Patents

Literature

51results about How to "Satisfy positioning accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

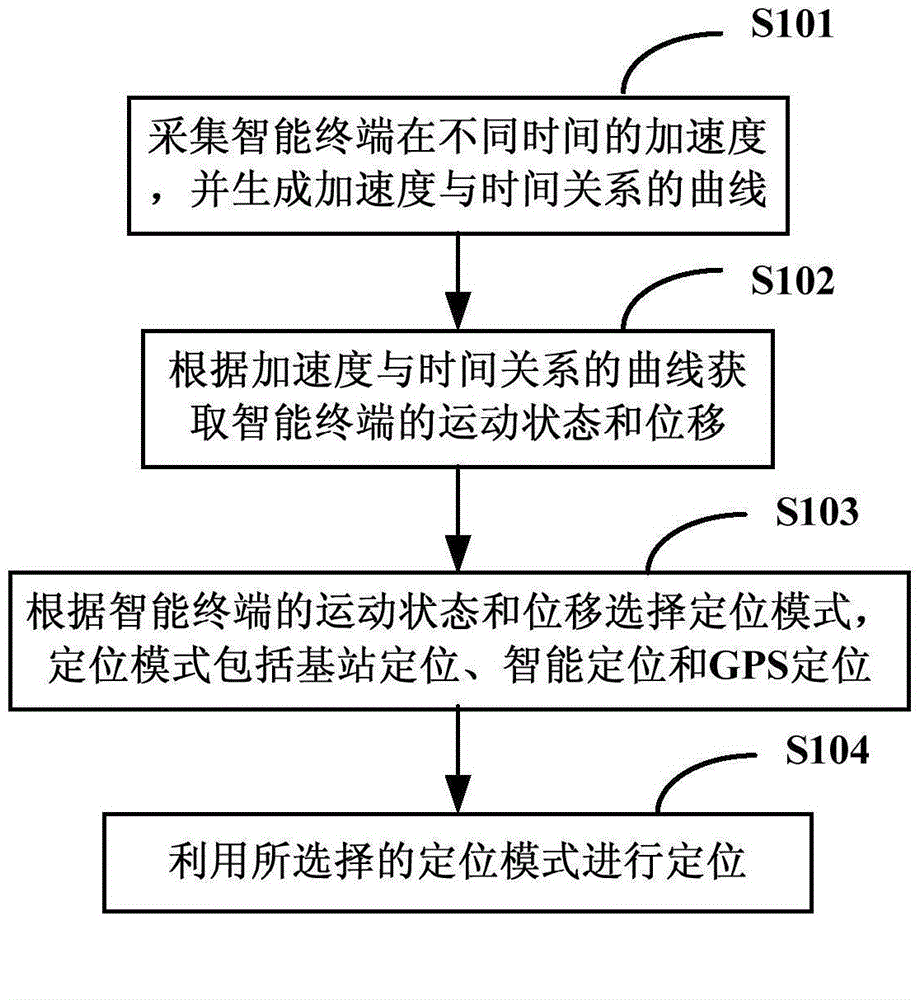

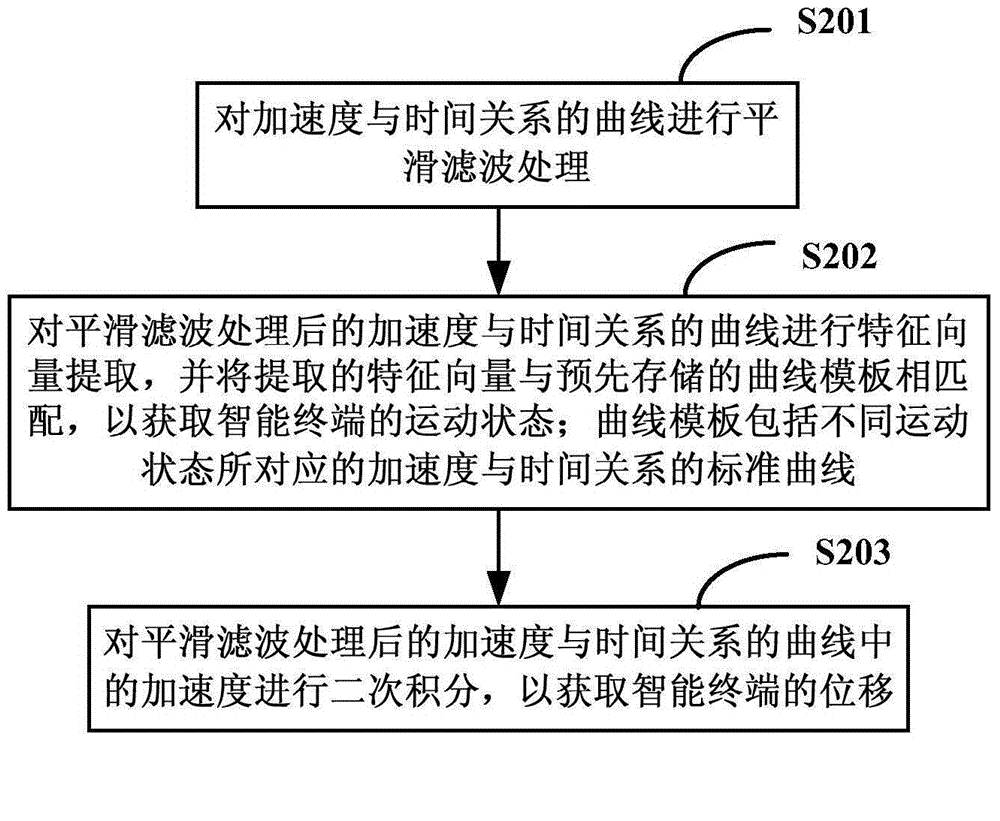

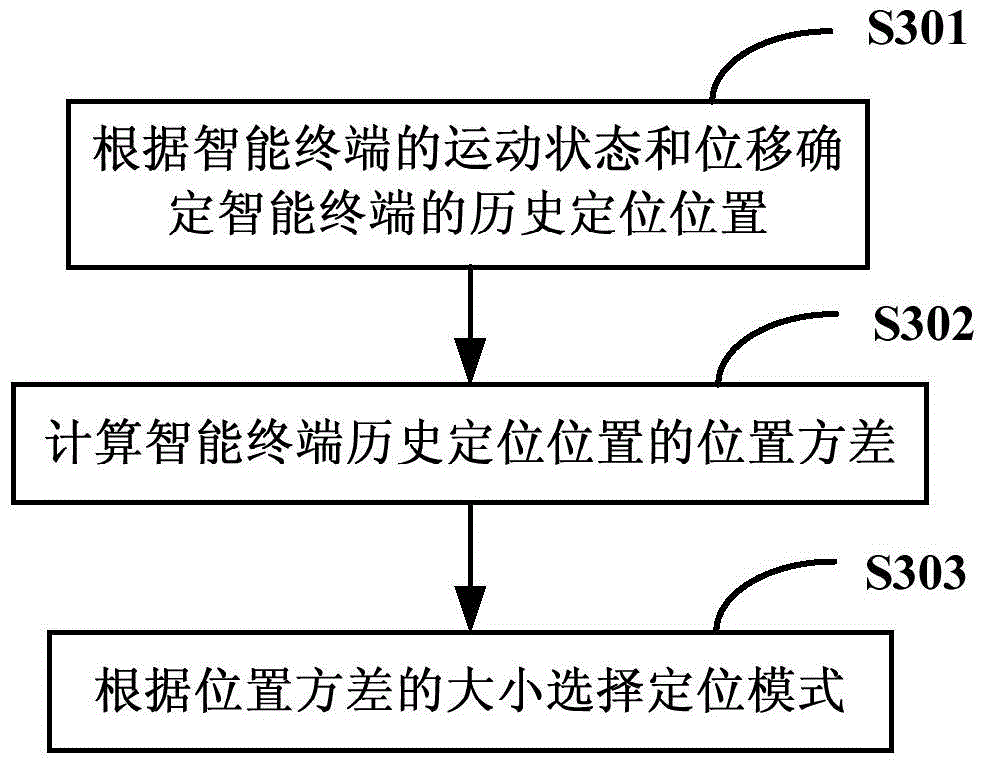

Intelligent terminal positioning method and system

ActiveCN104540220AGuaranteed positioning accuracyReduce positioning power consumptionHigh level techniquesWireless communicationExercise statePositioning technology

The invention provides an intelligent terminal positioning method and system and relates to the technical field of mobile positioning. The intelligent terminal positioning method comprises the steps that the accelerated speeds of an intelligent terminal at different times are acquired, and a curve of the relation between the accelerated speeds and the times is generated; the motion state and the displacement of the intelligent terminal are obtained according to the curve of the relation between the accelerated speeds and the times; a positioning mode is selected according to the motion state and the displacement of the intelligent terminal, and positioning is conducted in the selected positioning mode, wherein positioning modes include the base station positioning mode, the intelligent positioning mode and the GPS positioning mode. According to the intelligent terminal positioning method and system, the three positioning modes are set, the positioning modes can be switched automatically by the intelligent terminal according to the motion state and the displacement of the intelligent terminal, positioning power consumption is reduced on the premise that the positioning precision is guaranteed, and the requirements of people for positioning precision and positioning power consumption are met.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

