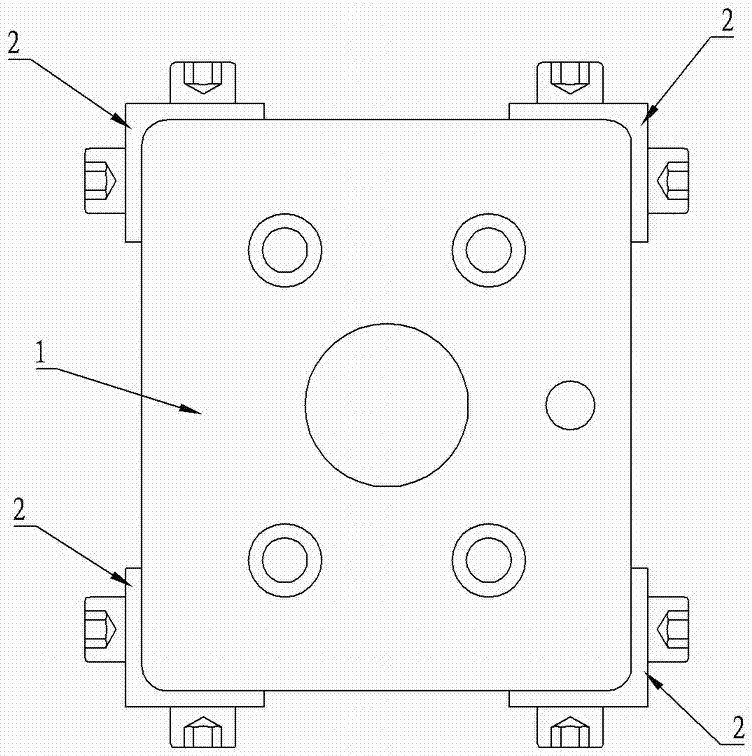

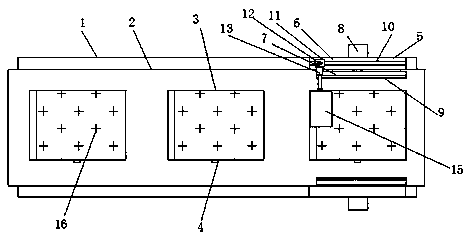

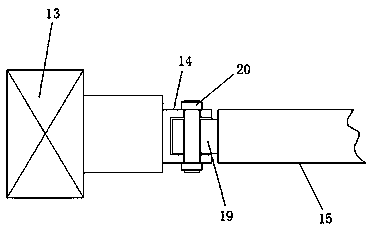

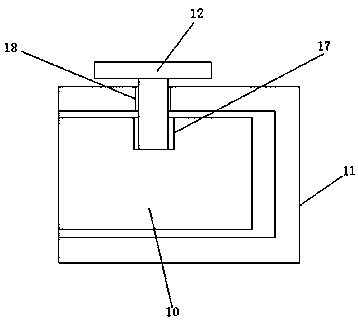

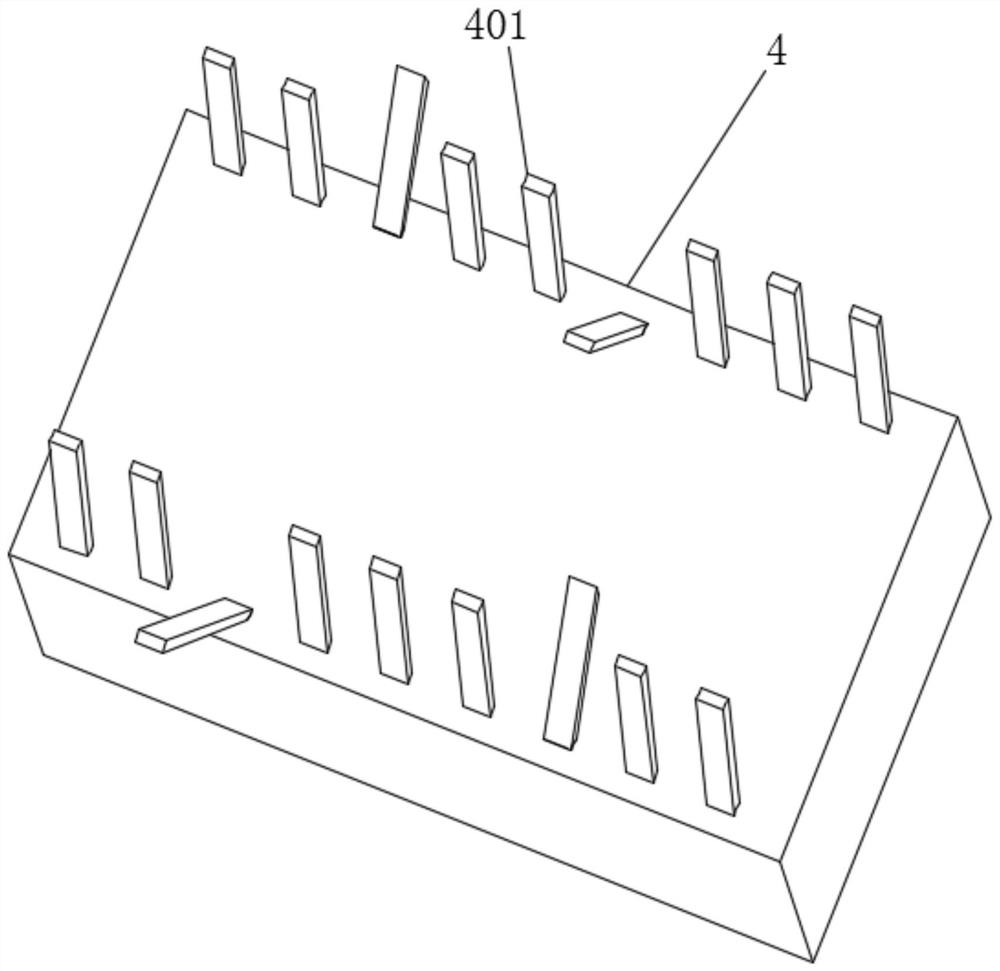

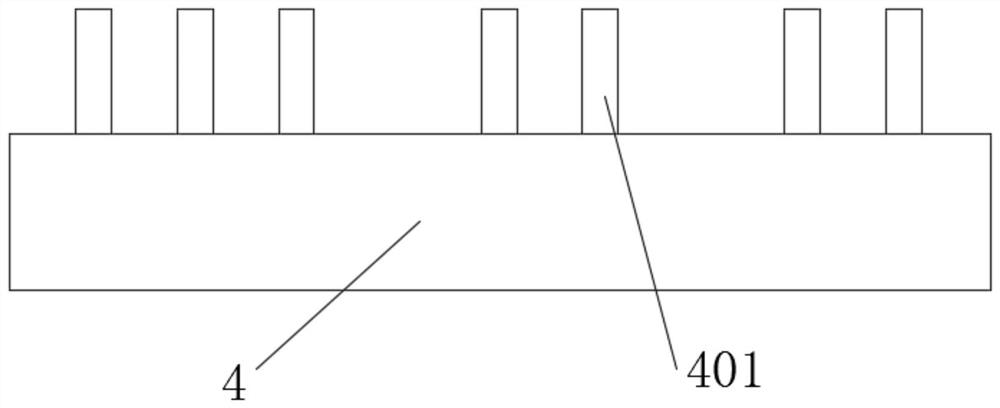

Vacuum absorption numerical control floating lattice bracket

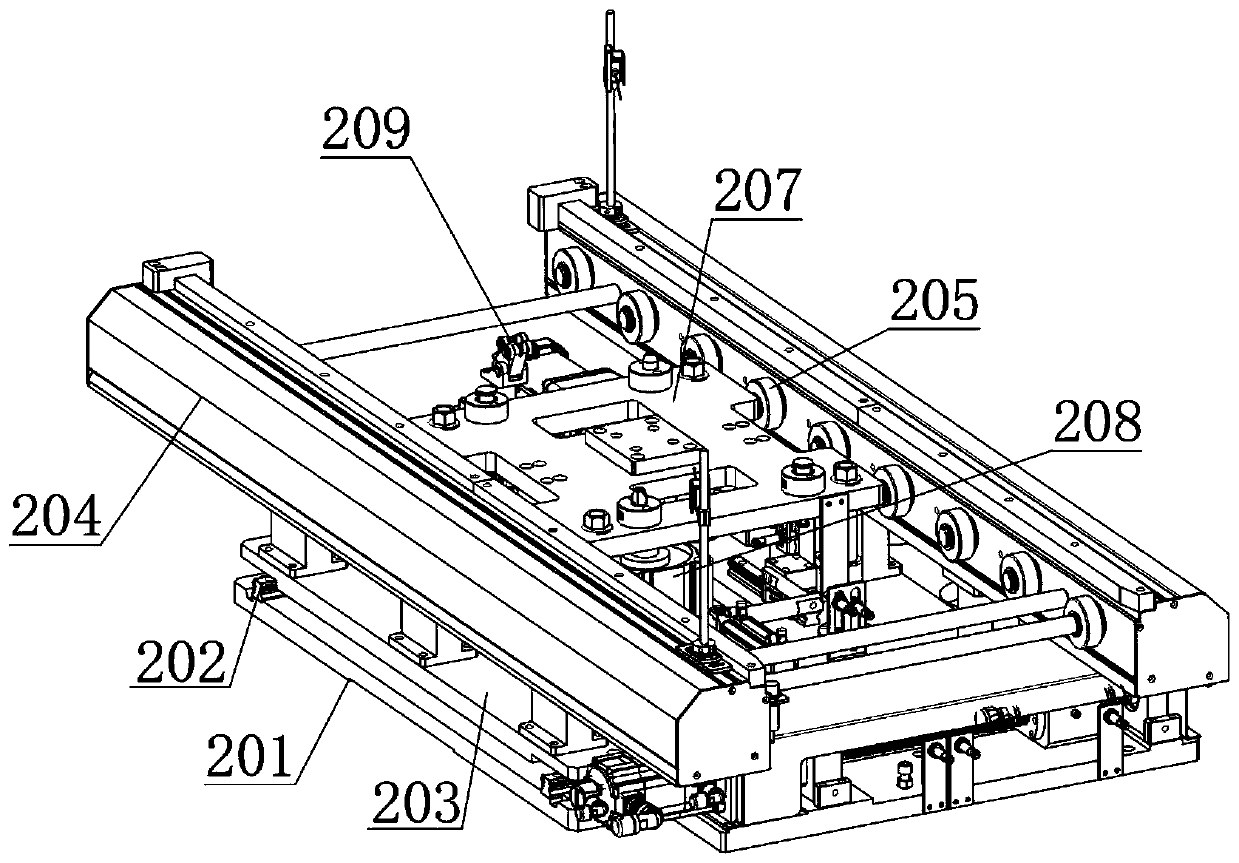

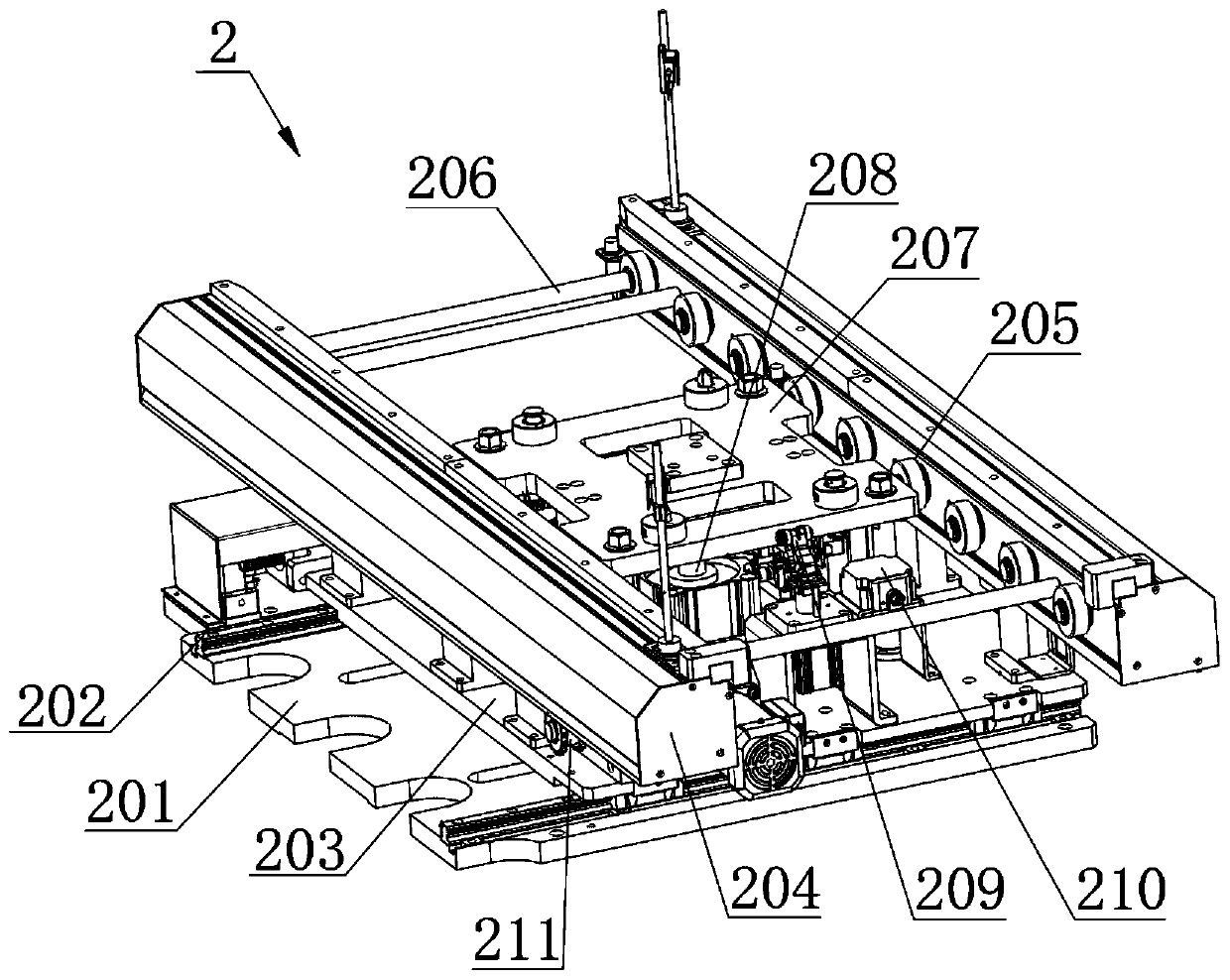

PendingCN106975955AHigh speedNo pollution in the processPositioning apparatusMetal-working holdersEngineeringCam

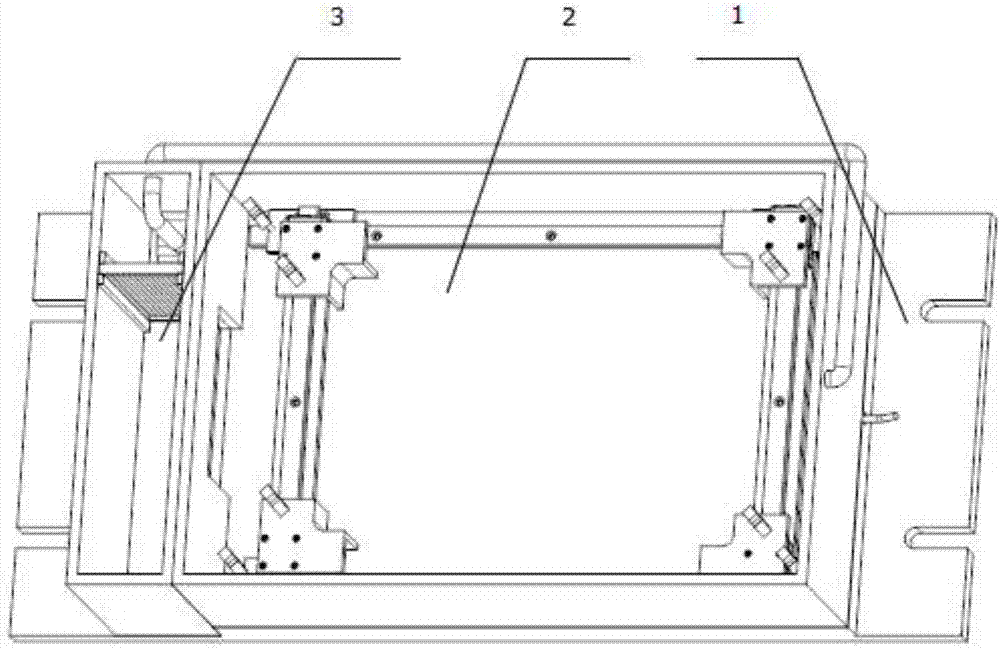

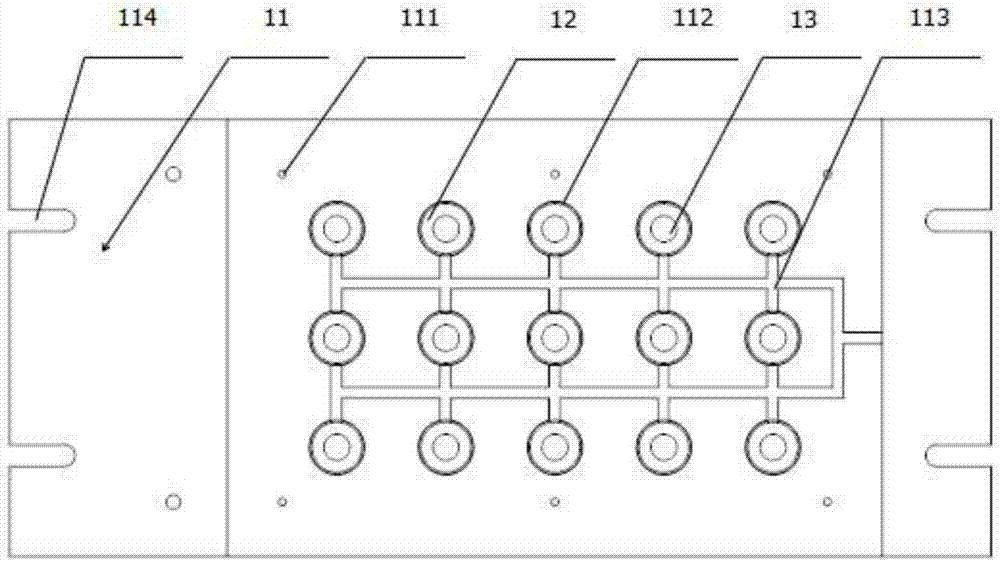

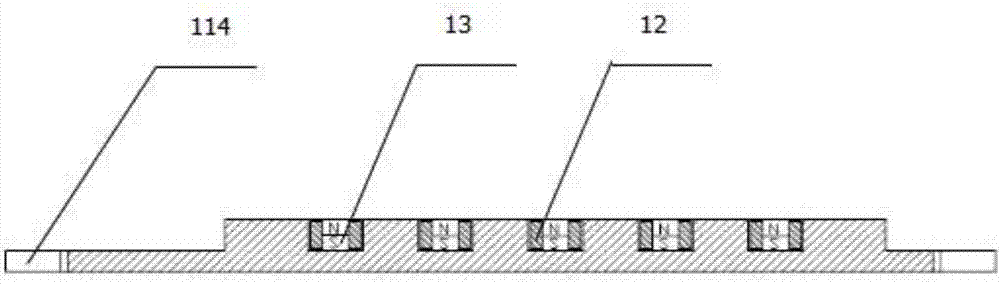

The invention provides a vacuum absorption numerical control floating lattice bracket. The bracket comprises a working table (1) and a plurality of floating bracket units (3) installed on the working table. The bracket is characterized in that the floating bracket units (3) are arranged on the working table (1) in a rectangular array mode, and supporting legs (24) are arranged on the working table (1); a positioning device used for positioning a structural member (2) is fixed to the working table, and the original point of the structural member (2) in CAM software is determined through the positioning device; according to the original point and the curved surface shape of the structural member (2), the CAM software in a numerical control system calculates the height of each floating bracket unit (3), according to the data calculated by the CAM software, the numerical control system drives spherical surface supporting points in the floating bracket units (3) to form the floating lattice bracket coincident with the curved surface of the structural member, and the structural member (2) is placed on the floating lattice bracket according to a set position and absorbed, so that the positioning and fixing of the structural member are completed. The vacuum absorption numerical control floating lattice bracket is simple in structure, convenient to position, high in universality and capable of meeting positioning requirements of structural members in various shapes, improving the positioning efficiency and reducing the machining cost.

Owner:DARDI INT CORP

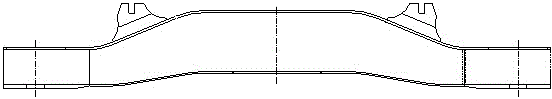

Multifunctional automatic welding jig

ActiveCN104368929ALow production costDoes not occupy storage spaceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a multifunctional automatic welding jig. The multifunctional automatic welding jig comprises a jig body, a side beam adjustment mechanism, cross beam adjustment mechanisms, cross beam and side beam pressing mechanisms and a transition disc, wherein the jig body is formed by welding two pieces of square steel and a steel plate, the two pieces of square steel are parallel to each other, the side beam adjustment mechanism is fixed to the middle upper portion of the jig body and is composed of a bottom surface, a top surface, a plurality of tension bolts and a plurality of puller bolts, the bottom surface is parallel to the top surface, the tension bolts and the puller bolts are arranged between the bottom surface and the top surface, the cross beam adjustment mechanisms are fixed to the two sides of the jig body, the two sides of each cross beam adjustment mechanism are each provided with two transverse steel plates, a series of long through sliding grooves which are parallel to one another are formed in each steel plate, V-shaped blocks are matched with the sliding grooves through sliding blocks on the sliding grooves, the cross beam and side beam pressing mechanisms are arranged at the two ends of the jig body, and each cross beam and side beam pressing mechanism comprises a supporting plate fixed above the jig body, a bolt, a cross beam pressing plate and a side beam pressing plate. The multifunctional automatic welding jig has the advantages that the universality is high, the welding jig can meet the requirement for automatic welding of various side beams in two different kinds of structures and sizes and various cross beams in two different kinds of structures and sizes, tool manufacturing cost is reduced, a small storage site is occupied, and the flexibility of the automatic welding process is improved.

