Positioning clamp applied to automatic welding equipment for inner seams of drive axle housing rear cover

A technology of drive axle housing and welding equipment, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. Cleaning and other issues, to achieve good practical results and commercial value, reduce the workload of adjustment, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and examples, and the implementation of the present invention includes but not limited to the following examples.

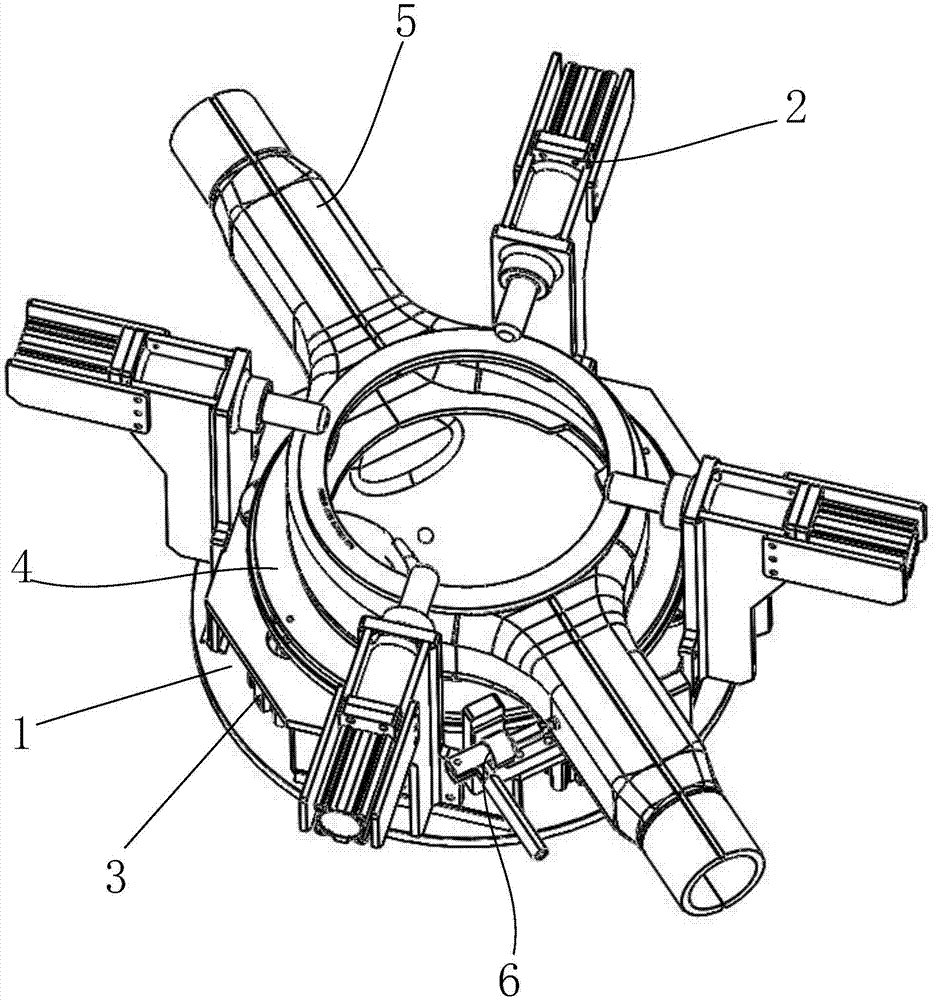

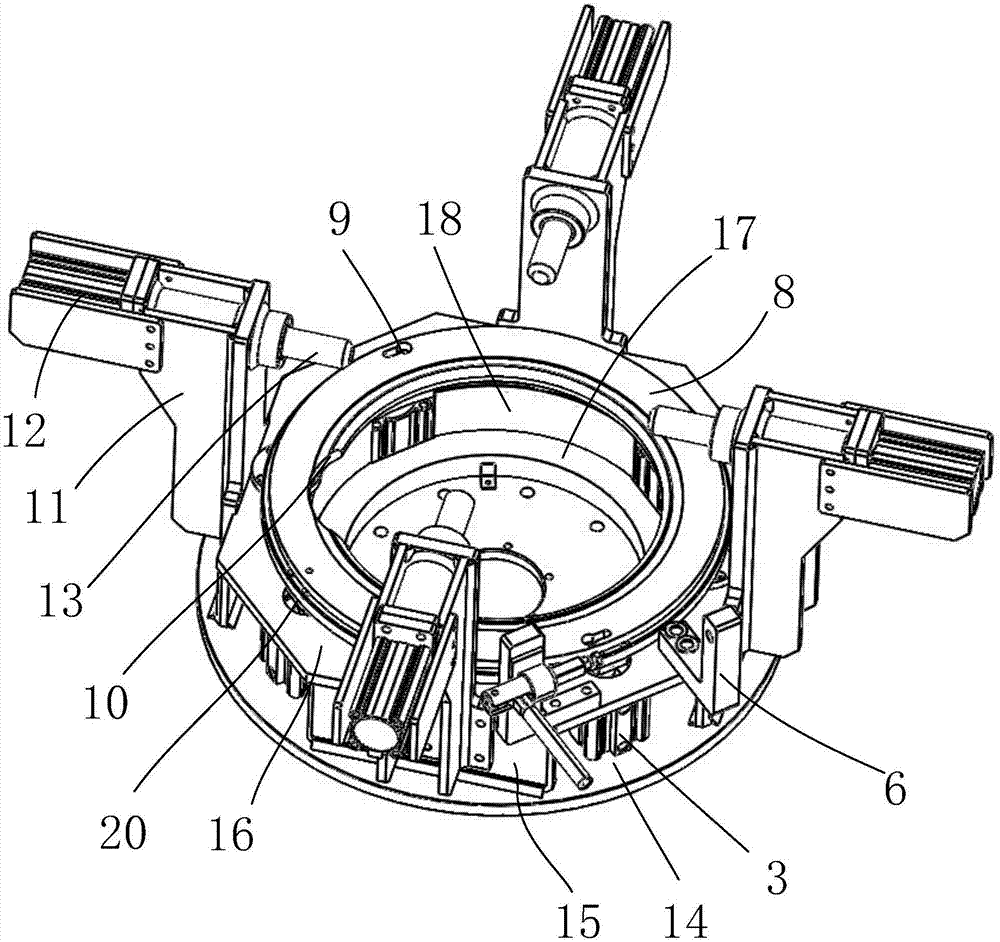

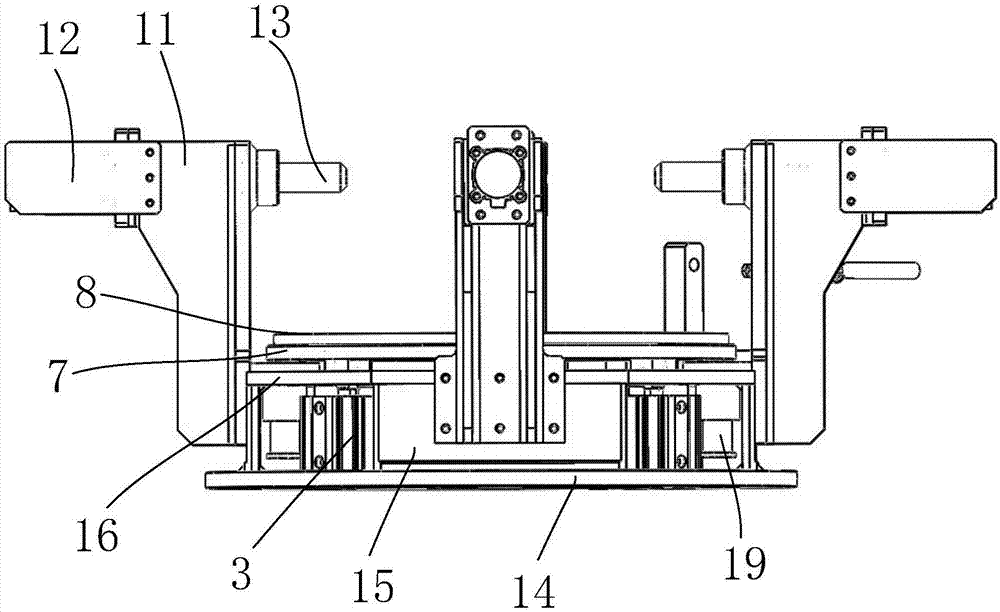

[0030] Such as Figure 1~3 As shown, the positioning fixture applied to the automatic welding equipment for the rear cover of the drive axle housing includes a base 1, a positioning cylinder assembly 2, a jacking cylinder 3, a rear cover positioning ring assembly 4, and a fixing mechanism 6; wherein, the rear cover positioning ring The assembly 4 includes an annular support ring 7 connected to the piston rods of the four jacking cylinders 3, and an annular positioning plate 8 arranged on the support ring 7 for positioning the rear cover 5 of the drive axle case; the positioning cylinder assembly 2 includes fixing with the base 1 The connected cylinder support arm 11, the cylinder 12 arranged on the cylinder support arm 11, the positioning shaft 13 connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com