Vehicle body flexible assembly operation island

A flexible assembly and body technology, applied in auxiliary devices, vehicle maintenance, vehicle parts, etc., can solve the problems of inconformity with precise production management and automotive ecological chain, action and efficiency waste, etc., to solve the bottom assembly bottleneck and promote flexible assembly The effect of docking and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

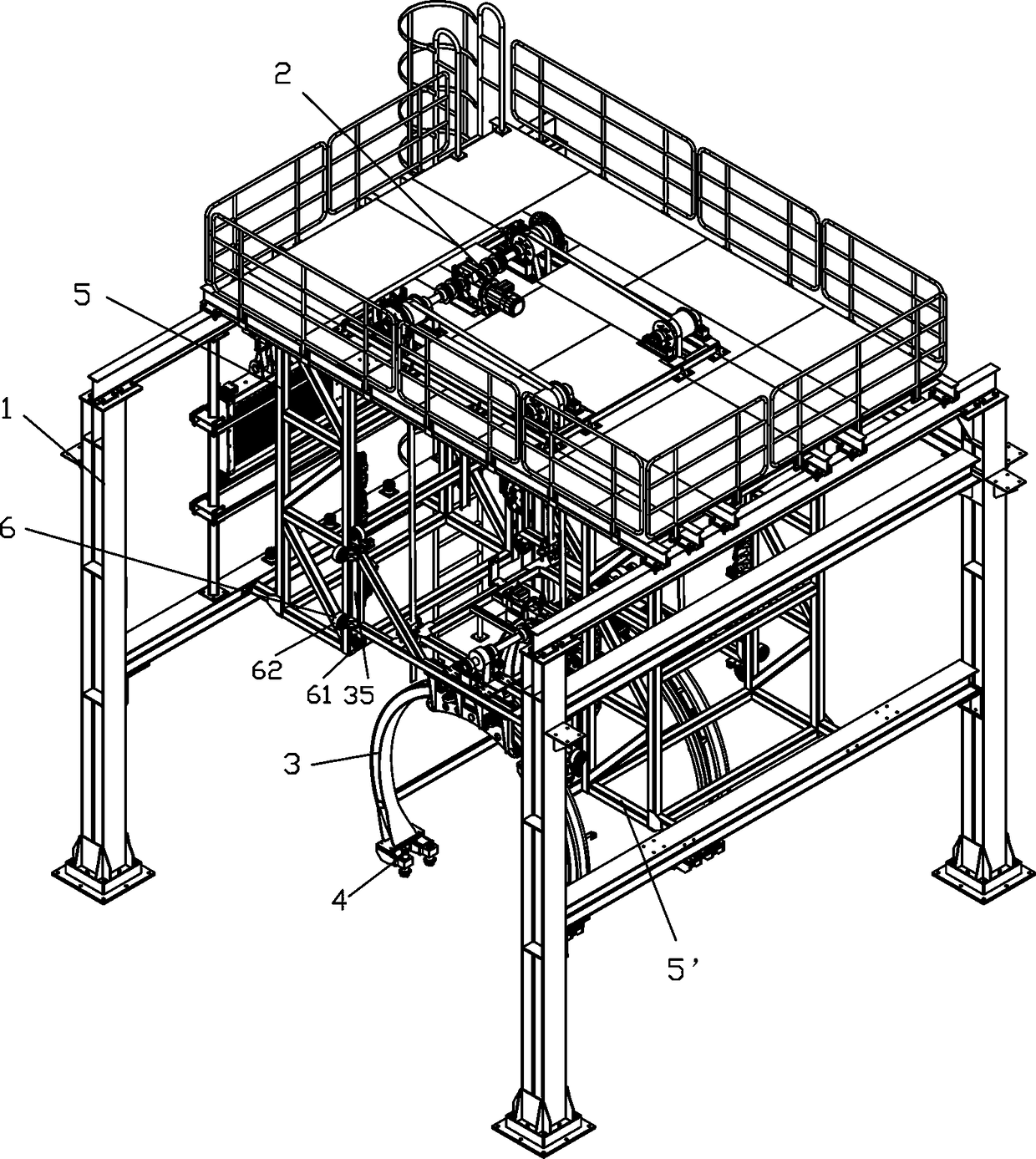

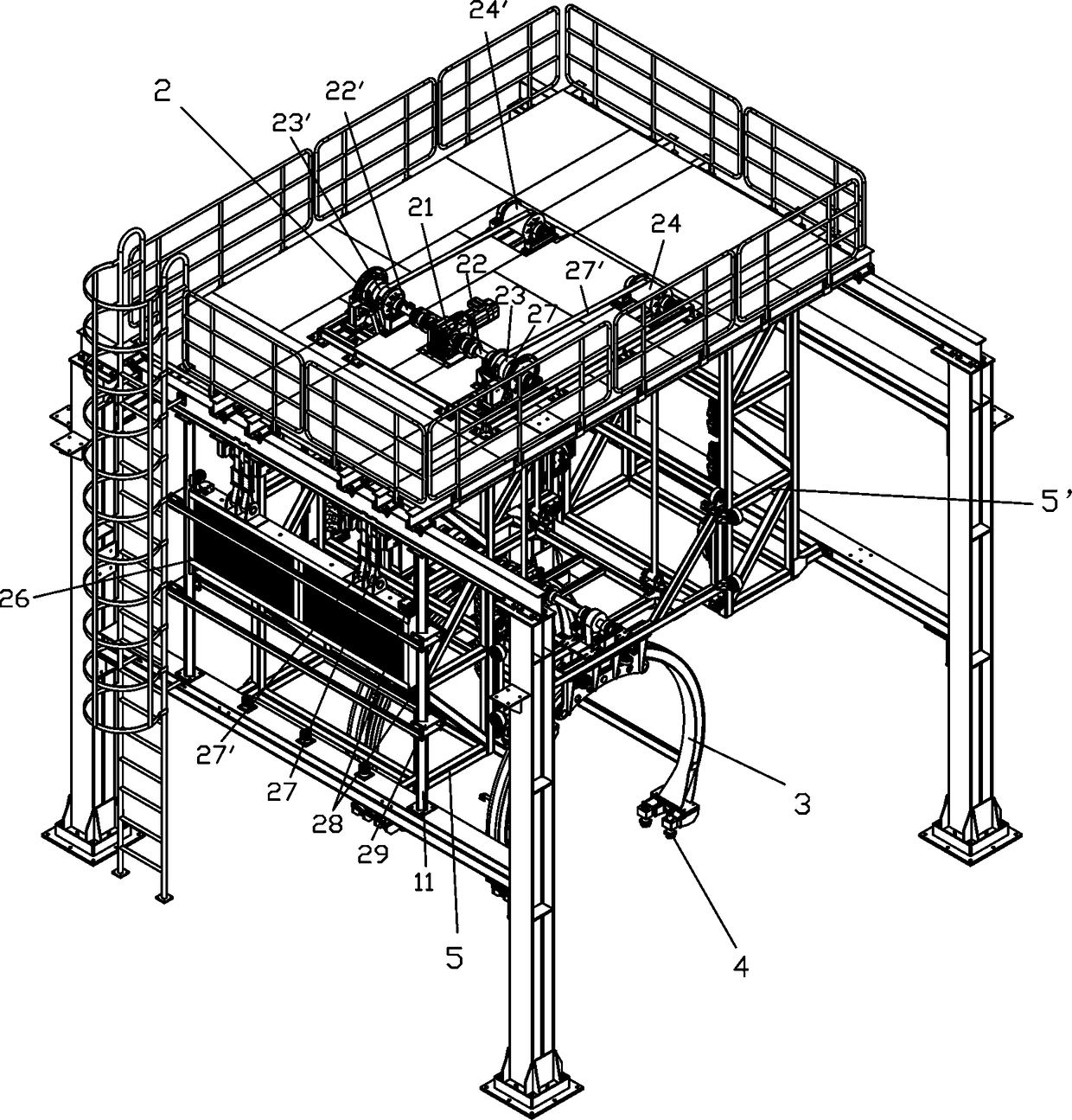

