Guide plate for laterally guiding a rail, and system for securing a rail on a foundation

A guide plate and track technology, applied in the field of guide plates, can solve expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

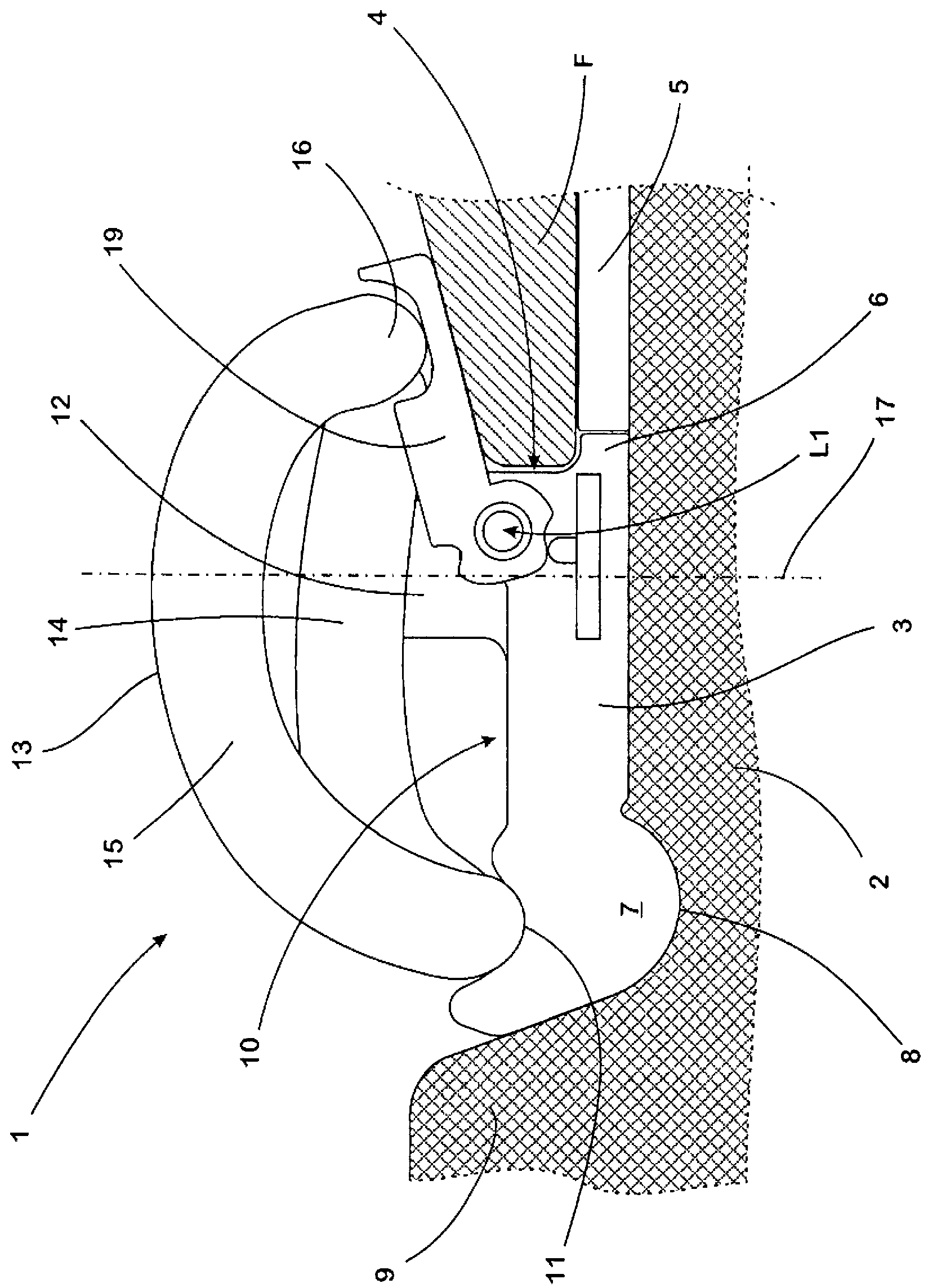

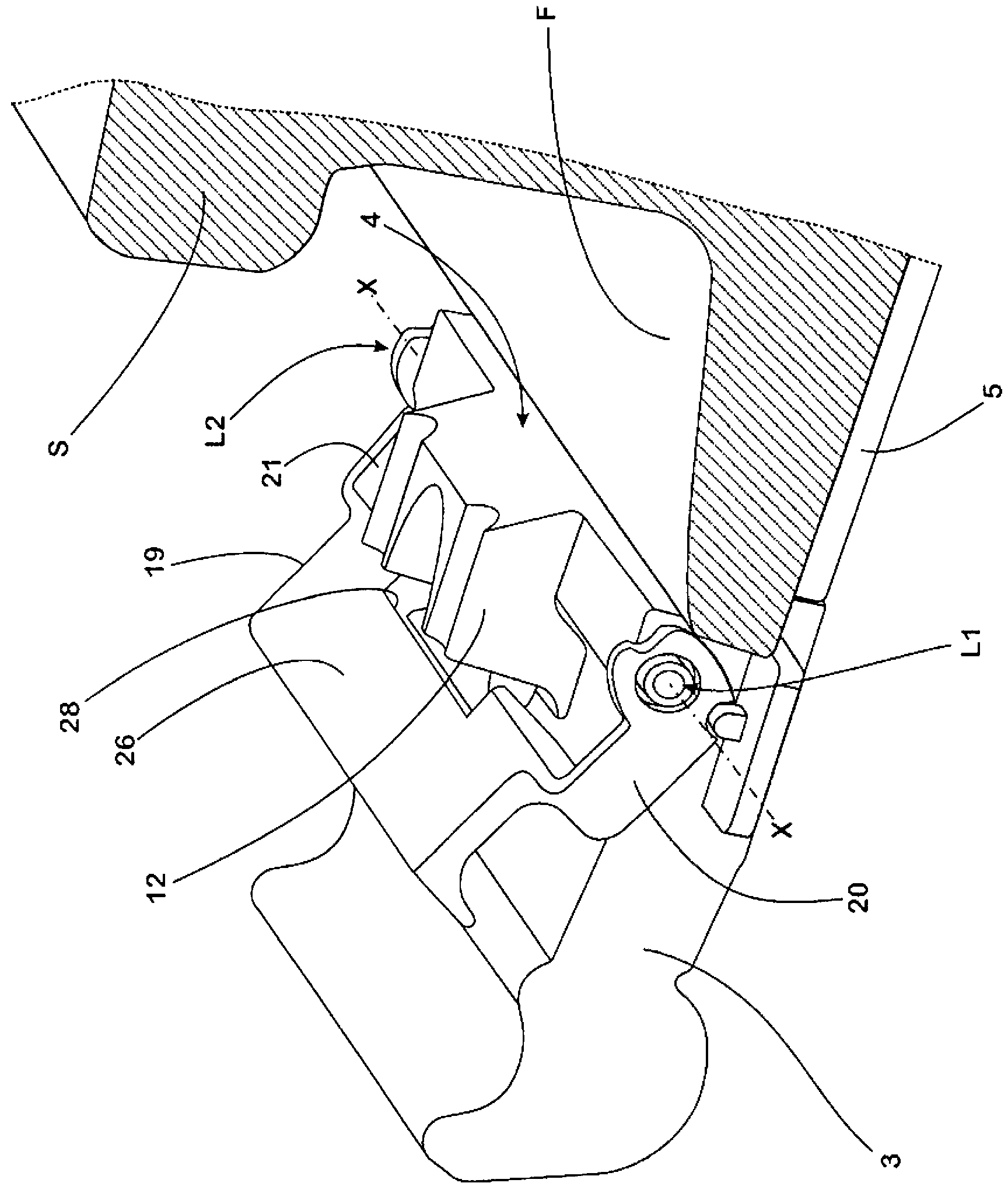

[0064] figure 1 The system 1 shown in , for securing a rail S on a foundation 2 formed, for example, of concrete sleepers, contains a guide plate 3 formed according to a conventional curved guide plate form, the track S having the size of its rail foot F The longitudinal sides are supported against the flat front side 4 of the guide plate.

[0065] In a manner that is also known, the track S is located on top of the elastic intermediate layer 5 on the base 2 . The elastic intermediate layer 5 ensures sufficient flexibility of the rail S at the fastening point formed by the system 1 and a correspondingly designed fastening system, not shown here, arranged on the opposite side of the rail.

[0066] On the lower edge of the front side 4 is molded on the guide plate 3 a protruding area 6 protruding in the direction of the rail S, which extends across the width of the front side 4 and clips onto the rail foot when assembly is complete Below the F. In this way, the nose region 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com