Owner:CRRC QINGDAO SIFANG CO LTD

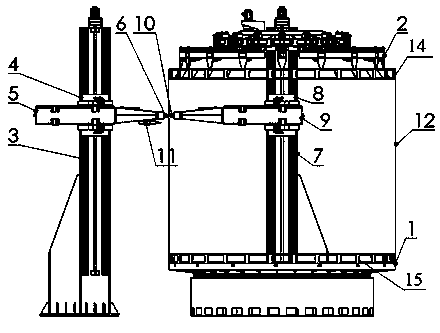

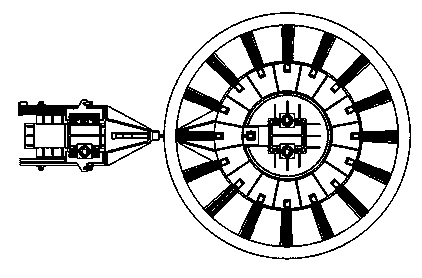

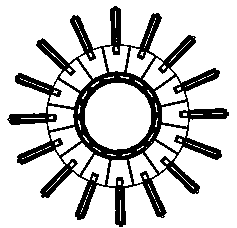

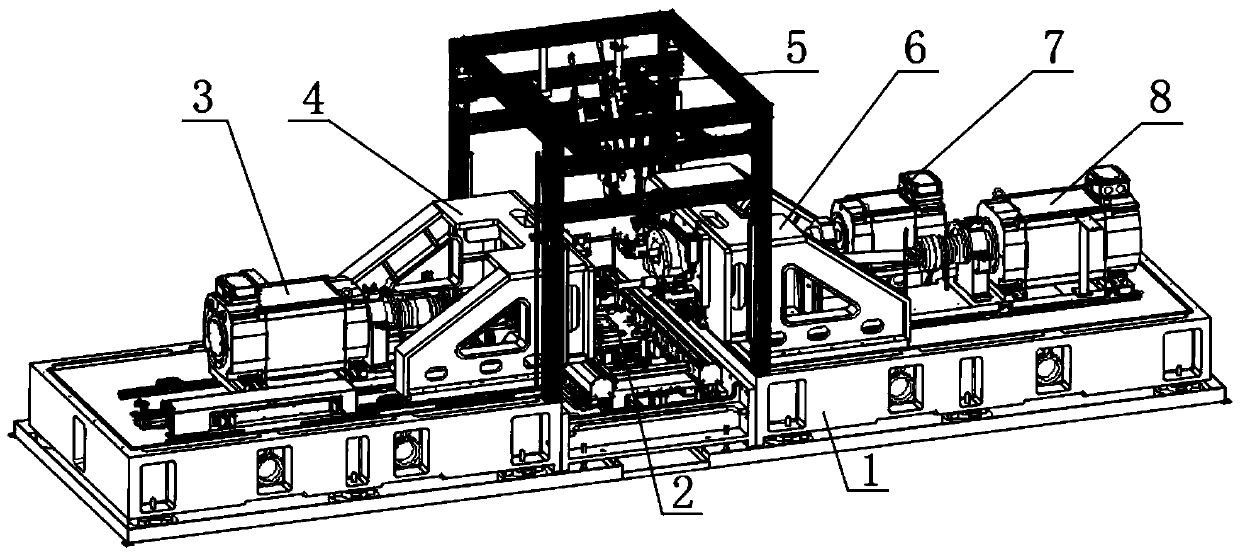

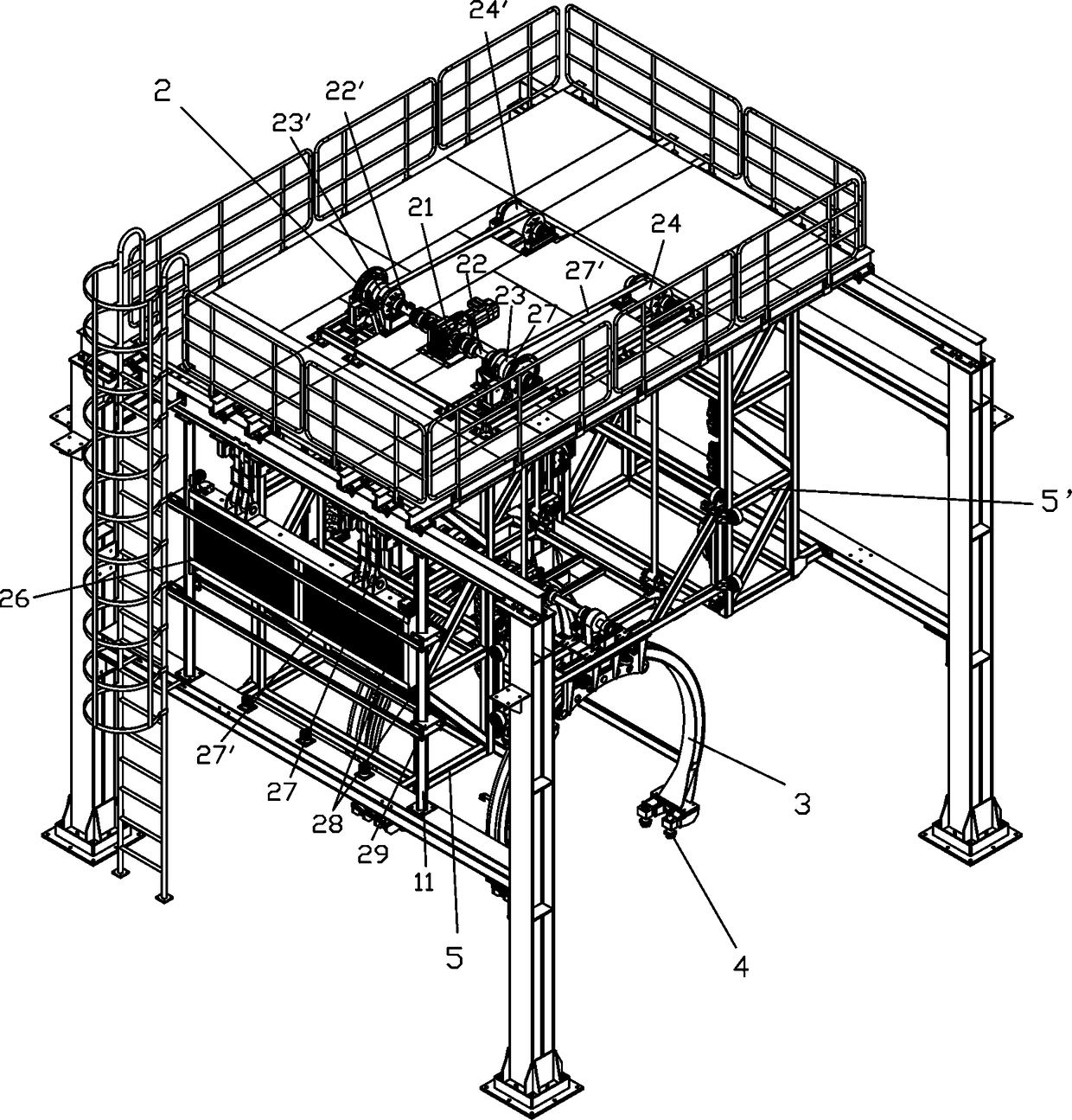

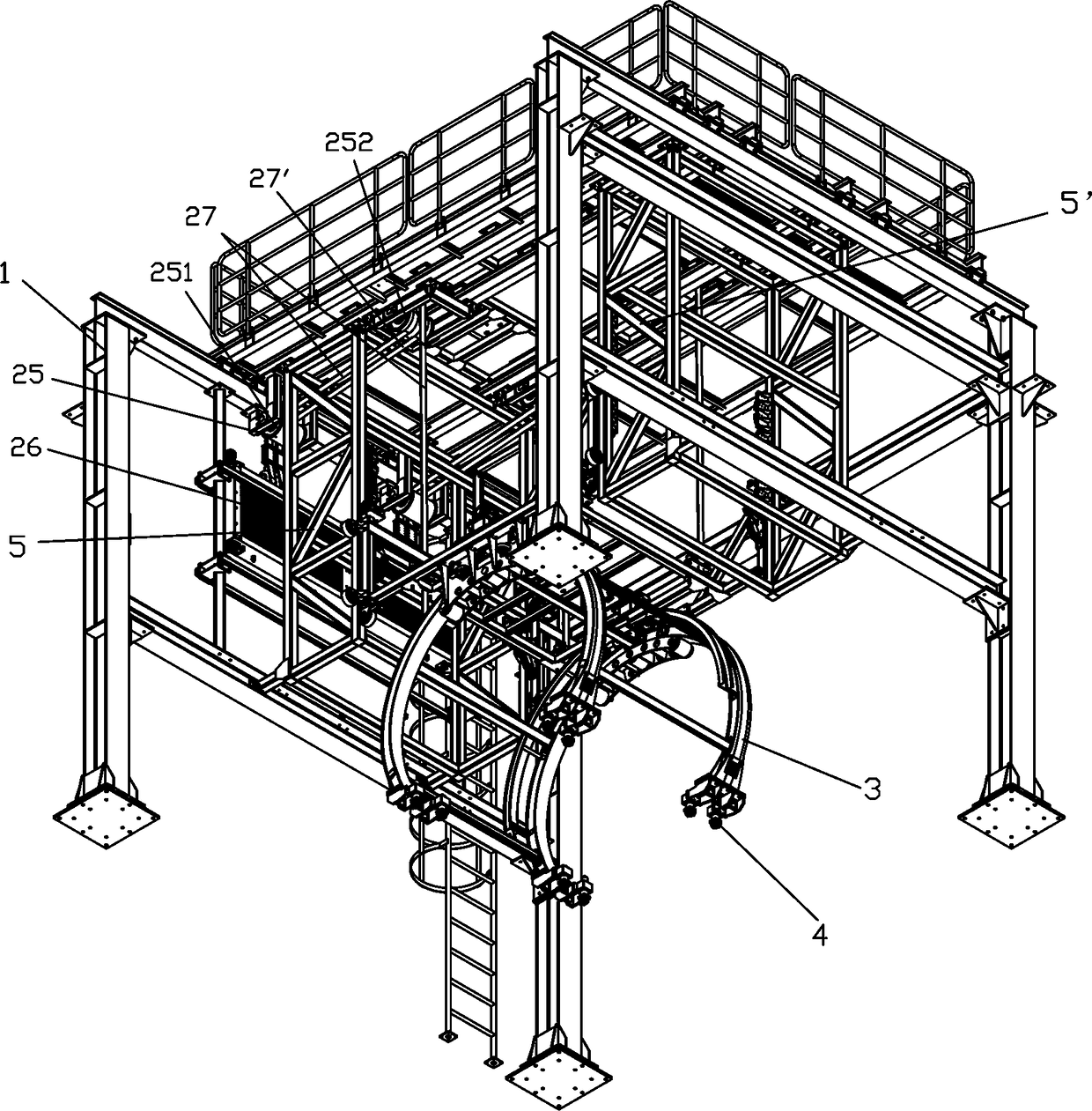

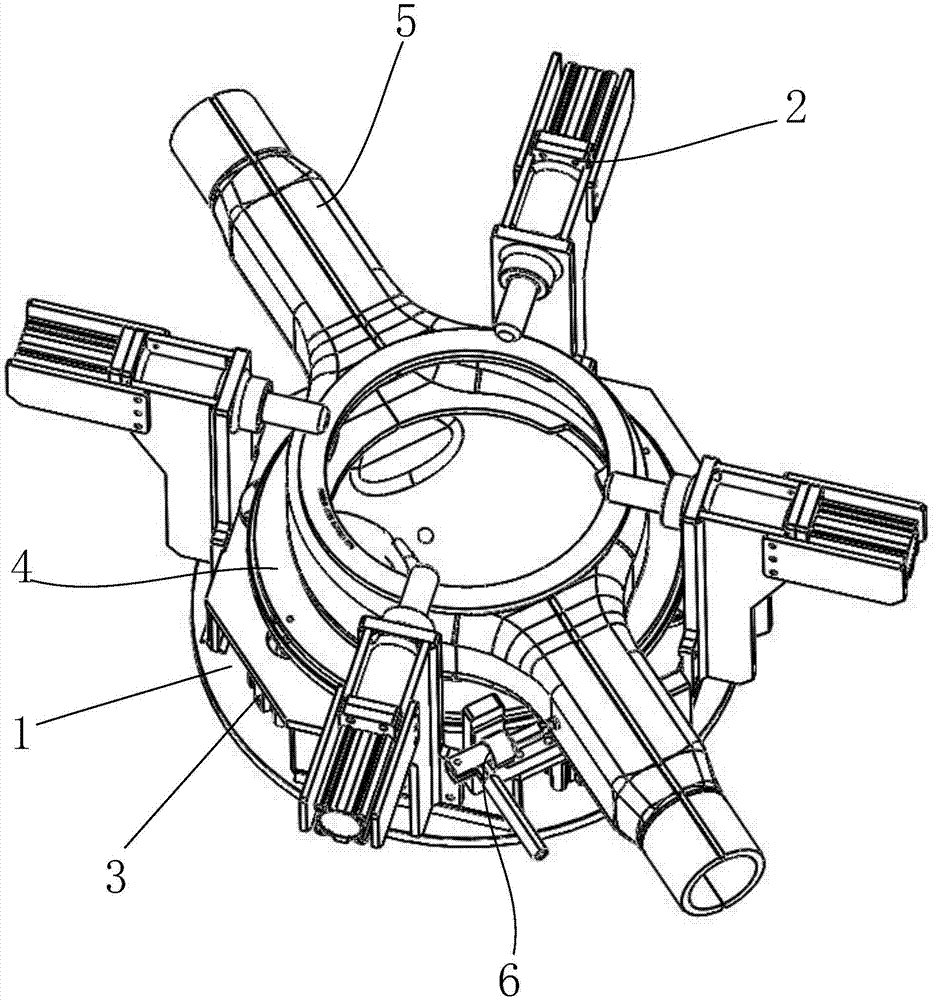

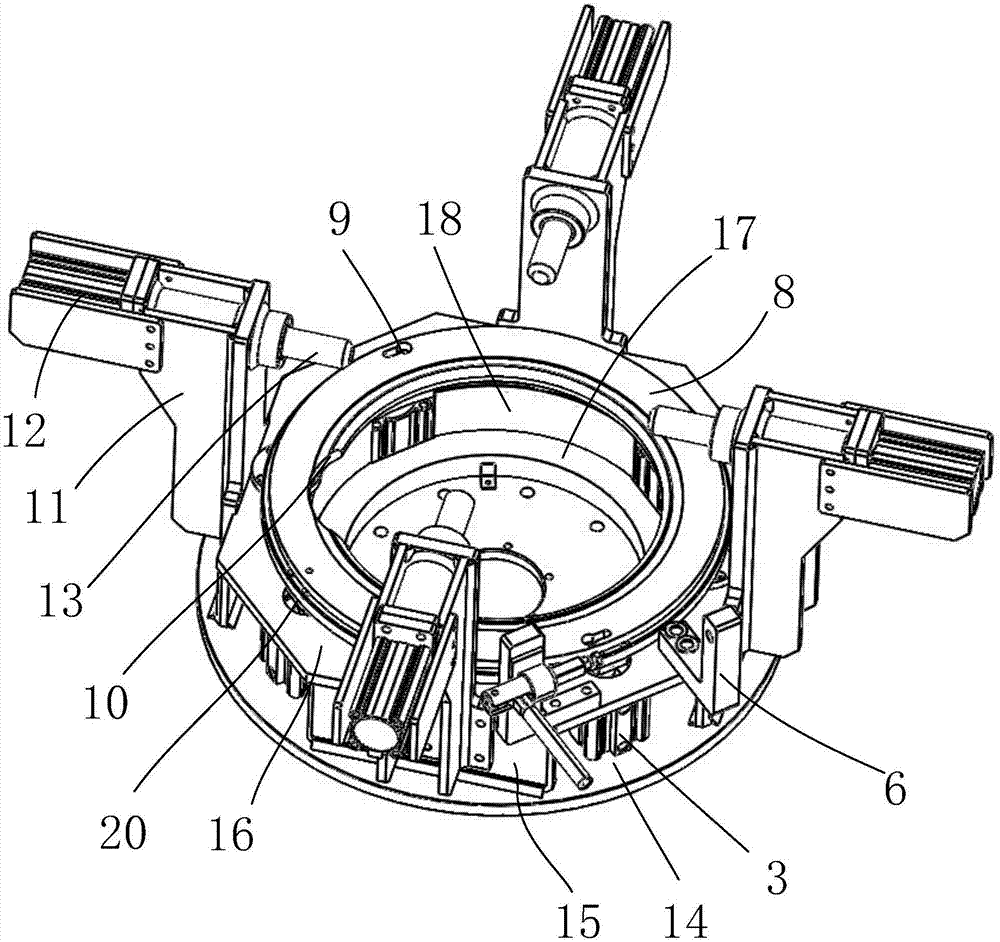

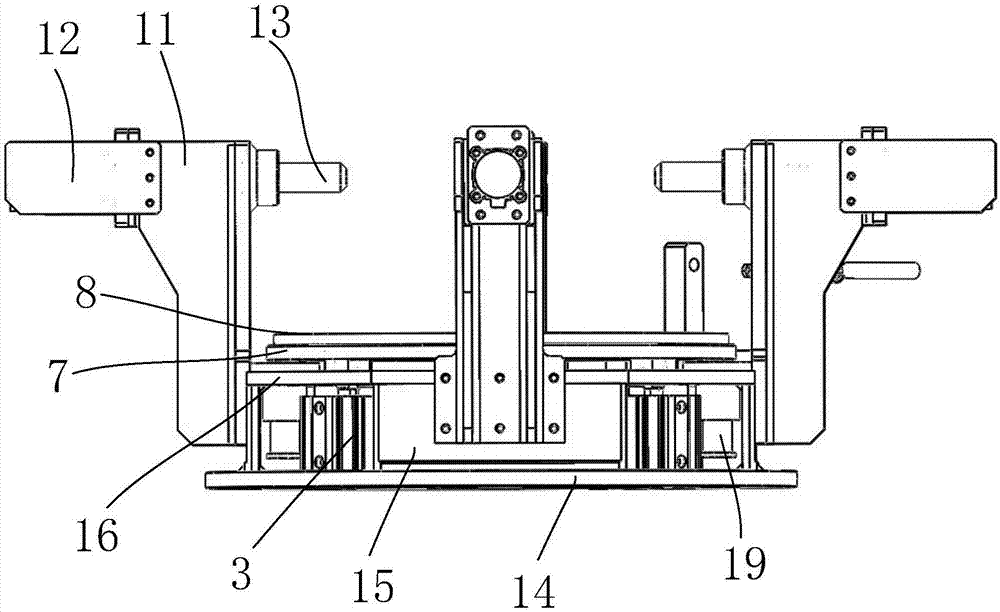

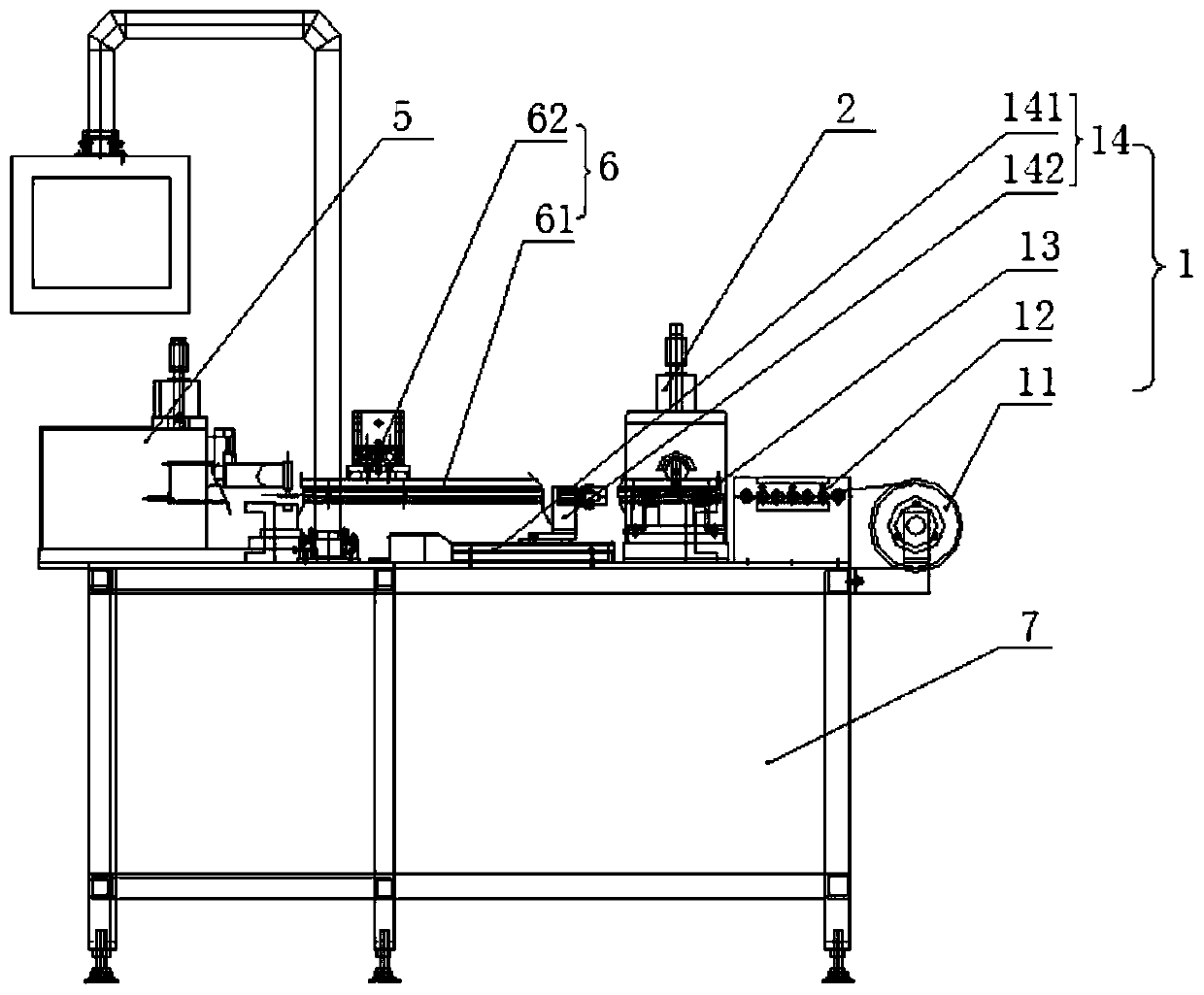

Integrated riveting device and integrated riveting method of large-scale cylinder section component

ActiveCN103386455AGuaranteed shape accuracyGuaranteed positioning accuracyAutomationNumerical control system

The invention discloses an integrated riveting device and an integrated riveting method of a large-scale cylinder section component. The integrated riveting device comprises a rotating table, a flexible clamping system with a liftable top part, a nail conveying device, a press riveting device, a left upright, a right upright, an upper location tool piece and a lower location tool piece, wherein the upper end of at least one workpiece is arranged on the flexible clamping system with the liftable top part through one upper location tool piece, the lower end of the workpiece is arranged on the rotating table through one lower location tool piece, the nail conveying device is positioned on the left upright, and the press riveting device is positioned on the right upright. According to the integrated riveting device disclosed by the invention, the integrated riveting of a large-scale cylinder section workpiece can be accurately realized, all the riveting work can be automatically completed once a numerical control system is set, human intervention is not needed, and the automation degree is high. The integrated riveting device has a strong universality and can be applied to the integrated riveting and processing of thin-wall cylinder section components in various diameters and various heights.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD