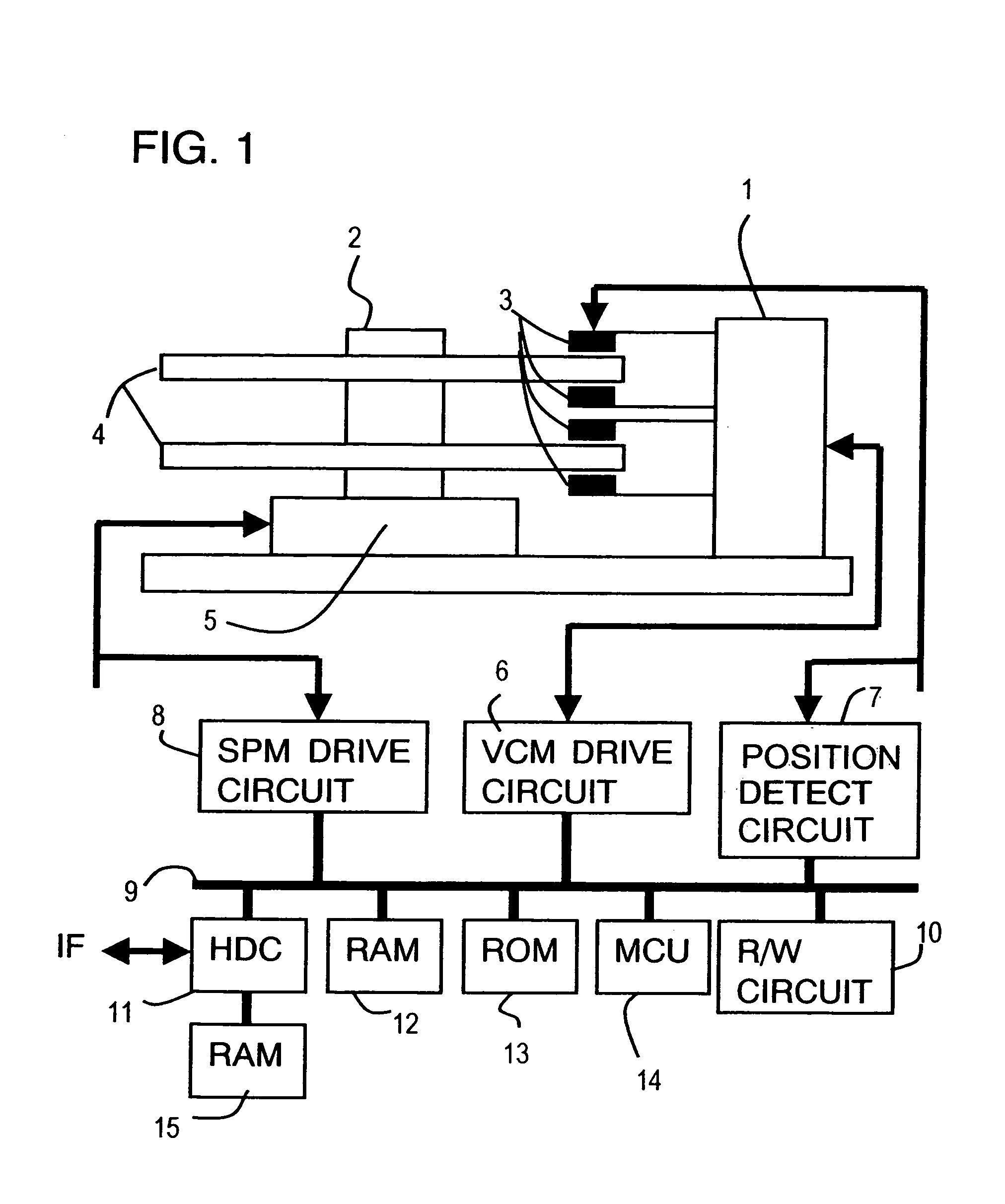

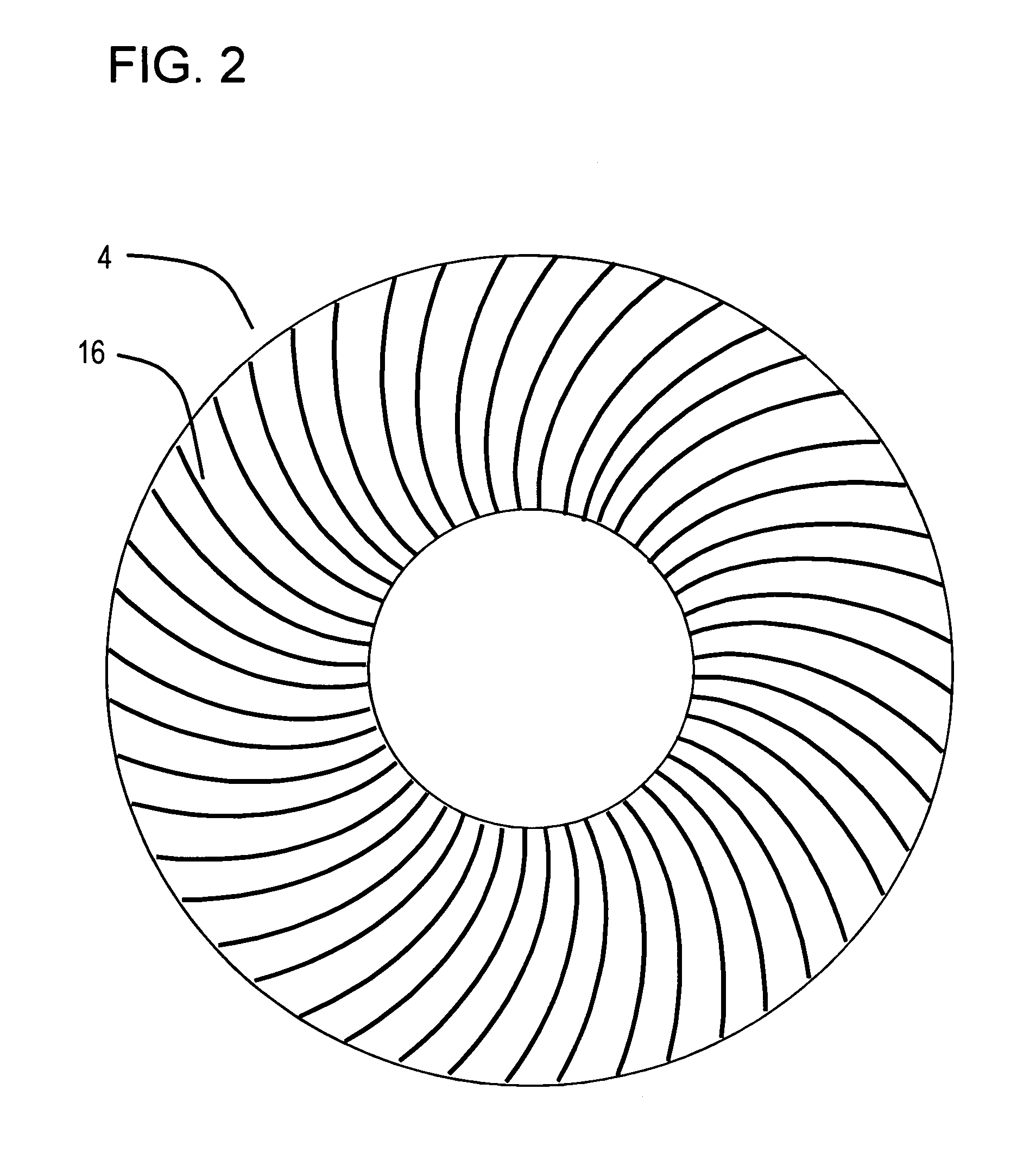

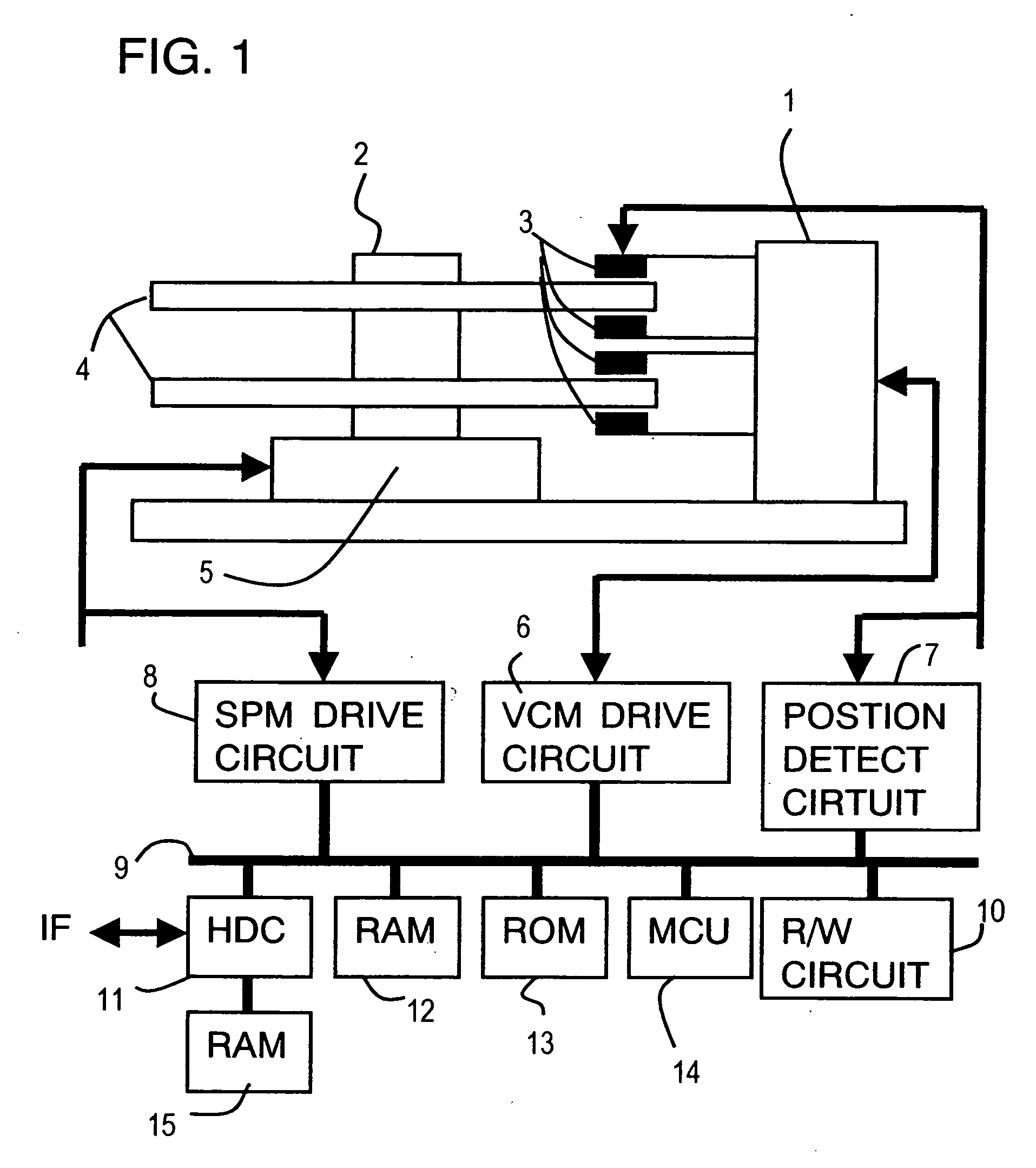

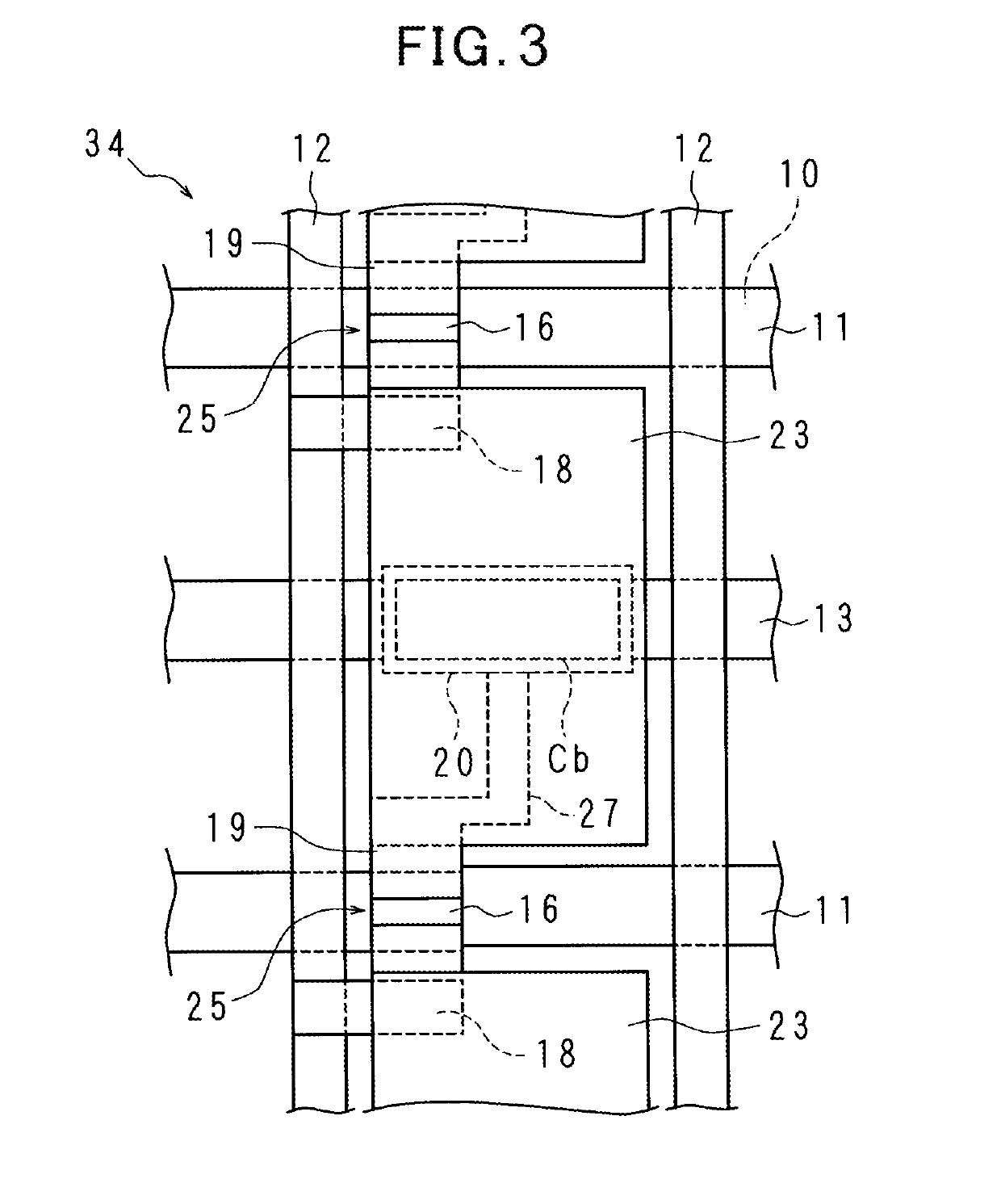

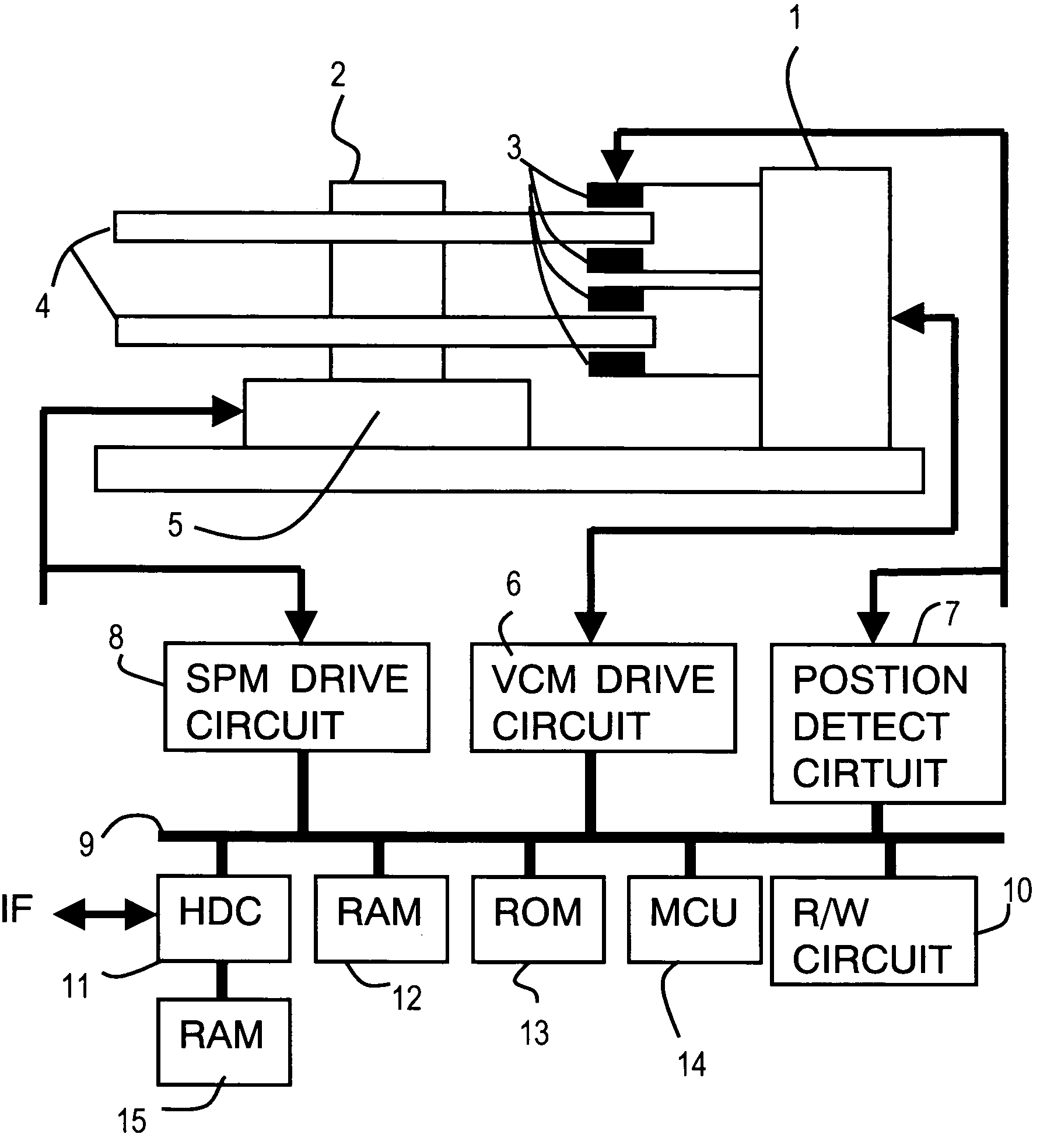

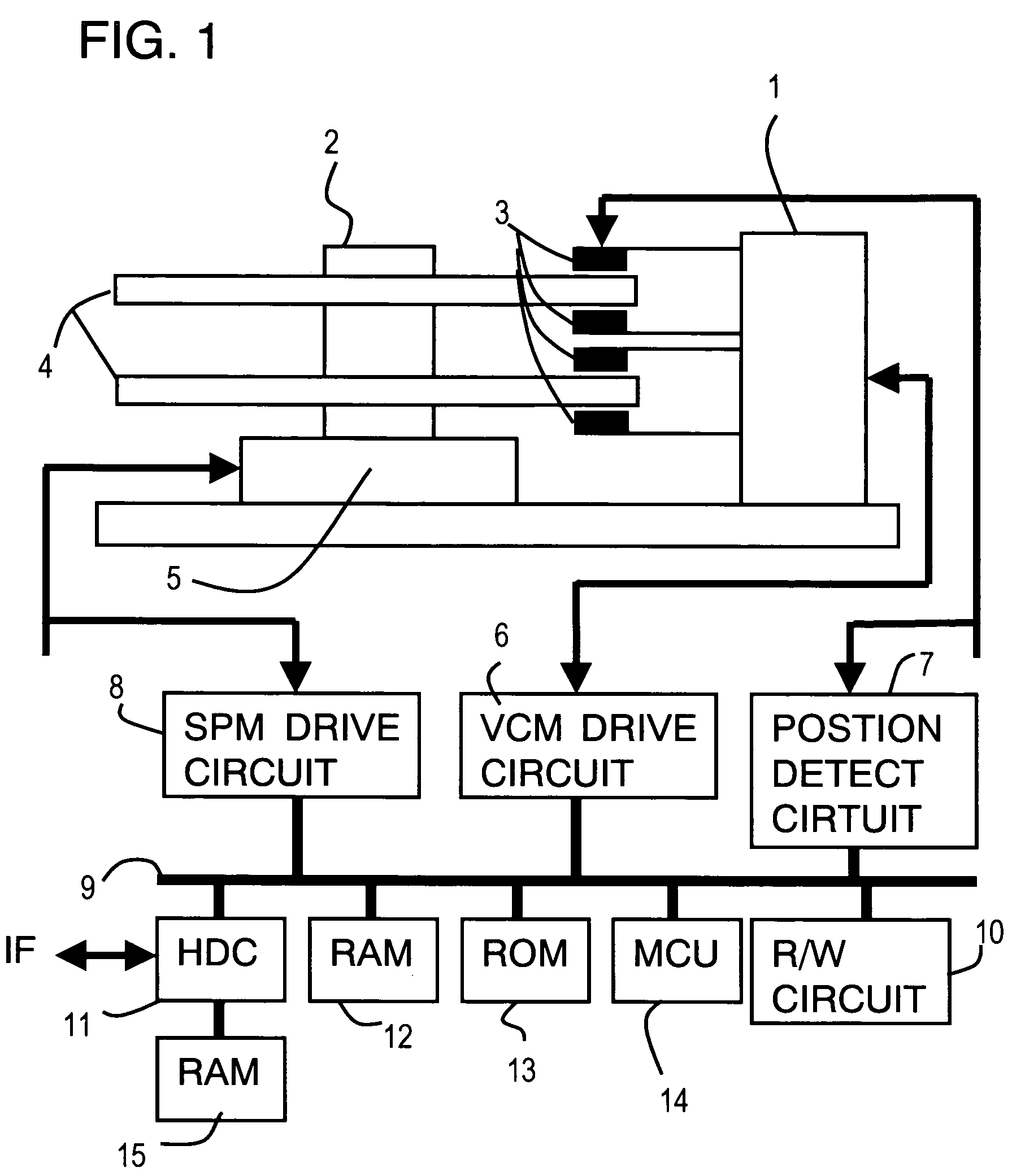

Correction table creation method for head position control, head position control method and disk device

ActiveUS7193808B2High gainSatisfies the specifications of the positioning accuracy in a short timeTrack finding/aligningRecord information storageDisks (device)Control engineering

