Deformable radiator assembling structure

A technology for assembling structure and radiator, applied in the direction of cooling/ventilation/heating transformation, etc., which can solve the problems of limited radiator and unfavorable radiator replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

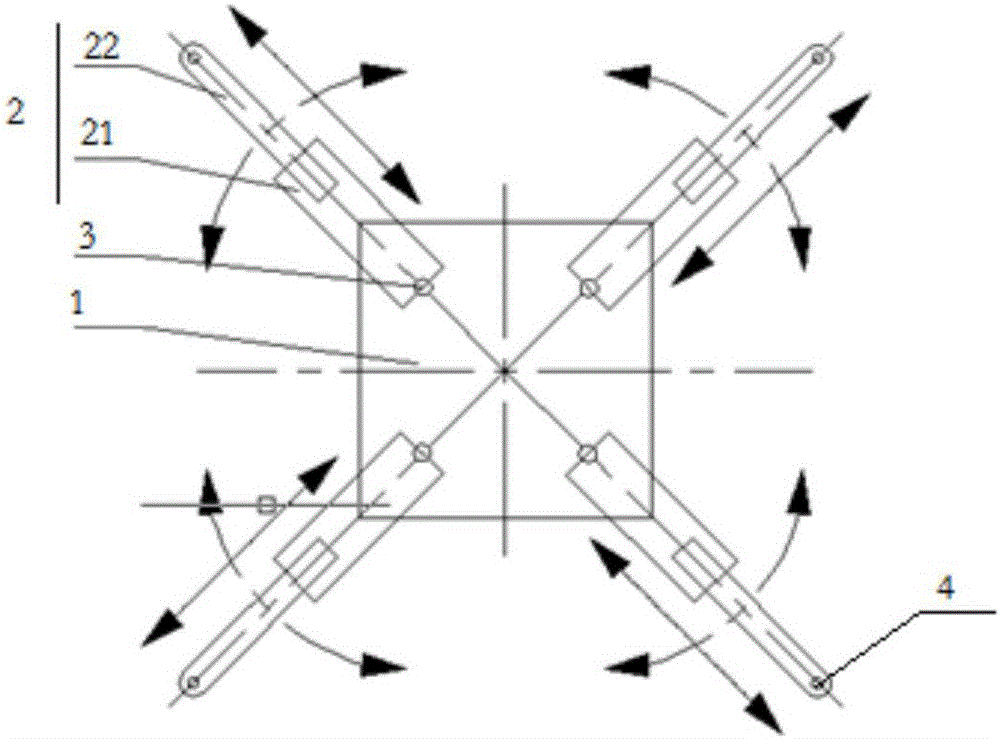

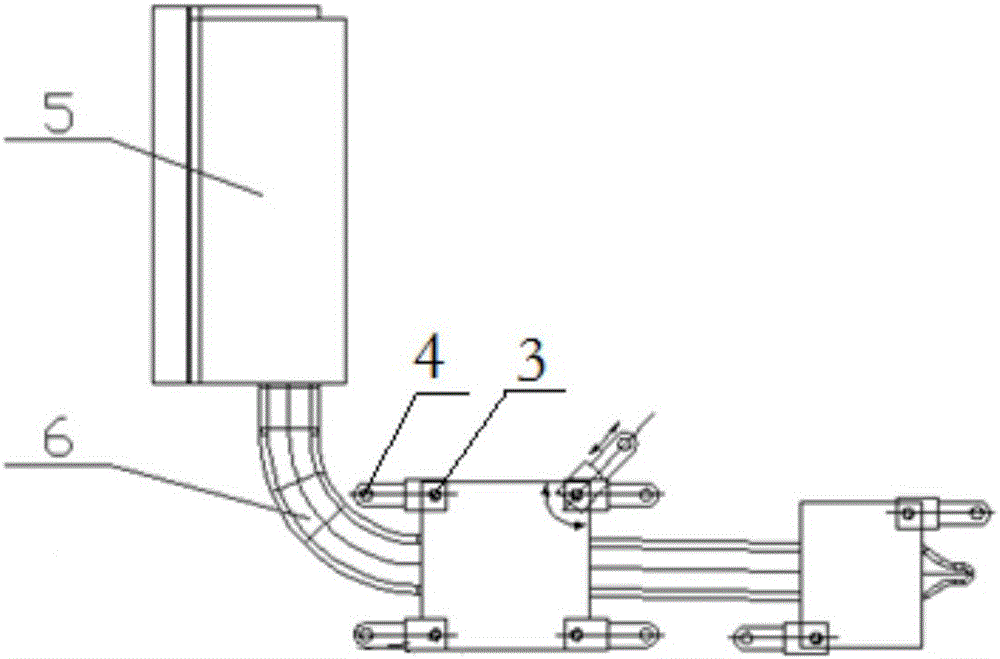

[0018] refer to figure 1 , figure 2 , a deformable heat sink assembly structure proposed by the present invention includes: a heat dissipation plate 1 , a telescopic rod 2 , a fan 5 and a heat pipe 6 .

[0019] The telescopic rods 2 are installed on one side of the cooling plate 1, and each telescopic rod 2 includes a first connecting rod 21 and a second connecting rod 22 installed coaxially, and the first end of the first connecting rod 21 passes through the first connecting mechanism 3 It is installed on the radiator plate 1 in a hinged manner, and the first connecting rod 21 can be rotated in a plane parallel to the radiator plate 1 on the axis of the first connecting mechanism 3, and the first end of the second connecting rod 22 is connected from the first connecting rod. Insert the second end of 21, the distance between the second end of the second connecting rod 22 and the first end of the first connecting rod 21 can be adjusted, the second end of the second connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com