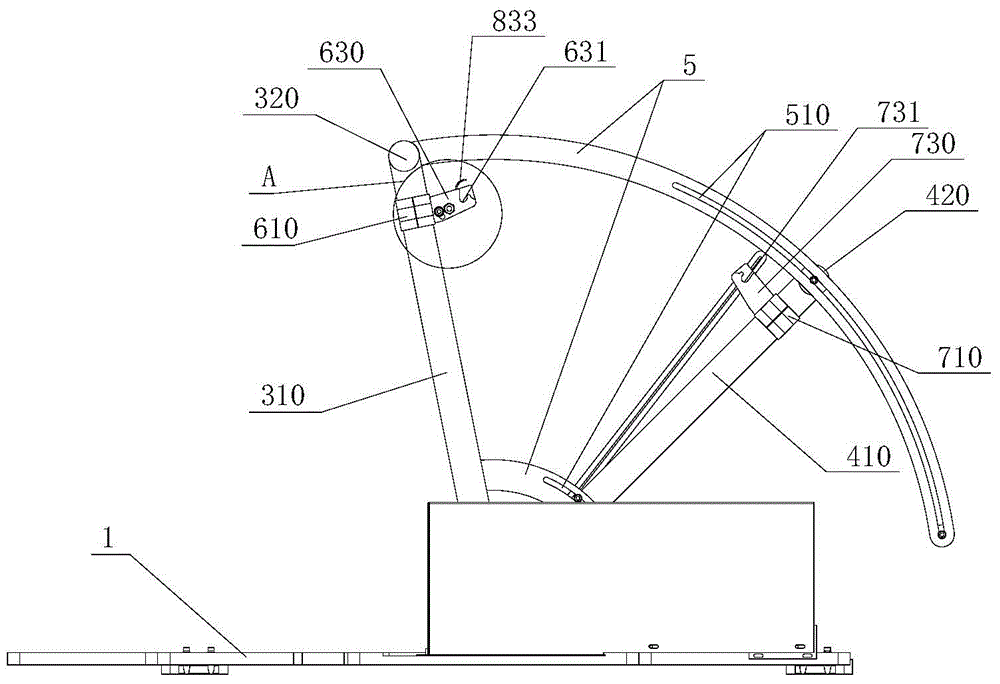

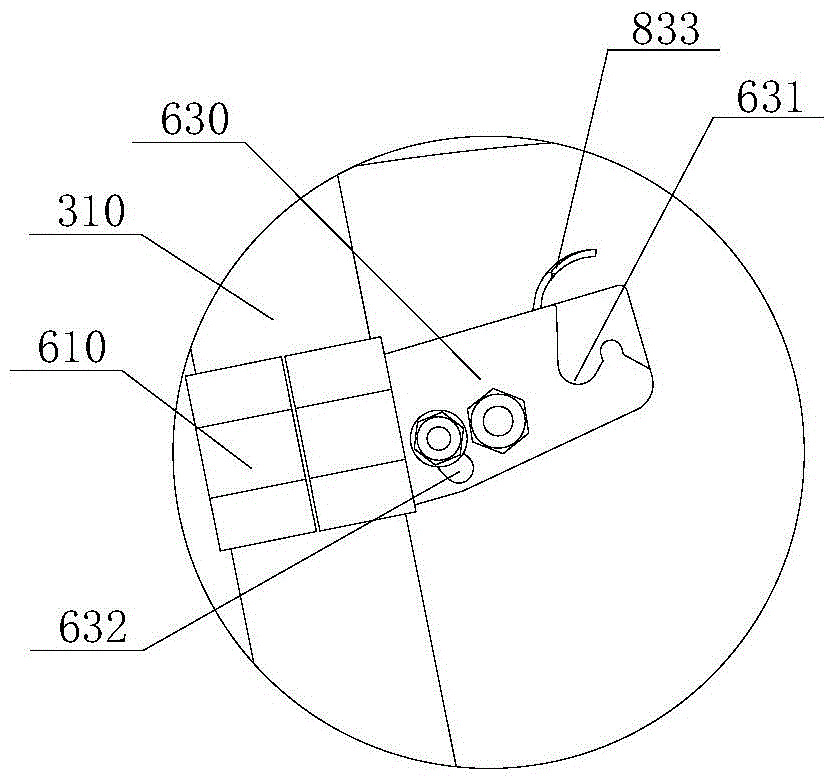

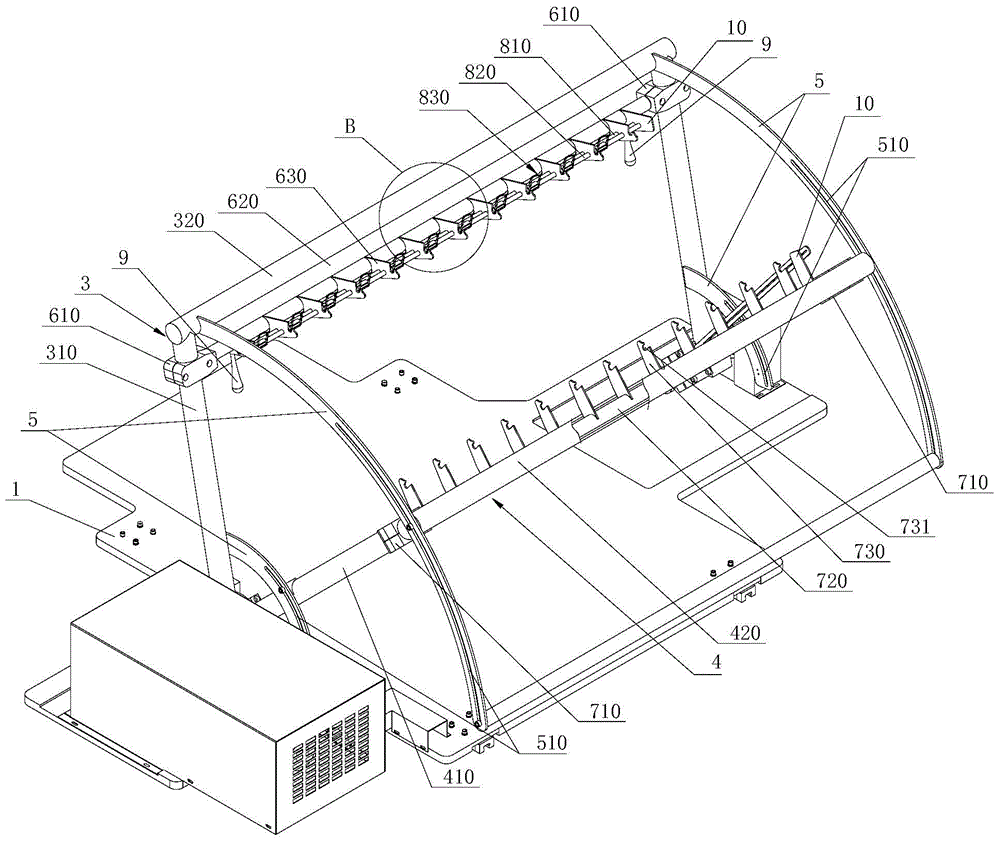

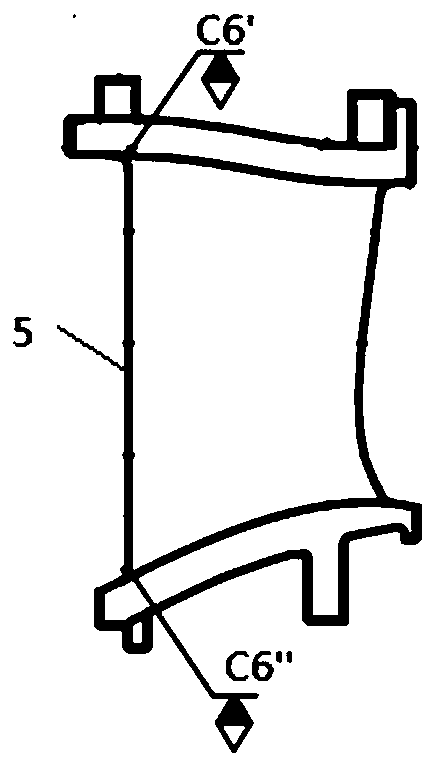

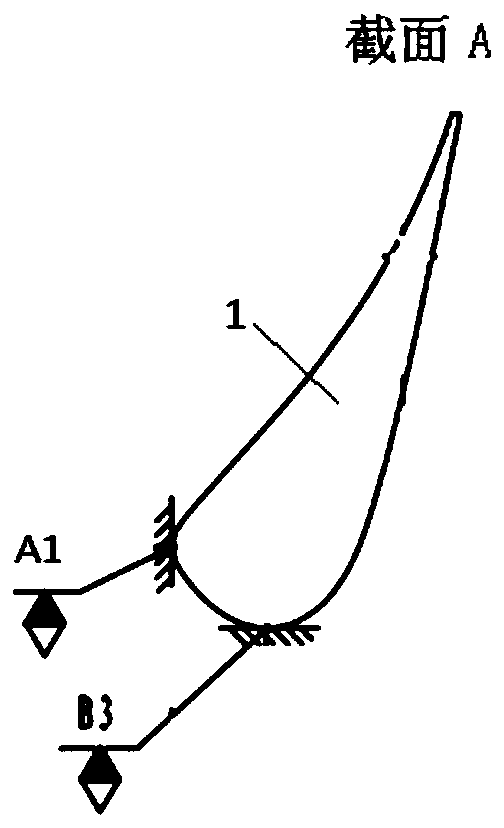

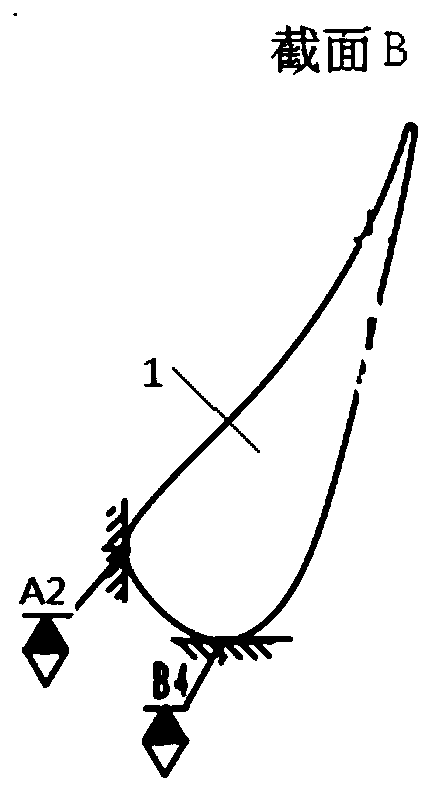

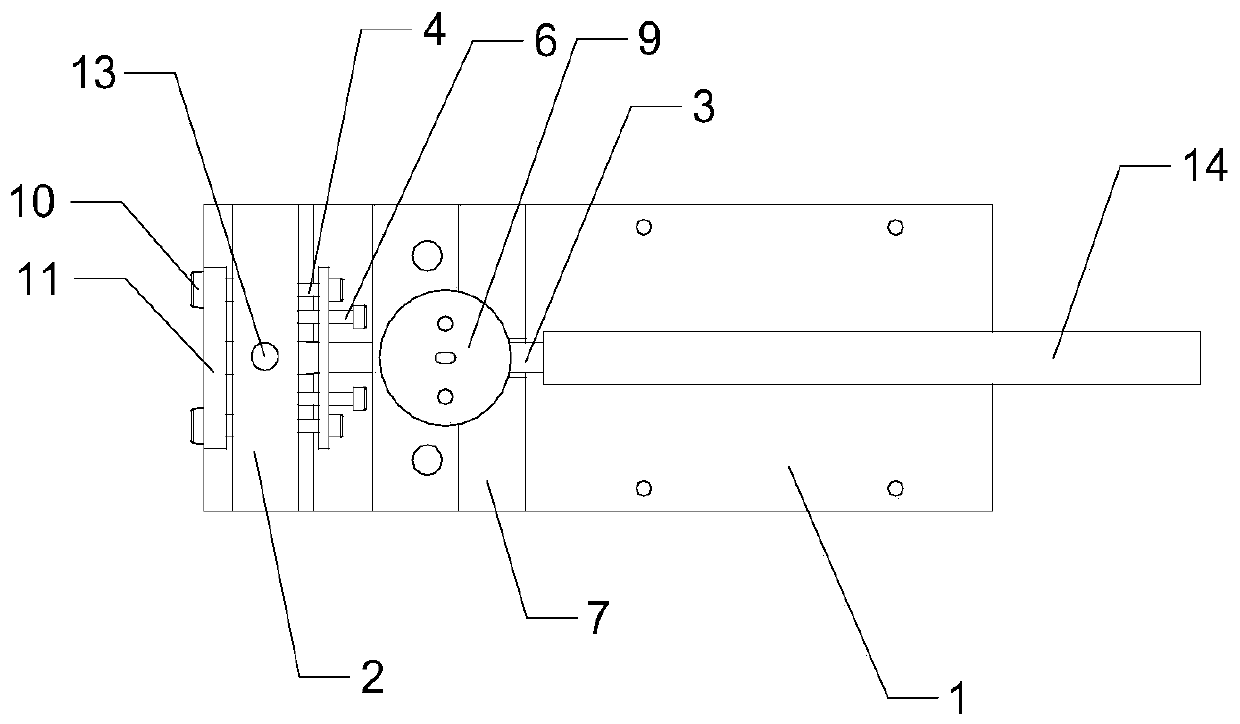

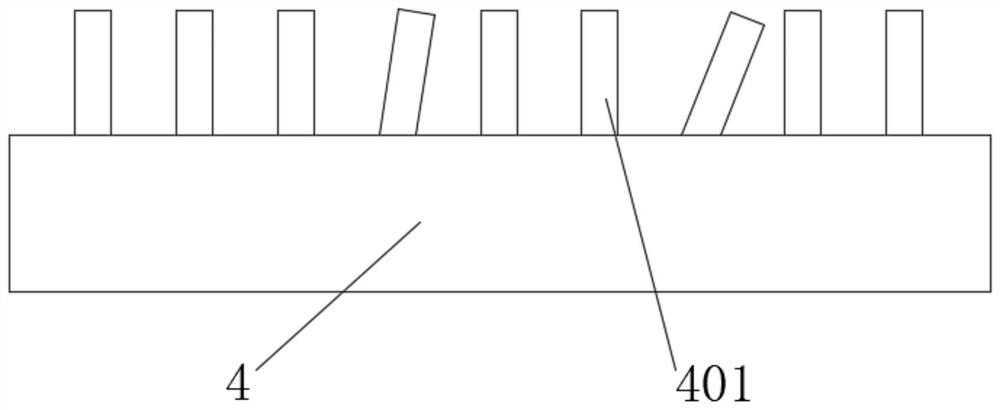

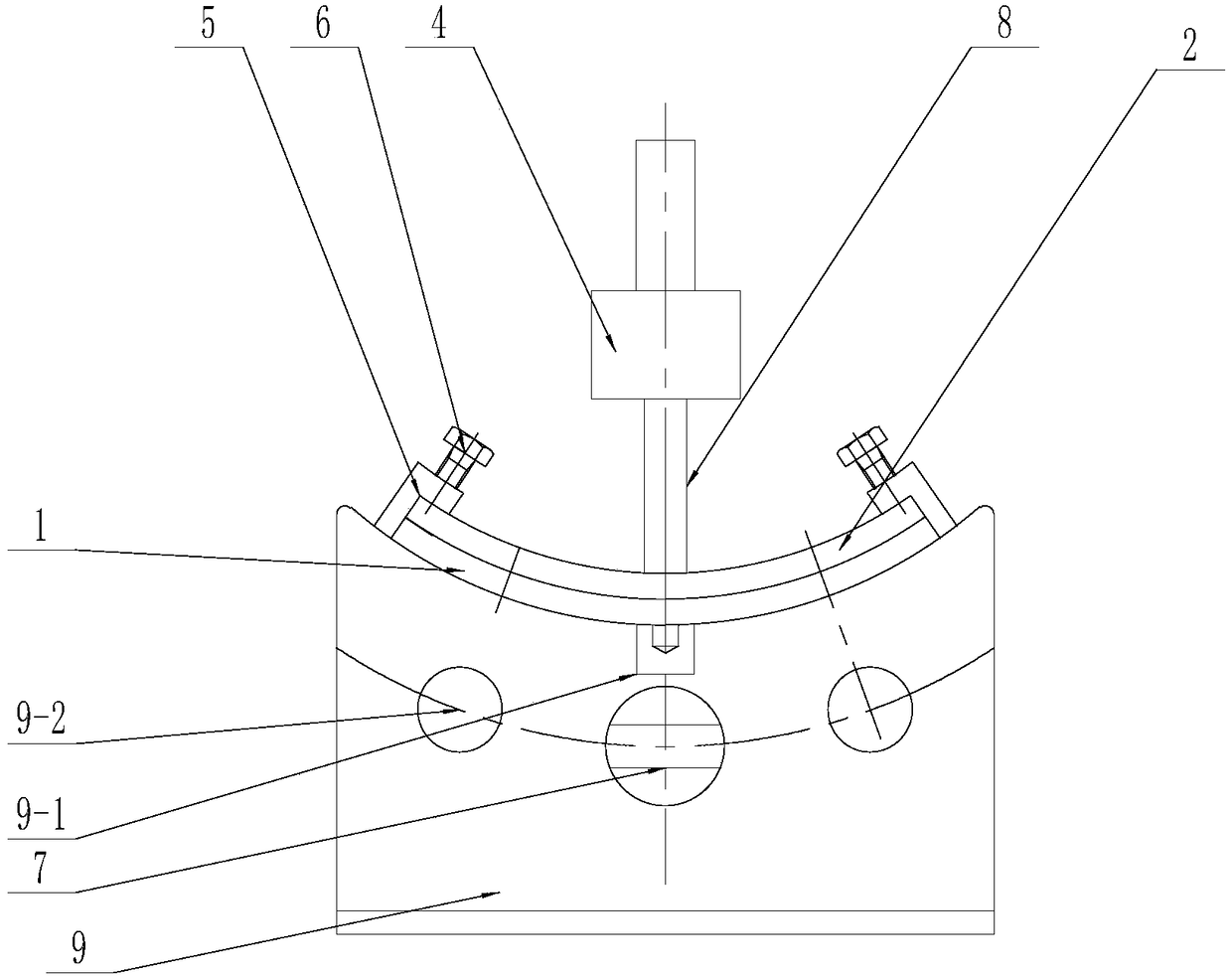

Rotary mounting and clamping device arranged on wood board laser cutting machine and used for arc-shaped board processing

ActiveCN104827229AMeet the positioningRealize one-time processing and moldingWelding/cutting auxillary devicesAuxillary welding devicesLaserReducer

A rotary mounting and clamping device arranged on a wood board laser cutting machine and used for arc-shaped board processing comprises a bottom platform, an adjusting shaft supported in the bottom platform, a speed reducer, a motor, a left inclined support, a right inclined support and multiple arc-shaped connection plates, wherein the speed reducer and the motor are installed on the bottom platform, the left inclined support and the right inclined support are supported on the adjusting shaft, and the arc-shaped connection plates are connected with the two inclined supports. The left inclined support comprises two fixed supporting arms and a fixing supporting beam, and the lower ends of the two fixed supporting arms are fixedly connected with the two ends of the adjusting shaft respectively. The right inclined support comprises two rotary supporting arms and a rotary supporting beam, and the lower ends of the two rotary supporting arms are rotationally connected with the two ends of the adjusting shaft respectively. One end of each arc-shaped connection plate is fixedly connected with the left inclined support, and the arc-shaped connection plates are detachably and fixedly connected with the right inclined support through screws penetrating through arc-shaped long connection holes. The device comprises a left side supporting plate assembly and a right side supporting plate assembly, the left side supporting plate assembly is supported on the two fixed supporting arms in a cross mode, the right side supporting plate assembly is supported on the two rotary supporting arms in a cross mode, and at least one side supporting plate assembly is provided with a pressing plate structure. The rotary mounting and clamping device achieves hollowed-out one-time machining and processing in the normal direction of the arc-shaped plates.

Owner:美克国际家私(天津)制造有限公司

Blade machining process

The invention discloses a blade machining process. The process dispersion principle is fully adopted; by utilizing a common plane abrasion device, the cost of the device is reduced and, flow line production can be carried out on a production site in batches; meanwhile, a low-melting-point alloy precise positioning mode is adopted, the machining benchmark is converted, a space positioning point isconverted into a plane, so that the machining process is reliable and stable, the production efficiency is improved, the machining quality is guaranteed, large-batch turbine guide blade production canbe met, and the process can be widely applied to machining of aero-engines and turbine guide blades of gas turbines.

Owner:AECC AVIATION POWER CO LTD

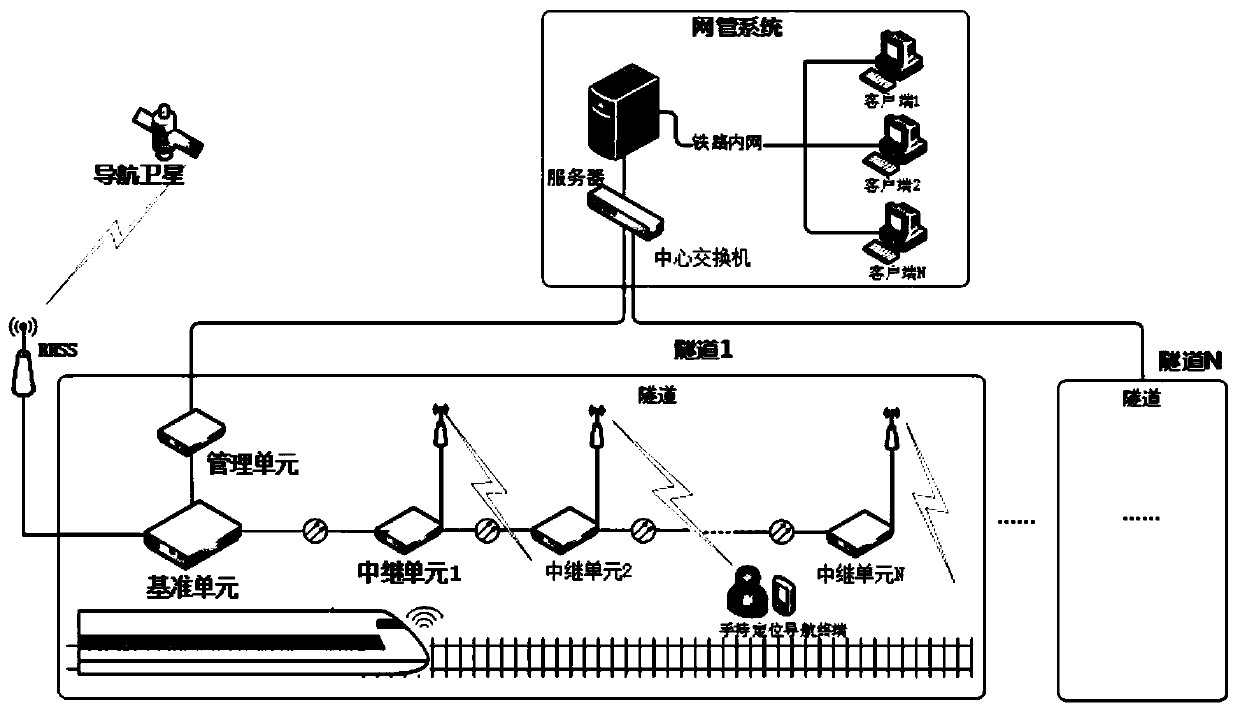

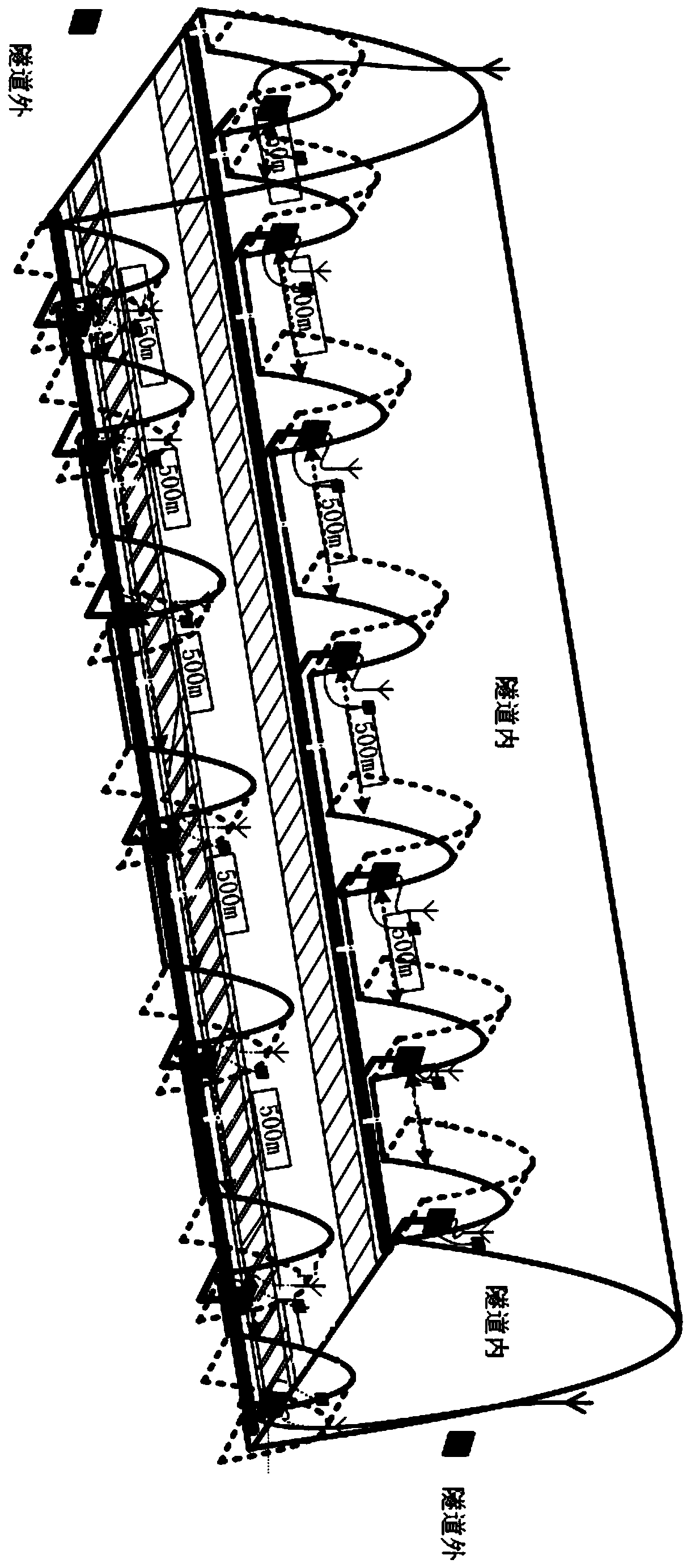

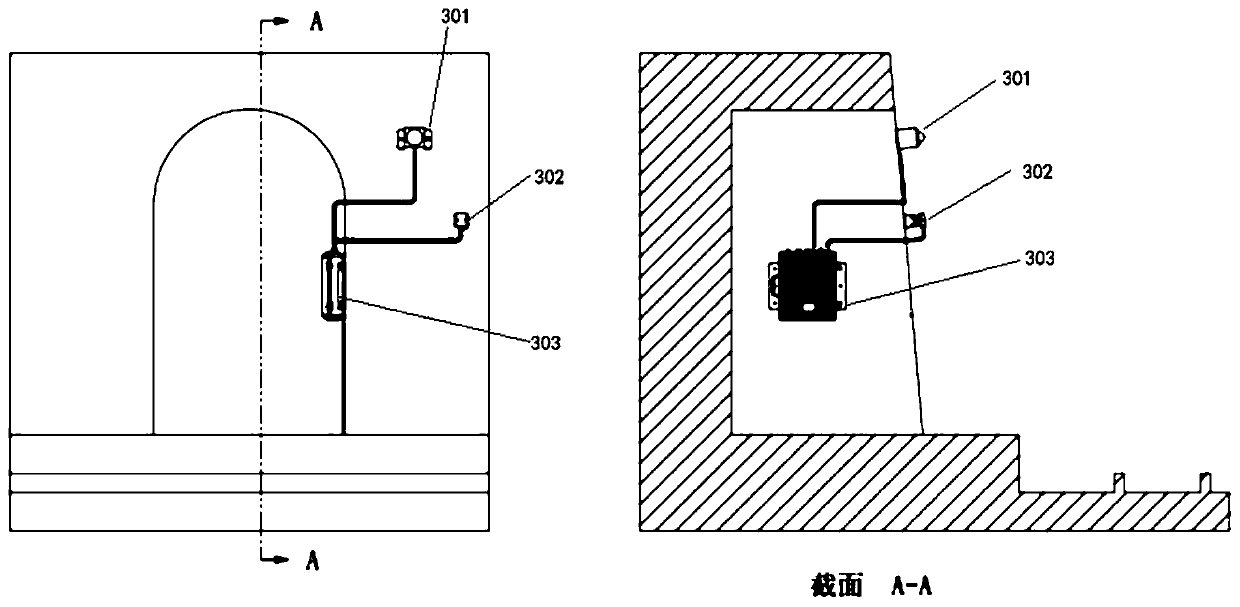

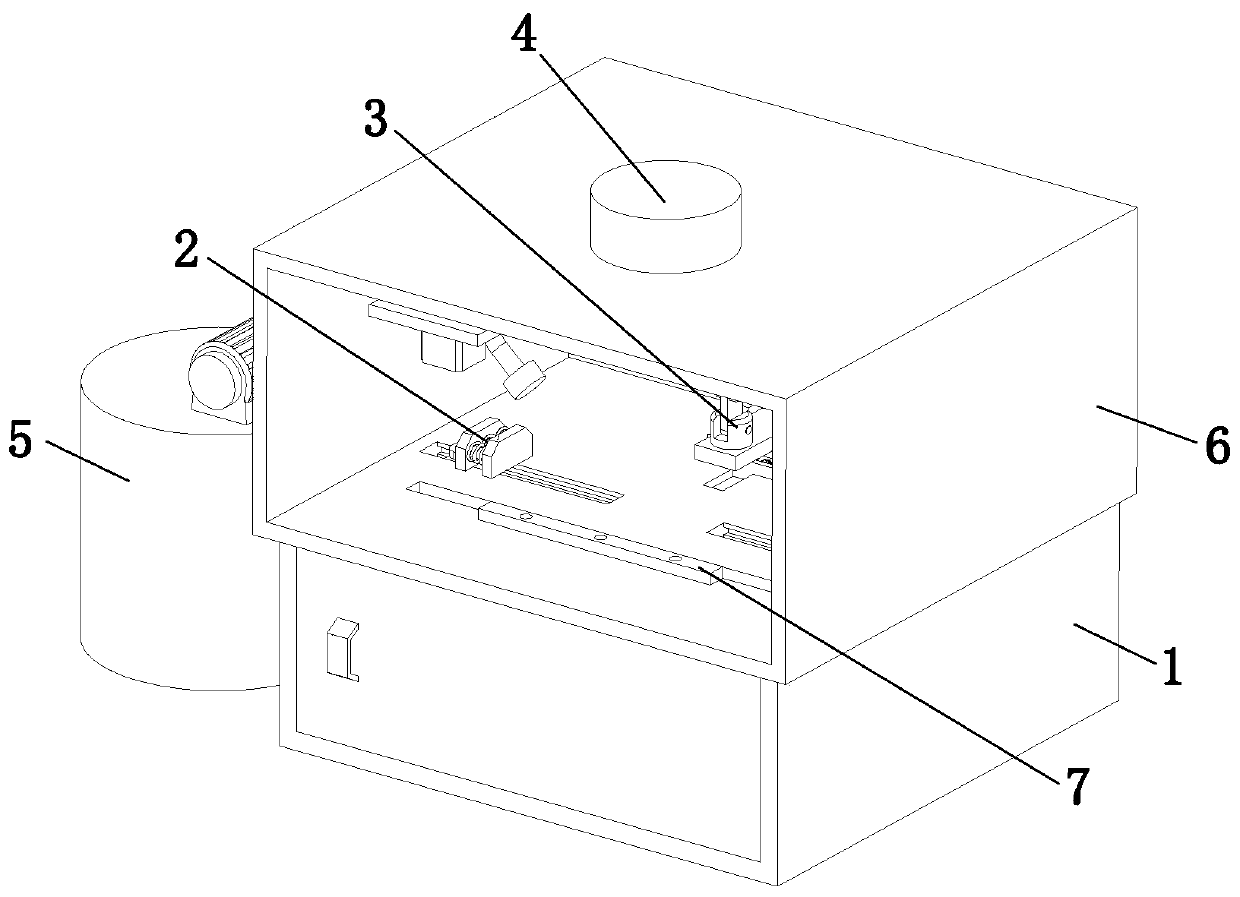

Beidou tunnel coverage system and layout method

ActiveCN110082784AMeet the positioningEnable seamless continuous navigationSatellite radio beaconingManagement unitTelecommunications link