Owner:KK TOSHIBA

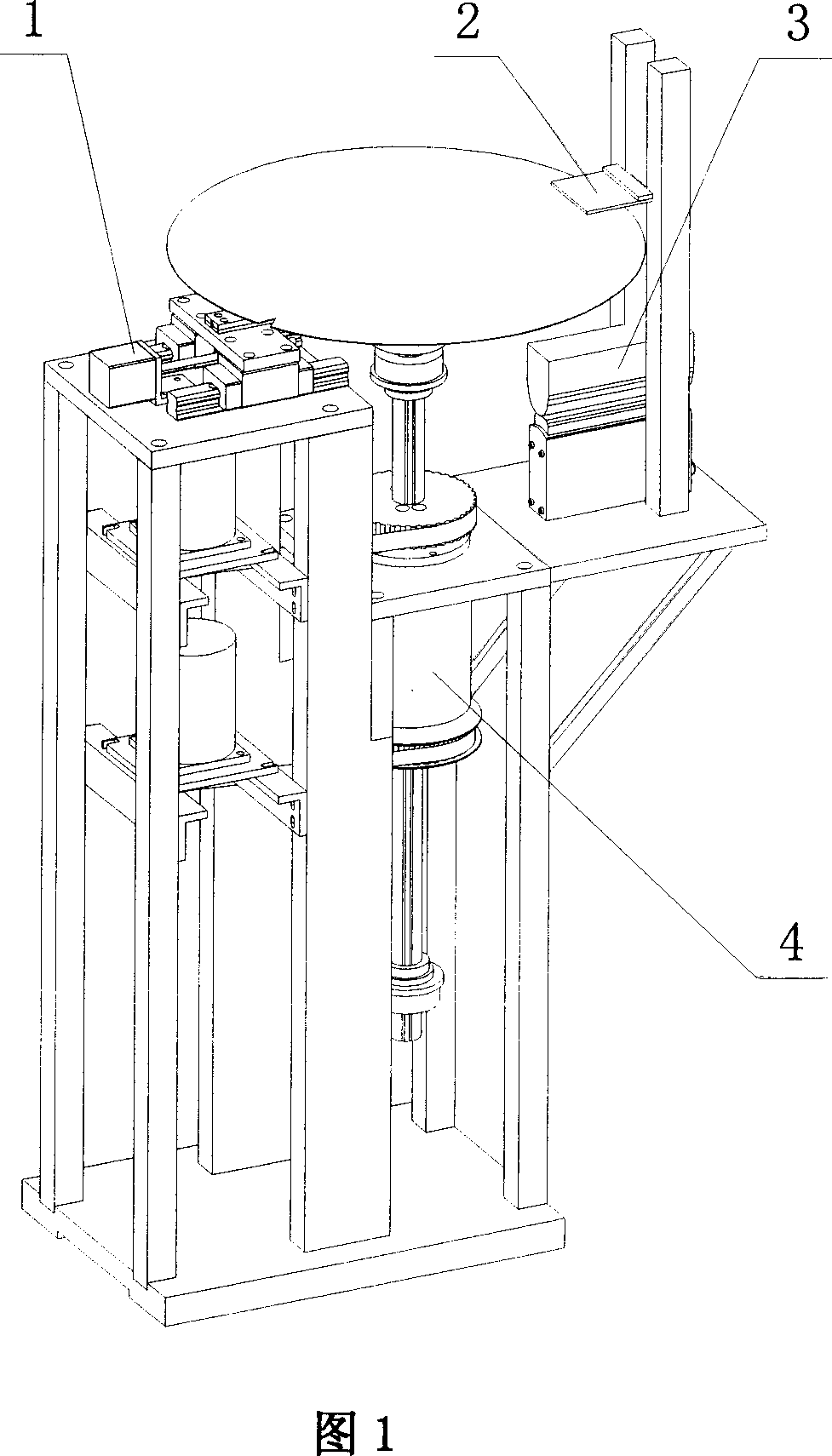

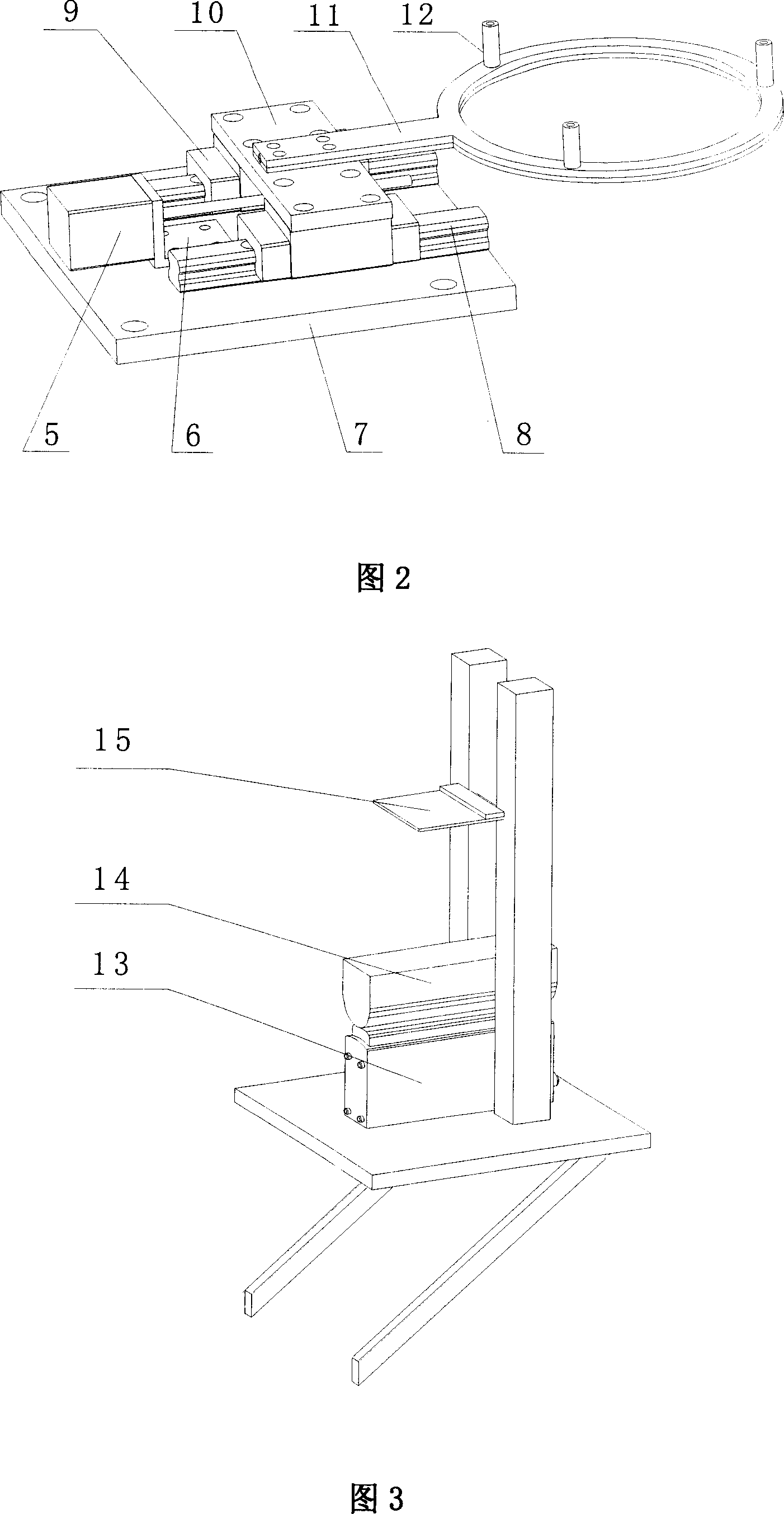

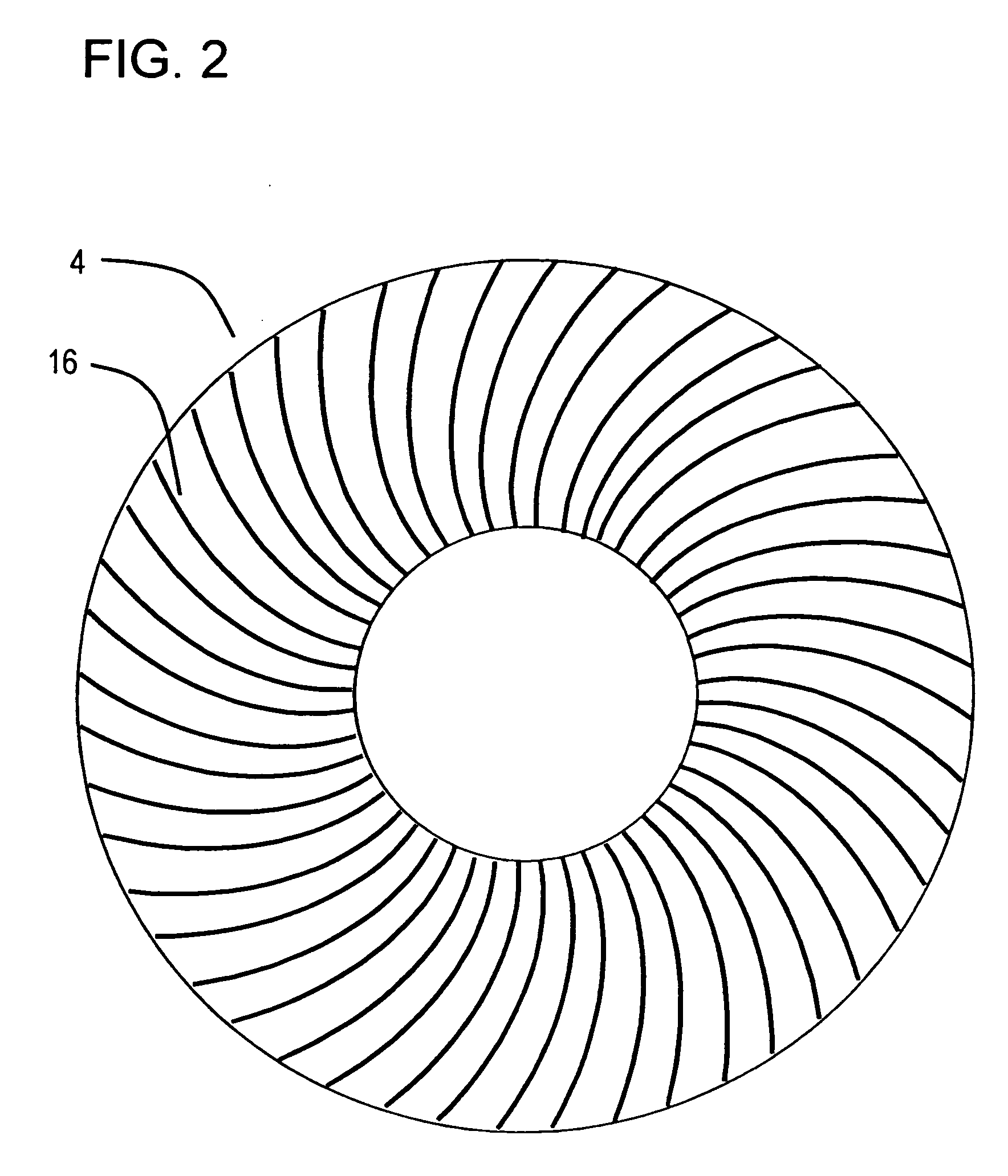

Silicon wafer prealigning device

InactiveCN1937202AImprove the precision of mechanical movementSatisfy positioning accuracySemiconductor/solid-state device manufacturingManufacturing technologyEngineering

The pre alignment apparatus includes horizontal center align unit, TCD detection unit, unit for projecting light, chip load unit, data conversion and control unit. The align unit is in use for adjusting deviation in Y direction of silicon chip. The TCD detection unit is in use for detecting positions of edge, cutting edge, or notch of silicon chip. The unit for projecting light is in use for transmitting parallel beam. The chip load unit is in use for rotating and lifting silicon chip. The data conversion and control unit is in use for receiving, transforming, and sending signal of light intensity of TCD detection unit as well as controlling movement of step motor. Using optical detection instrument and cooperated simple mechanism, the method realizes positioning silicon chip including geometric center, cutting edge or notch in high accuracy. The method can compensate position error of silicon occurred in transmission procedure. Features are: simple algorithm and low cost.

Owner:DALIAN UNIV OF TECH

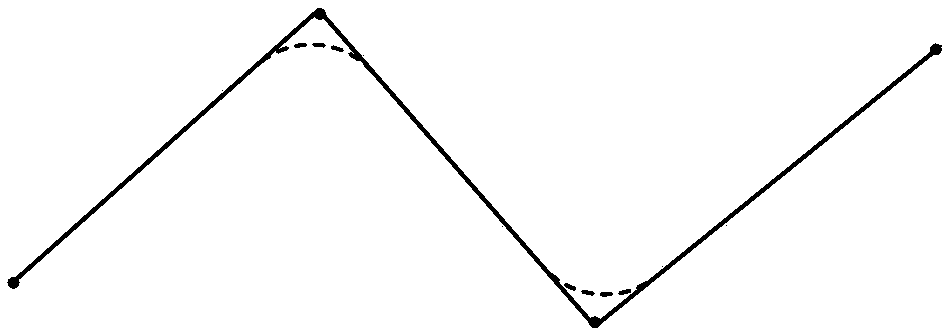

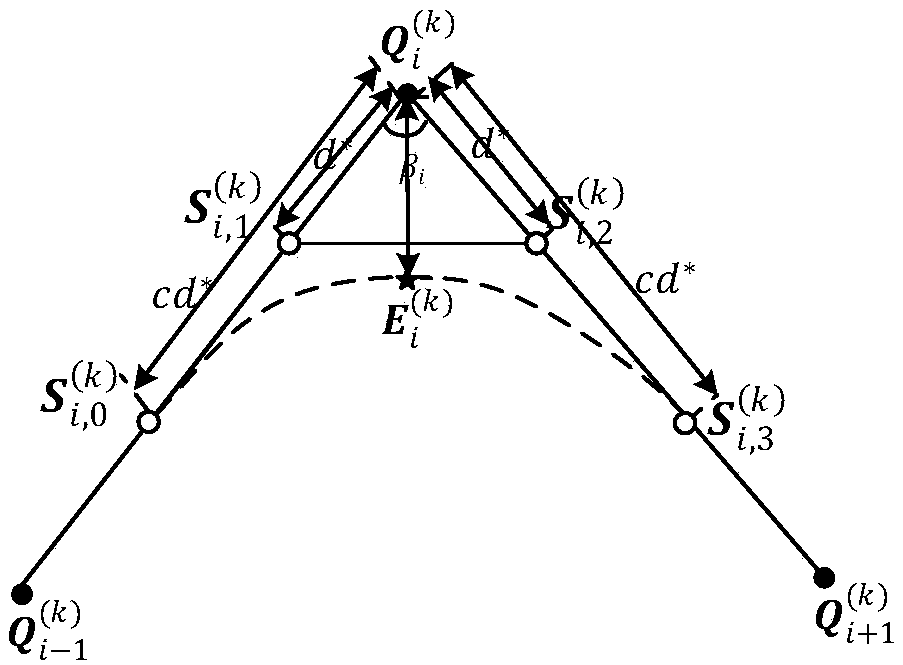

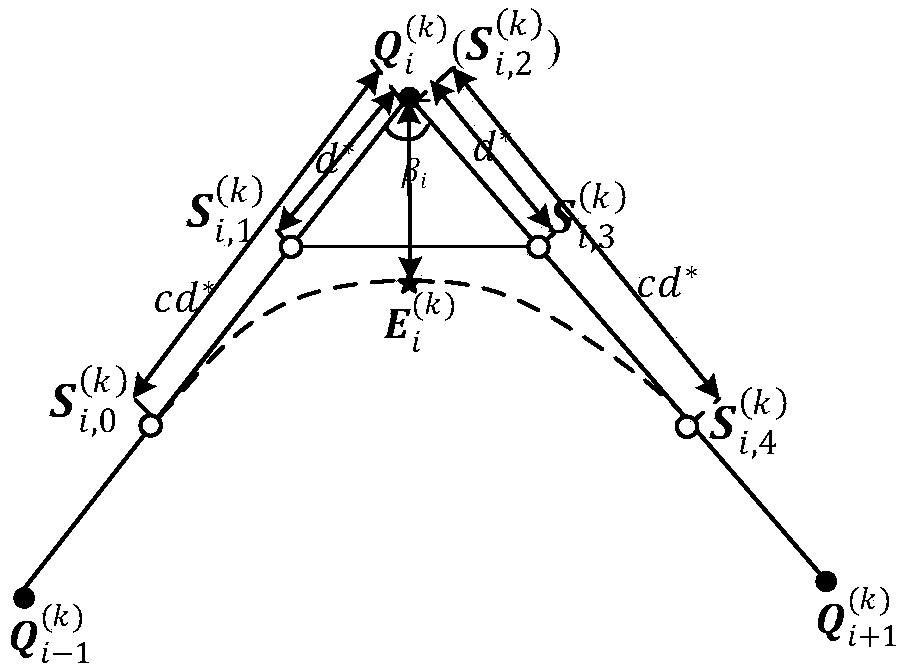

Error-controllable four-axis industrial robot B-spline transition type smooth trajectory generating method

ActiveCN109664303ASatisfy positioning accuracyImprove continuityProgramme-controlled manipulatorPointing errorControl theory

The invention discloses an error-controllable four-axis industrial robot B-spline transition type smooth trajectory generating method which comprises the following steps of step1, pretreatment of a fourth-axis industrial robot trajectory: the trajectory is divided into a trajectory segment requiring smoothness and a trajectory segment without requiring the smoothness, and pretreatment is performedon a four-axis attitude to ensure an inferior arc trajectory between two trajectory points; and step 2, smoothing of a four-axis trajectory B-spline: the trajectory segment, requiring the smoothness,generated in the step 1 is traversed, and a geometric iteration method is adopted to generate a B-spline transition type smooth trajectory according to a trajectory point error threshold value, a position point chord height error threshold value and the continuity requirement for each trajectory segment. The B-spline transition type smooth trajectory is composed of a linear trajectory and a B-spline trajectory, and the whole trajectory has the G1 or G2 continuity with synchronization of a position and a posture, and a position chord height error between the trajectory point error and each trajectory point is satisfied; and in addition, trajectory smoothing of complex application of a four-axis industrial robot can be realized by adopting a spline trajectory, so that the operation efficiency and the quality of the four-axis industrial robot are improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

