Automatic welding device for inner seam of rear cover of driving axle housing and application method for automatic welding device

A technology for drive axle housings and welding devices, applied in welding equipment, welding accessories, arc welding equipment, etc., which can solve problems such as unclean workpiece surfaces, cracks in the back cover, and angle deviation of welding torches, so as to reduce adjustment workload and facilitate handling And the effect of convenient placement, replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described below with reference to the accompanying drawings and examples, and the implementation of the present invention includes but not limited to the following examples.

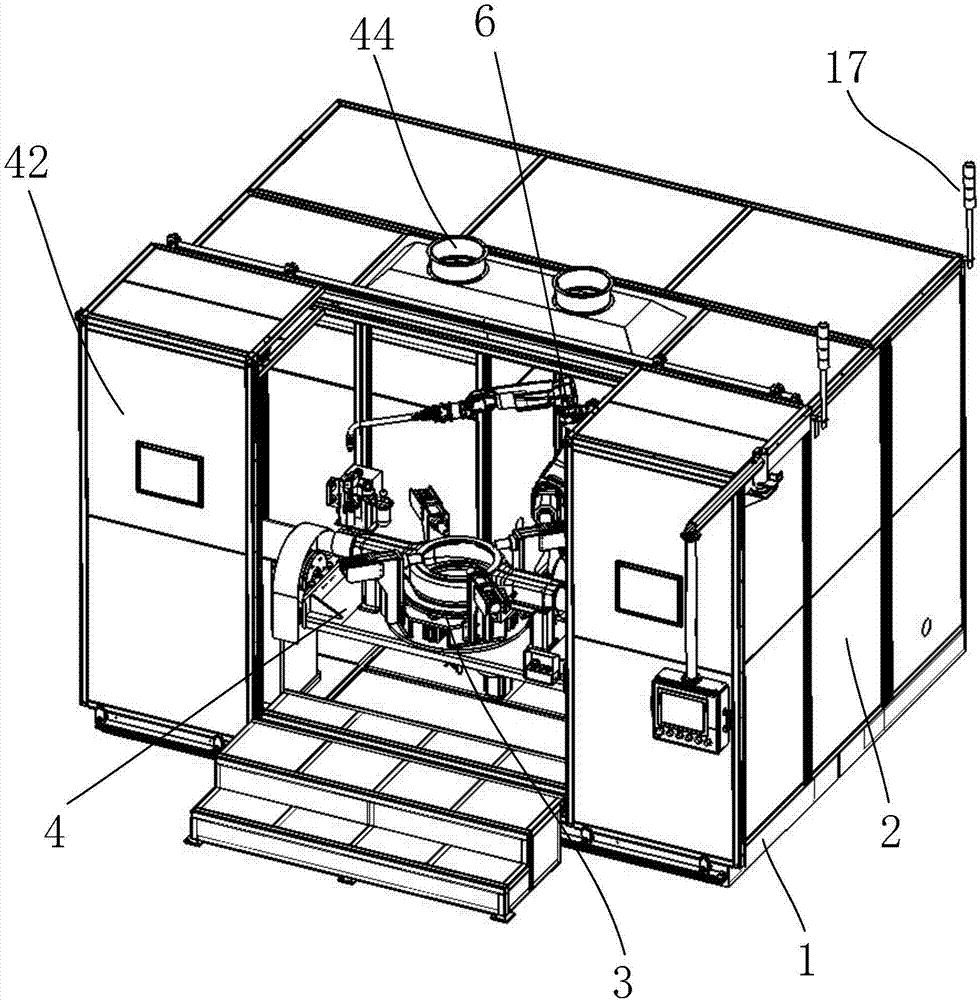

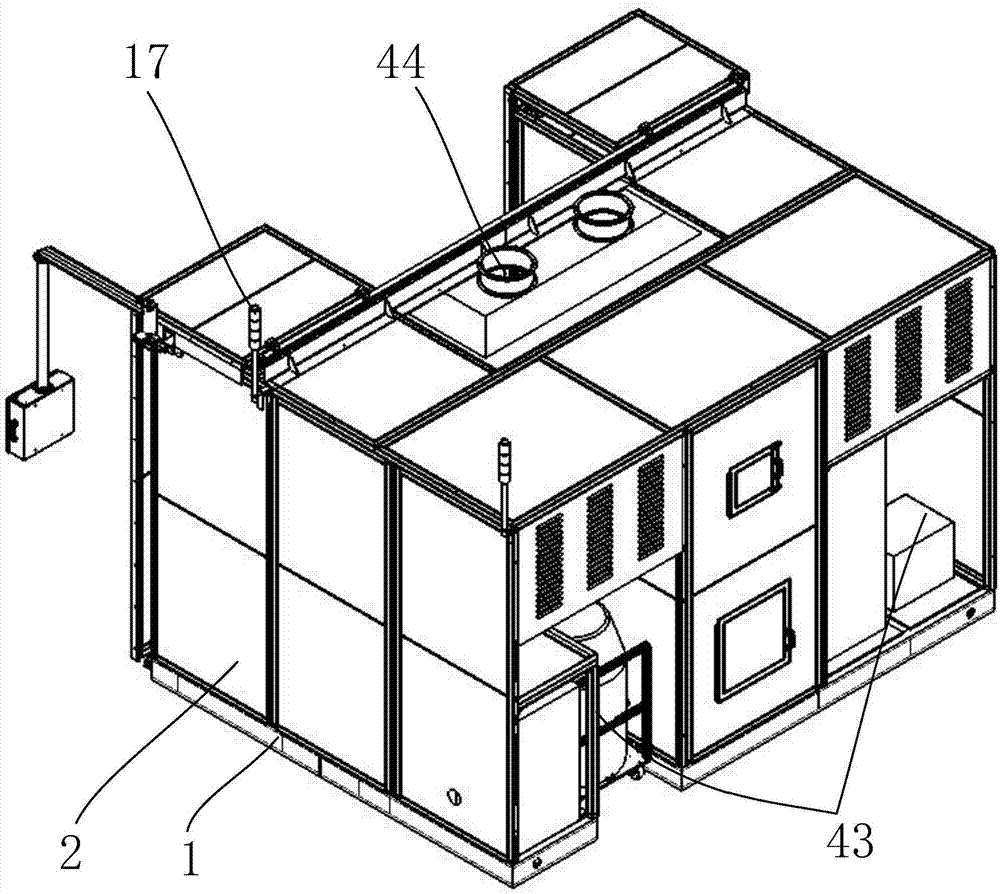

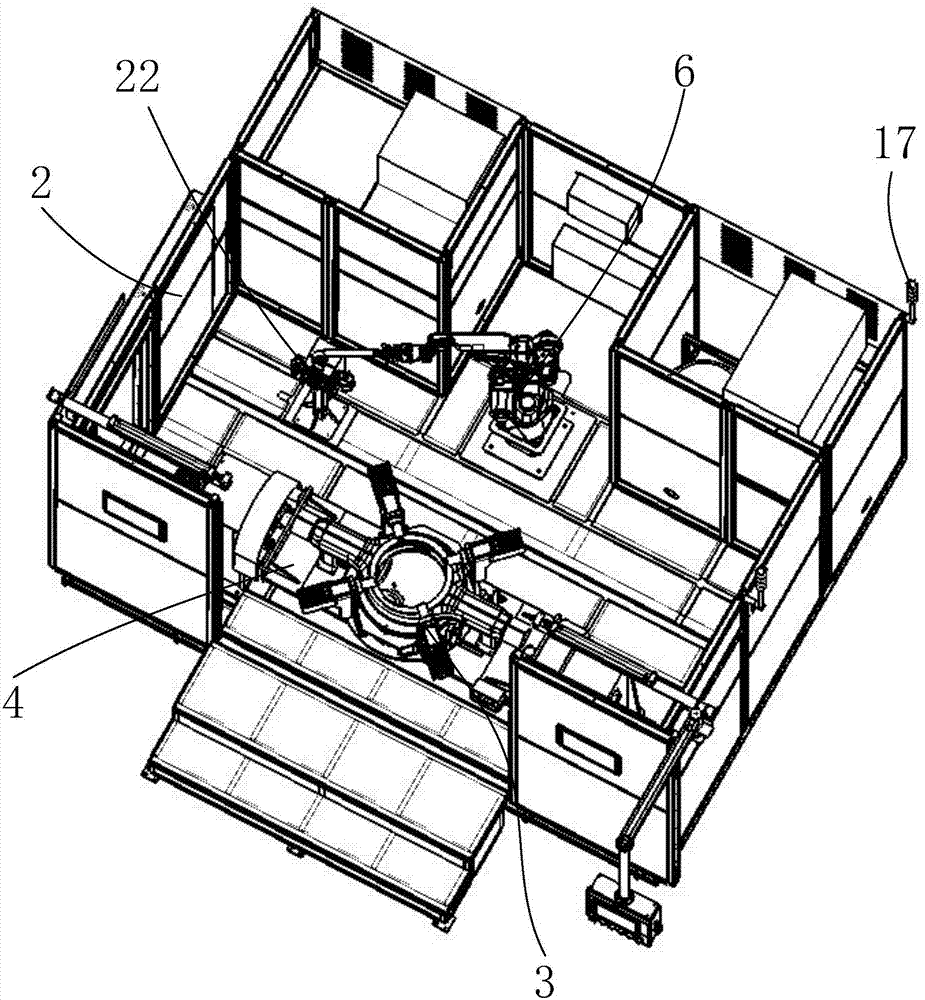

[0057] Such as Figure 1-9 As shown, an automatic welding device for the inner seam of the rear cover of the drive axle housing is characterized in that it includes an integral base 1, a fully enclosed protective cover 2, a positioning fixture 3, a turning mechanism 4, a rotating mechanism 5, and a robot welding system 6; wherein, Turnover mechanism 4 comprises head support base 8, and the driven tailstock 9 that is parallel with the nose support base 8 and is oppositely arranged, connects nose support base 8 and driven tailstock 9 and is used for installing positioning fixture 3 and rotating mechanism 5 Installation frame 10, and the first drive motor 11 that is arranged on the nose support base 8, the rotation mechanism 5 includes the support shaft 12 that p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com