The embodiment of the invention provides a Beidou tunnel coverage system and a layout method. A communication link is formed through a management unit, a reference unit and at least one relay unit, satellite navigation signals synchronous with the real satellite navigation signals in time and frequency are simulated and regenerated according to the received real satellite navigation signals, and broadcasting is conducted through an antenna, so that it is guaranteed that regeneration signals can be effectively received in a tunnel; an appropriate arrangement position is set according to the tunnel environment, it is guaranteed that seamless continuous navigation can be achieved when a train enters a closed area from an open area, and locomotive positioning, personnel positioning, containerpositioning and precise time service services are met under the condition that all vehicle-mounted terminals, handheld terminals and the like are not changed.

Owner:BEIJING CENTURY DONGFANG COMMUNICATION EQUIPMENT CO LTD +1

Graphene chip processing and cutting device

ActiveCN110774462ARealize the clamping effectImplement slackSemiconductor/solid-state device manufacturingWorking accessoriesEngineeringGraphene

The invention relates to the technical field of graphene chip processing, and discloses a graphene chip processing and cutting device. The graphene chip processing and cutting device comprises a workbench, a first positioning mechanism, a second positioning mechanism, a cutting mechanism and a protection mechanism, wherein the workbench is of a hollow rectangular structure; a cover plate is arranged on the top of the workbench; the protection mechanism is positioned beside the workbench; the output end of the protection mechanism is fixed on the cover plate; a limiting strip used for limitingone side of a graphene chip is arranged at the top of the workbench; the limiting strip is fixedly connected with the workbench through a plurality of bolts; a material falling groove communicating with the interior of the workbench is formed in the position, positioned beside the limiting strip, of the workbench; the material falling groove is of a long-strip-shaped structure; and an air blowingunit is arranged on the inner side wall of the cover plate. According to the graphene chip processing and cutting device, layer-by-layer positioning of the graphene chip can be realized, so that the positioning is stable, and the subsequent cutting effect is improved; and automatic positioning of graphene chips with different sizes can be met, and the overall practical performance is improved.

Owner:拓普瑞机器人科技东台有限公司

Machine tool clamp

InactiveCN106002361AMeet the positioningSatisfy millingDrilling/boring measurement devicesPositioning apparatusEngineeringMachine tool

The invention discloses a machine tool clamp which comprises a positioning plate, a clamp body, a clamping device and a guide device. The machine tool clamp is simple in structure, is strong in universality, is used for processing a common machine tool, can meet milling processing needs of most of workpieces, and has the advantage of reducing production cost.

Owner:镇江市宏业科技有限公司

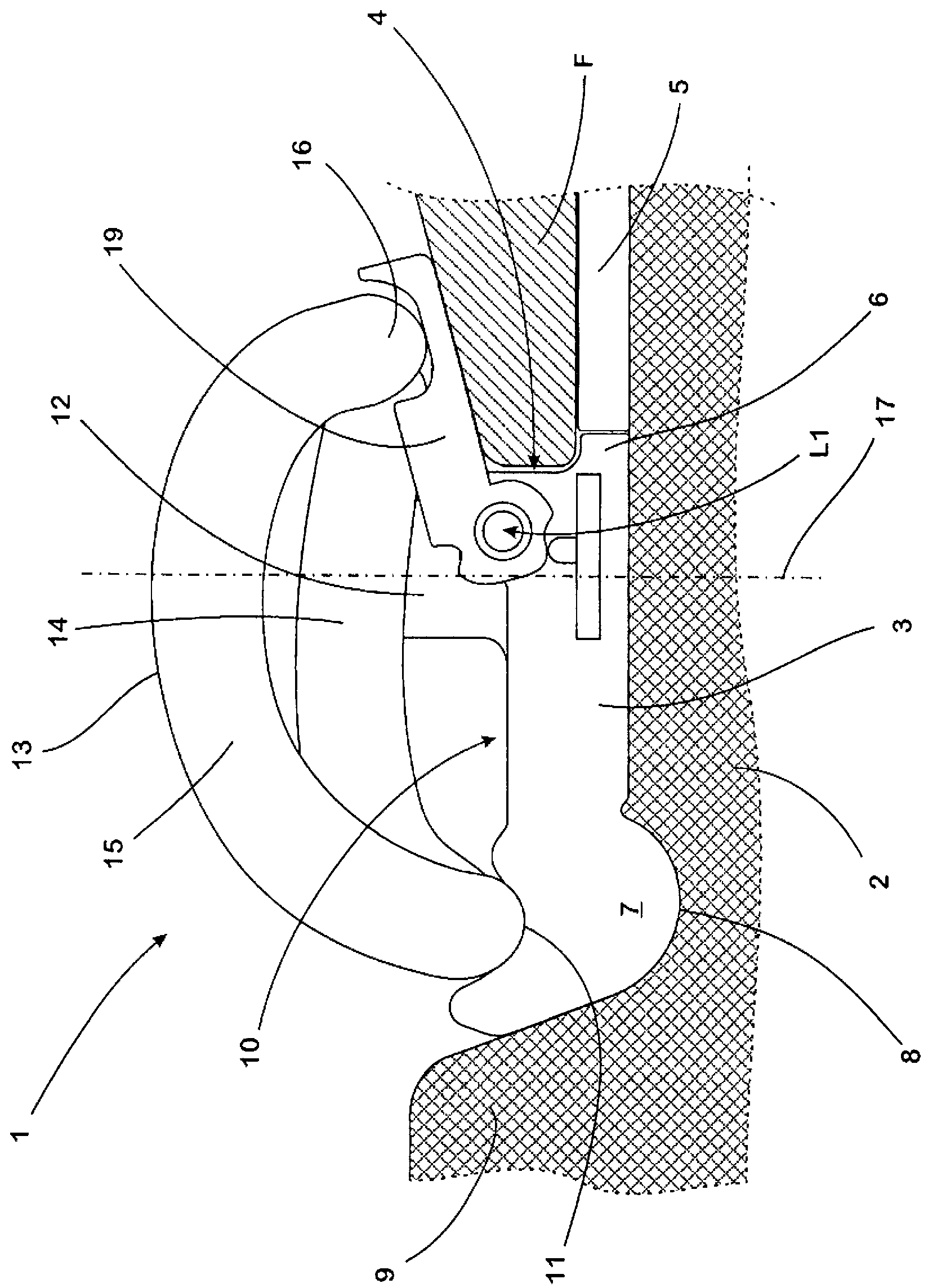

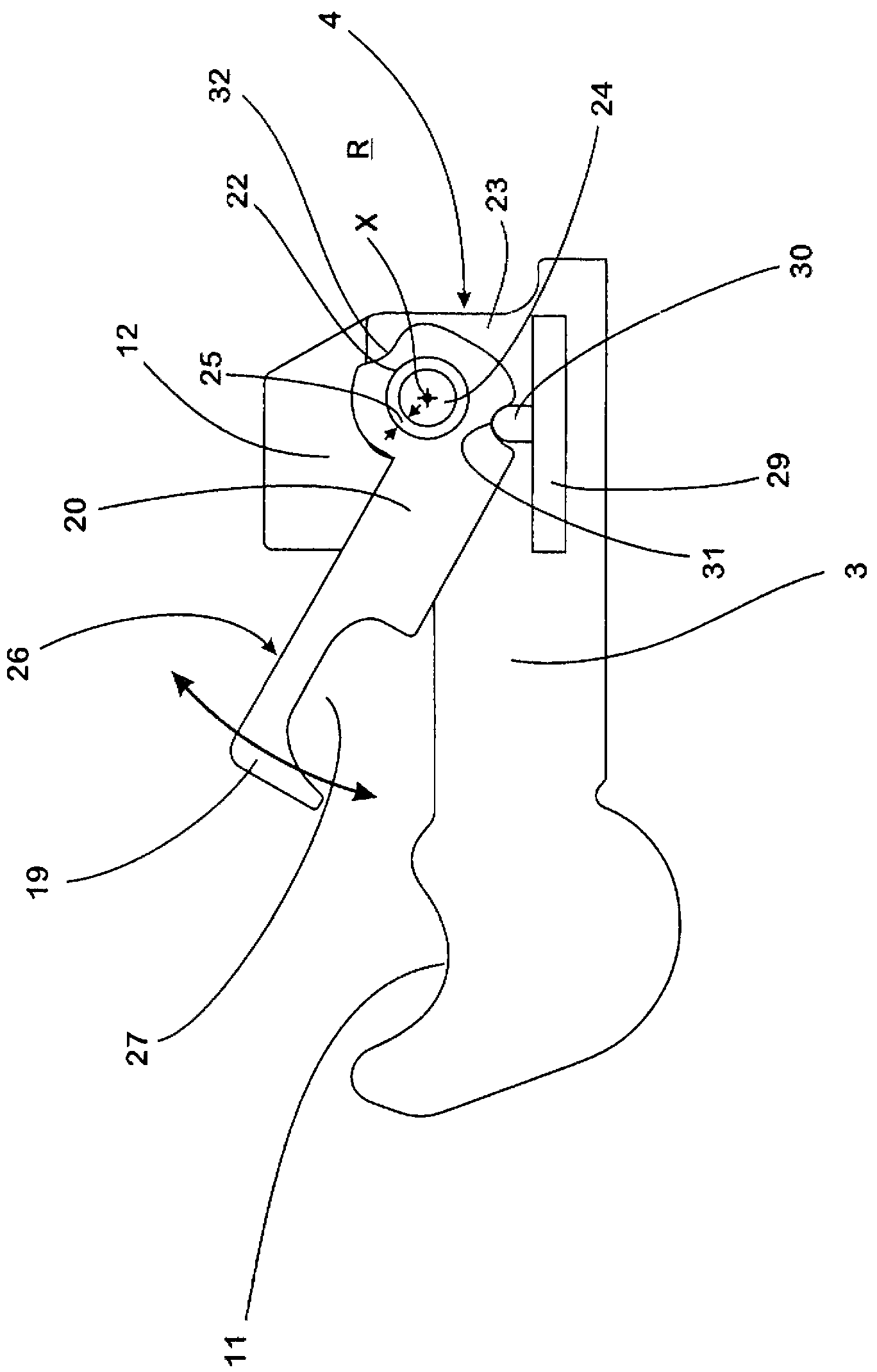

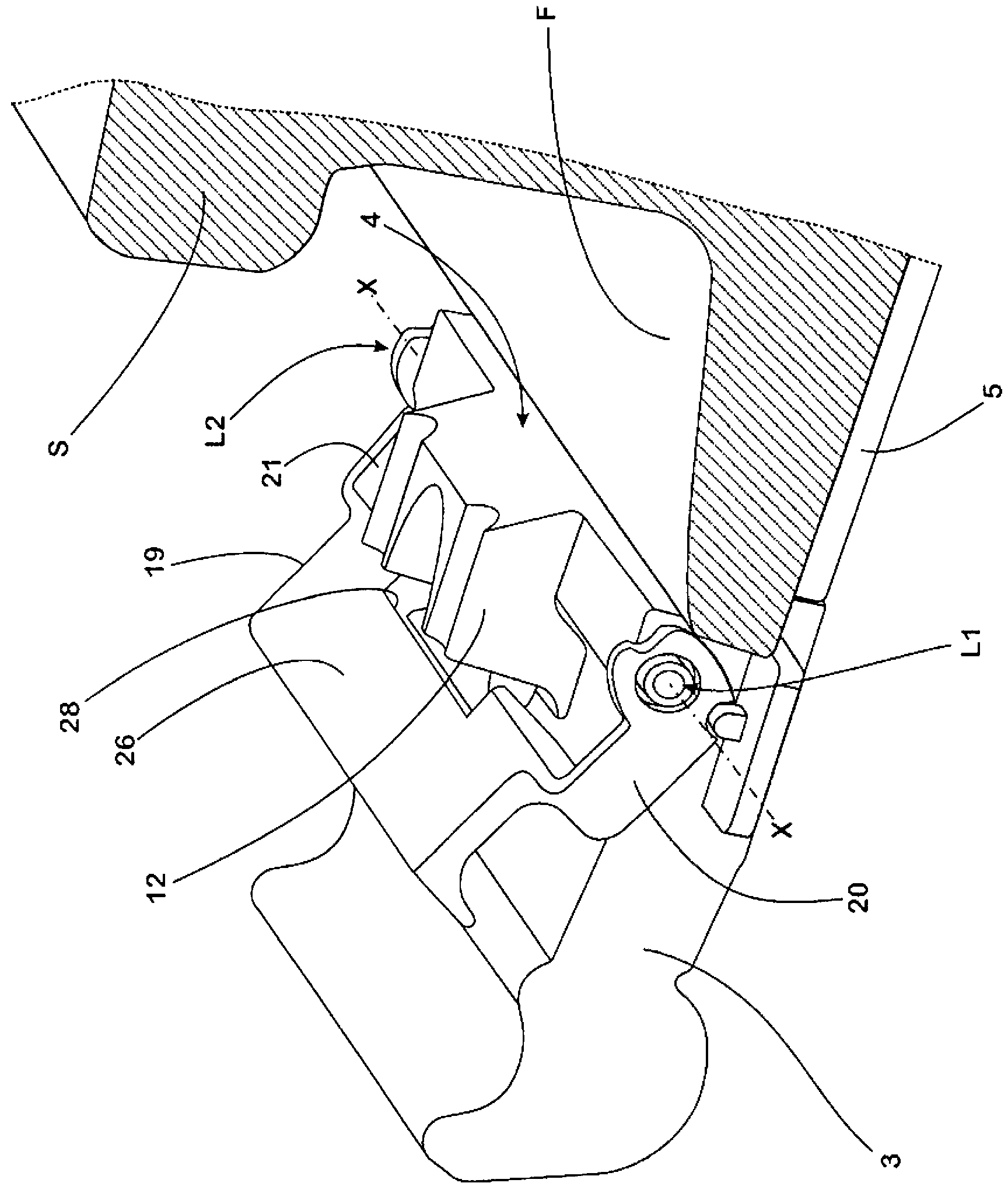

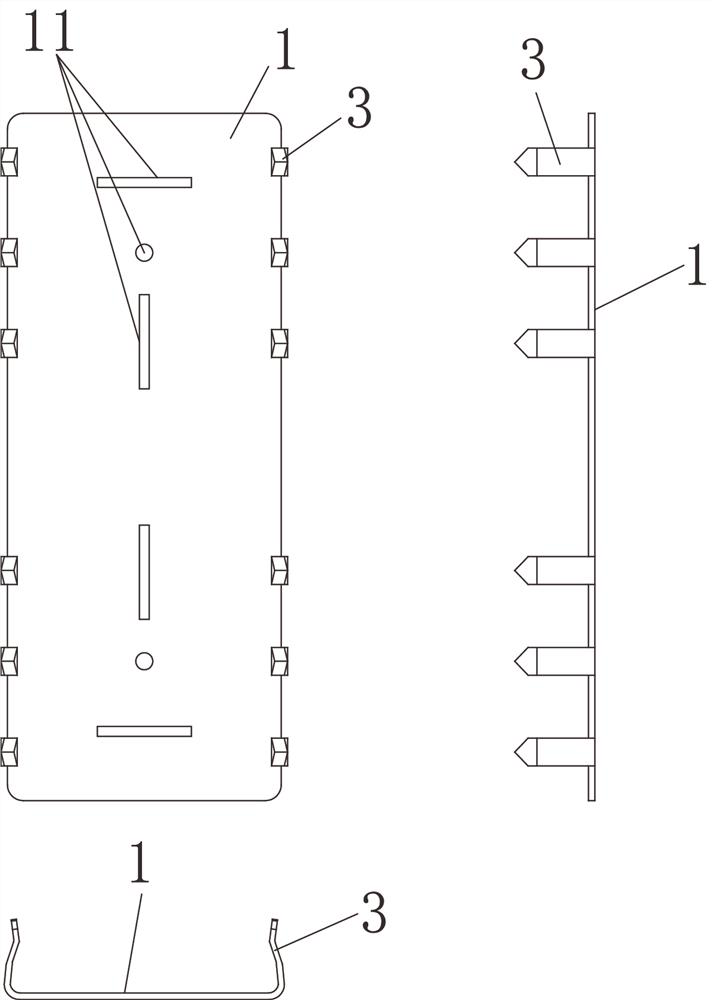

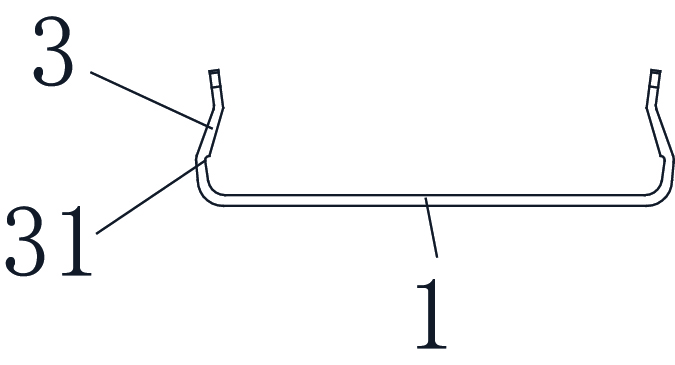

Guide plate for laterally guiding a rail, and system for securing a rail on a foundation

ActiveCN102939417AMeet the positioningReduce the overall heightRail fastenersSystems designEngineering

The invention relates to a guide plate for laterally guiding a rail (S) for rail vehicles which is to be secured on a foundation (2) by means of a spring element (13), the guide plate comprising an end face against which the rail (S) is supported in the assembled position and an insulating element (19) that can be placed on the foot (F) of the rail to be secured, said spring element (13) acting on the foot (F) of the rail (S) via said insulating element in the assembled position. According to a system that comprises such a guide plate (3) for securing a rail, the insulating element (19) is pivotably mounted on the guide plate (3).

