Brake block and friction plate drilling tool

A technology of drilling tooling and friction plates, which is applied in the direction of manufacturing tools, boring/drilling, drilling/drilling equipment, etc., can solve the problems of low efficiency, poor interchangeability, and low precision of processing methods, and achieve the reduction of tooling Investment, reduced energy consumption, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

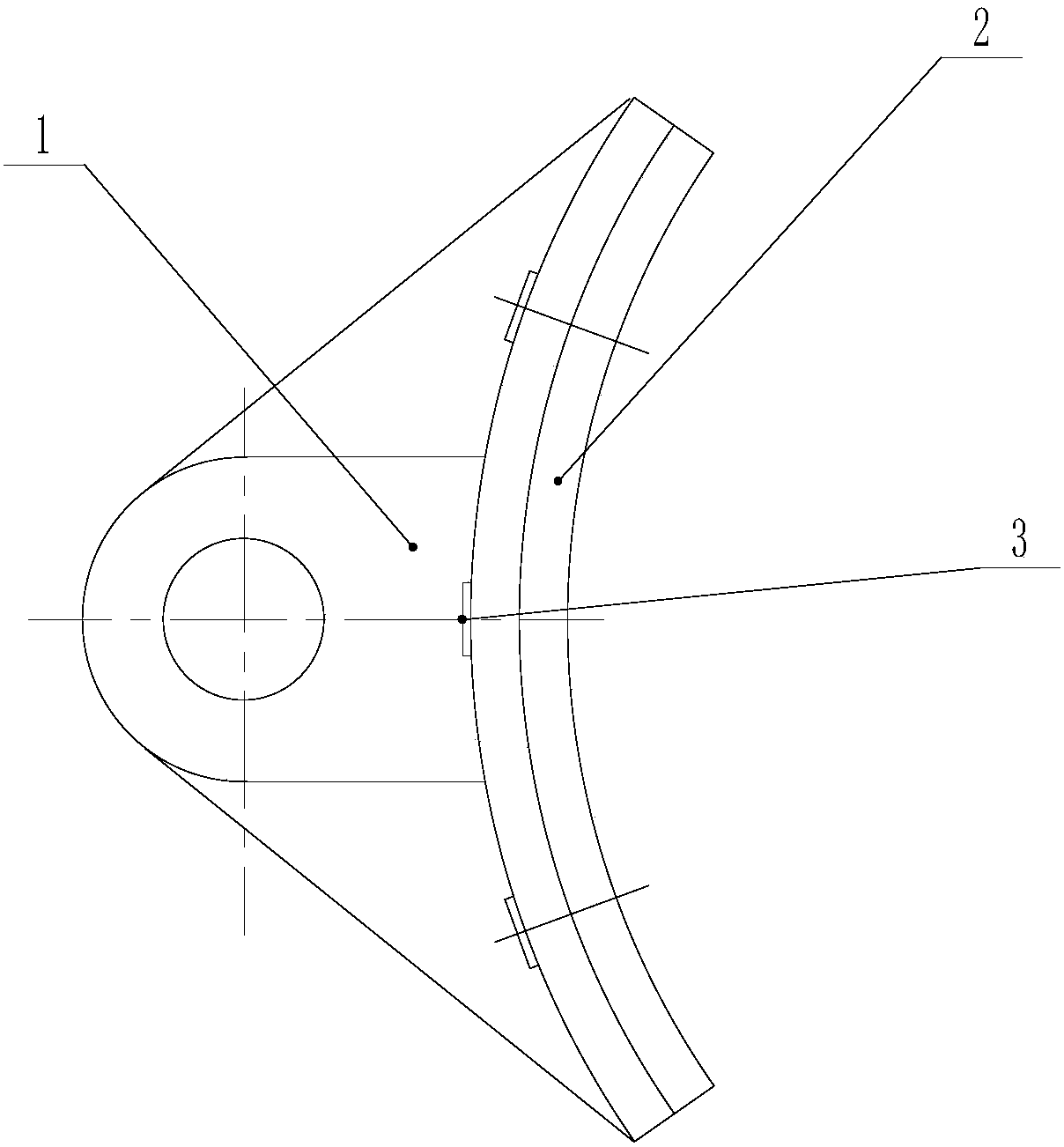

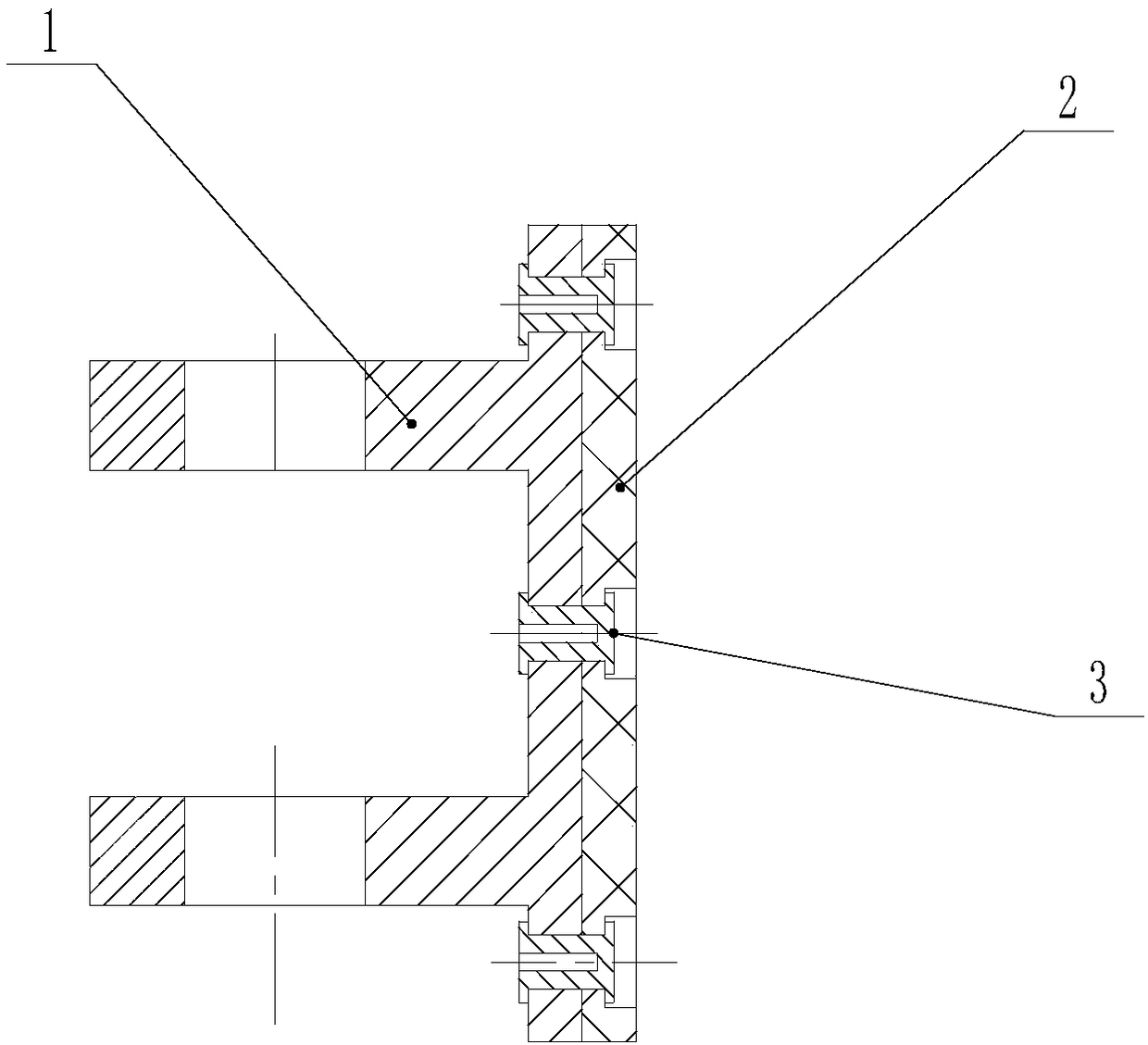

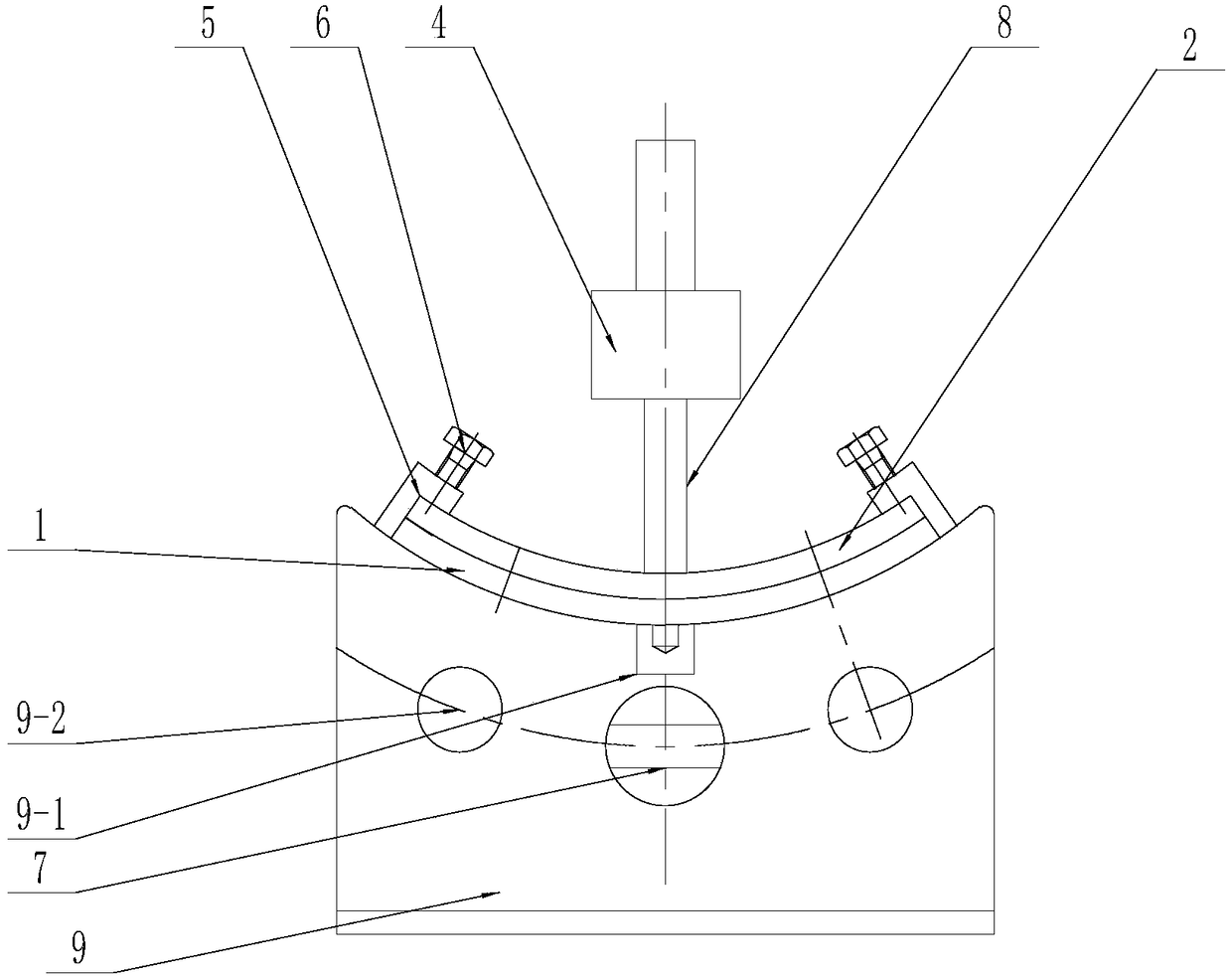

[0021] A brake block and friction plate drilling tool, wherein the main body includes a brake block 1 and a friction plate 2, and is characterized in that it includes: a seat frame 9, a multi-axis device 4, a clip 5, a positioning block 7, and a combined drill bit 6. Wherein the main body is fixed together by the clip 5, and the clamping bolt 6 is provided on the clip 5 to loosen and tighten the main body; wherein the main body can be placed on the seat frame 9, and can slide in an arc on the seat frame 9; wherein the seat frame 9 is provided with Positioning holes (9-2); the positioning block 7 and the positioning holes (9-2) fix the main body on the seat frame 9; wherein the seat frame 9 is fixed on the drilling ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com