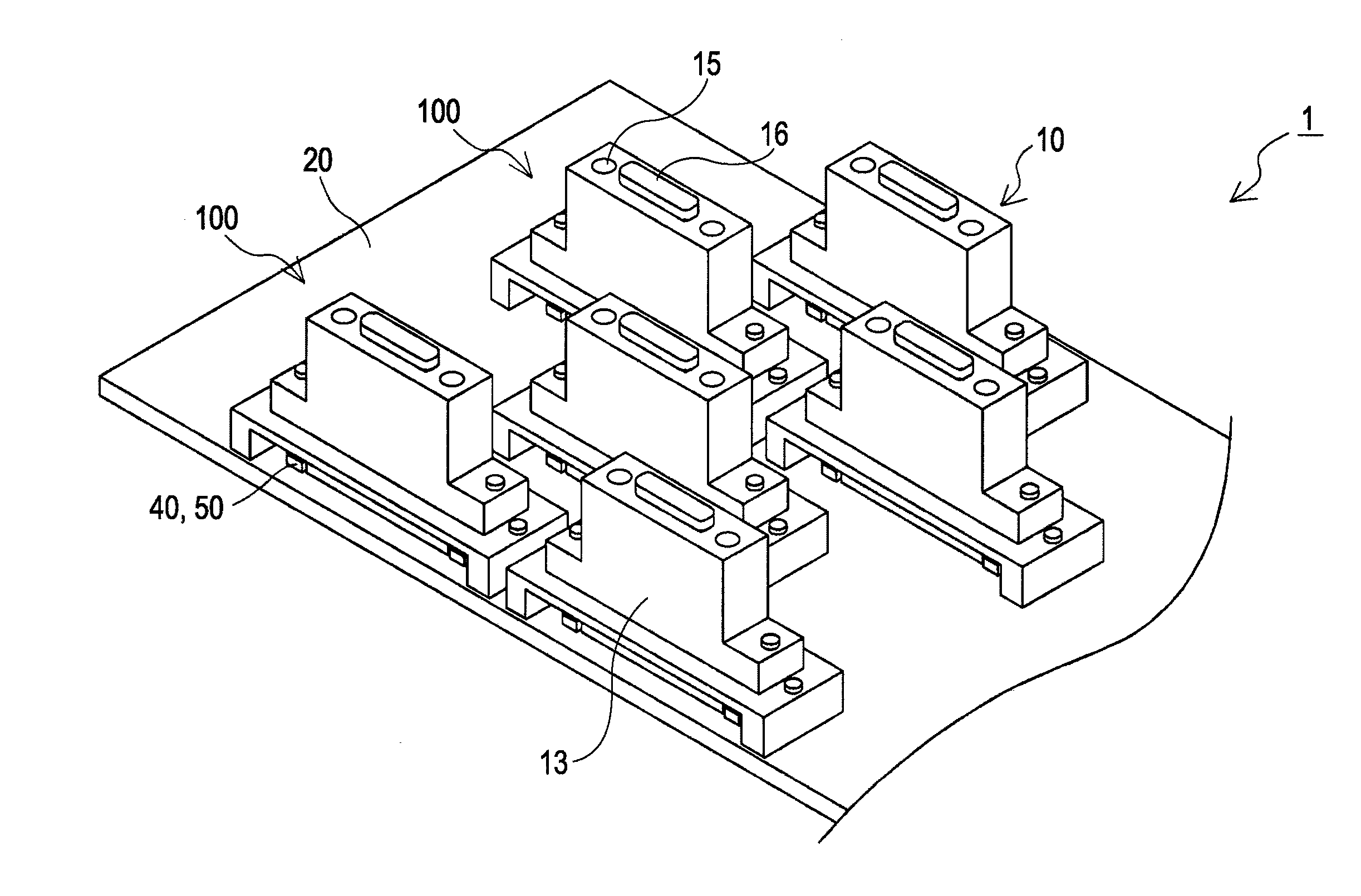

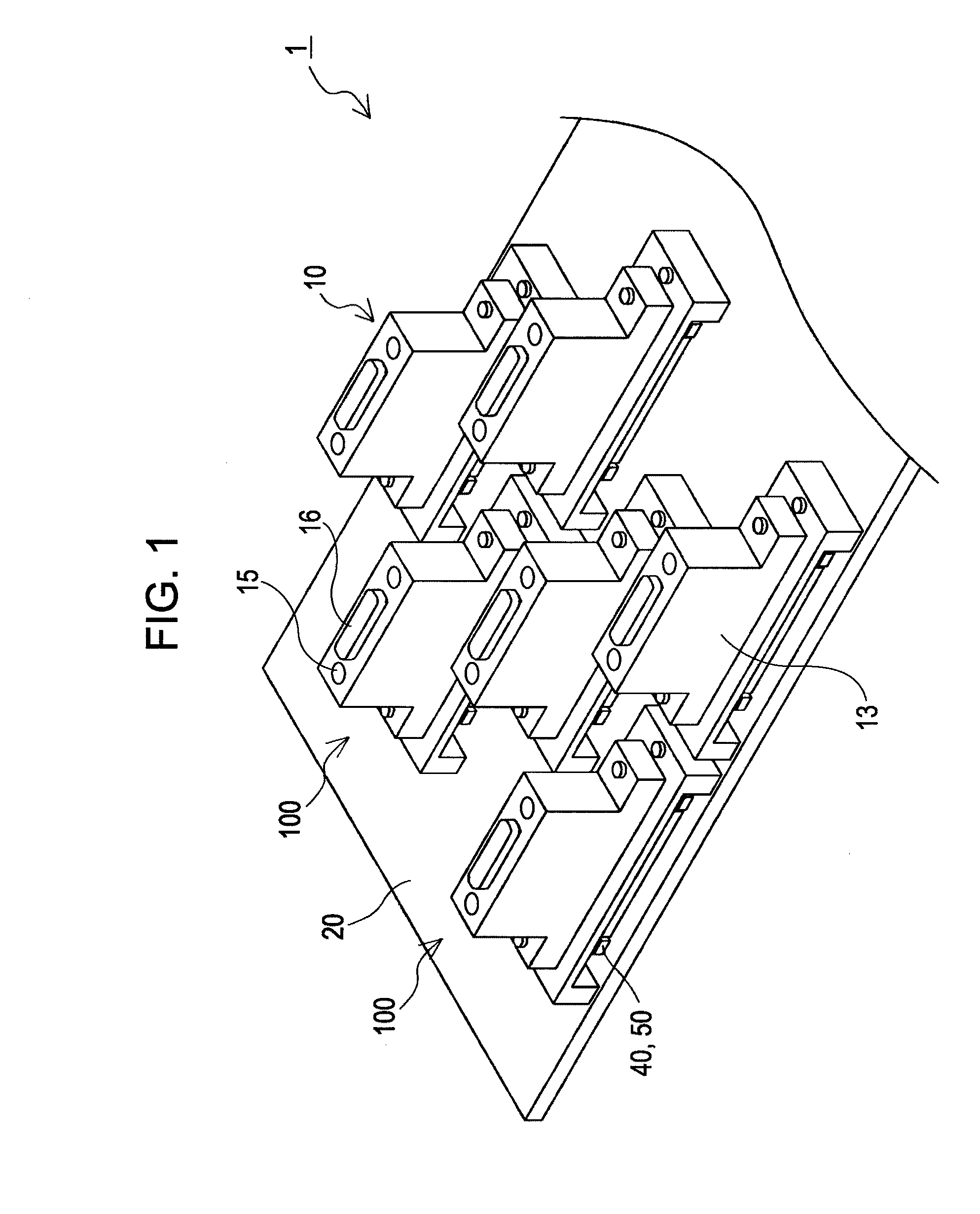

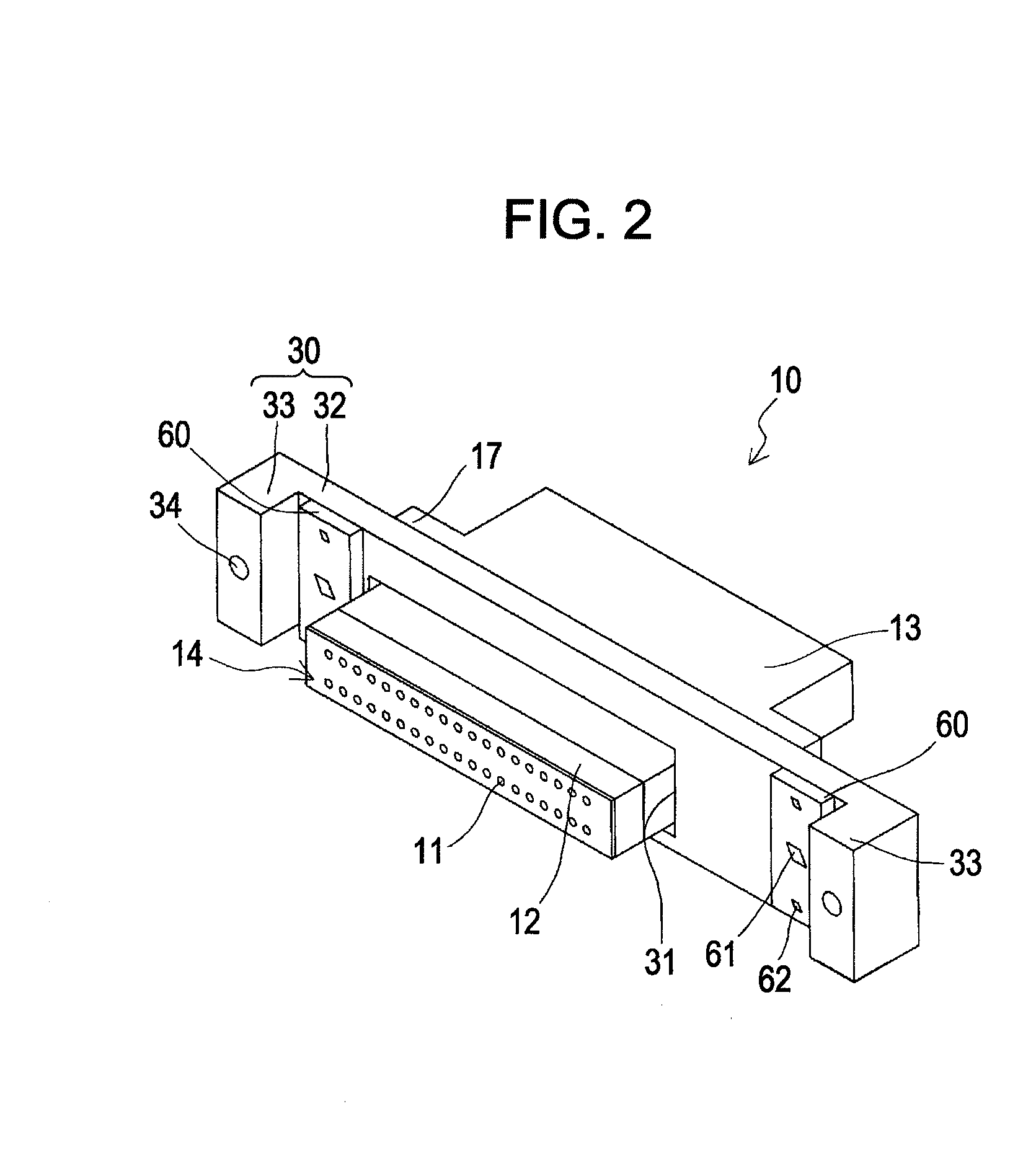

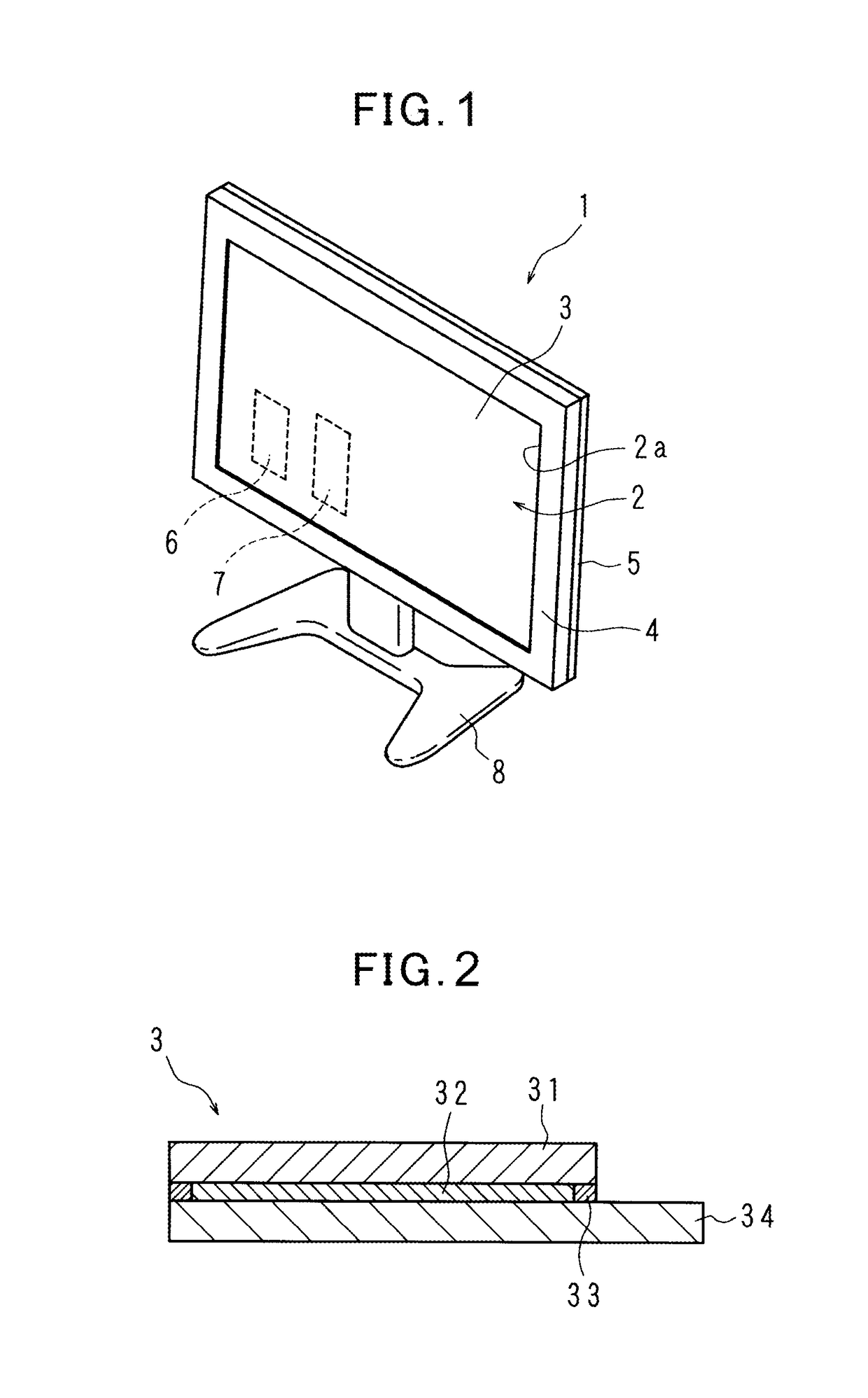

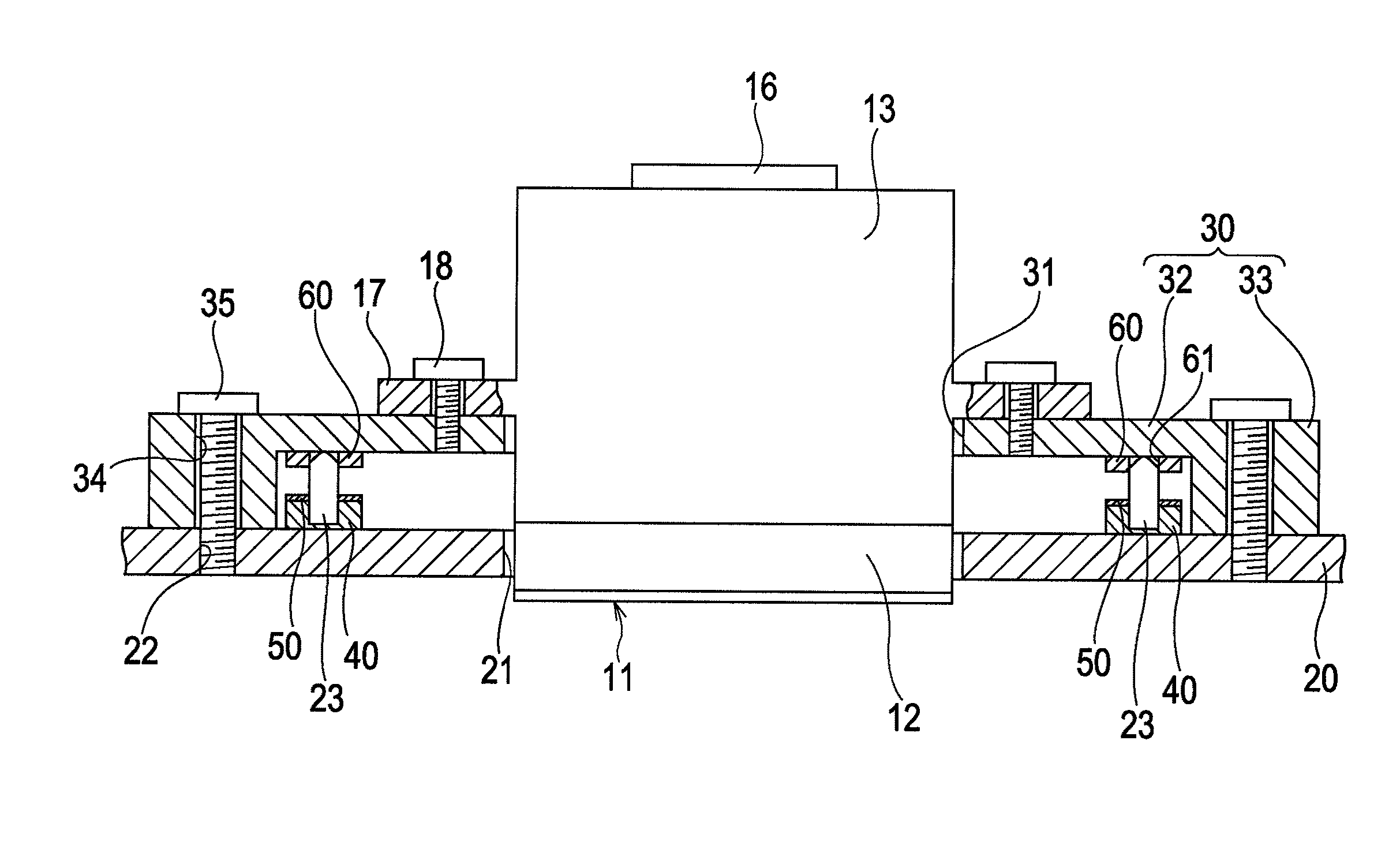

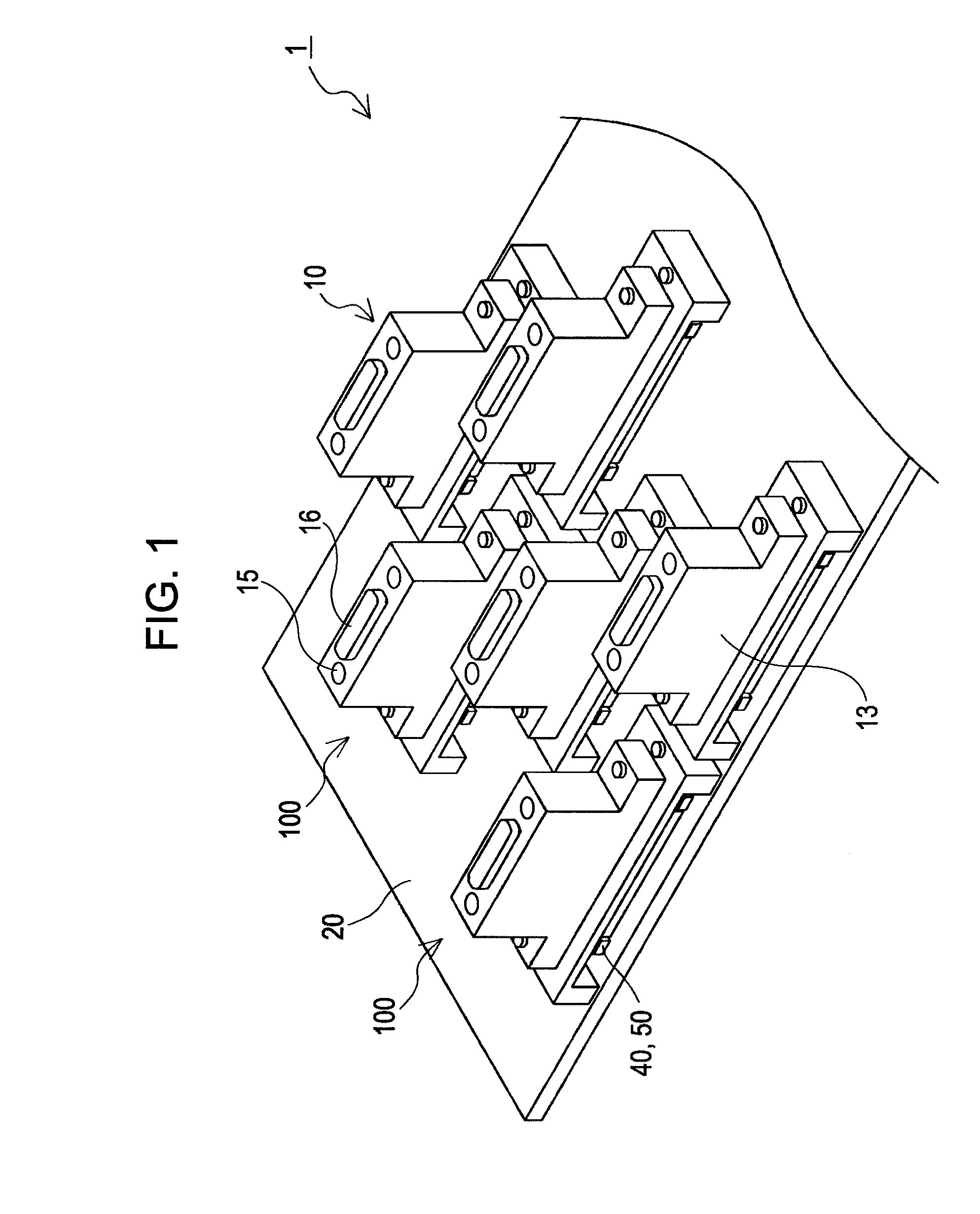

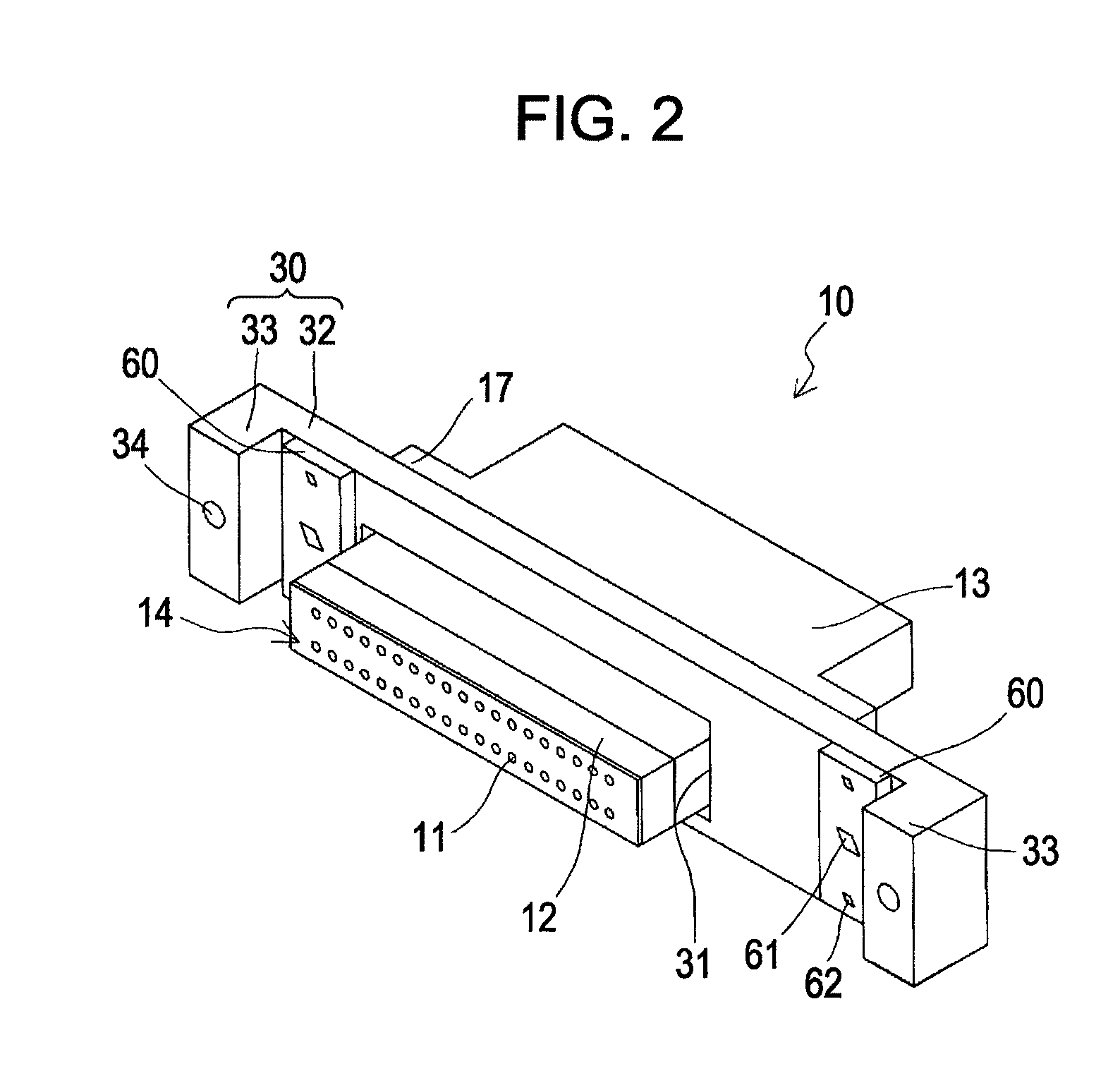

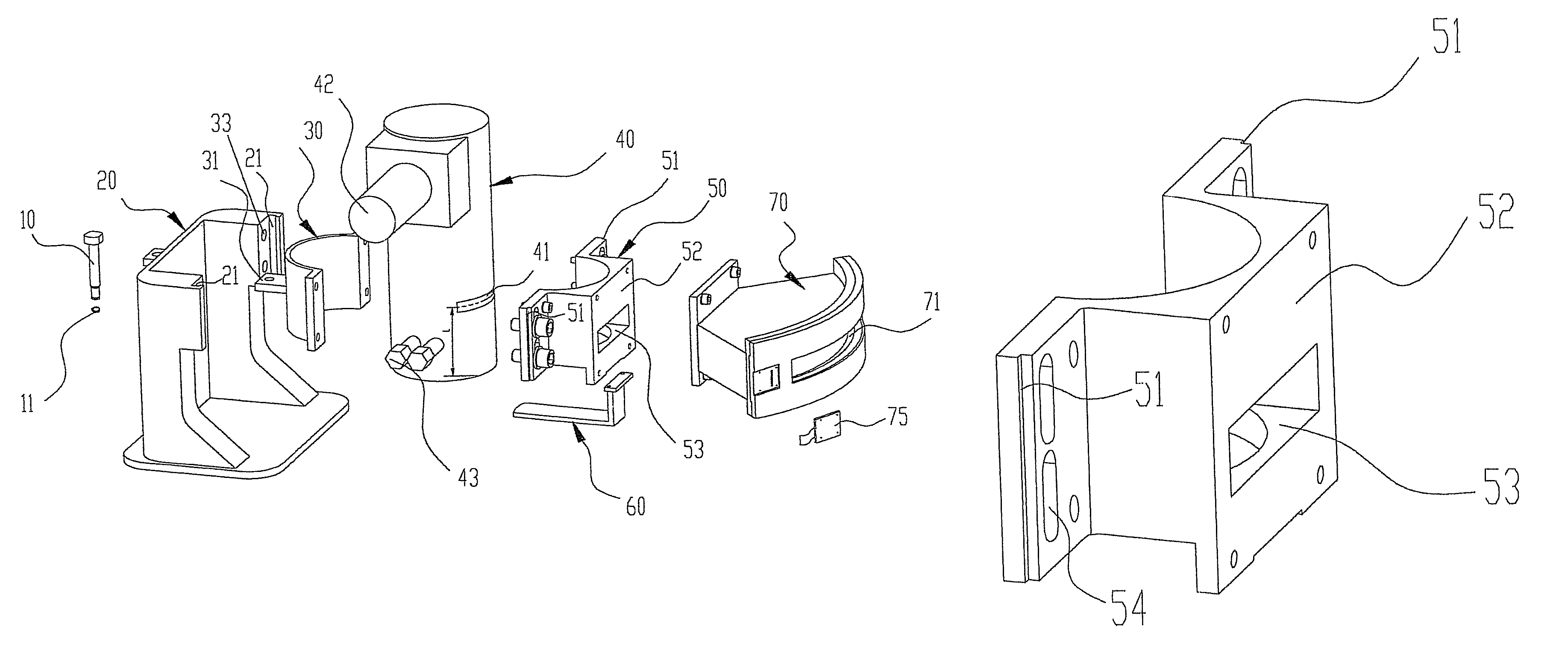

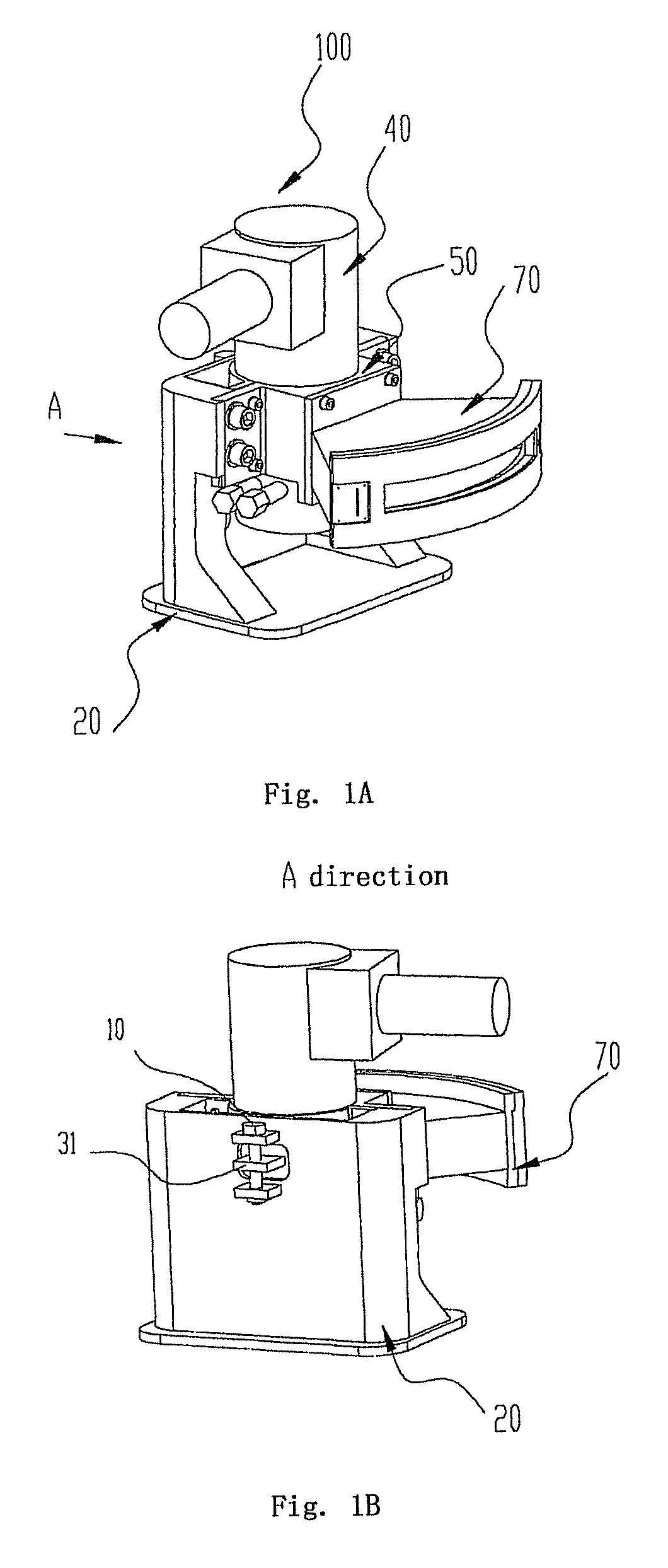

Liquid ejecting head unit and liquid ejecting apparatus

ActiveUS20100214350A1Improve accuracySatisfy positioning accuracyInking apparatusOther printing apparatusEngineeringLiquid drop

A liquid ejecting head unit includes: a plurality of liquid ejecting heads, each of which has a nozzle array in which nozzles ejecting liquid droplets are arrayed; a base plate to which the plurality of liquid ejecting heads are fixed in a state being positioned at predetermined positions thereof; and positioning pins which are fixed to the base plate and engaged with positioning holes formed in the liquid ejecting heads. Each of the positioning pins is held in a holding hole provided in a fixing plate fixed to the base plate. A reference plate is joined to a surface of each of the fixing plates. Further, in each of the reference plates, there are provided: an insertion hole in which the positioning pin is substantially inscribed; and a minute hole that serves as a reference for positioning the positioning pin to the base plate.

Owner:SEIKO EPSON CORP

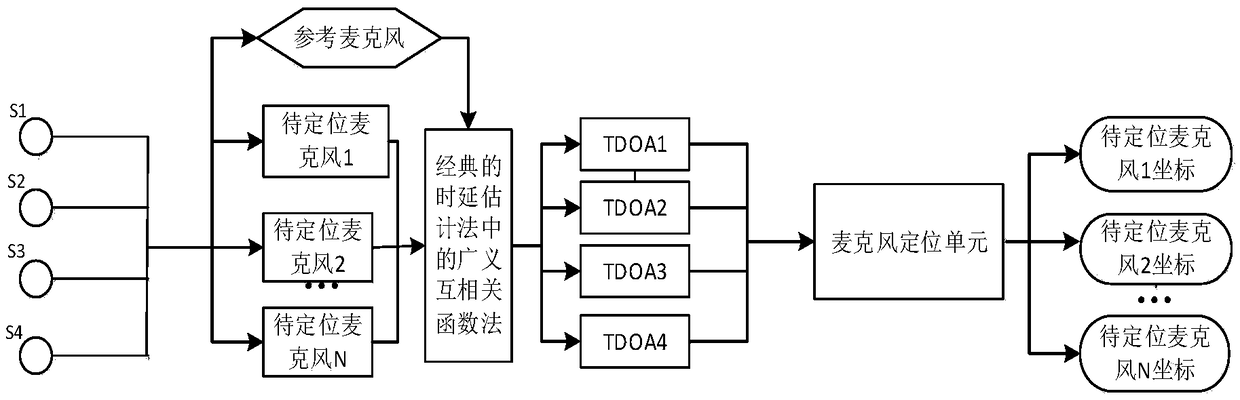

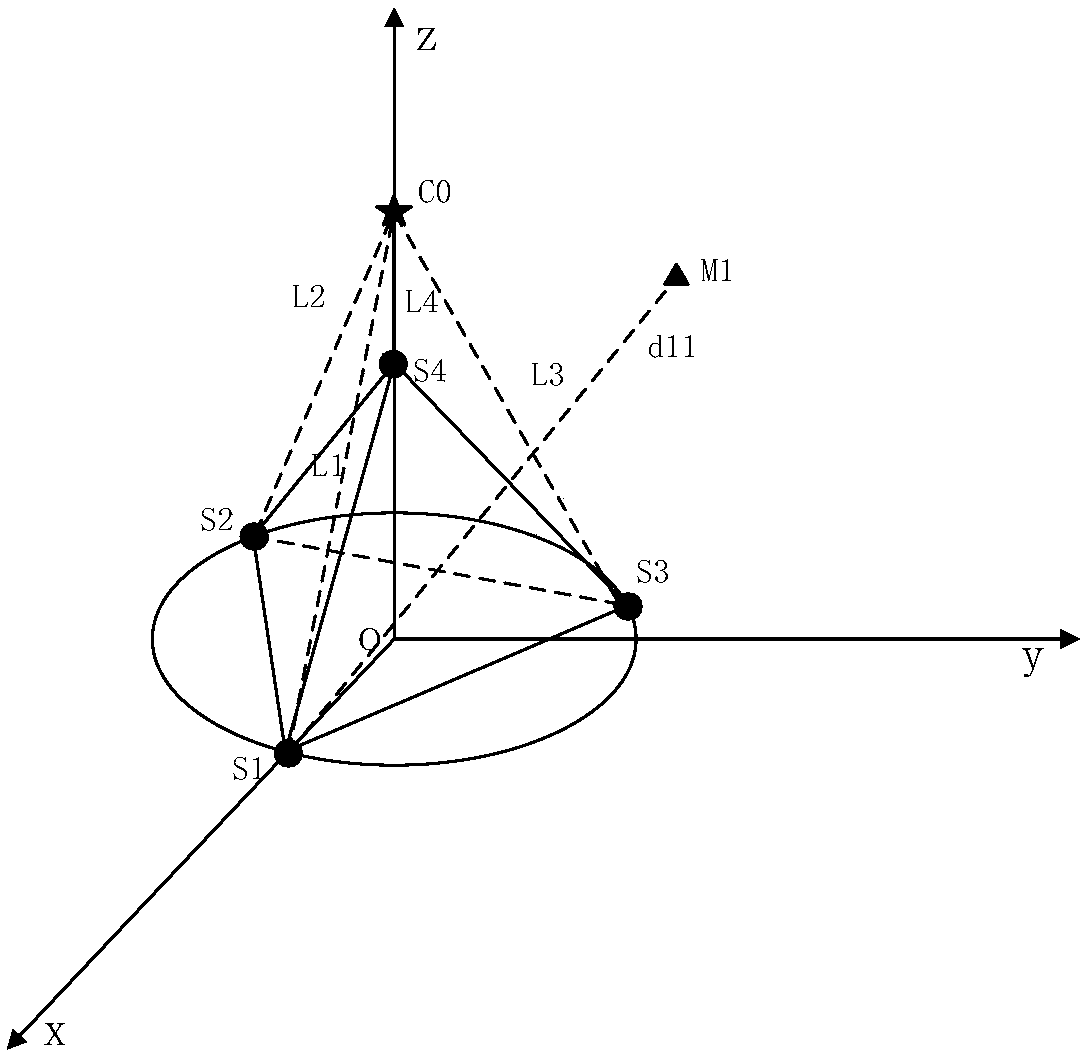