Owner:VOSSLOH WERKE GMBH +1

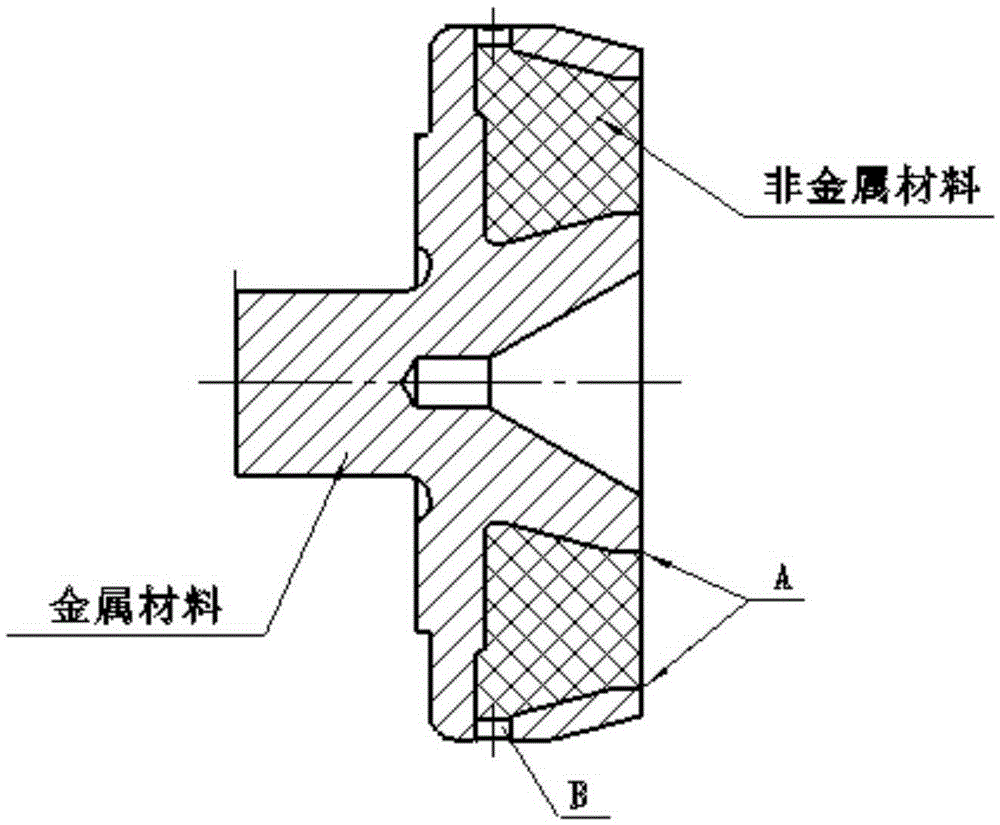

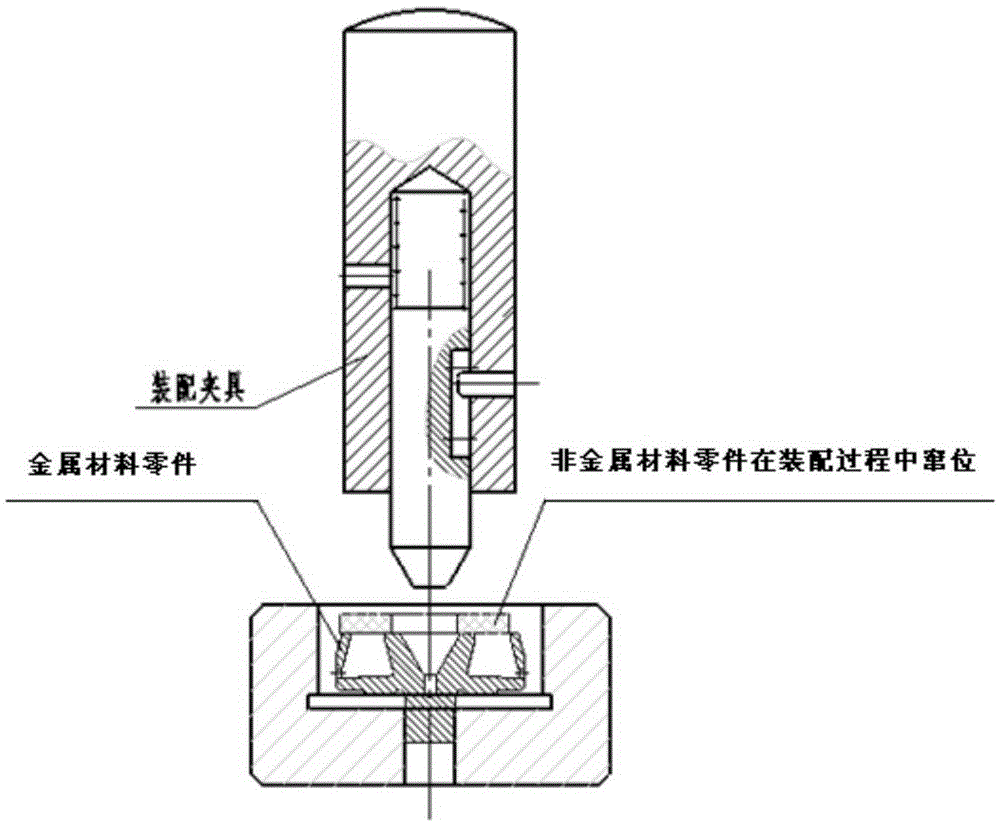

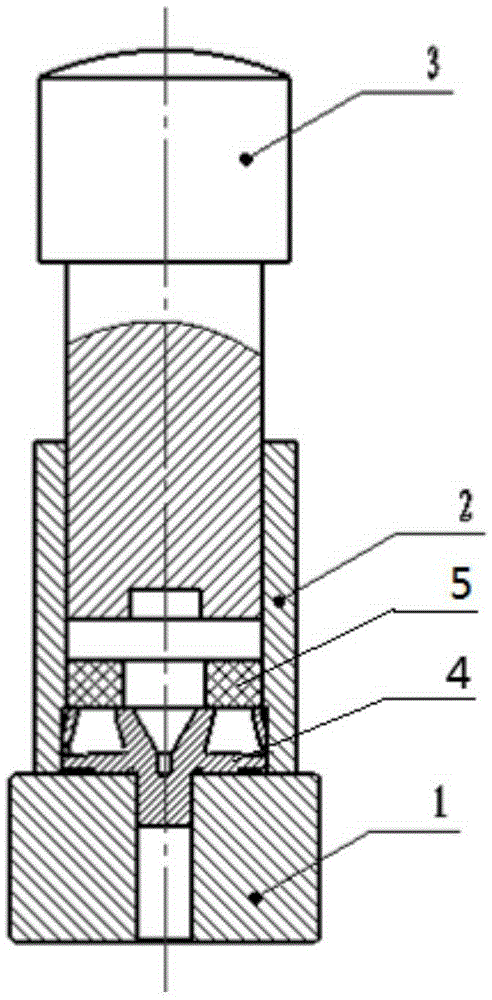

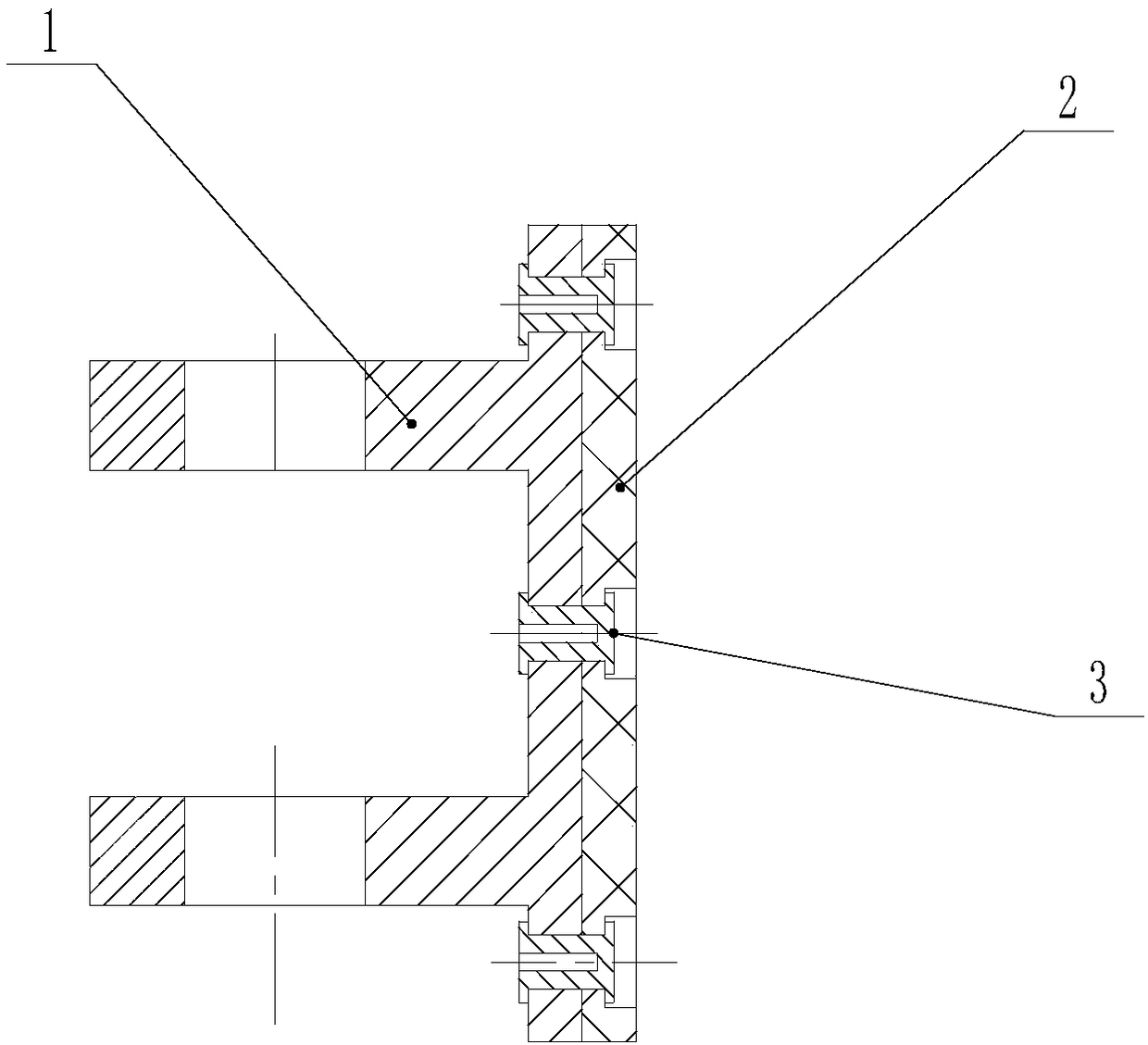

Sealing assembly assembling tool and method

InactiveCN105252481AEliminate Assembly DefectsMeet assembly requirementsMetal-working hand toolsPunchingEngineering

The invention provides a sealing assembly assembling tool and method. The tool comprises a base, a positioning sleeve arranged at the upper end of the base in a matched manner, and a punch arranged in the positioning sleeve in a sleeved manner. The base is provided with a positioning hole used for containing a small end outer cylinder face of a metal component. The large end of the positioning sleeve is used for being arranged on a large end outer cylinder face of the metal component in a sleeving manner. The small end inner diameter part and the outer diameter part of a non-metal component are matched in a sleeved manner. The punching end of the punch is a protruding annular punch. The outer diameter of the punch is the same as the outer diameter of the non-metal component. The positions of to-be-assembled components in a clamp are limited by adding the positioning sleeve, the component base and the punch of the clamp and the two to-be-assembled components are connected through the positioning sleeve in series and are kept with the center consistency. The assembling defects caused by the fact that in an original assembly clamp, positioning elements are lacked, and the assembling positions of the to-be-assembled components are not determined are eliminated. The assembling requirement can be met, the design and concept are ingenious, and the structure is compact; and the manufacturing cost is low, using is easy, and operation is convenient.

Owner:AECC AVIATION POWER CO LTD

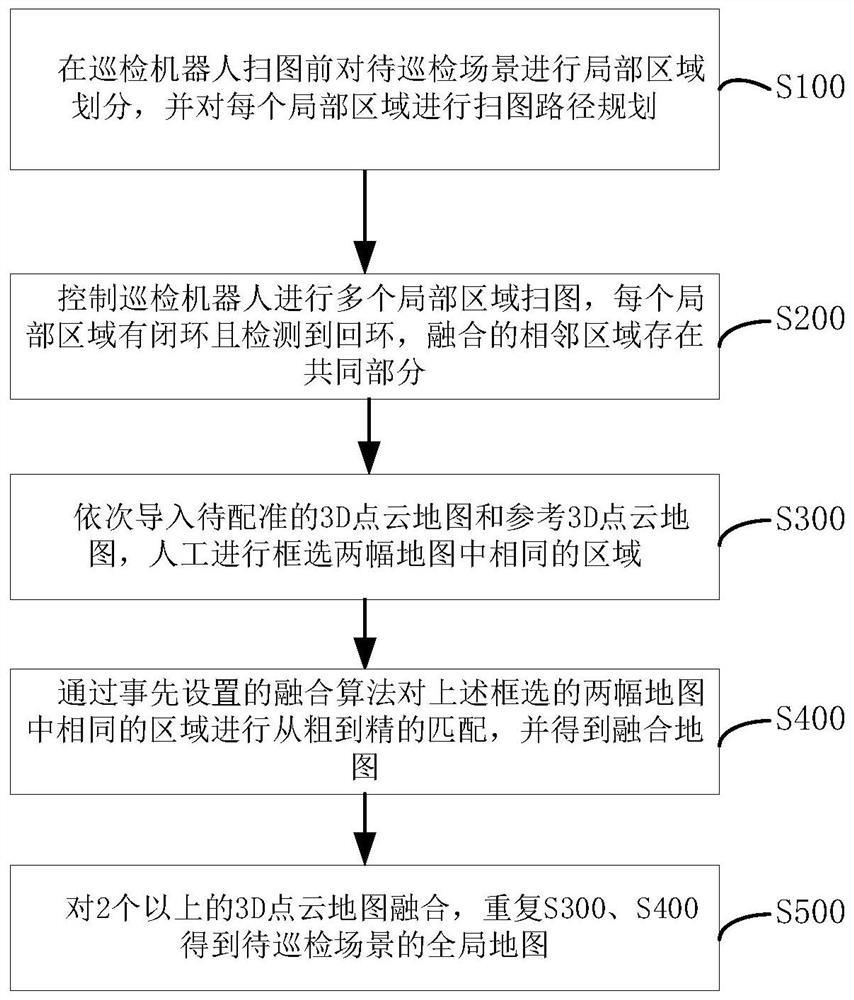

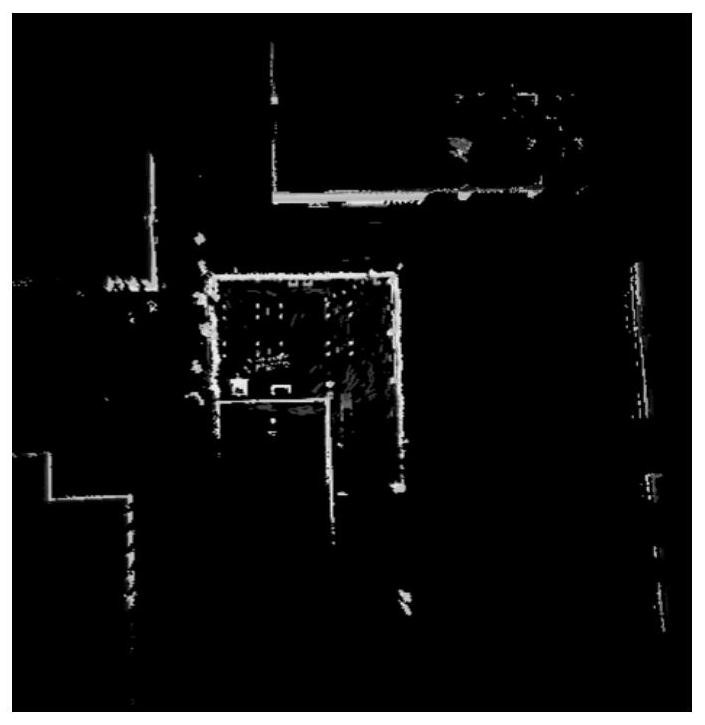

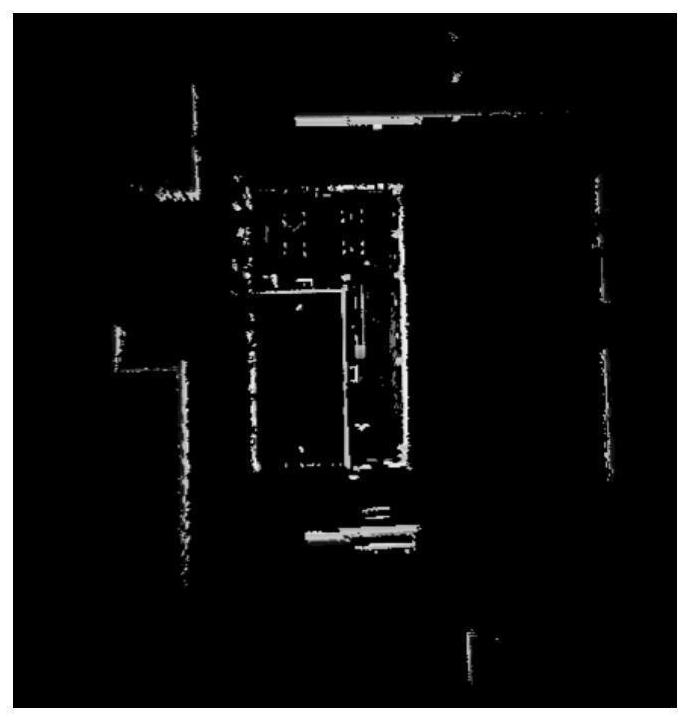

3D point cloud map fusion method and system for transformer substation inspection robot

ActiveCN112183285ASatisfy positioning accuracyExact fusion matrixImage enhancementImage analysisPoint cloudEngineering

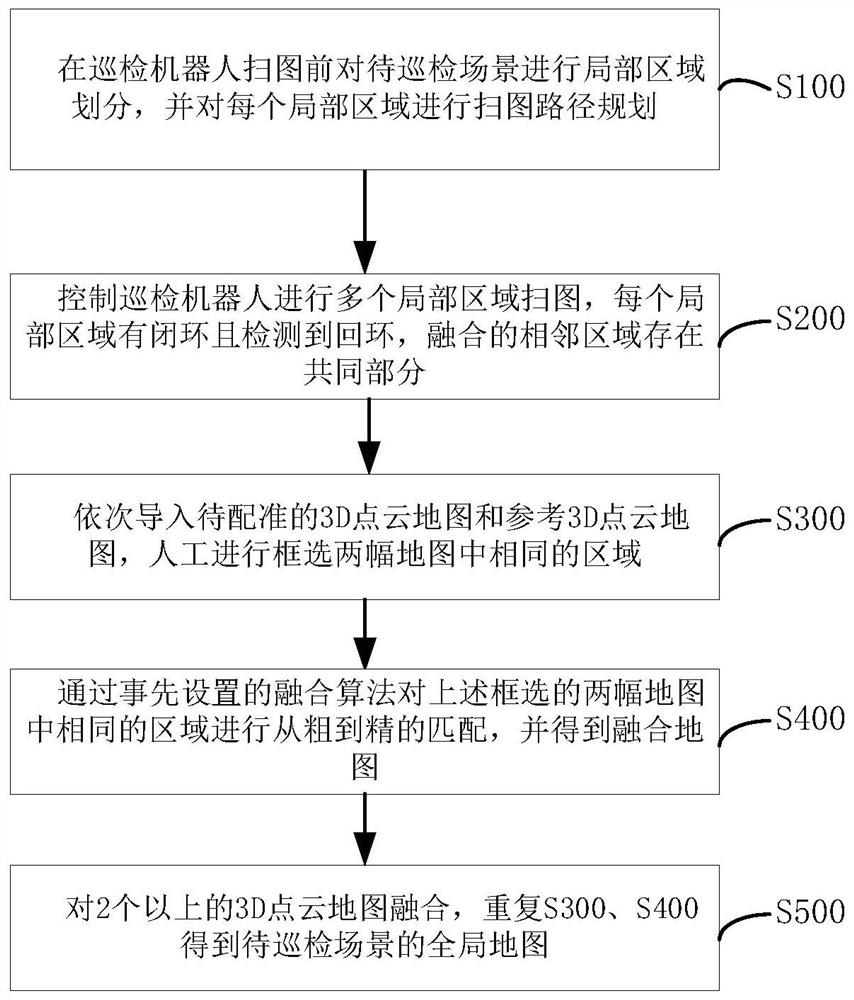

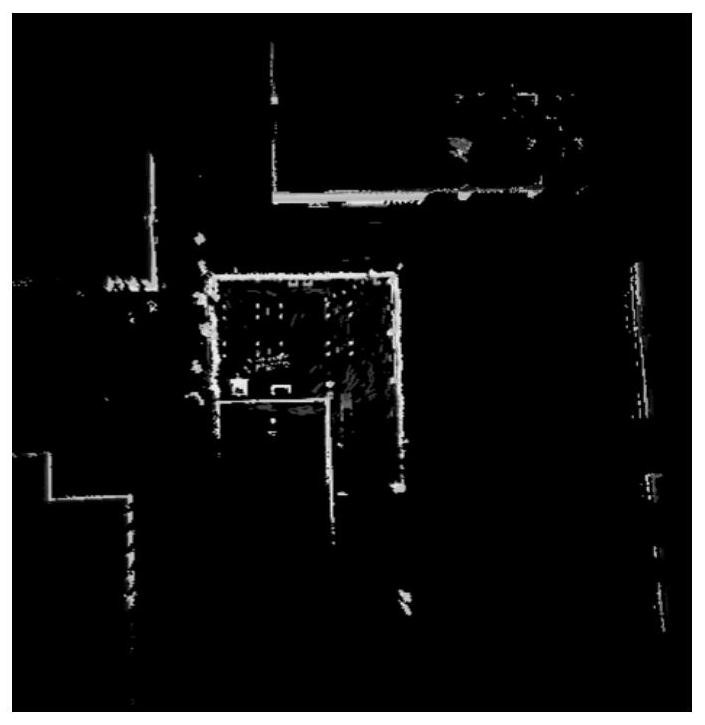

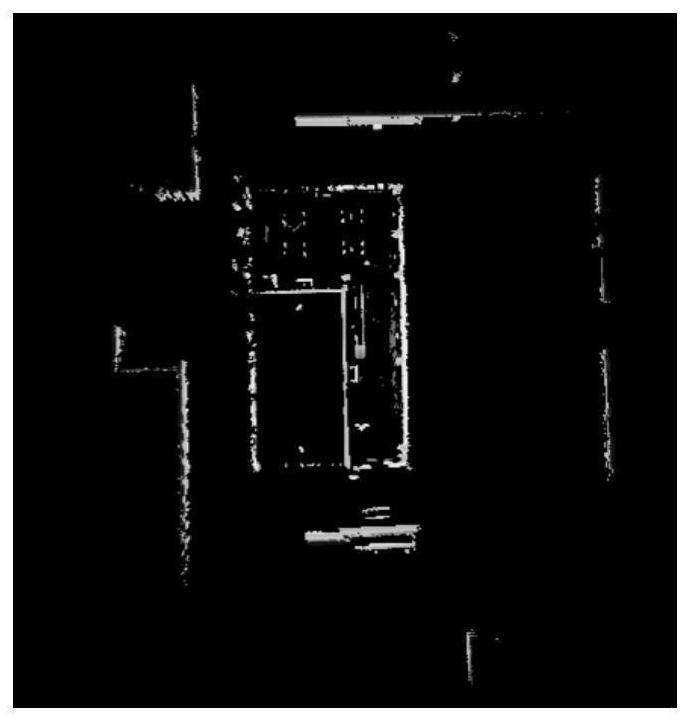

The invention discloses a 3D point cloud map fusion method and system for a transformer substation inspection robot, and the method comprises the following steps: carrying out the local region division of a to-be-inspected scene before the scanning of the inspection robot, and carrying out the scanning path planning of each local region; controlling the inspection robot to scan images of multiplelocal areas, each local area having a closed loop and detecting a loop, and the fused adjacent areas having a common part; sequentially importing a 3D point cloud map to be registered and a reference3D point cloud map, and manually selecting the same areas in the two maps; and carrying out coarse-to-fine matching on the same areas in the two selected maps through a preset fusion algorithm, and obtaining a fused map. According to the 3D point cloud map fusion method of the transformer substation inspection robot, the risk of global optimization failure can be avoided, multi-local 3D point cloud map high-precision fusion of a transformer substation scene of 100,000 levels or above is achieved, and the requirements for positioning and navigation of the inspection robot are met.