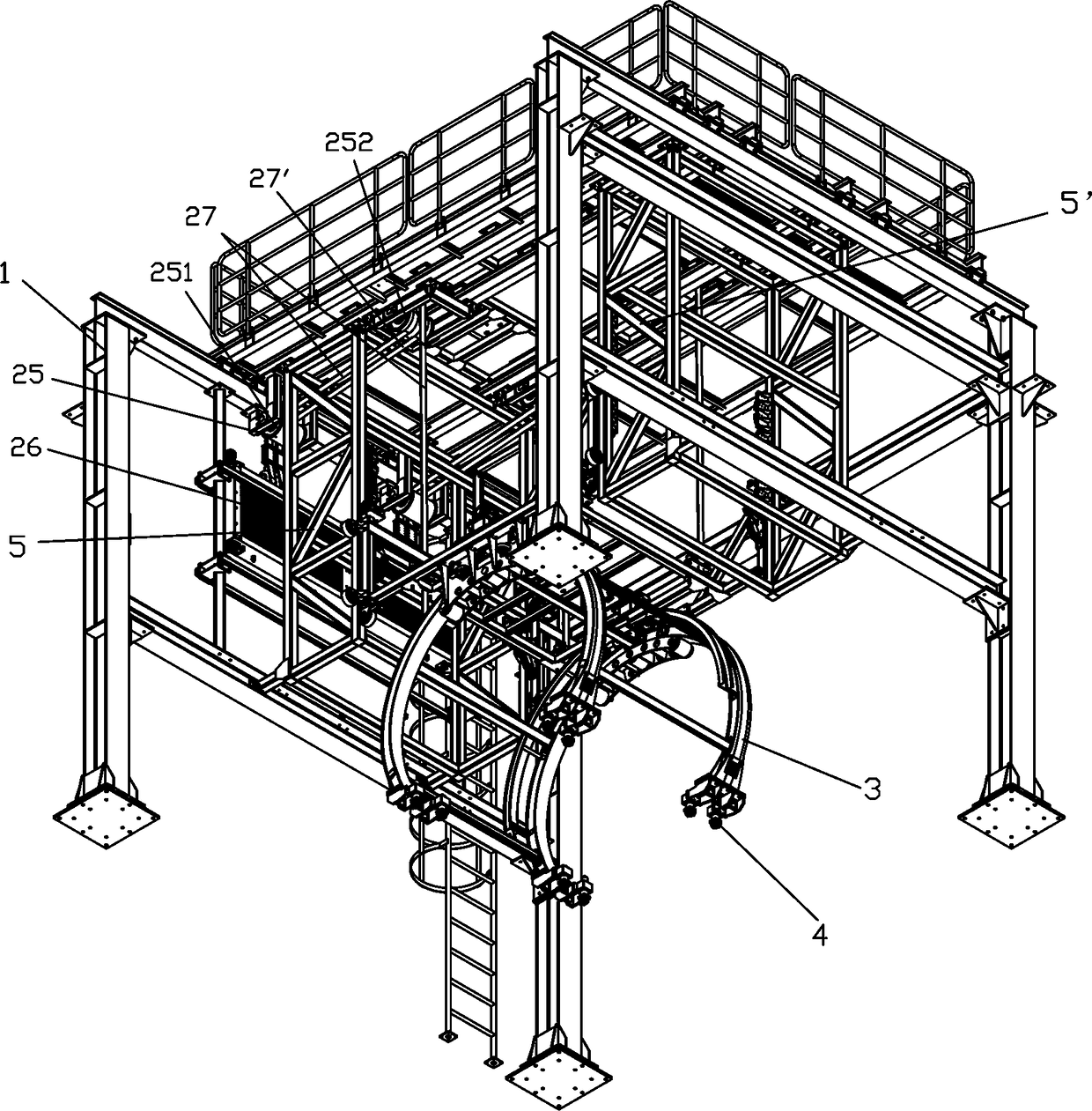

[0040] see Figure 1 to Figure 22 , a vehicle body flexible assembly operation island of the present invention, which includes:

[0041] Fixed frame 1, which is a truss gantry structure;

[0042] Lifting drive mechanism 2, including:

[0043] The drive motor 21 and the reducer are arranged on the top side of the fixing frame 1 through the mounting plate;

[0044]Two drive shafts 22, 22', one end of which is respectively connected to the two output ends of the reducer through a coupling, and the other end of the drive shaft is installed on the top surface of the fixed frame 1 through a bearing seat;

[0045] The two pulleys 23, 23' are respectively coaxially arranged at the other ends of the two drive shafts 22, 22';

[0046] The two lifting guide wheels 24, 24' are respectively installed on the other side of the top surface of the fixing frame 1 through the bearing seat, and are respectively arranged opposite and parallel to the two pulleys 23, 23';

[0047] Two sets of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com