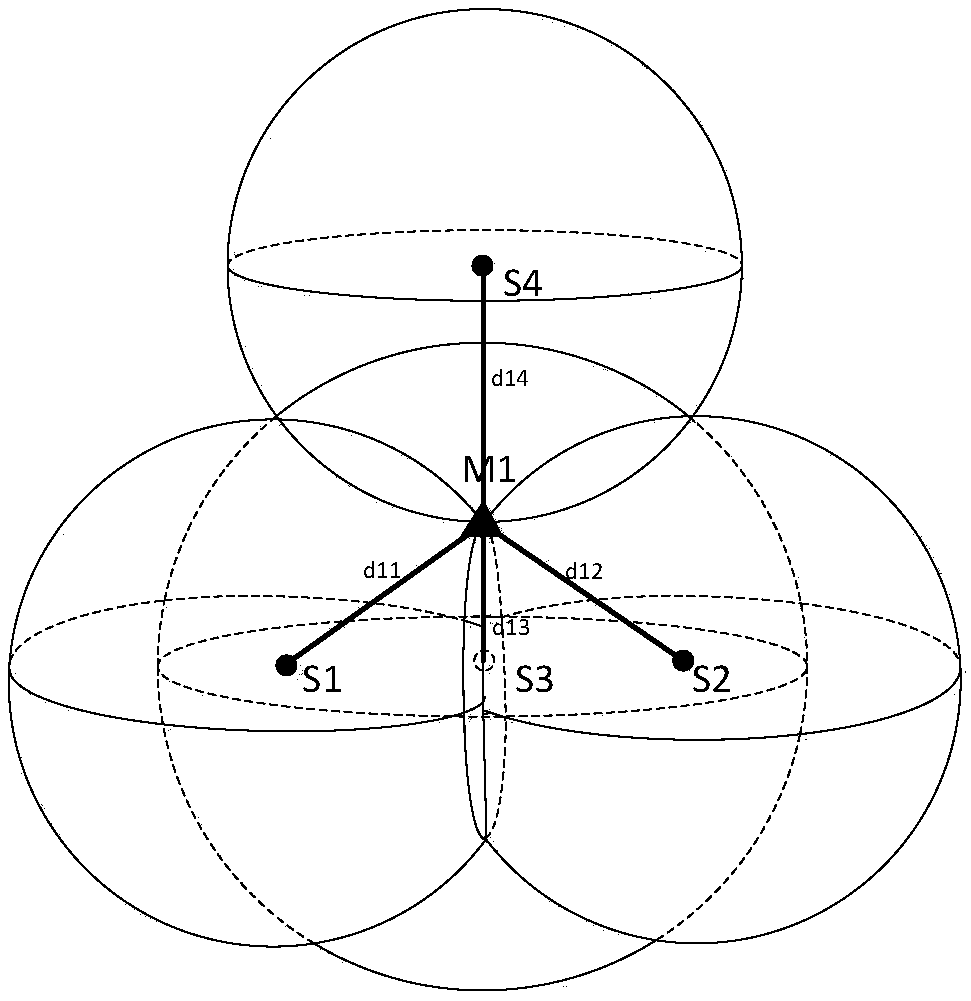

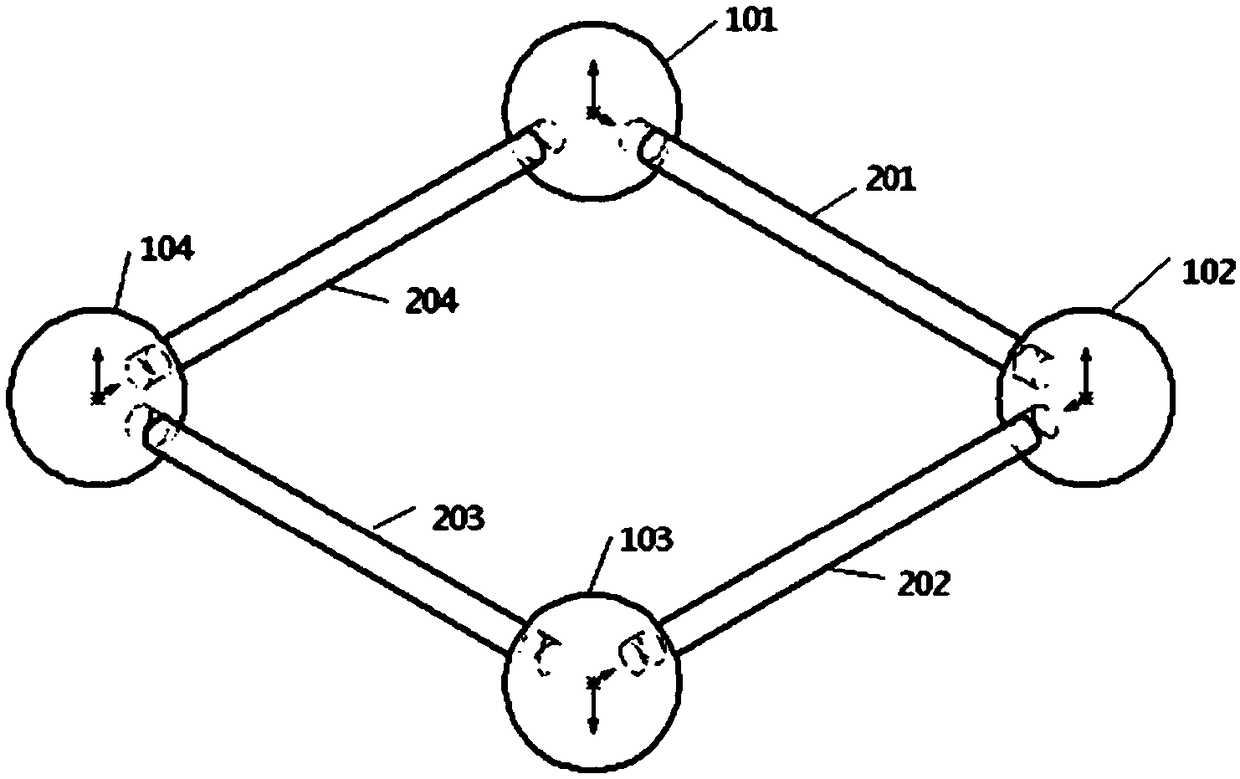

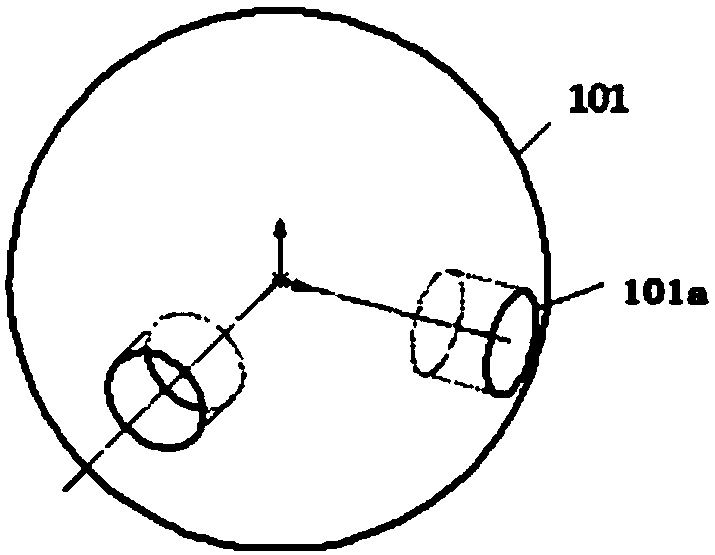

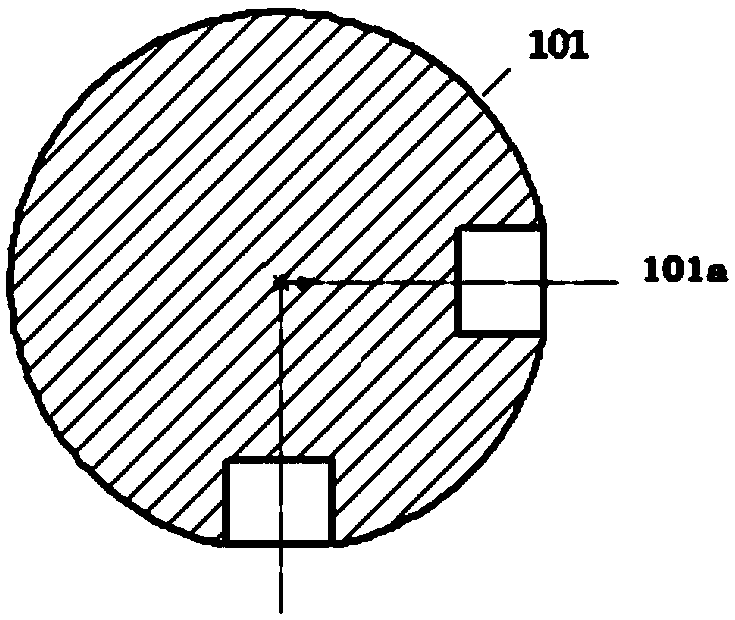

Space microphone positioning method based on sound source array

ActiveCN108802689AOutstanding FeaturesHighlight significant progressPosition fixationSound sourcesThree-dimensional space

The invention discloses a space microphone positioning method based on a sound source array and relates to sound wave application. Cooperation of multiple position lines determined by path differencemeasuring is utilized to determine position of a signal source, and online positioning of a microphone in three-dimensional space is realized by utilizing sound signals of four sound sources and fixeddistance between a reference microphone and each sound source. The method includes steps: subjecting the sound sources to quaternary three-dimensional array distribution; arranging the reference microphone; marking a to-be-positioned microphone; using a microphone positioning unit to position spatial position of the to-be-positioned microphone. By the method, the defects that signal collection istroublesome in operation and low in efficiency, only offline calculation is supported, online estimation of microphone position cannot be realized and position estimation of spatially distributed microphones cannot be realized due to the fact that position estimation is performed only on planar microphone arrays are overcome.