Owner:HEFEI CSG SMART ROBOT TECH CO LTD +2

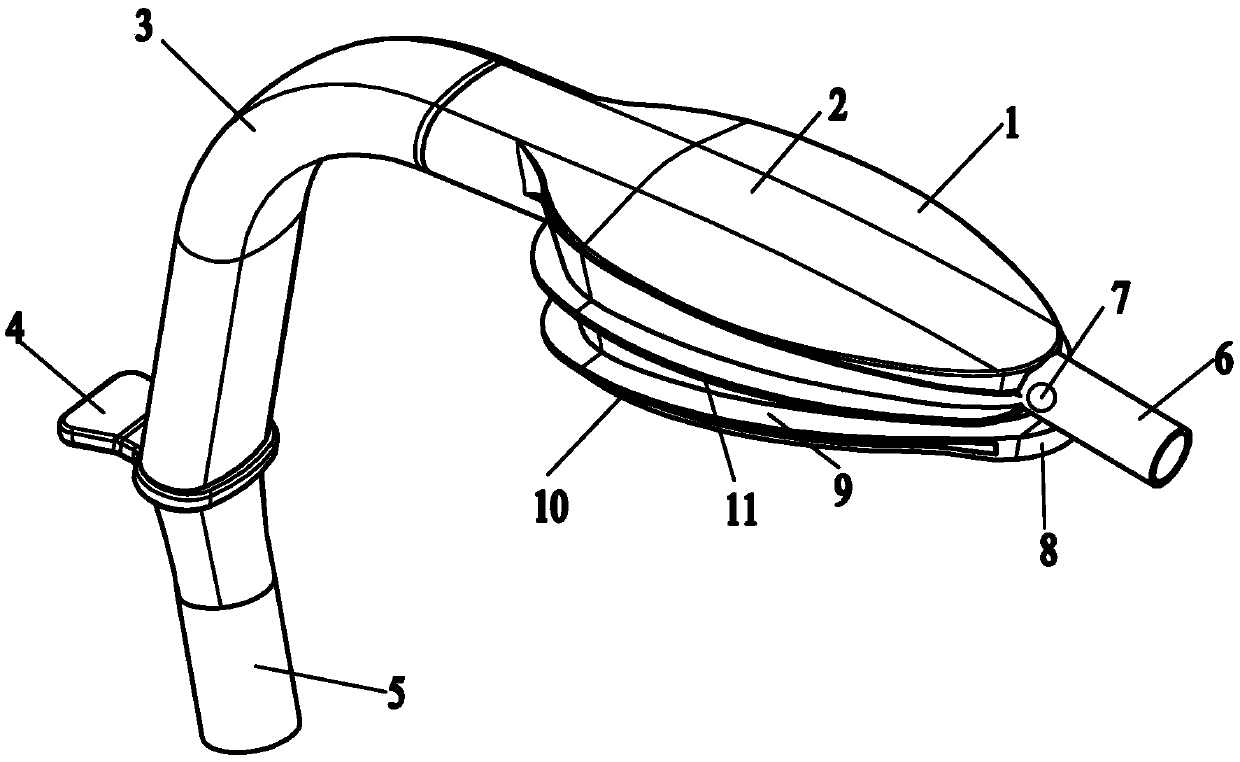

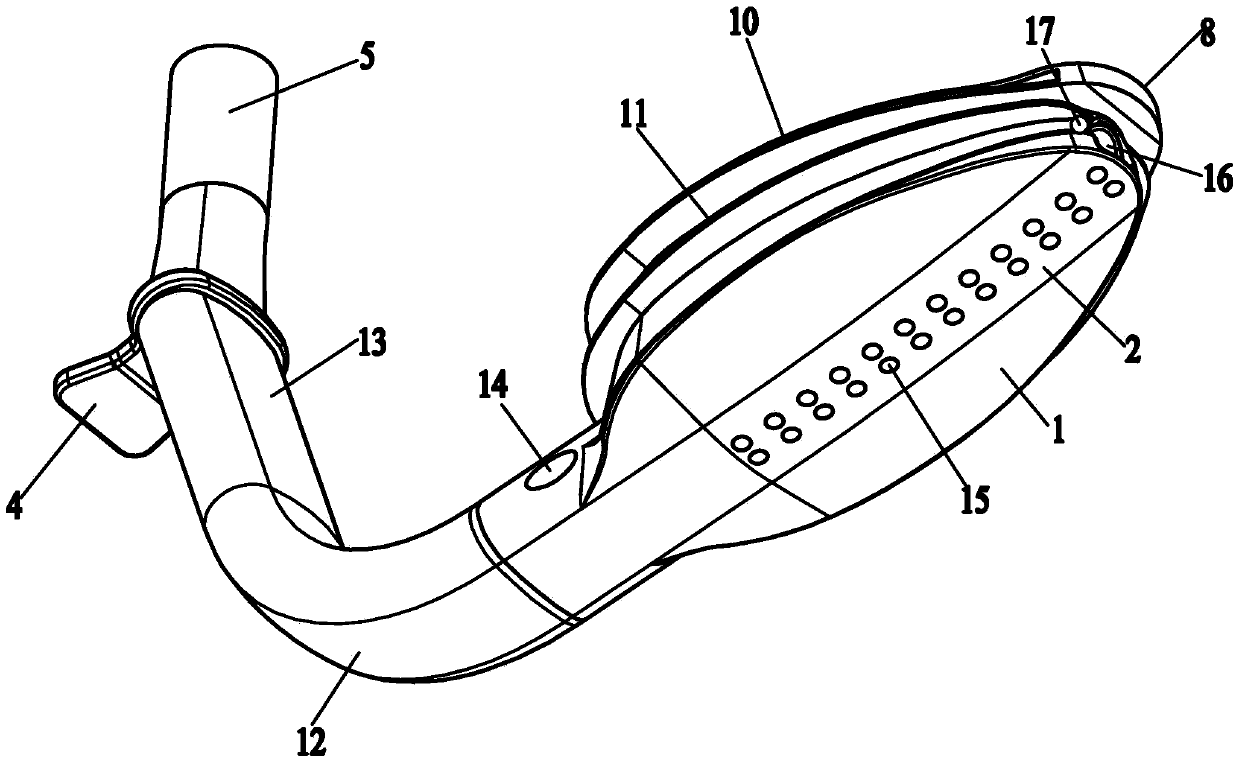

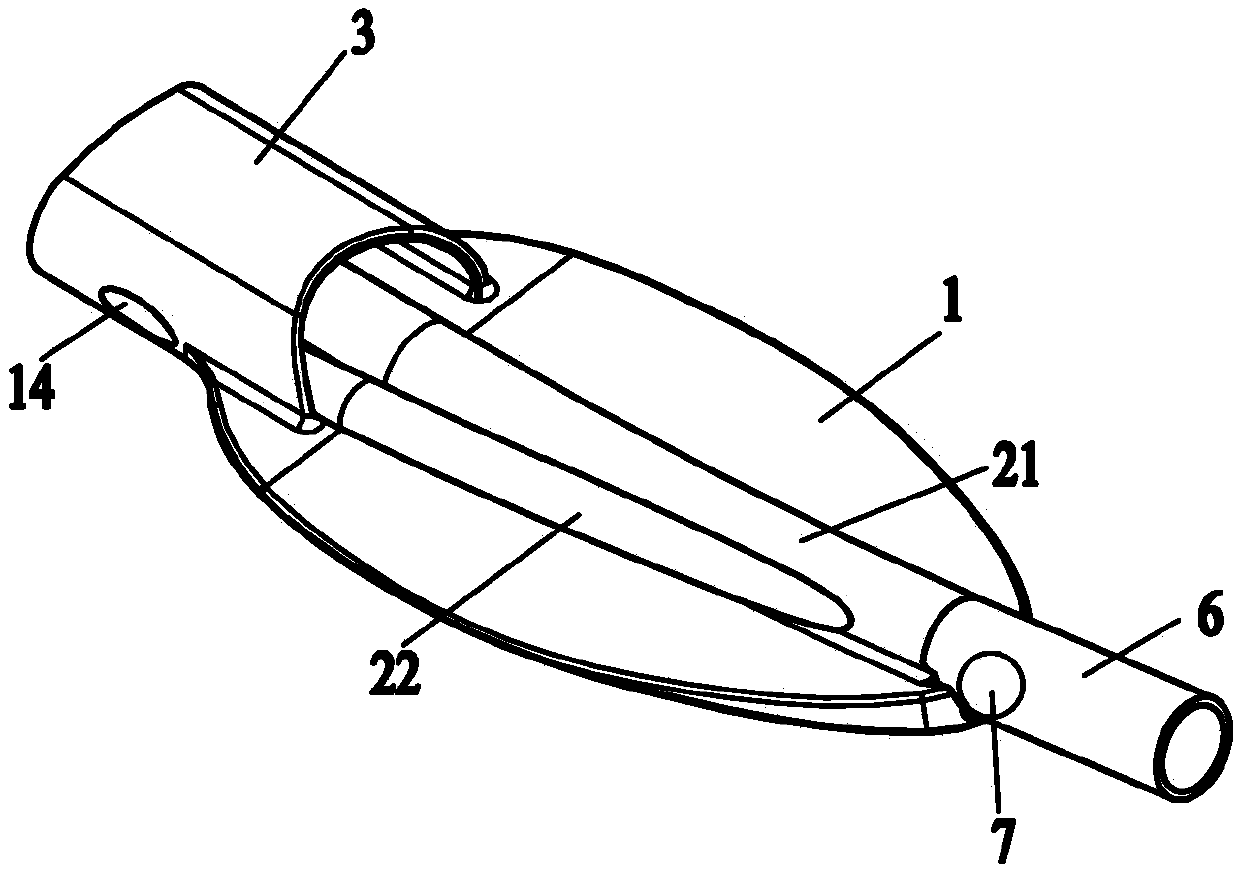

Positioning sputum suction laryngeal mask

PendingCN108671346AGuaranteed ventilationIncrease success rateRespiratorsMedical devicesLaryngeal MasksEngineering

The invention relates to a positioning sputum suction laryngeal mask. The positioning sputum suction laryngeal mask comprises a cover body and a cover body tube; the cover body comprises a cover bodybottom plate and a cover main body arranged on the cover body bottom plate, a central region in the cover main body is provided with a cover body cavity which can be communicated with the cover body tube, an appetite tube corresponding to the appetite is arranged on the back side of the cover body bottom plate, the appetite tube is isolated from the cover body cavity through the cover body bottomplate; the positioning sputum suction laryngeal mask also comprises a connection suction mechanism which can realize the negative pressure suction in the gas supply process, wherein the connection suction mechanism comprises a suction connection pipe which is arranged in the cover body bottom plate, and the end part, in the cover body bottom plate, of the suction connection pipe is communicated with the appetite pipe. The positioning sputum suction laryngeal mask can effectively meet the positioning of the laryngeal mask, reduce the complexity of the laryngeal mask and the using cost, and canensure the ventilation and sealing effect of the laryngeal mask when the laryngeal mask is in use, can realize the suction of the secretion in the ventilation process, avoid the epiglottis and the dead air passage, and improve the stability and the reliability of the laryngeal mask.

Owner:WUXI SHENGNUOYA TECH CO LTD

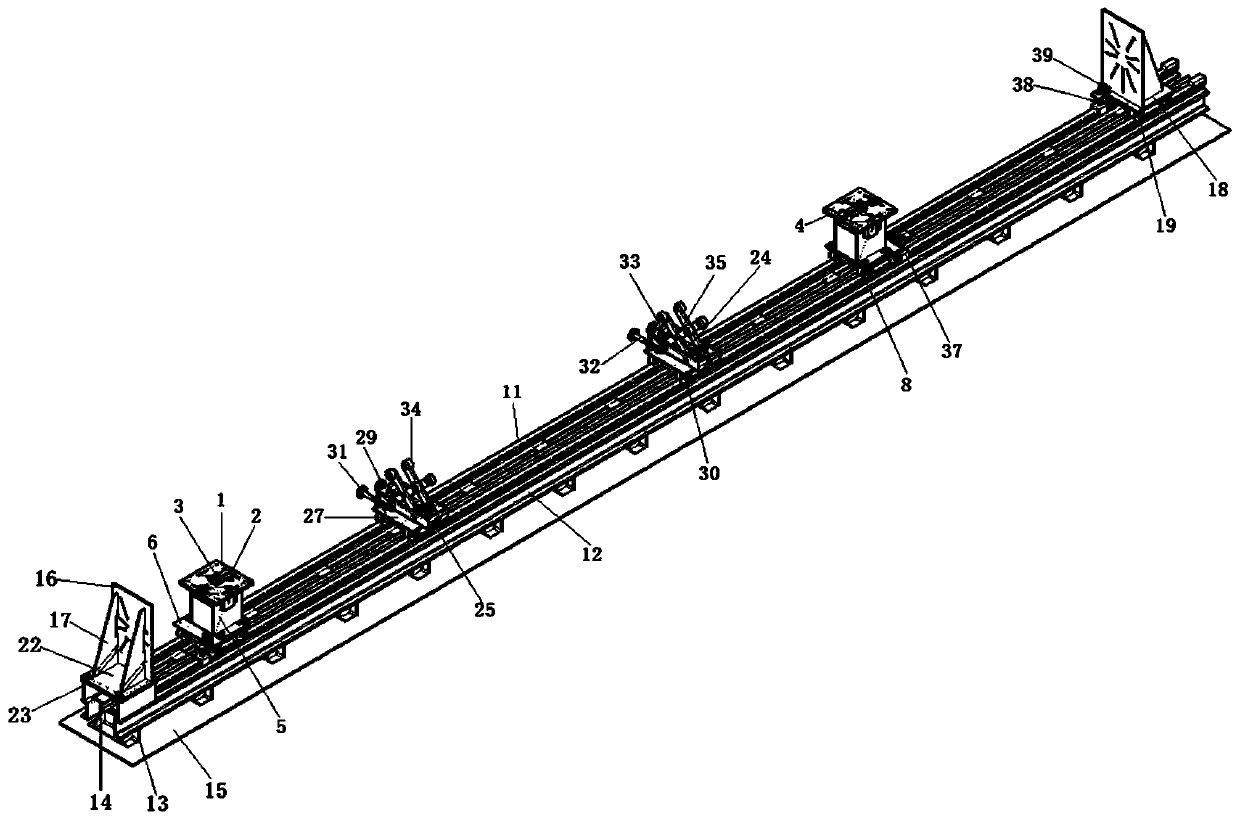

Multifunctional gearbox testing device

PendingCN111238809ACompact structureReasonable structureMachine part testingControl engineeringStructural engineering

The invention relates to a multifunctional gearbox testing device including a test bench; two ends of the test bench are provided with an auxiliary enclasping mechanism and a wallboard positioning mechanism which are used for fixing different types of gearboxes and can realize oil-way and circuit connection with the gearboxes; the device also includes the load mechanism II and the load mechanism Ithat can axially move to respectively simulate two front wheels of an automobile, and the main driving mechanism that simulates an automobile engine, wherein the output ends of the load mechanism II,the load mechanism I and the main driving mechanism can respectively extend out of the auxiliary enclasping mechanism and the wallboard positioning mechanism to extend above the test bench; after thegearbox is adjusted and positioned through the test bench, the gearbox is fixed by selecting the auxiliary enclasping mechanism or the wallboard positioning mechanism according to different models and is mechanically connected with corresponding output. The vibration data acquisition mechanism is used for completing test data acquisition, so that complete test operation of different types of gearboxes on the same platform is realized, the field is saved, and the efficiency and the equipment utilization rate are improved.

Owner:WUXI DAJINYI TECH CO LTD

Tool for assembling pole tower branch pipes

ActiveCN111215816AImprove production and processing efficiencyImprove pairing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesFlangeIndustrial engineering

The invention discloses a tool for assembling pole tower branch pipes. The tool for assembling the pole tower branch pipes comprises an inserting plate positioning device, a flange positioning device,a bracket and a base. The tool for assembling the pole tower branch pipes can assemble the branch pipes with various types of inserting plates such as a U-shaped inserting plate, a C-shaped insertingplate and a cross-shaped inserting plate at the same time and can quickly assemble the branch pipes with the inserting plate or a flange, so that the production and processing efficiency is effectively improved; an arranged inserting plate positioning panel can rotate by 360 degrees so as to achieve positioning of inserting plates with different hole numbers and different hole apertures; multipleinserting plate positioning devices can be arranged on a track, therefore, multiple groups of people can conduct assembly at the same time, and the assembly efficiency is higher; the tool for assembling the pole tower branch pipes is wide in application range and basically meets assembly of existing branch pipes of different specifications and sizes; and the tool for assembling the pole tower branch pipes is simple in structure, convenient to operate, rapid in assembly, and high in assembly efficiency and assembly precision.

Owner:GUANGZHOU ZENGLI STEEL STRUCTURE

Deformable radiator assembling structure

InactiveCN105163560AMeet the positioningCooling/ventilation/heating modificationsArchitectural engineeringHeat spreader

Owner:HEFEI BITLAND INFORMATION TECH

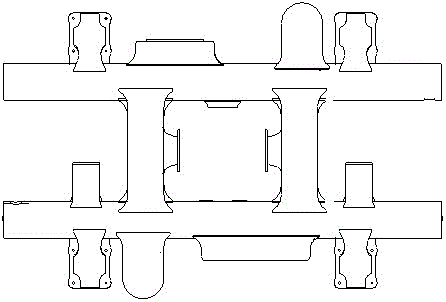

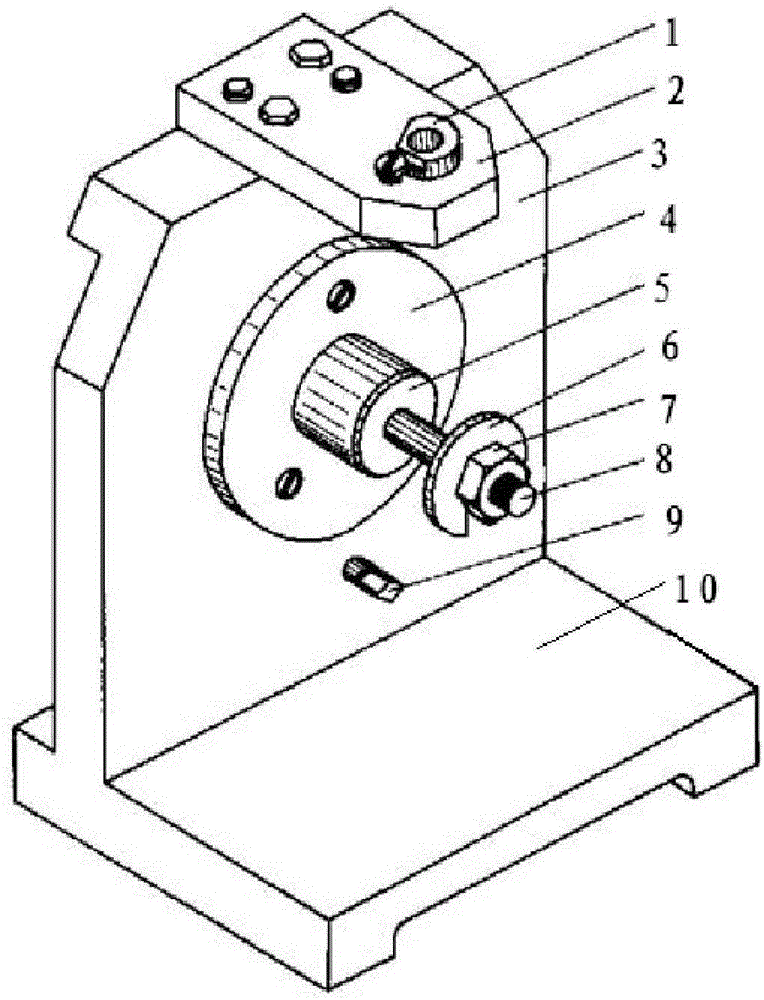

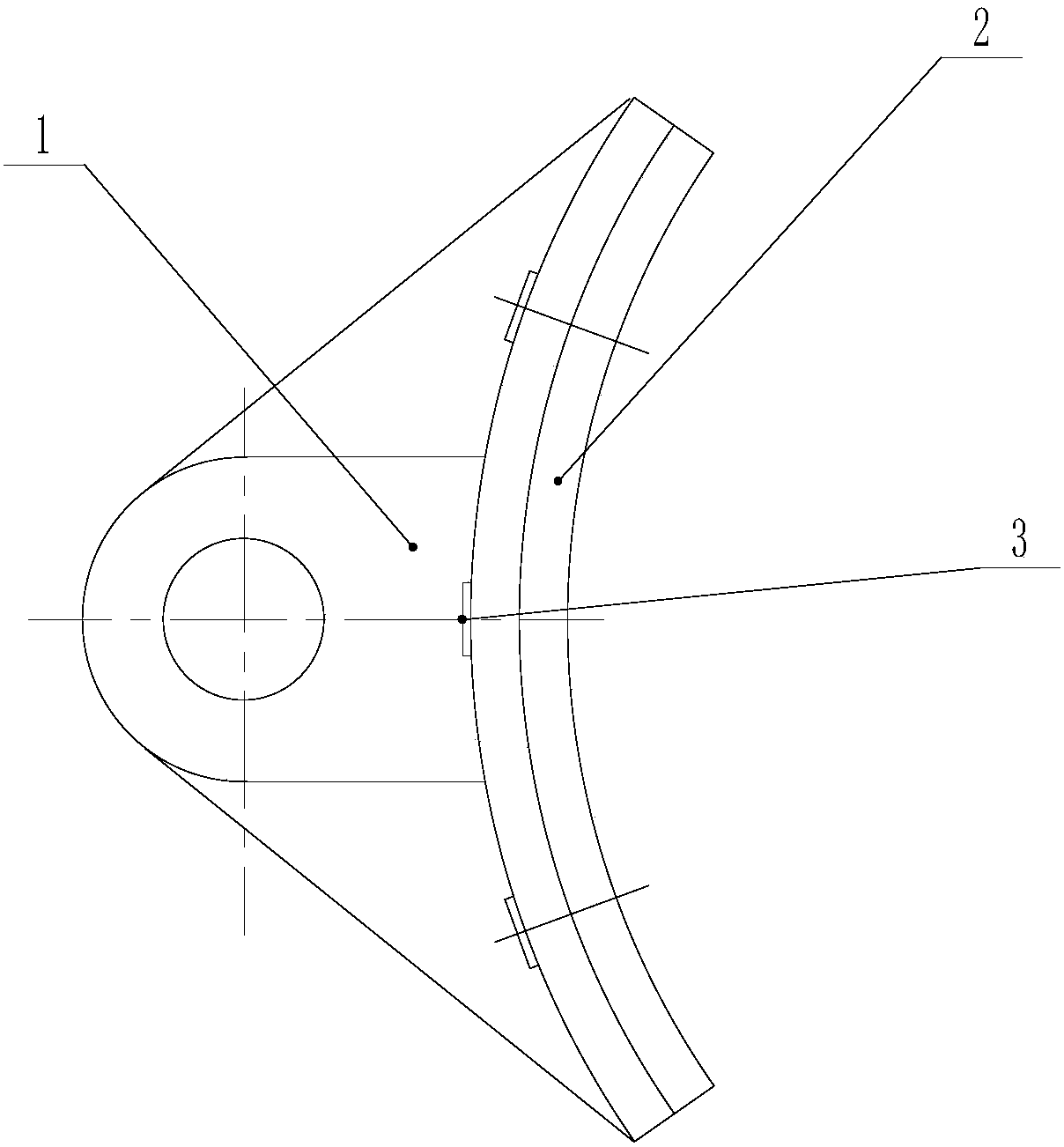

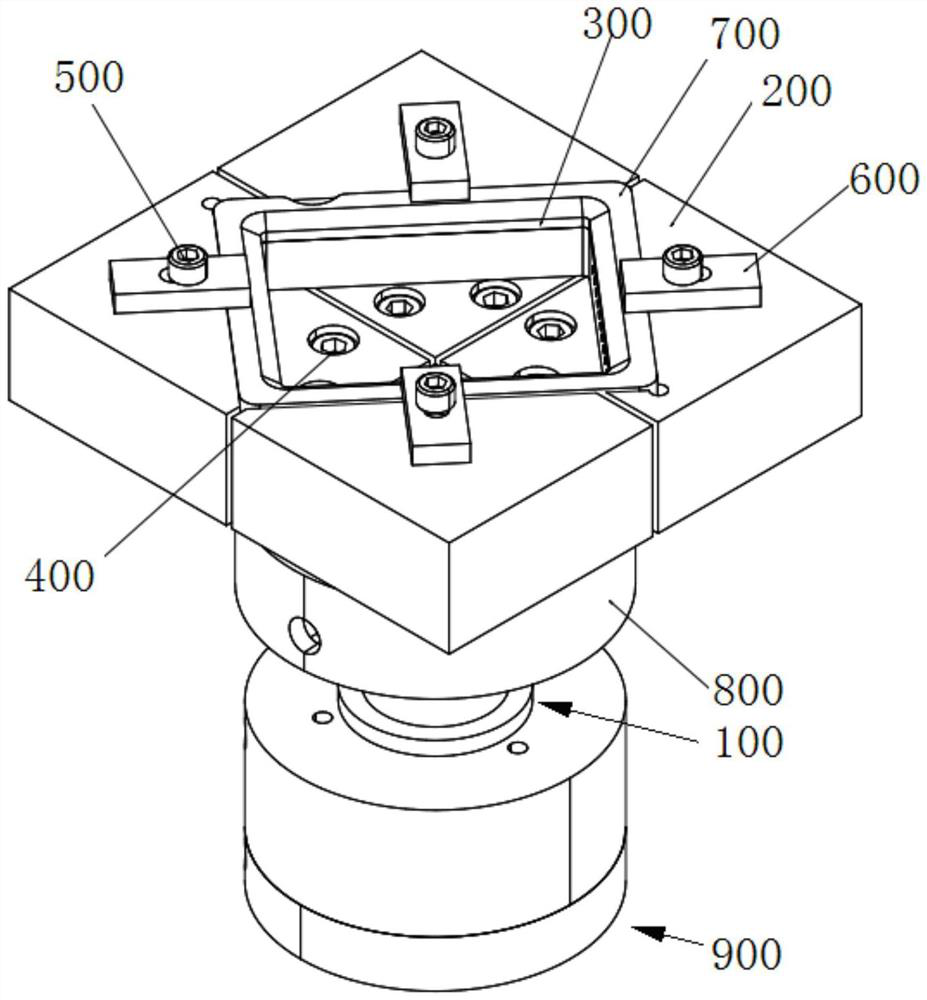

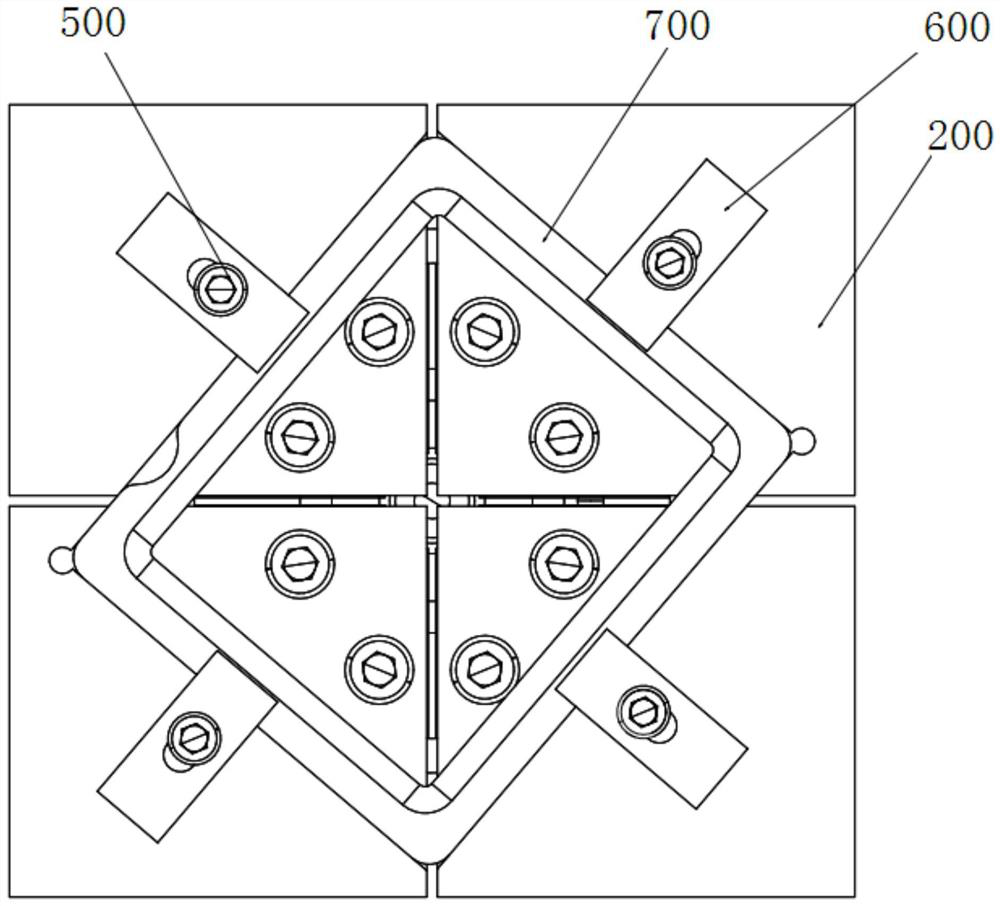

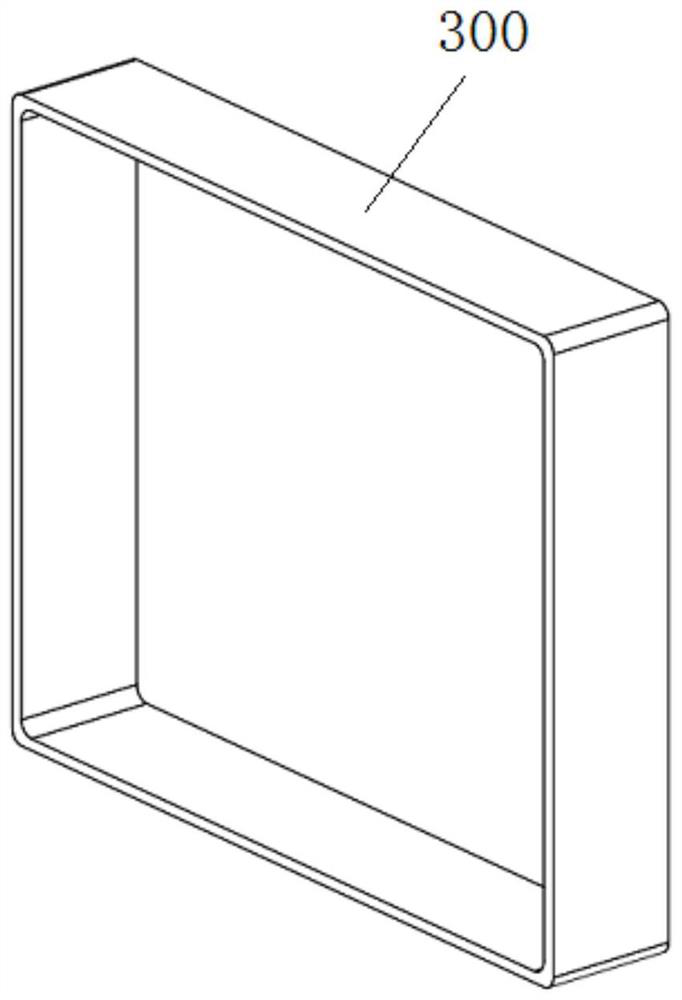

Universal shot blasting fixture used for shot blasting of root of compressor blade

ActiveCN105437087AMeet clampingMeet clamping requirementsAbrasive machine appurtenancesSlide plateCompressor blade

The invention provides a universal shot blasting fixture used for shot blasting of the root of a compressor blade. The universal shot blasting fixture aims at solving the problem of high jig manufacture and maintenance cost due to poor universality of an existing shot blasting fixture of the compressor blade and comprises a base, a positioning and adjusting component and an adjustable blade profile enclasping component, wherein height supports with equal heights are respectively vertically arranged at four corner ends of the base, the positioning and adjusting component is supported on the height supports, the adjustable blade profile enclasping component is arranged on the positioning and adjusting component; the positioning and adjusting component comprises positioning guide blocks and sliding plates, the two positioning guide blocks are arranged on the height supports in parallel along the longitudinal direction and are connected through the two horizontally parallel sliding plates, and the sliding plates can move along the positioning guide blocks to achieve adjustment; and a blade inner arc pressing device and a blade back arc pressing device of the adjustable blade profile enclasping component are respectively oppositely arranged at the horizontal inner sides of the two positioning guide blocks with adjustable angles.

