Decorative plate mounting positioning piece and method for mounting decorative plate by using decorative plate mounting positioning piece

A technology of positioning parts and decorative panels, applied in the processing of building materials, covering/lining, construction, etc., can solve the problems of decorative panels falling off, unfriendly environment, short service life, etc., to avoid shortening service life and be environmentally friendly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

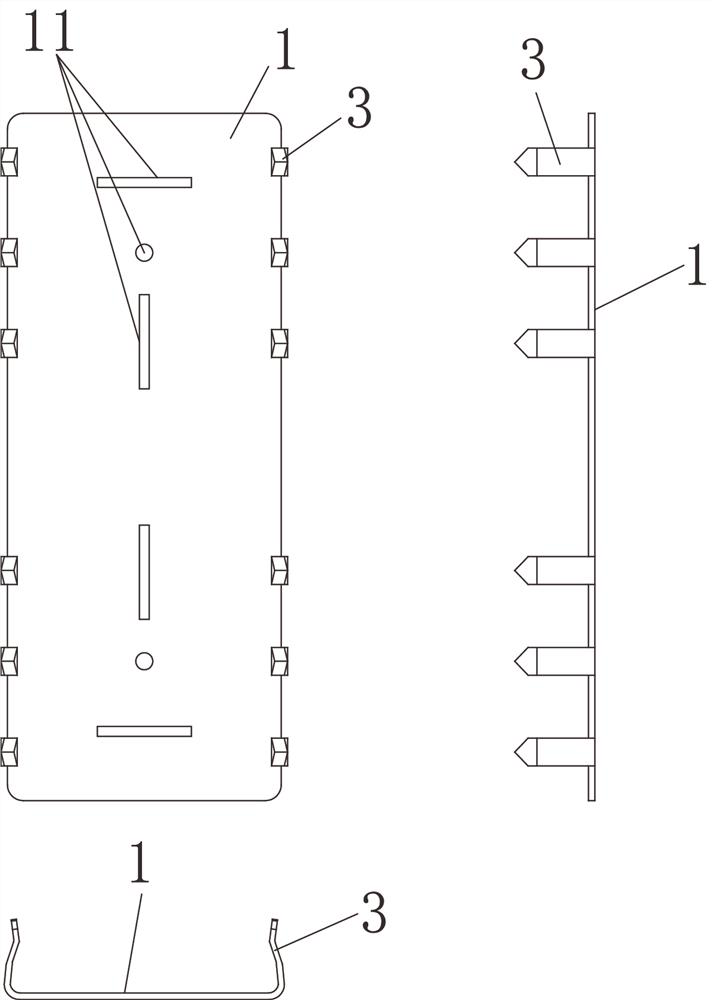

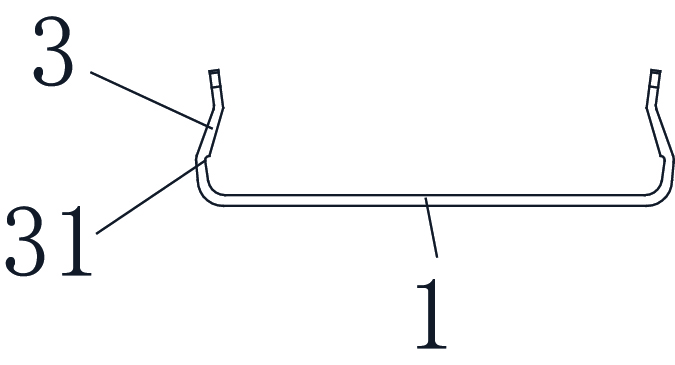

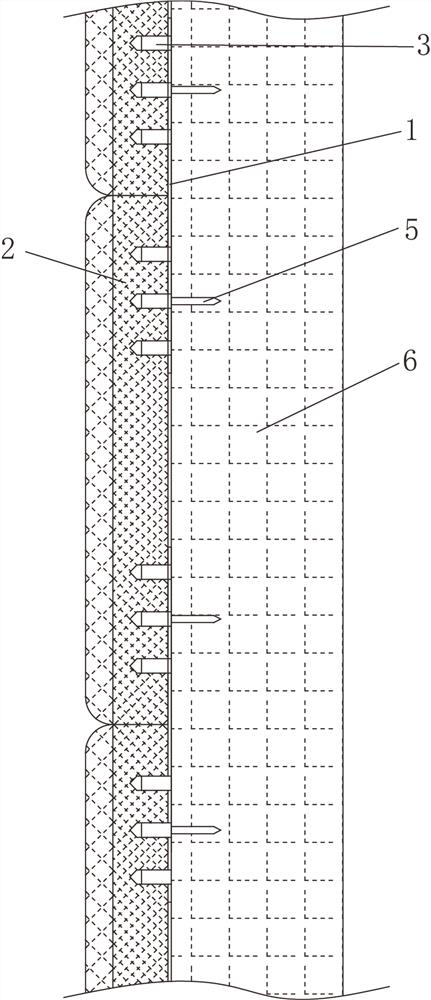

Method used

Image

Examples

Embodiment 2

[0032] The two methods of installing the decorative board with the positioning member in Embodiment 2 are the same as those in Embodiment 1. 4. It can slide more stably between each set of positioning thorns 3 to open or close the positioning thorns 3.

[0033]Both the positioning member for installing the decorative board and the method for installing the decorative board in the above two embodiments can satisfy the long-life positioning of the decorative board, avoid the shortening of the service life caused by degumming, and will not cause the exposure of the positioning nails to affect the appearance, and at the same time The installation method of glue sticking is discarded, which is more friendly to the environment, will not cause harm to human safety, and the decorative panel will be smoother after installation, and the outer drum of the decorative panel will not be deformed due to degumming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com