Owner:HEBEI UNIV OF TECH

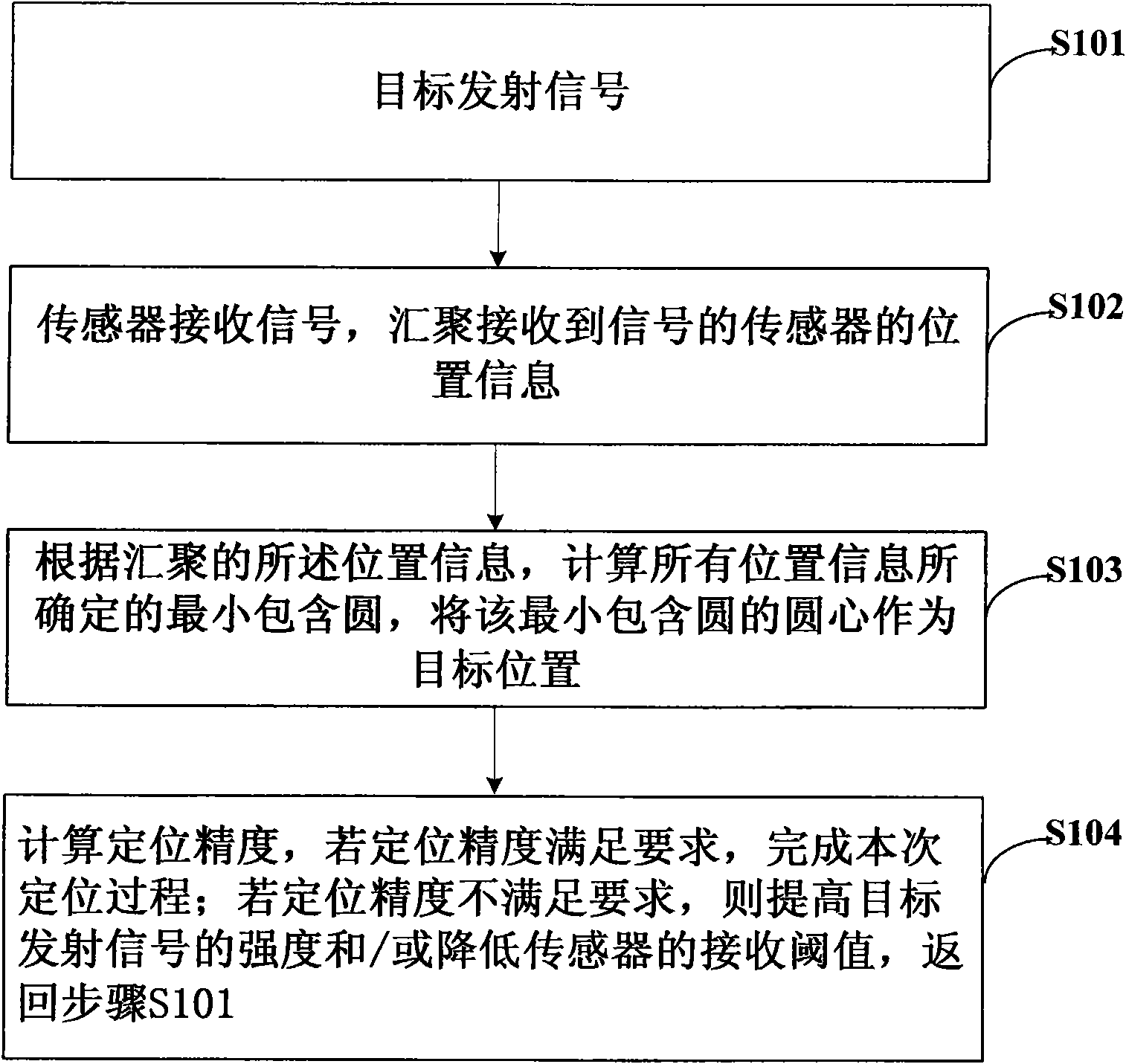

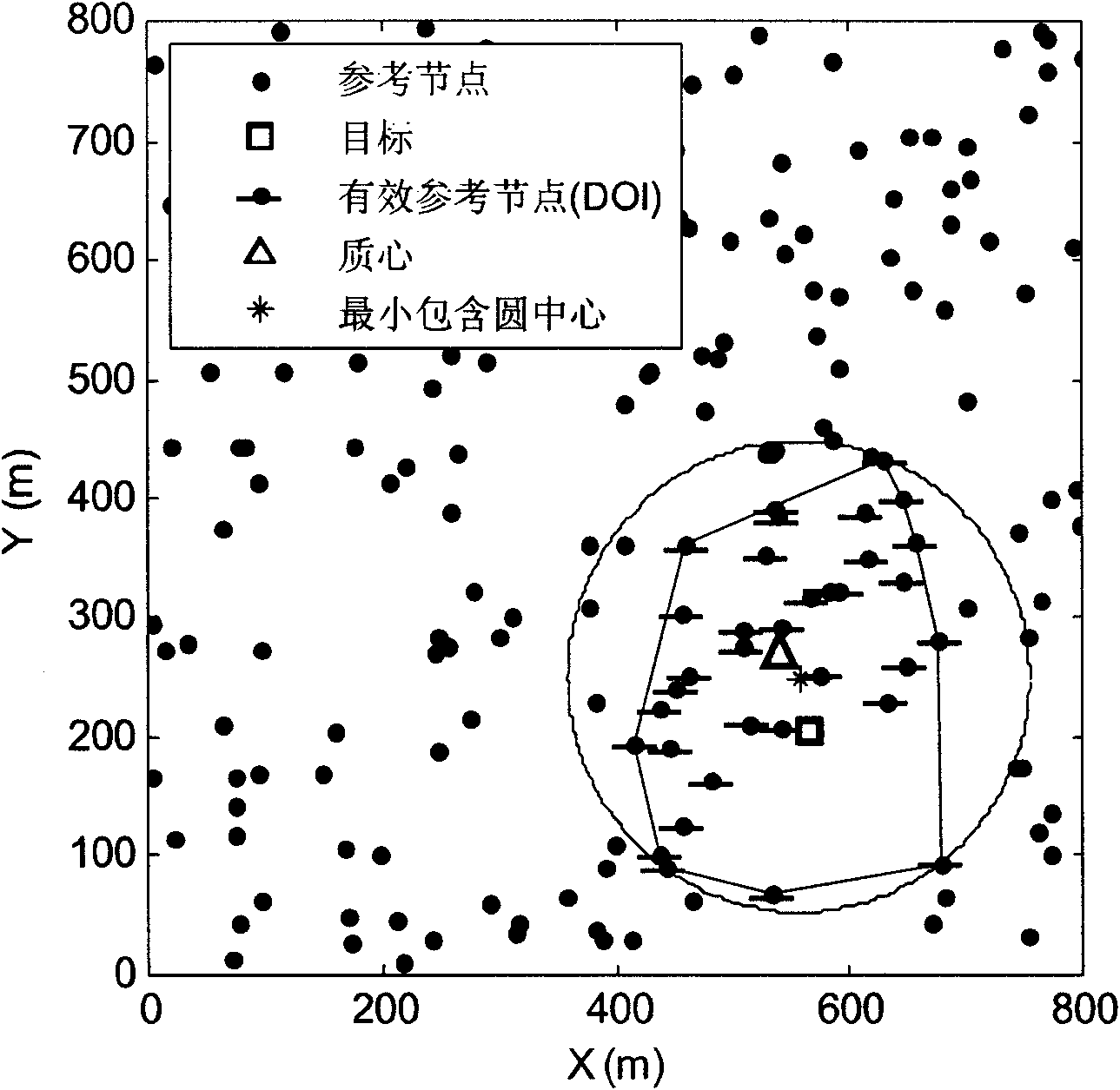

Positioning method and device in sensor network

ActiveCN101634699ASatisfy positioning accuracyReduce communication load and power consumptionPosition fixationReal-time computingSensor web