Owner:WUXI TURBINE BLADE

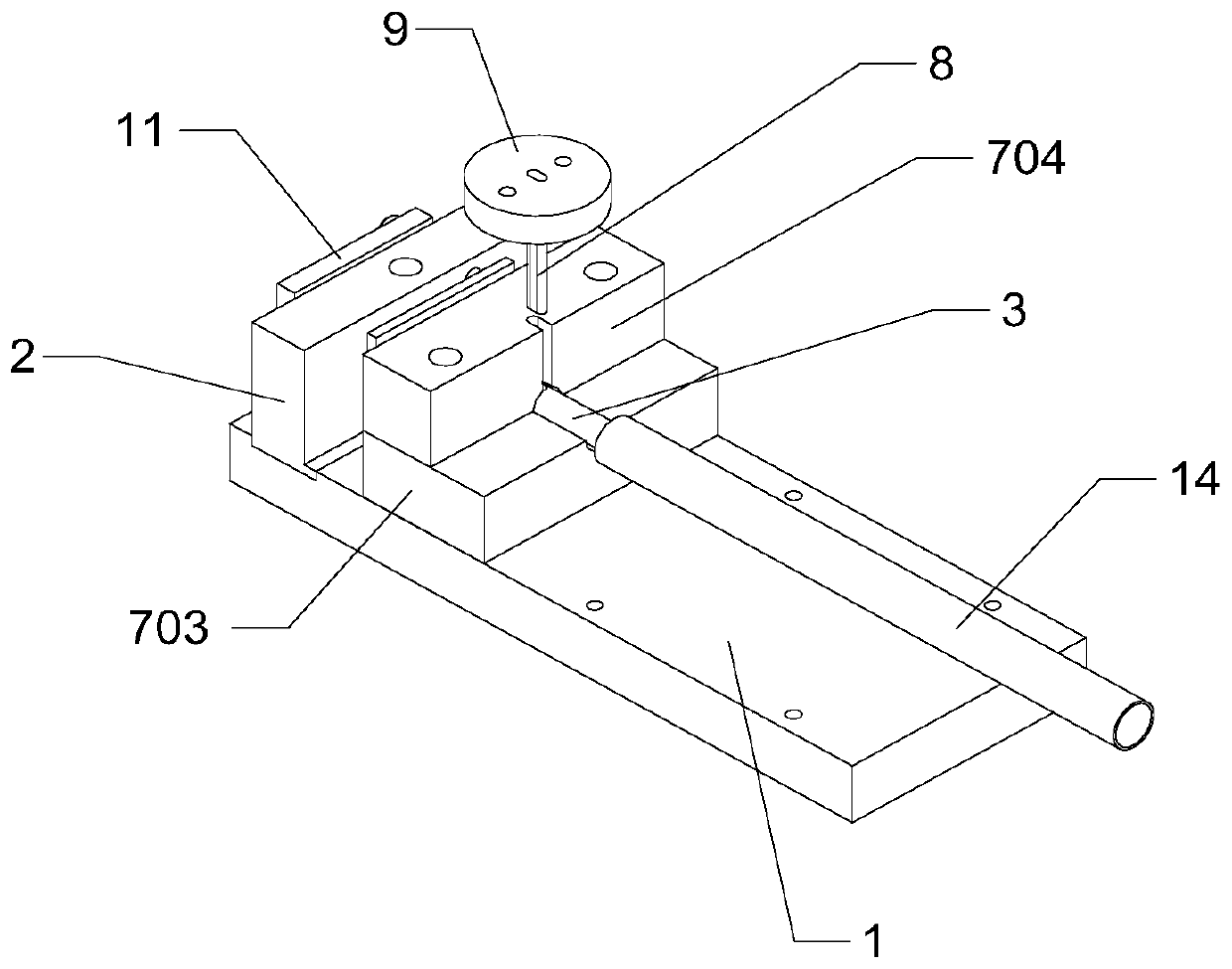

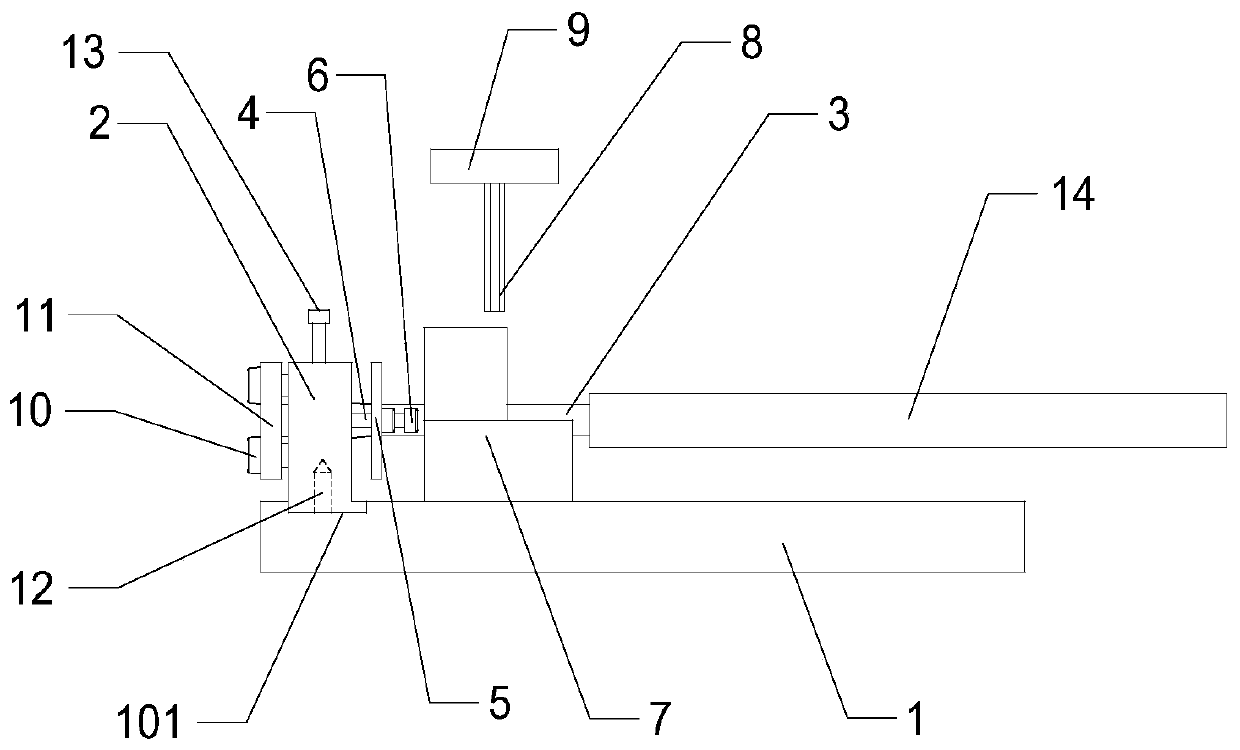

Pipe opening device and hole opening method

PendingCN110681764AEasy to replacePrecise positioningMetal-working feeding devicesPositioning devicesPipe fittingStructural engineering

The invention discloses a pipe opening device and a hole opening method. The pipe opening device comprises a bottom plate, a positioning boss and a punching rod, wherein the bottom plate, the positioning boss and the punching rod are mounted on a machine tool workbench, a groove is formed in the bottom plate, the bottom of the positioning boss is matched with the groove to be installed on the bottom plate, and a first through hole is formed in the middle of the positioning boss; a positioning adjusting plate is fixed to the front side of the positioning boss through a bolt A, a second throughhole is formed in the positioning adjusting plate, and an adjusting bolt is also in threaded connection with the positioning adjusting plate; and the pipe opening device comprises a positioning pad, the positioning pad is arranged on the front side of the positioning adjusting plate, a third through hole is formed in the positioning pad, the punching rod penetrates through the first through hole,the second through hole and the third through hole, a punching groove is further formed in the positioning pad, and the punching groove is in communication with the third through hole. The pipe opening device has the advantages that the pipe is accurate in positioning and high in stability, and the positioning adjusting plate can be adjusted to be suitable for pipes with different lengths.

Owner:四川龙立可不锈钢管业有限公司

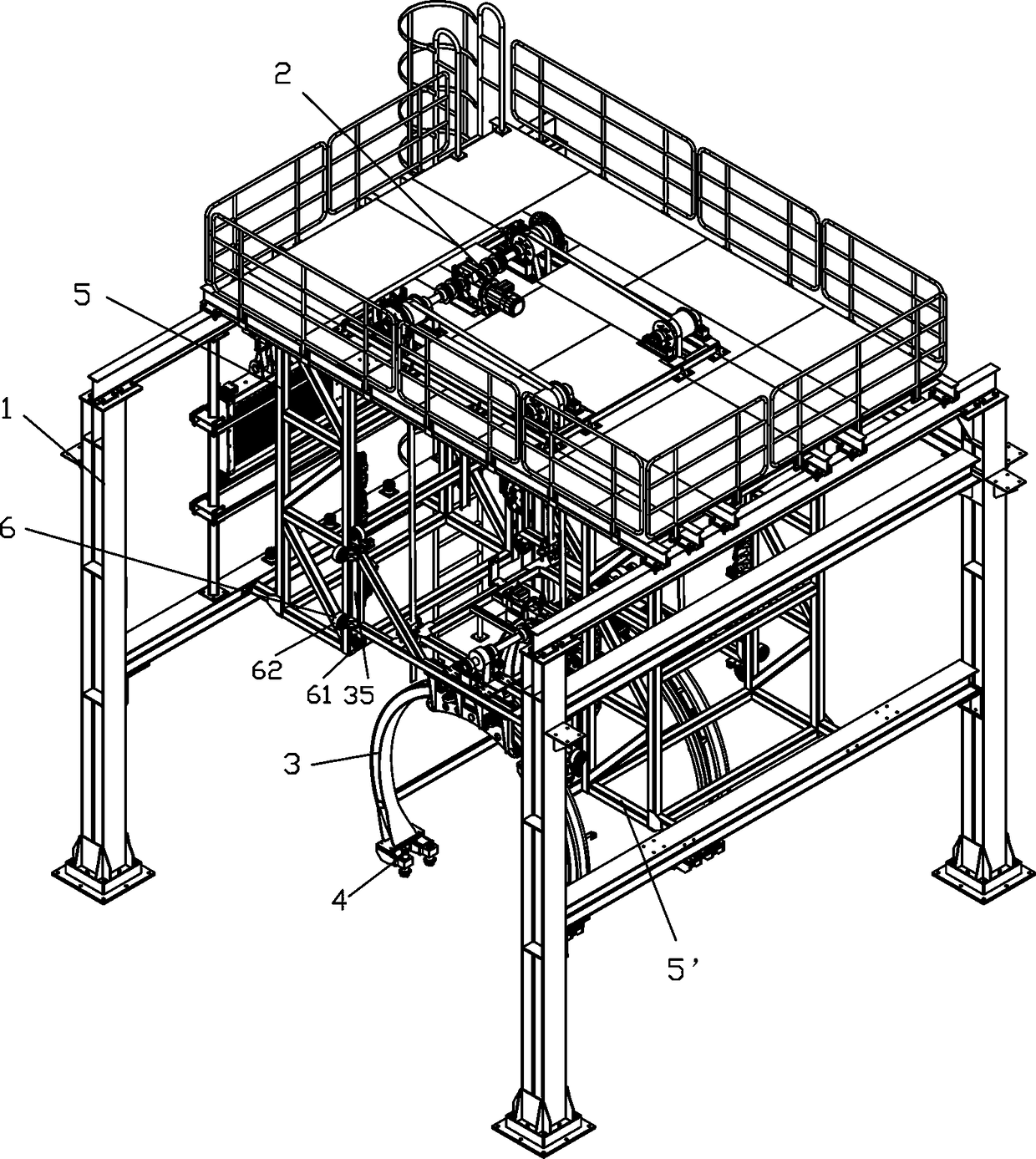

Vehicle body flexible assembly operation island

ActiveCN109014685AMeet the positioningMeet fixedWelding/cutting auxillary devicesAuxillary welding devicesSteering wheelButt joint

The invention discloses a vehicle body flexible assembly operation island. The vehicle body flexible assembly operation island comprises a fixed frame, a lifting drive mechanism, two drive axles, twobelt wheels, two lifting guide wheels, two steering wheel groups, a counterweight block and a vehicle body flexible rotary embracing tool, wherein the fixed frame is of a truss portal structure; the lifting drive mechanism comprises a drive motor and a speed reducer, and is arranged at one side of the top surface of the fixed frame; ends of the two drive axles are separately linked to two output ends of the speed reducer, and the other ends of the two drive axles are mounted on the top surface of the fixed frame through bearing bases; the two belt wheels are separately arranged at other ends of the two drive axles; the two lifting guide wheels are separately arranged at the other side of the top surface of the fixed frame, and are opposite and parallel to the two belt wheels; each steeringwheel group comprises two steering wheels, wherein one steering wheel is arranged at one side of the fixed frame, and the other steering wheel is arranged on the fixed frame under the belt wheels; the counterweight block is arranged at one side of the fixed frame in a sliding mode, and two lifting belts are arranged at the two sides of the counterweight block, one lifting belt downwards extends through the belt wheels, and the other lifting belt downwards extends through the lifting guide wheels; and the vehicle body flexible rotary embracing tool is connected to the lifting belts. The vehicle body flexible assembly operation island meets one-station type operation of assembly integration among different position areas of a vehicle as well as flexible assembly butt-joint for bottom deviation of different vehicle models.

Owner:上海永乾机电有限公司

Adjustable positioning mechanism for packaging box

InactiveCN109018942APrecise positioningMeet the positioningConveyorsControl devices for conveyorsEngineeringFront edge

The invention relates to an adjustable positioning mechanism for a package box, and the adjustable positioning mechanism for the package box comprises a transfer table, and a transfer belt is arrangedaround the transfer table, and L-shaped rubber positioning plates are arranged equidistantly from left to right on the transfer belt, and a sensor is embedded in the front edge of each L-shaped rubber positioning plate. By providing the L-shaped rubber positioning plates, the surface of a packaging box is accurately positioned when spraying or pasting characters, pictures, etc, and practicabilityis high. By providing a positioning cover plate, the packaging box can be used for spraying or pasting the label, and the position is exposed, so that the position of the logo spraying or pasting isneat and uniform, and the appearance is beautiful. By providing a rubber cushion layer, the friction force can be increased, and the fixing is firm. By providing the positioning plate, the positioningof a cosmetic packaging box of different sizes can be effectively satisfied, and the adaptability is strong. By providing the slide rail and the slider, the adjustment is convenient. The adjustable positioning mechanism for the package box has high work efficiency and high degree of automation, and is suitable for wide promotion.

Owner:苏州凤羽包装材料有限公司

Pin correction equipment for transformer production and manufacturing

InactiveCN112216497ASolve the fragileSolve efficiency problemsInductances/transformers/magnets manufactureTransformerGas passing

The invention relates to the technical field of electrical apparatus element manufacturing equipment, and discloses pin correction equipment for transformer production and manufacturing. The equipmentcomprises a supporting seat, positioning rods are arranged on the left side and the right side of the upper part of the supporting seat, and an arc-shaped groove and a rectangular groove are formed in the lower side of a hinge device; push rods are connected in the arc-shaped grooves and the rectangular grooves in the hinge devices, steel balls are connected in the arc-shaped grooves, the pistondevices and the hinge devices are connected with air pipes, and rectangular plates are connected to the inner side ends of the lower portions of the hinge devices. Rollers on the lower side of the driving device drive a belt to rotate, the belt drives a lead screw to rotate through a rotating disc, a threaded cylinder drives a hinge device to move upwards, and the lower portion of the hinge deviceextrudes pins for correction; gas pushes the steel ball to move through the sealing block, the steel ball pushes the push rod to move, the push rod assists in correcting the bent pin, and the structure solves the problems that an existing pin correcting device for transformer production and manufacturing is prone to damage, low in working efficiency and poor in correcting accuracy in the pin correcting process.

Owner:广州零汇科技有限公司

Brake block and friction plate drilling tool

InactiveCN108543987AHigh precisionImprove efficiencyPositioning apparatusMetal-working holdersDrive shaftEngineering

The invention discloses a brake block and friction plate drilling tool. A body comprises a brake block and a friction plate. The brake block and friction plate drilling tool is characterized by comprising a base frame, a multi-shaft device, a clamp, a locating block and combined drill bits. Parts of the body are fixed together through the clamp, and the body is placed on the base frame and can slide on the base frame. Locating holes are formed in the base frame, and the body can be fixed in the locating holes through the locating block. The base frame is fixed to a base of a drilling machine,the multi-shaft device is installed on a transmission shaft of the drilling machine, and a plurality of combined drill bits are installed on the multi-shaft device. After the body moves to one position on the base frame and is located, a spindle of the drilling machine drives the multi-shaft device to move downwards, and drives the combined drill bits of the multi-shaft device to rotate at the same time, the drilling operation of a plurality of T-shaped holes of the body is accomplished, and the operation of all the T-shaped holes can be accomplished when the body is matched with the multi-shaft device to move for a few times. The brake block and friction plate drilling tool has the beneficial effects that a plurality of T-shaped holes are processed at the same time, and formed at one time, the accuracy is high, the efficiency is improved, and the energy consumption is reduced.

Owner:张栩沧

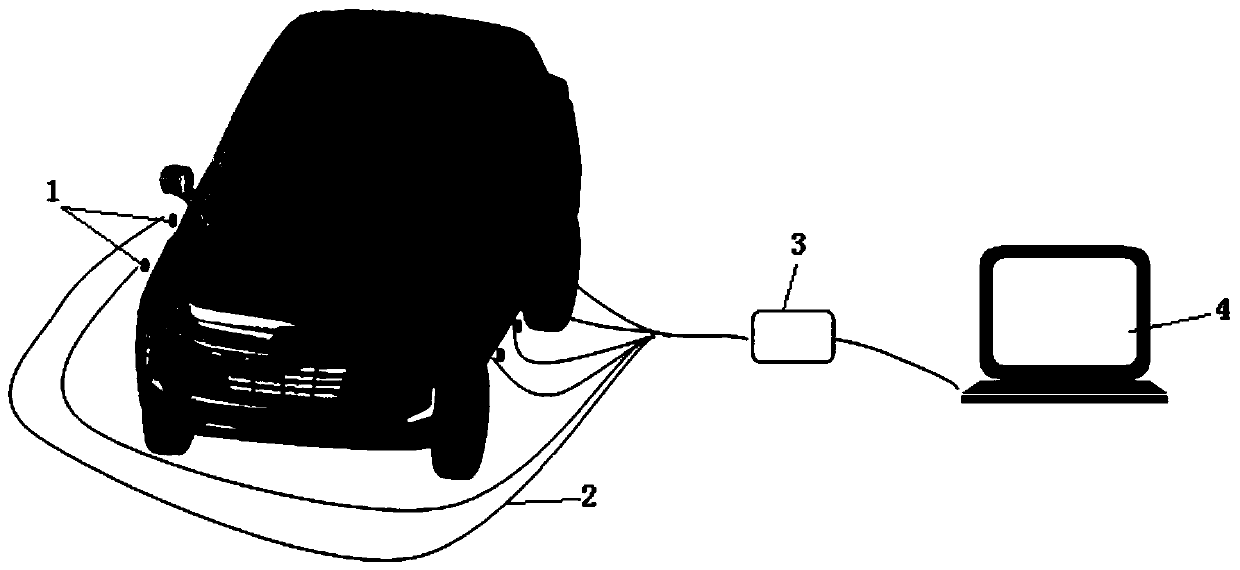

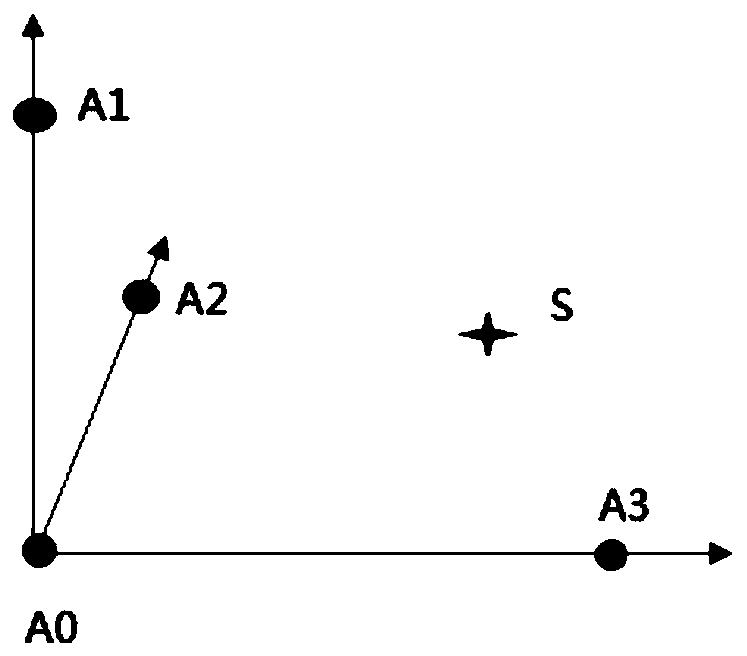

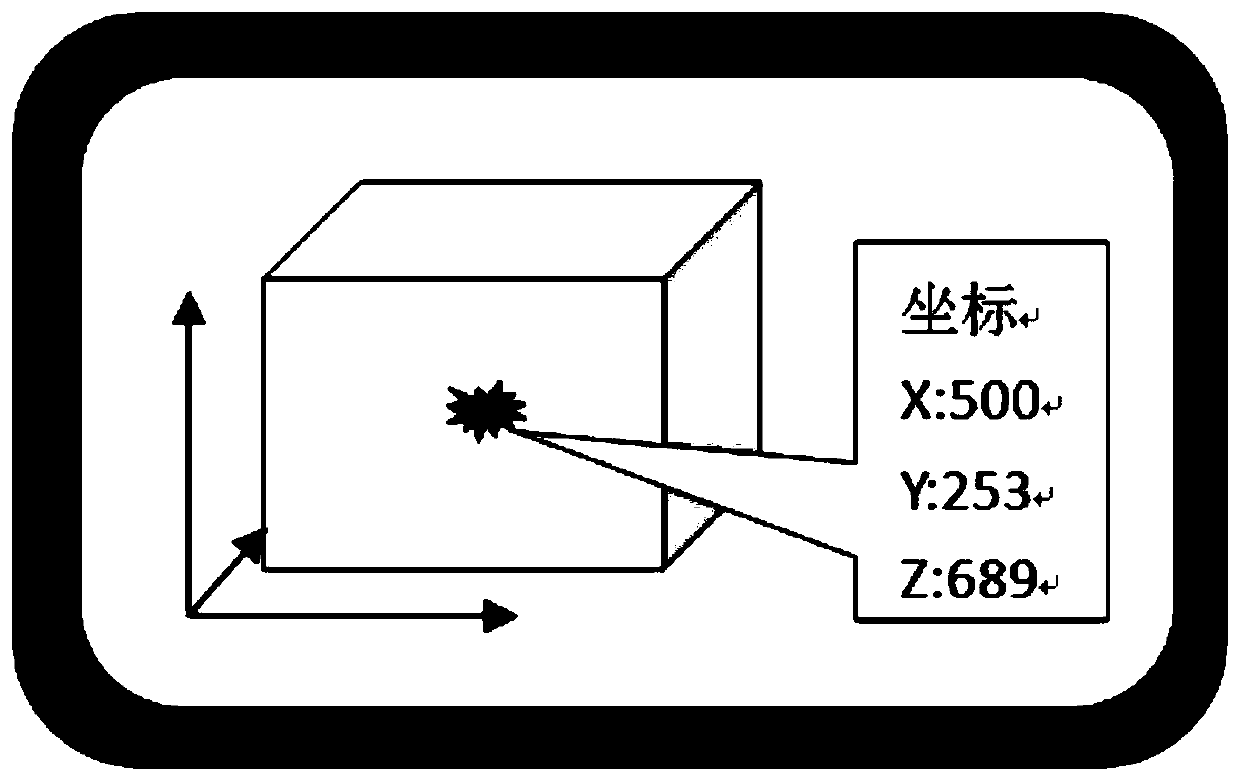

Variable matrix sound positioning system and positioning method

InactiveCN110749862AMeet the positioningApplicable environment is not limitedPosition fixationSound sourcesEngineering

The invention provides a variable matrix sound positioning system and a positioning method. The variable matrix sound positioning system comprises a plurality of sound sensors, a data processing device and a plurality of data transmission lines with equal lengths, wherein the plurality of sound sensors are used for constructing a three-dimensional coordinate system and picking up sound data; the data processing device is used for constructing the three-dimensional coordinate system based on the positions of the plurality of sensors, marking the position of each sensor in the three-dimensionalcoordinate system, receiving the sound data picked up by the sound sensors, calculating the distance between a sound source and each sound sensor, and calculating the position of the sound source in the three-dimensional coordinate system based on the position data of each sensor; and each data transmission line is connected between each sound sensor and the data processing device. Compared with some acoustic cameras or stethoscopes, the positioning system provided by the invention can arrange a detection matrix according to the will of a user or a use site, is not limited by the application environment, and can meet the positioning of abnormal sound sources in a chassis and a cabin of a vehicle in the running process.

Owner:BAIC MOTOR CORP LTD

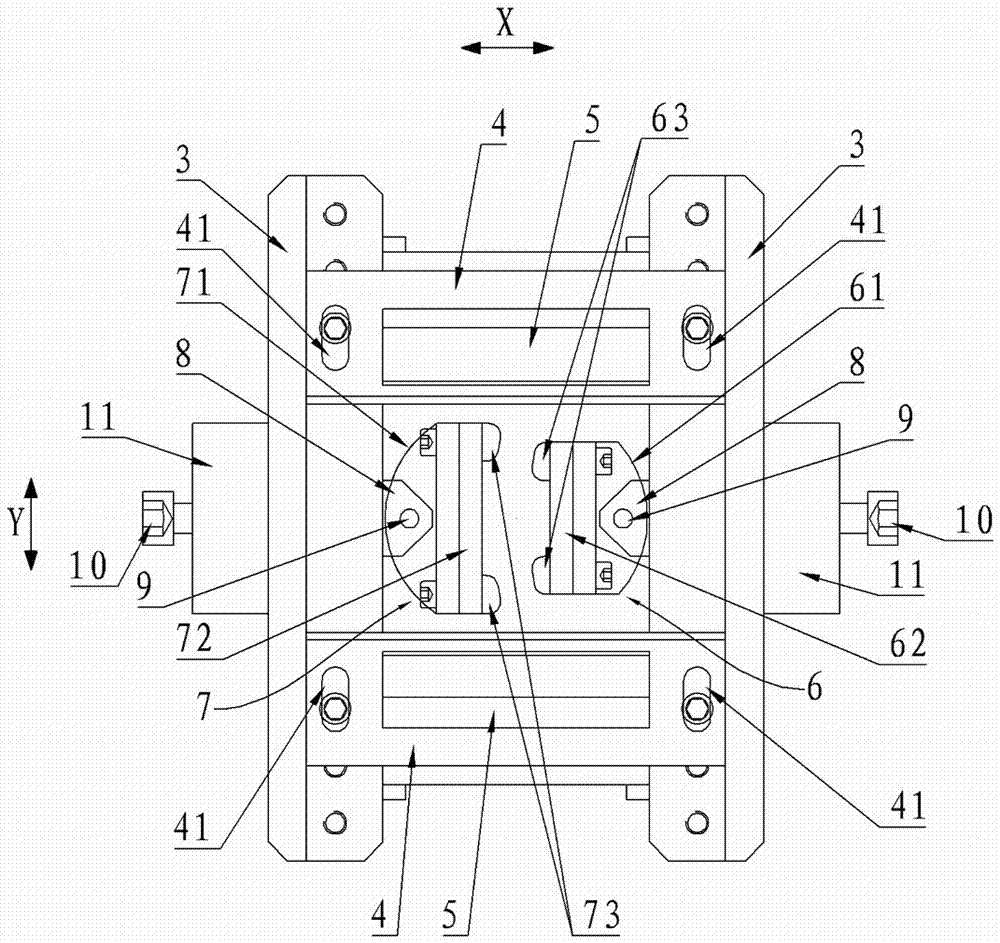

Clamping fixture

PendingCN113977480AEffective positioningImprove clamping stabilityWork holdersPhysicsMechanical engineering

A clamping fixture comprises a four-piece fixture, four positioning blocks and a chuck sleeve. The four-piece clamp is provided with a supporting sleeve, and two first chucks and two second chucks which are elastically arranged on the supporting sleeve. The outer side faces of the first chucks and the outer side faces of the second chucks are the same in shape and size. The top of the inner ring face of the chuck sleeve is in a circular-truncated-cone side face shape. The bottoms of the outer side faces of the first chucks and the bottoms of the outer side faces of the second chucks are curved surfaces matched with the top of the inner ring surface of the chuck sleeve. The top surfaces of the two first chucks and the top surfaces of the two second chucks are flush and are respectively provided with the positioning blocks. The four positioning blocks are used for limiting a workpiece in a matched mode. The two first chucks and the two second chucks are concentrated together and are arranged in the chuck sleeve in a penetrating manner. The clamping fixture further comprises a power structure which is connected with the chuck sleeve and used for driving the chuck sleeve to axially move relative to the first chucks and the second chucks. The clamping fixture is accurate in positioning, high in clamping stability and high in repeated positioning accuracy.

Owner:SHENZHEN FLYTA TECH DEV

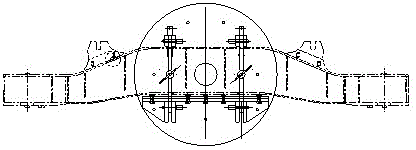

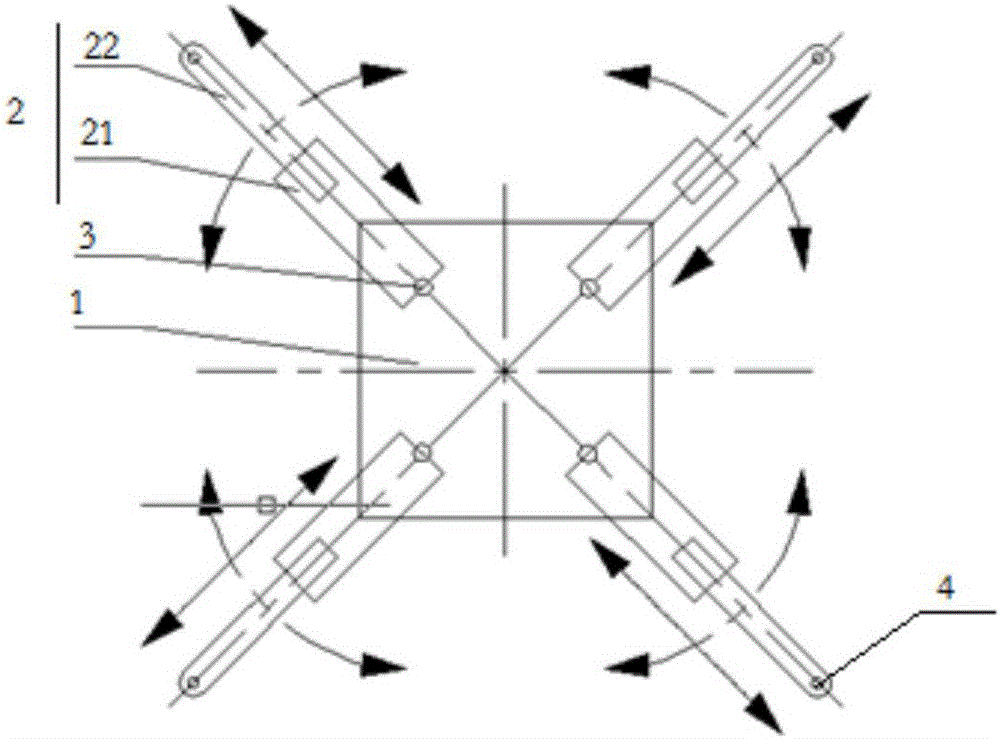

Positioning clamp applied to automatic welding equipment for inner seams of drive axle housing rear cover

PendingCN107263002AEasy to get on and off manuallyGuaranteed concentricityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWeld seam

The invention discloses a positioning clamp applied to automatic welding equipment for inner seams of a drive axle housing rear cover. The positioning clamp comprises a base, four positioning air cylinder assemblies which are fixedly mounted on the base and are uniformly distributed along the periphery of the base, four jacking air cylinders, a rear cover positioning ring assembly arranged on the base, and a fixing mechanism arranged on the base for preliminarily fixing the drive axle housing rear cover; axle centers of the four positioning air cylinder assemblies are at equal altitude for guaranteeing height of the inner seams of the drive axle housing rear cover to be consistent; the rear cover positioning ring assembly is used for guaranteeing positions of the inner seams of the drive axle housing rear cover and concentricity of the rear cover; and the four jacking air cylinders and the four positioning air cylinder assemblies are arranged in a spaced mode. The positioning clamp is reasonable in design, is simple in structure, can be used for clamping and positioning the drive axle housing rear cover, realizes manual workpiece loading and unloading, automatically positions and clamps the workpieces, meets consistency of positions of welding seams of the rear cover after the workpieces are clamped, and has a very good practical effect and a very good commercial value.

Owner:CHENGDU HANYAN TECH

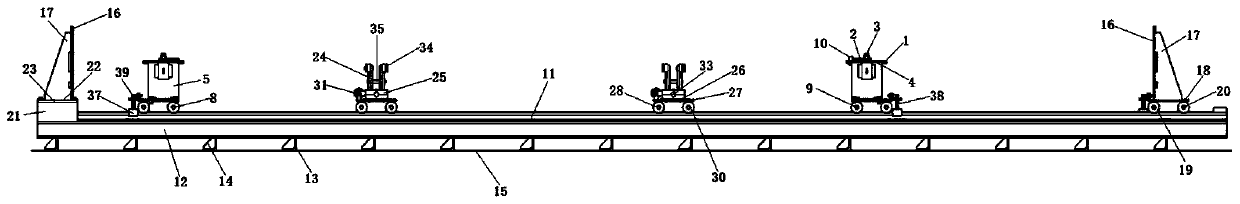

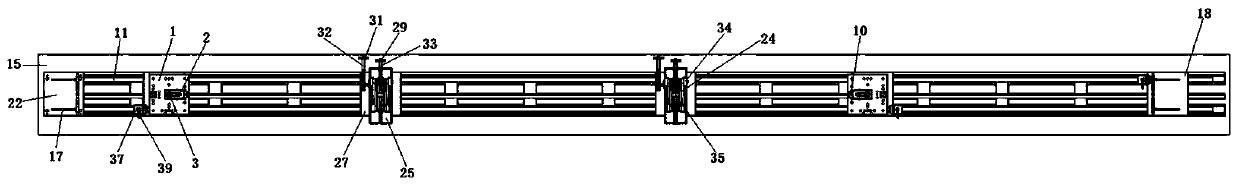

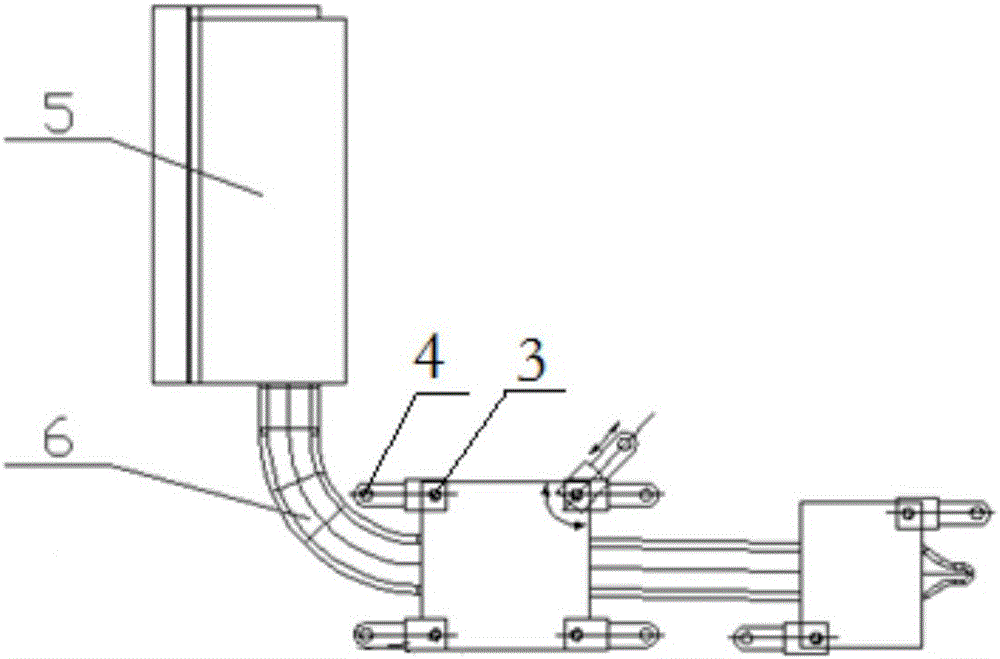

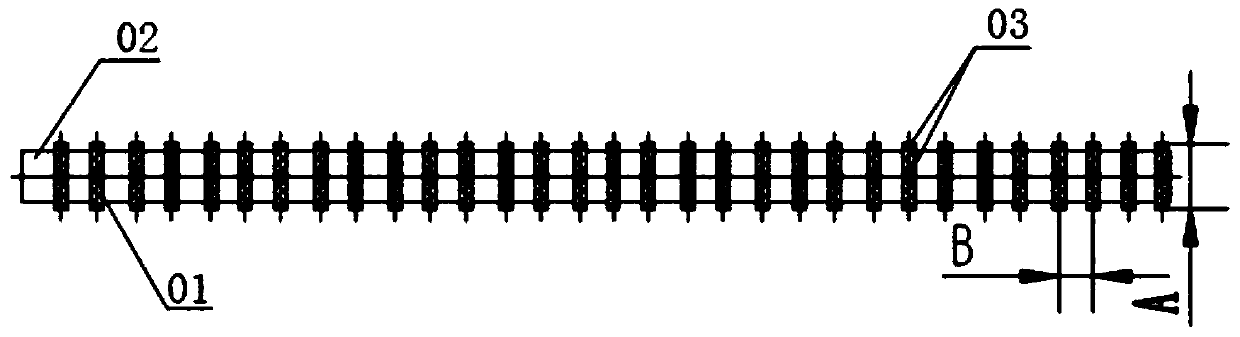

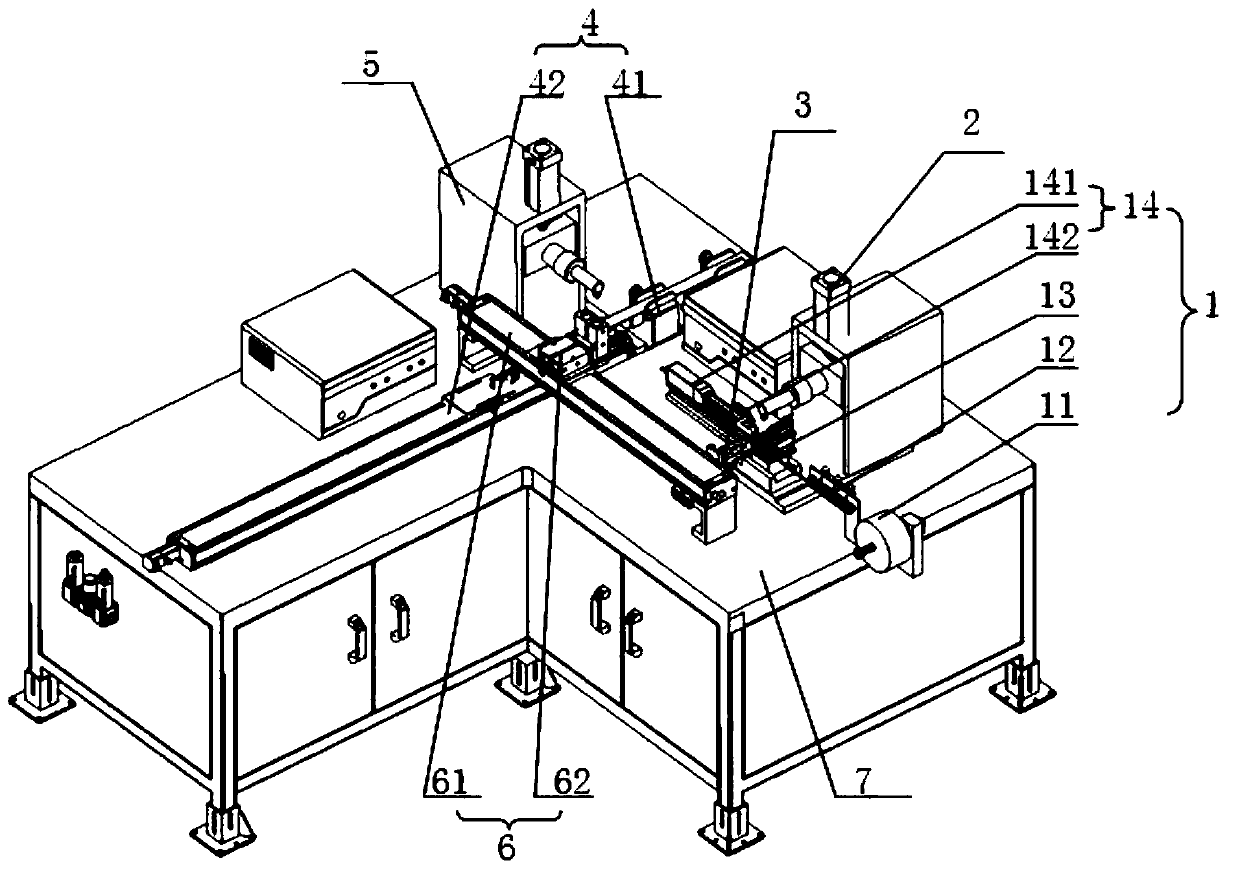

Centipede-shaped connecting piece welding machine

The invention relates to a welding machine, in particular to a centipede-shaped connecting piece welding machine, and the problems that during manual welding, the welding efficiency is low, the laborcost is high, and the welding quality is difficult to guarantee are solved. The welding machine comprises a braided wire feeding mechanism, a first welding machine, a cutting mechanism, a copper stripfeeding mechanism, a second welding machine and a braided wire transferring mechanism; the braided wire feeding mechanism comprises a wire wheel, a braided wire leveling mechanism, two braided wire positioning and clamping mechanisms and a braided wire conveying mechanism which are sequentially arranged in the left-and-right direction; a first welding machine welding head is arranged between thetwo braided wire positioning and clamping mechanisms; the cutting mechanism is arranged between the braided wire positioning and clamping mechanisms and the braided wire conveying mechanism; the copper strip feeding mechanism is arranged on the outer side of the left end of the braided wire feeding mechanism, and comprises a copper strip positioning mechanism and a copper strip conveying mechanism, wherein the copper strip positioning mechanism and the copper strip conveying mechanism are arranged in the front and back direction; and a second welding machine welding head is arranged between the copper strip positioning mechanism and the copper strip conveying mechanism; and the braided wire transferring mechanism comprises a four-degree-of-freedom mechanical arm and a third linear movementmechanism.

Owner:SHAANXI AEROSPACE ELECTROMECHANICAL ENVIRONMENTAL ENG DESIGNING INST CO LTD

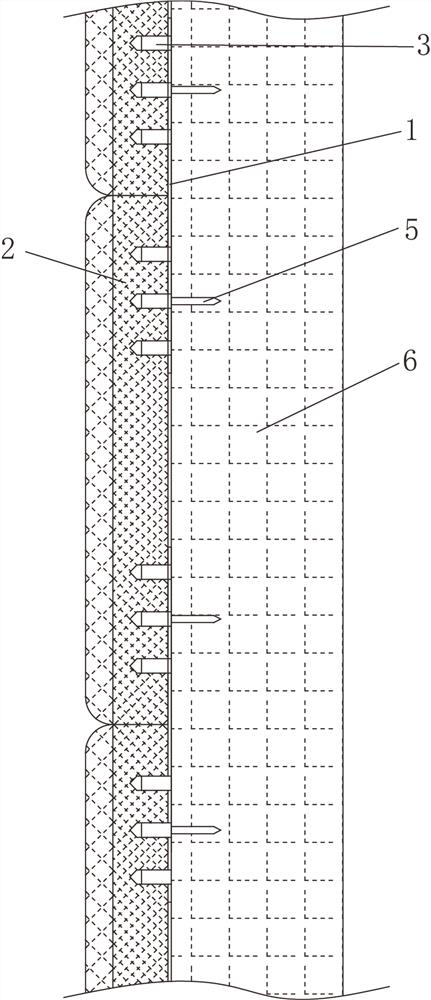

Decorative plate mounting positioning piece and method for mounting decorative plate by using decorative plate mounting positioning piece

PendingCN114541684AAvoid short service lifeEnvironmentally friendlyCovering/liningsBuilding material handlingAdhesive glueEnvironmentally friendly

The invention discloses a decorative plate installation positioning piece and a method for installing a decorative plate, the decorative plate installation positioning piece comprises a positioning piece main body, the positioning piece main body is provided with a plurality of through holes for positioning nails to penetrate through, and the positioning piece main body is provided with a plurality of positioning thorns inserted into the decorative plate to position the decorative plate. The positioning nail penetrates through the through hole to fix the positioning piece main body on the wall body, and the positioning thorn is back to the wall body; the decorative plate is pressed back to the positioning thorns, and the positioning thorns penetrate into the back of the decorative plate to position the decorative plate, so that long-life positioning of the decorative plate can be met, shortening of the service life caused by degumming is avoided, the situation that the appearance is affected by exposure of the positioning thorns is avoided, meanwhile, the mounting mode of glue pasting is abandoned, and the decorative plate is more environmentally friendly; in addition, the decorative plate is smoother after being installed, and the decorative plate is prevented from bulging outwards and deforming due to degumming.

Owner:浙江金达莱装饰材料有限公司

A 3D point cloud map fusion method and system for a substation inspection robot

ActiveCN112183285BExact fusion matrixMeet the positioningImage enhancementImage analysisPoint cloudComputer graphics (images)

A 3D point cloud map fusion method and system for a substation inspection robot of the present invention includes the following steps: before the inspection robot scans the image, the scene to be inspected is divided into local areas, and the scanning path is planned for each local area. ; Control the inspection robot to scan multiple local areas, each local area has a closed loop and a loop is detected, and the adjacent areas fused have a common part; sequentially import the 3D point cloud map to be registered and the reference 3D point cloud map, Manually frame the same areas in the two maps; perform rough-to-fine matching on the same areas in the above-mentioned frame-selected two maps through a pre-set fusion algorithm, and obtain a fusion map. The 3D point cloud map fusion method of the substation inspection robot of the present invention can avoid the risk of global optimization failure, realize the high-precision fusion of multi-local 3D point cloud maps of substation scenes of more than 100,000 square meters, and satisfy the positioning and navigation of the inspection robot.

Owner:HEFEI CSG SMART ROBOT TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com