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

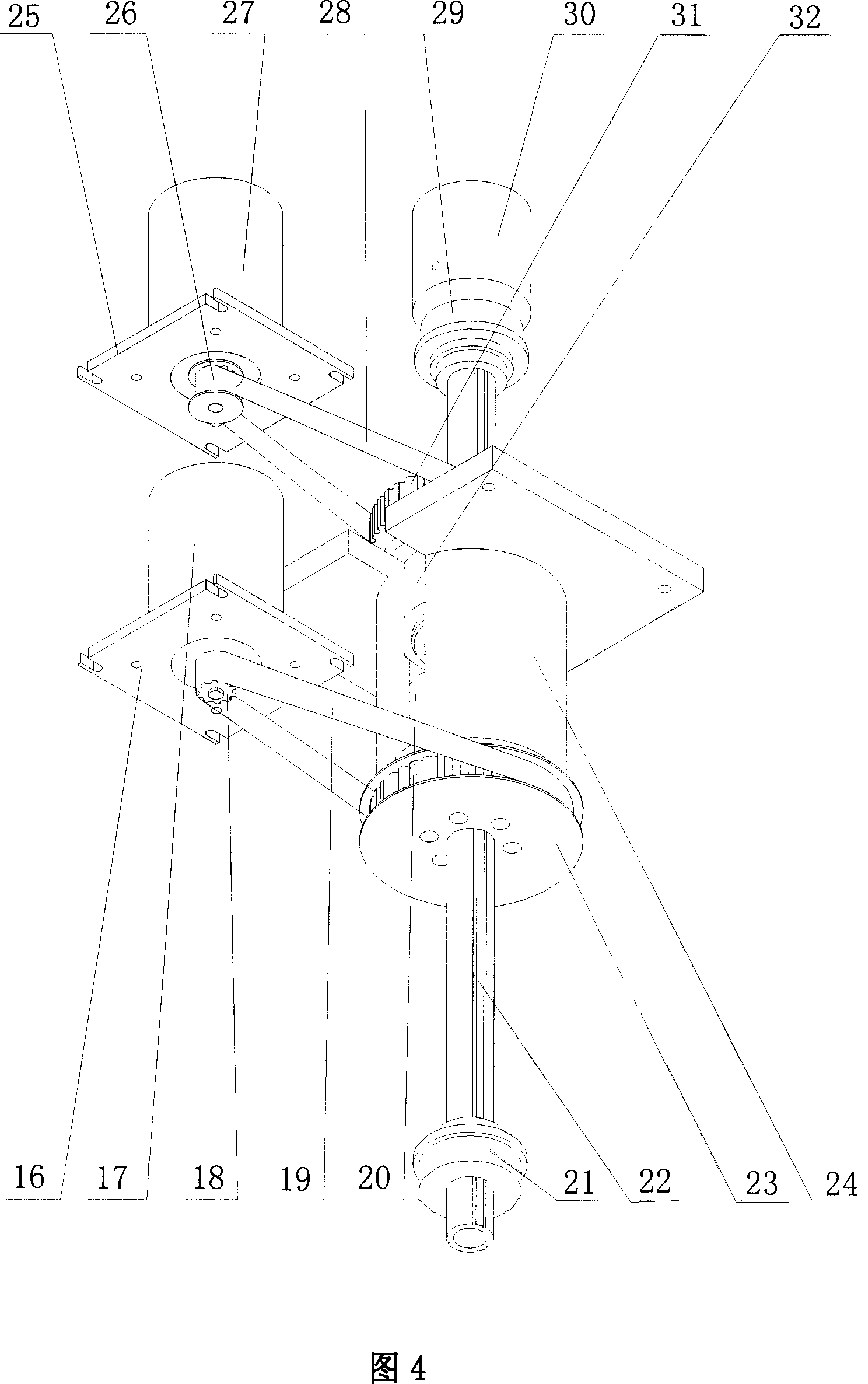

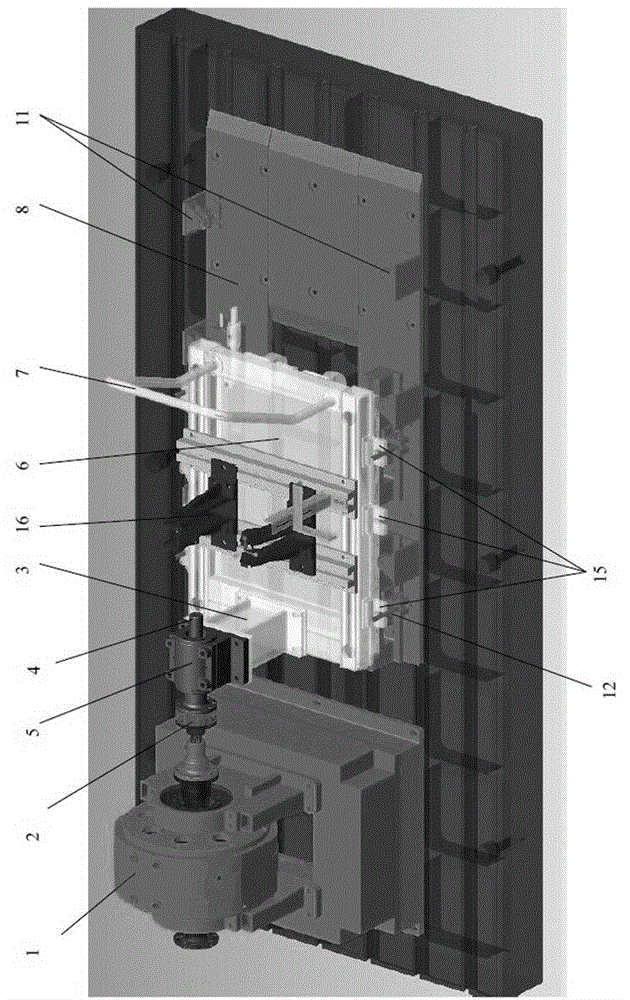

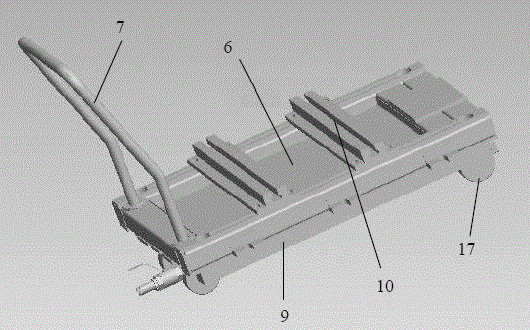

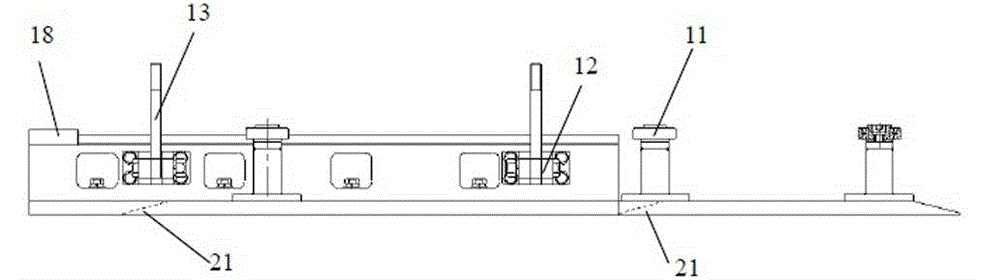

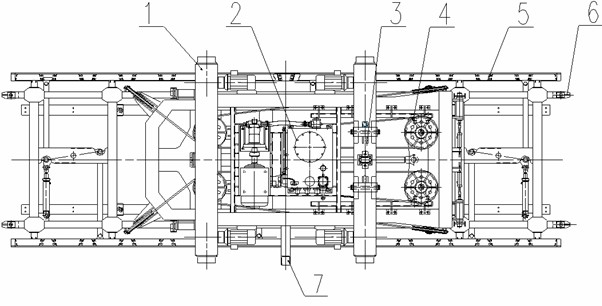

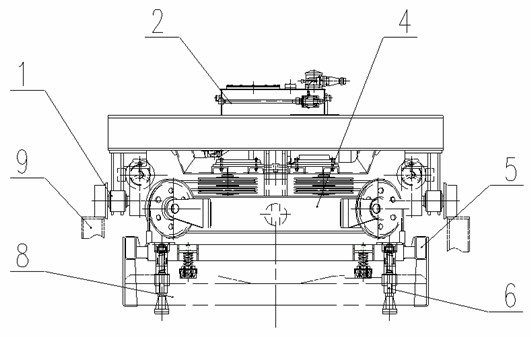

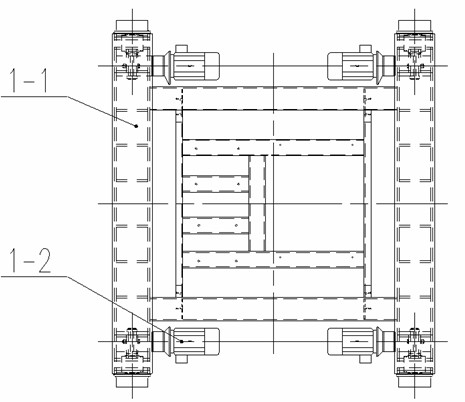

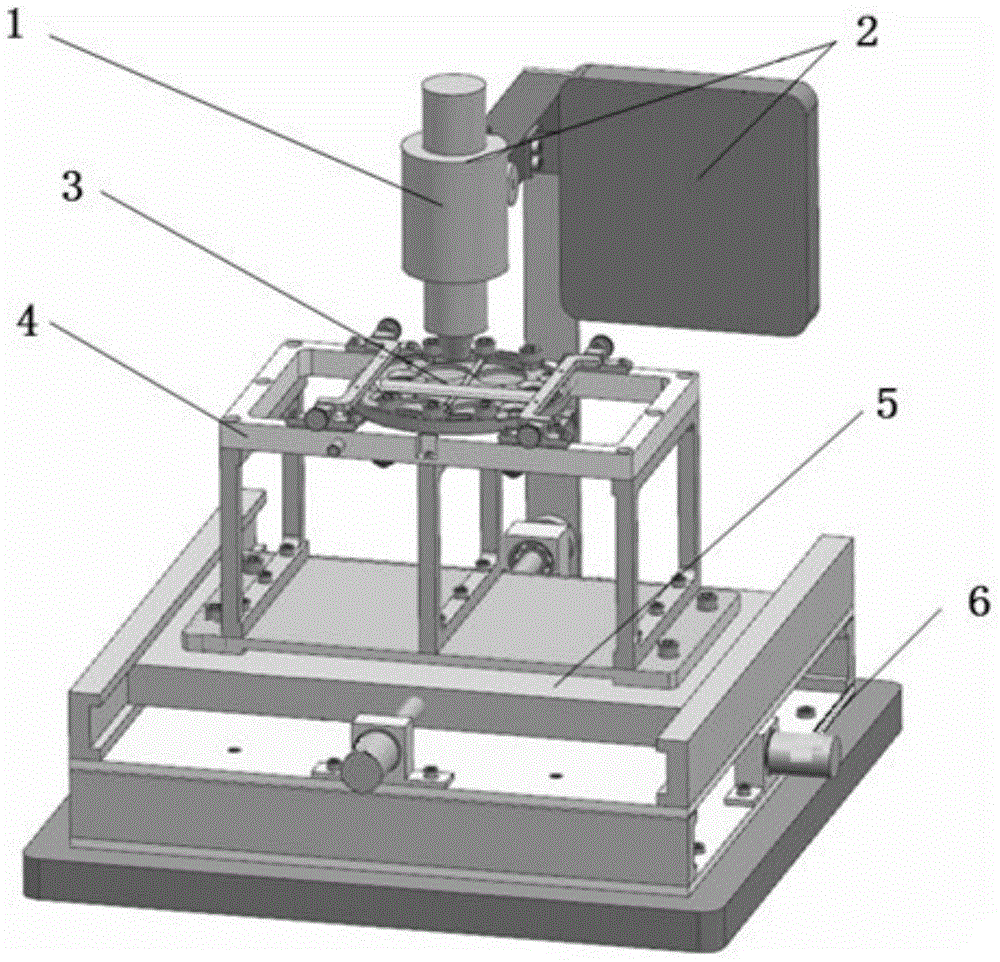

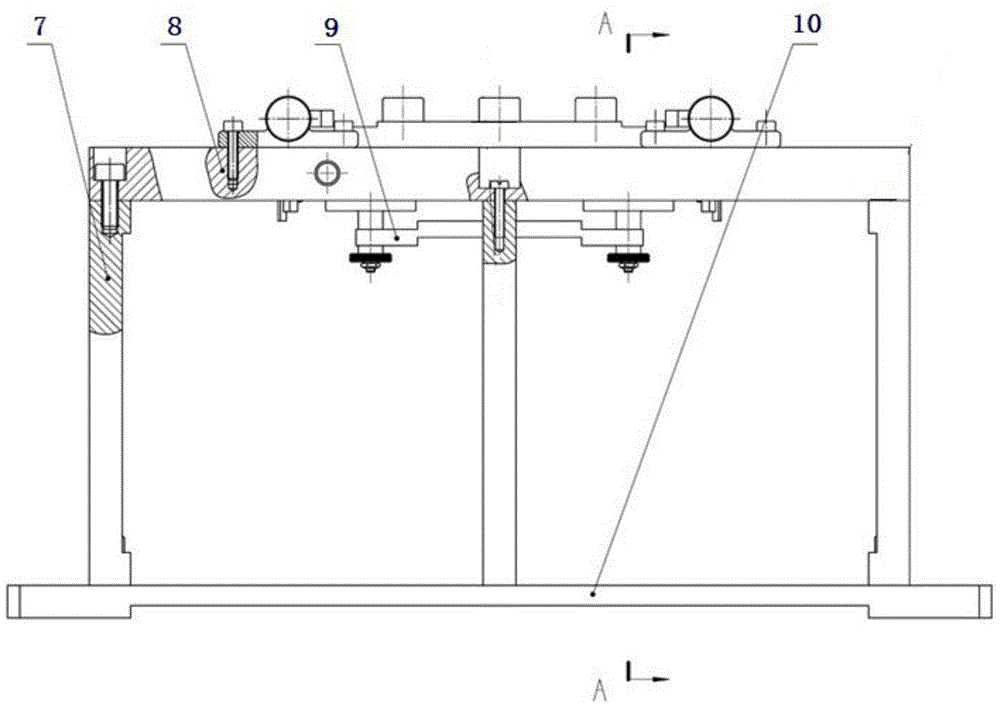

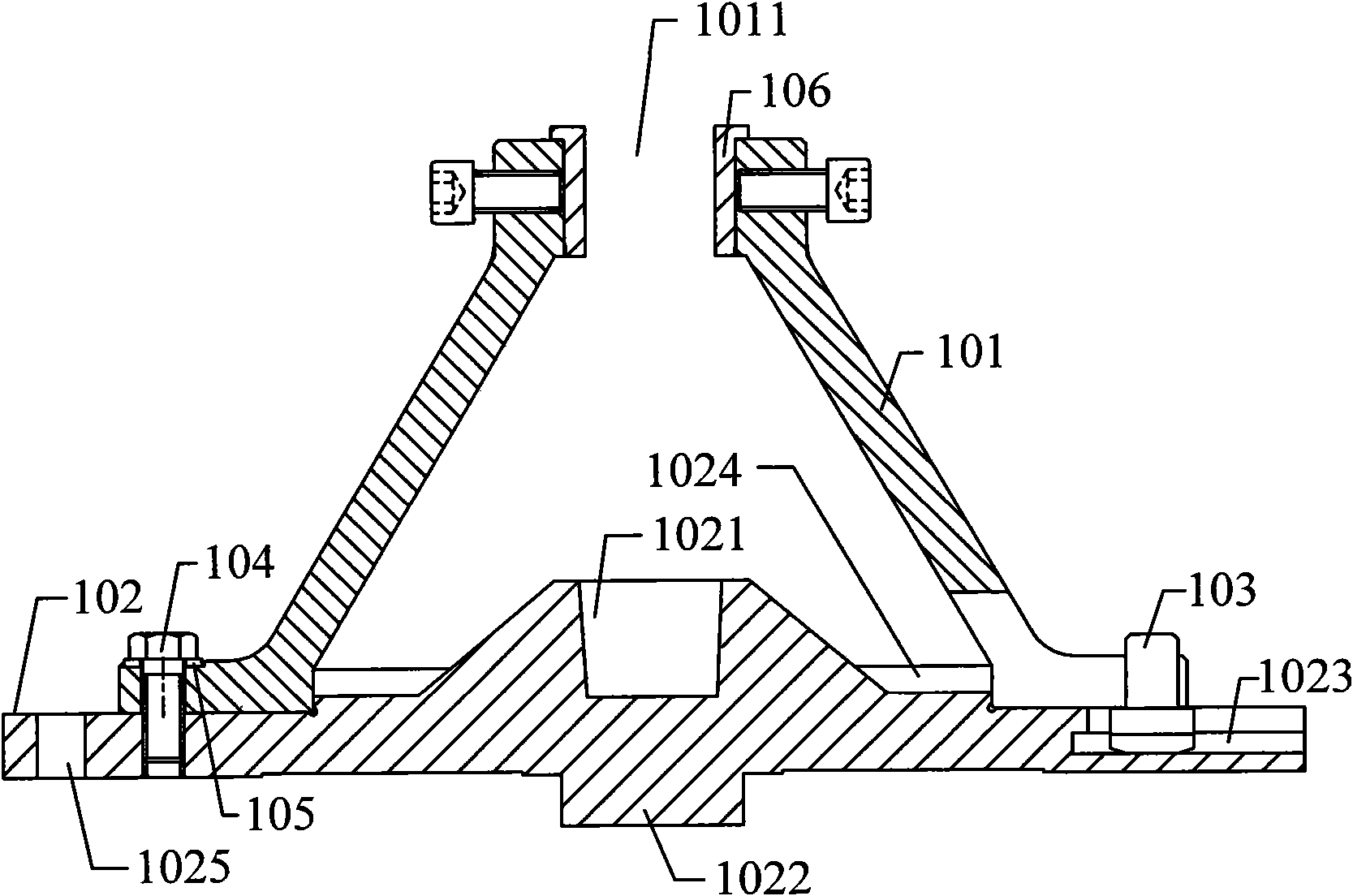

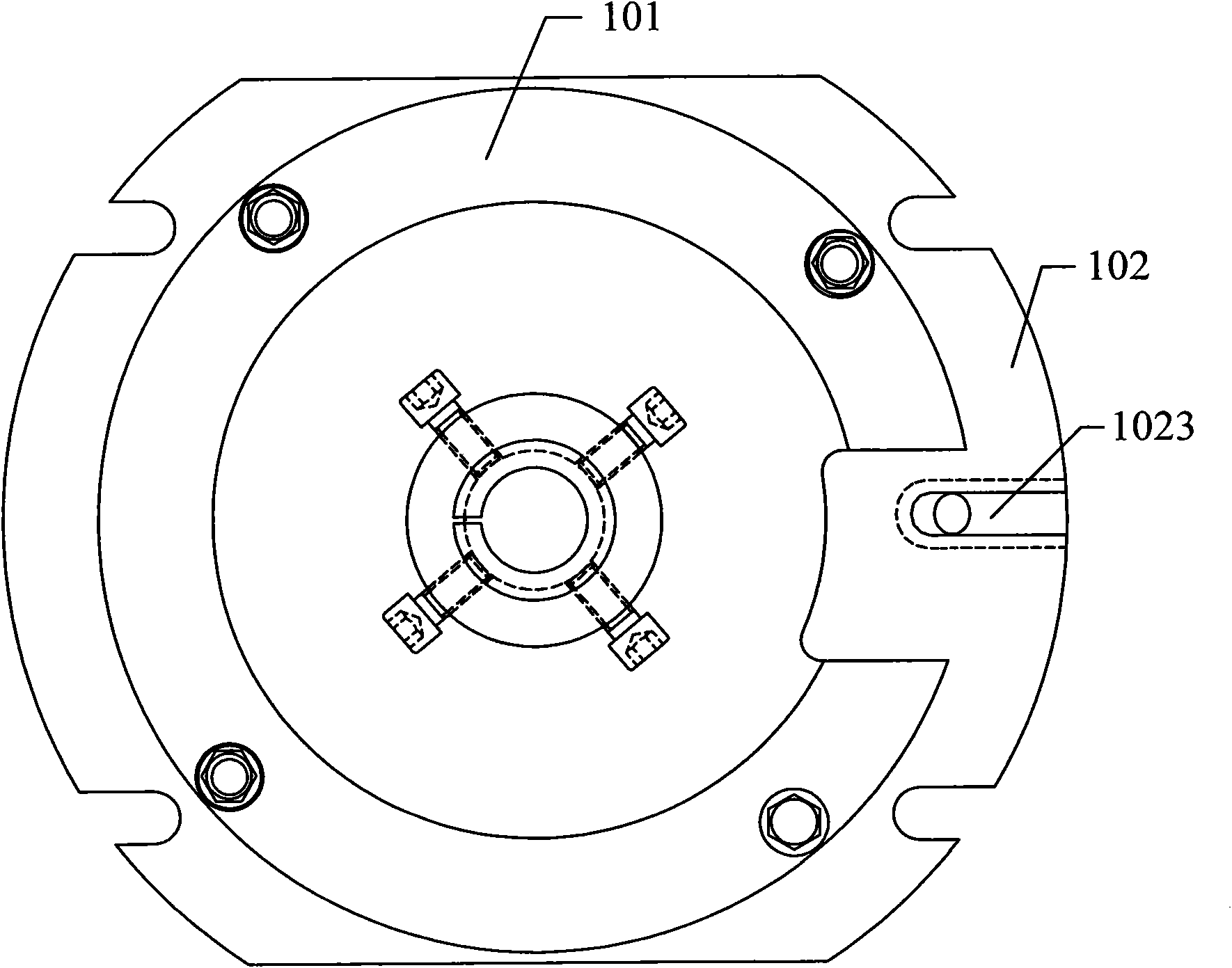

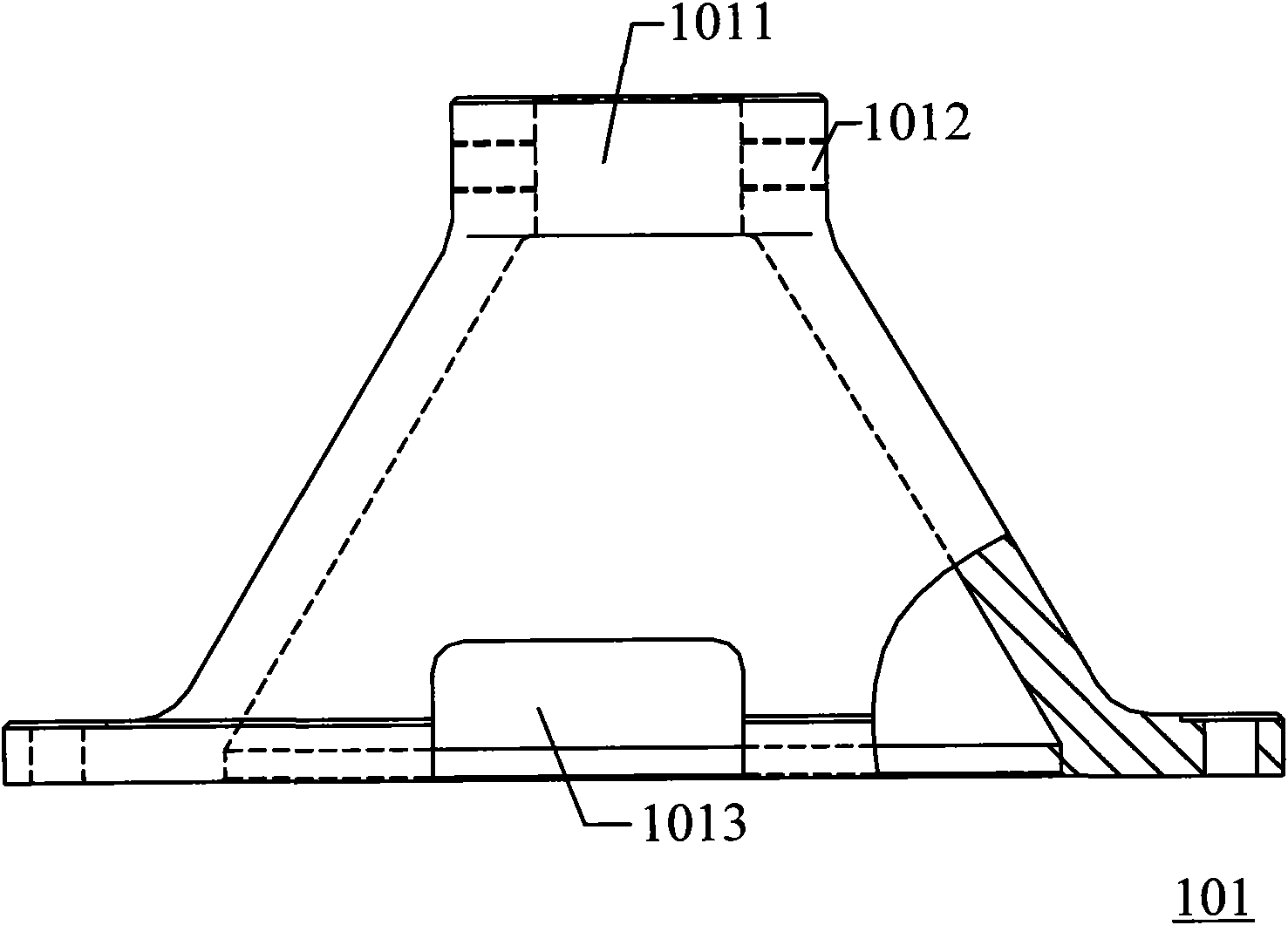

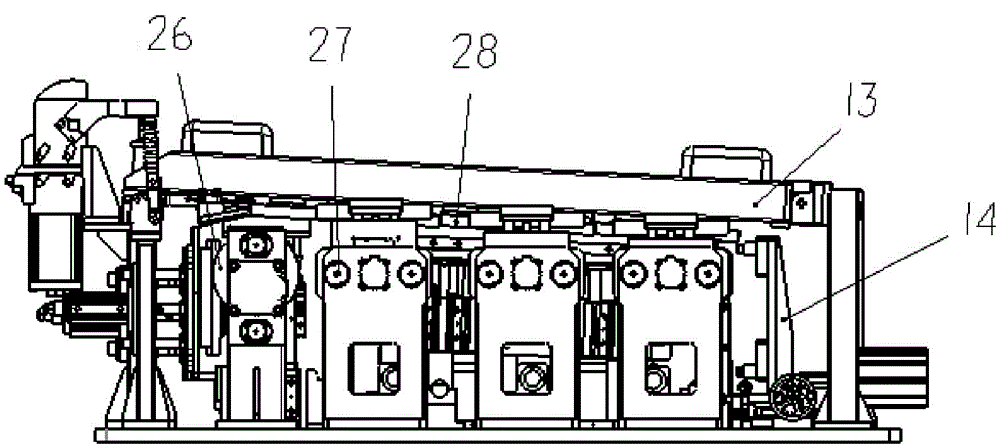

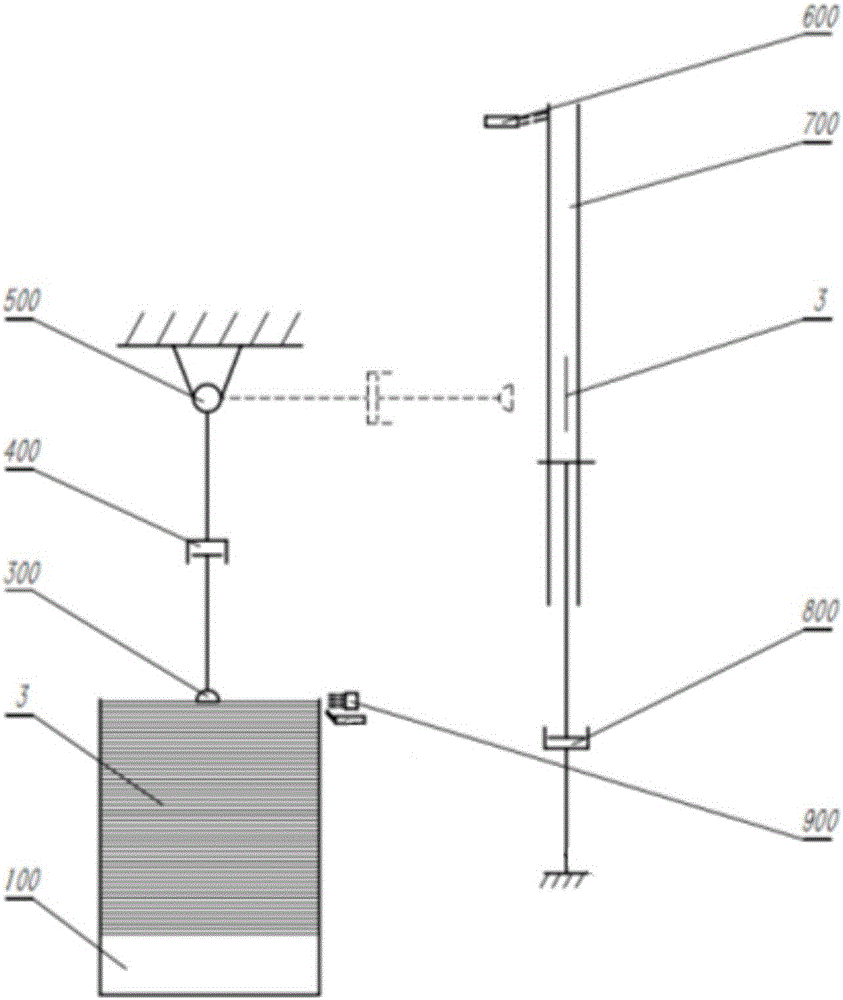

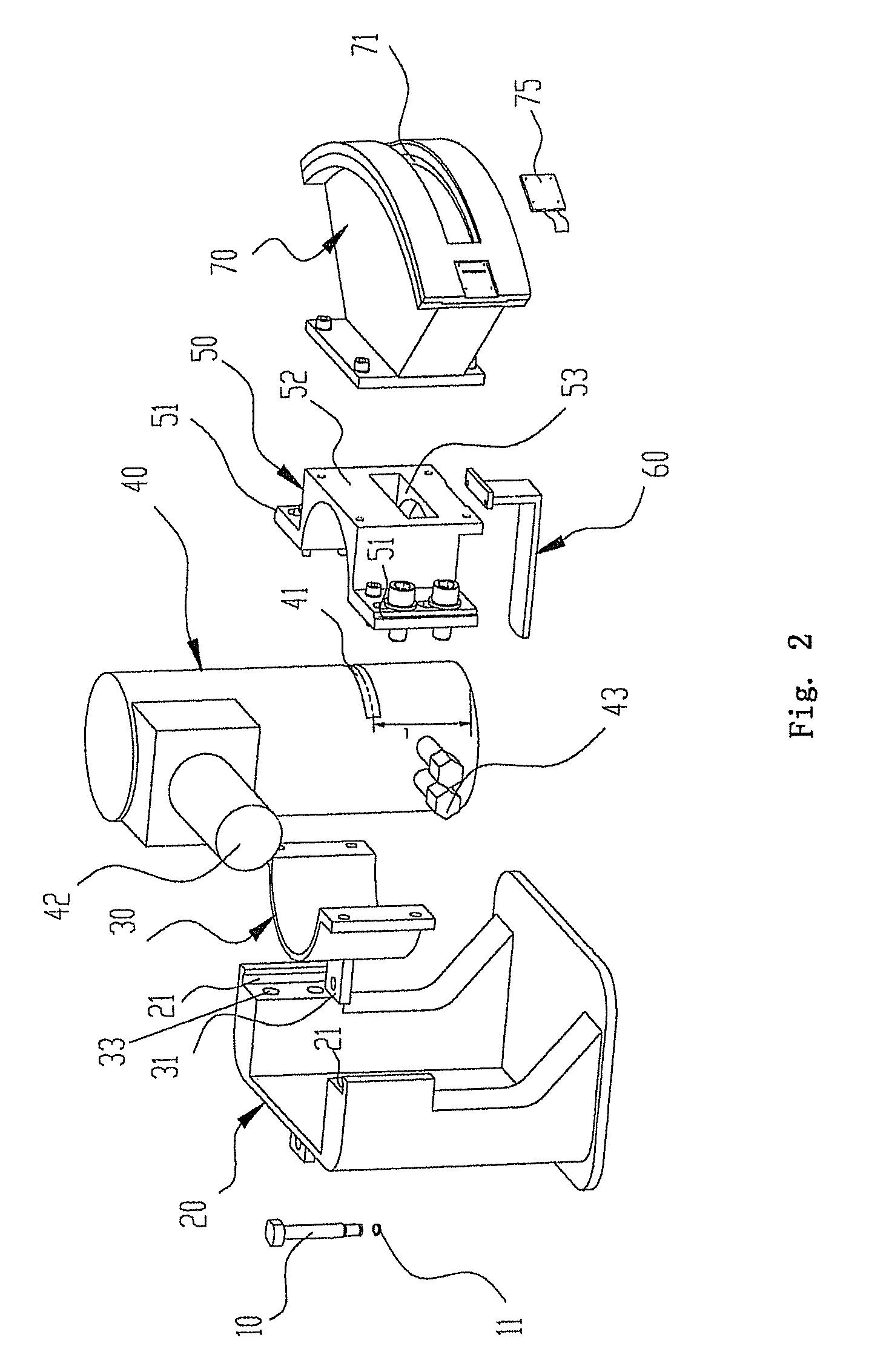

Motor test platform

ActiveCN103063435AEasy to move and dockSatisfy positioning accuracyEngine testingEngine test standButt joint

The invention relates to a testing device of a motor, in particular to a motor test platform which comprises a butt joint guide rail and a movable platform, wherein the butt joint guide rail backward and forward extends along the butt joint direction and is arranged on the test platform, the movable platform is capable of moving on the butt joint guide rail in a guiding mode due to the fact that the movable platform is provided with a platform guide rail which fits in with the butt joint guide rail. At least two pairs of idler wheels are arranged at the bottom of the movable platform along the backward and forward direction. Rollaway nests which are used for the idler wheels to roll and move backward and forward are arranged on the test platform. Each rollaway nest is provided with steps which are used for enabling each idler wheel to drop, wherein the drop height is higher than height difference between the butt joint guide rail and the platform guide rail when the movable platform is supported on the rollaway nests through the idler wheels. A lifting mechanism is provided with the butt joint guide rail, the platform guide rail, the rollaway nests or the idler wheels, the lifting mechanism is provided with vertical displacement output and enables the idler wheels to be supported on the rollaway nests, and the butt joint guide rail and the platform guide rail move and are close to each other to form sliding fitting through the lifting mechanism or the butt joint guide rail and the platform guide rail move and separate in the opposite direction through the lifting mechanism. The motor test platform has the advantages of being capable of easily achieving transfer of the movable platform from a preparation room to a test room and butt joint when the motor test platform is used for testing.

Owner:CAMALUOYANGELECTROMECHANIC

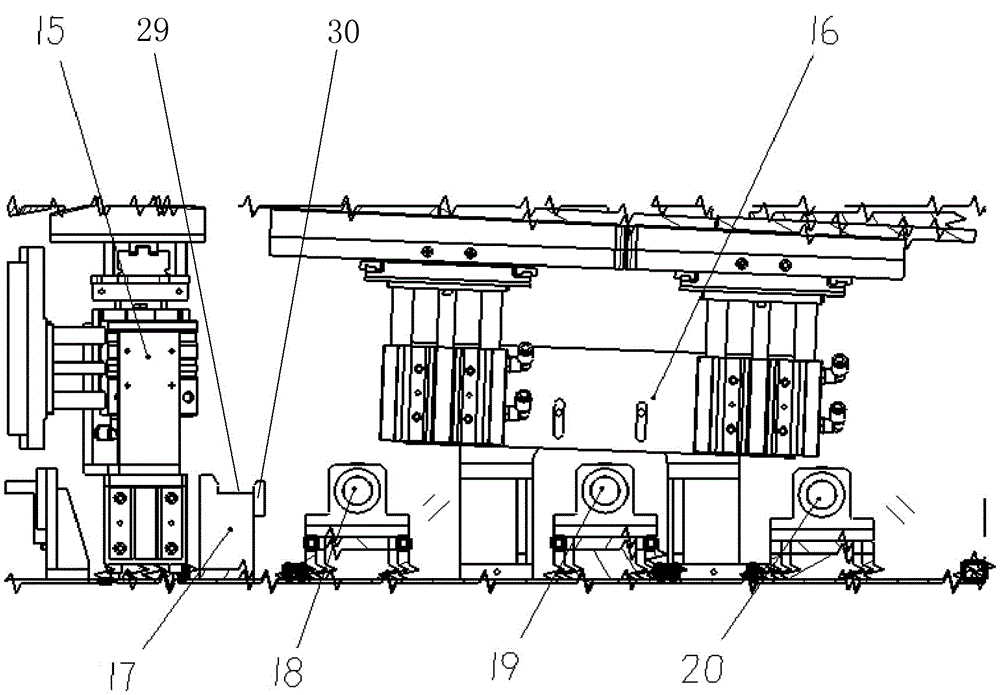

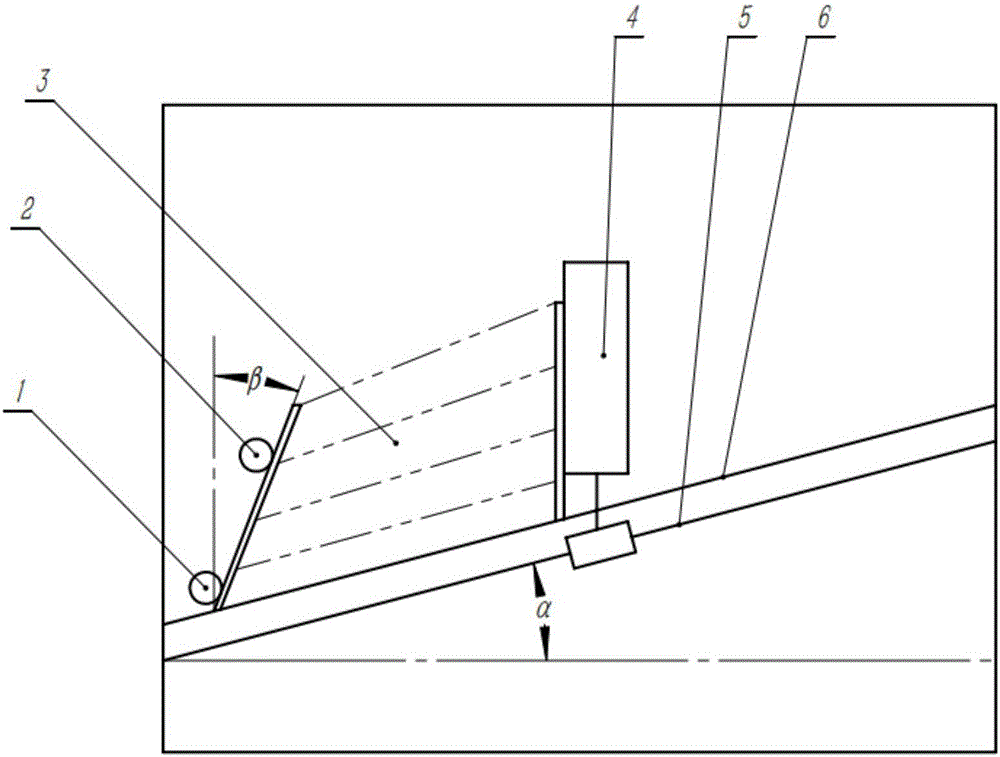

Sleeper laying method and device of railway line main tracklayer

ActiveCN102080349ASimple structureHigh degree of automationRailway track constructionEngineeringRailway line

The invention discloses a sleeper laying method and a device of a railway line main tracklayer. A one-time laying method is adopted, the main tracklayer is provided with a sleeper layer, the sleeper layer is positioned above a walking beam on the top of the front end of the main tracklayer, and the procedure for sleeper laying is implemented by the sleeper layer. The sleeper layer comprises a sleeper laying trolly, a sleeper lifting mechanism, a sleeper clamping mechanism, a hydraulic system, a transverse movement mechanism, a limiting mechanism and a milometer. The track laying of the railway line is completed by means of the coordinated operation of the sleeper laying trolly, the sleeper lifting mechanism, the sleeper clamping mechanism, the hydraulic system, the transverse movement mechanism, the limiting mechanism and the milometer. The method and the device have the advantage of simplifying construction process compared with the domestic sleeper laying at present; the sleeper layer is simple in structure, high in automated degree and convenient in maintenance, and saves the unit cost of construction; the device can complete a series of procedures at a time, including clipping and dropping of a plurality of sleepers and the like, is simple and convenient in operation, high in construction efficiency and safe and reliable, and can reach the positioning precision and the sleeper laying precision.

Owner:株洲长远智造股份有限公司

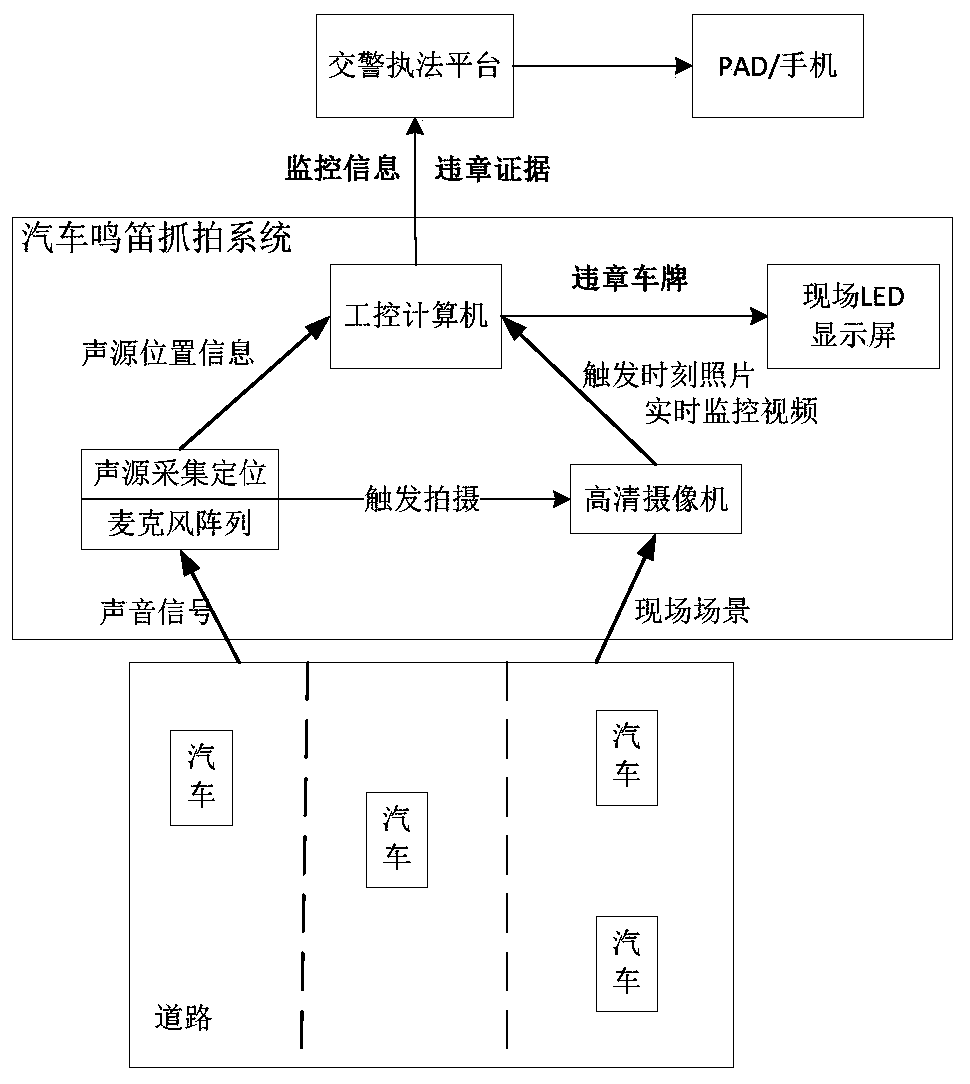

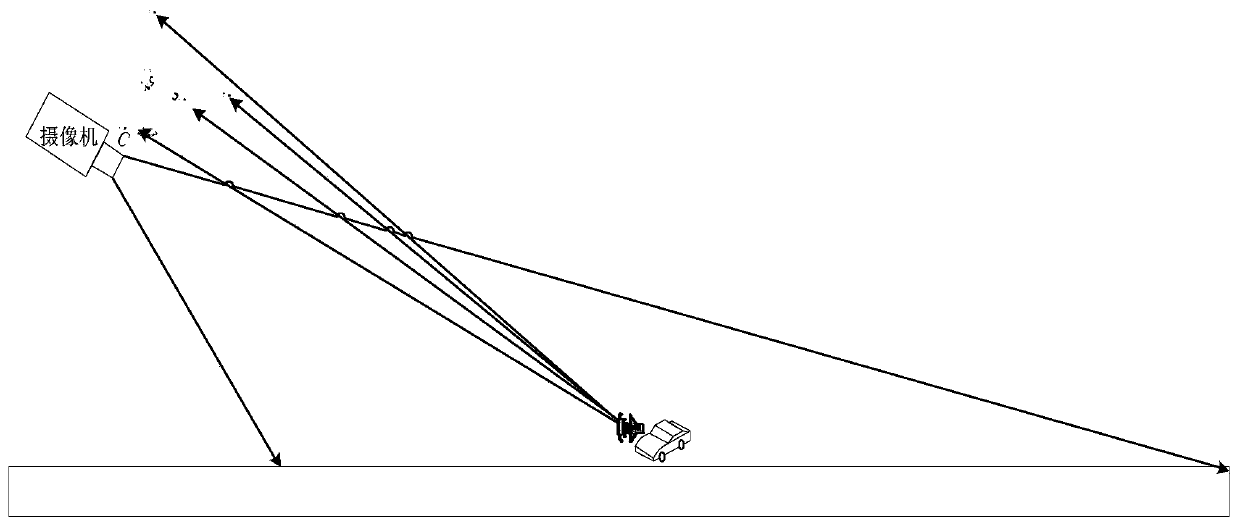

Vehicle whistling snapshot device and method based on regular tetrahedron microphone array

ActiveCN110689727ALower deployment costsGood real-time captureRoad vehicles traffic controlPosition fixationSound source locationSound sources

The disclosure discloses a vehicle whistling snapshot device and method based on a regular tetrahedron microphone array. The device comprises a regular tetrahedron microphone array and an industrial control computer. The regular tetrahedron microphone array is installed on a road monitoring rod; four microphones are arranged in the regular tetrahedron microphone array and are used for collecting road surface sound signals on road and transmitting the collected road surface sound signals to the industrial control computer. The industrial control computer is used for processing the road surfacesound signals to obtain a sound source position of a whistling signal, triggering the snapshot function of a monitoring camera after obtaining of the sound source position of the whistling signal, carrying out snapshot processing on a license plate at the sound source position, carrying out license plate number identification on the snapshot license plate image, shooting an image of the whistlingvehicle at the whistling moment, recording sounds of sounds signals within a time range before and after the whistling moment, and uploading the identified license plate number, the shot image of thewhistling vehicle at the whistling moment, and recorded sounds to a traffic police law enforcement server. And the e traffic police law enforcement server sends monitoring information to a traffic police terminal.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

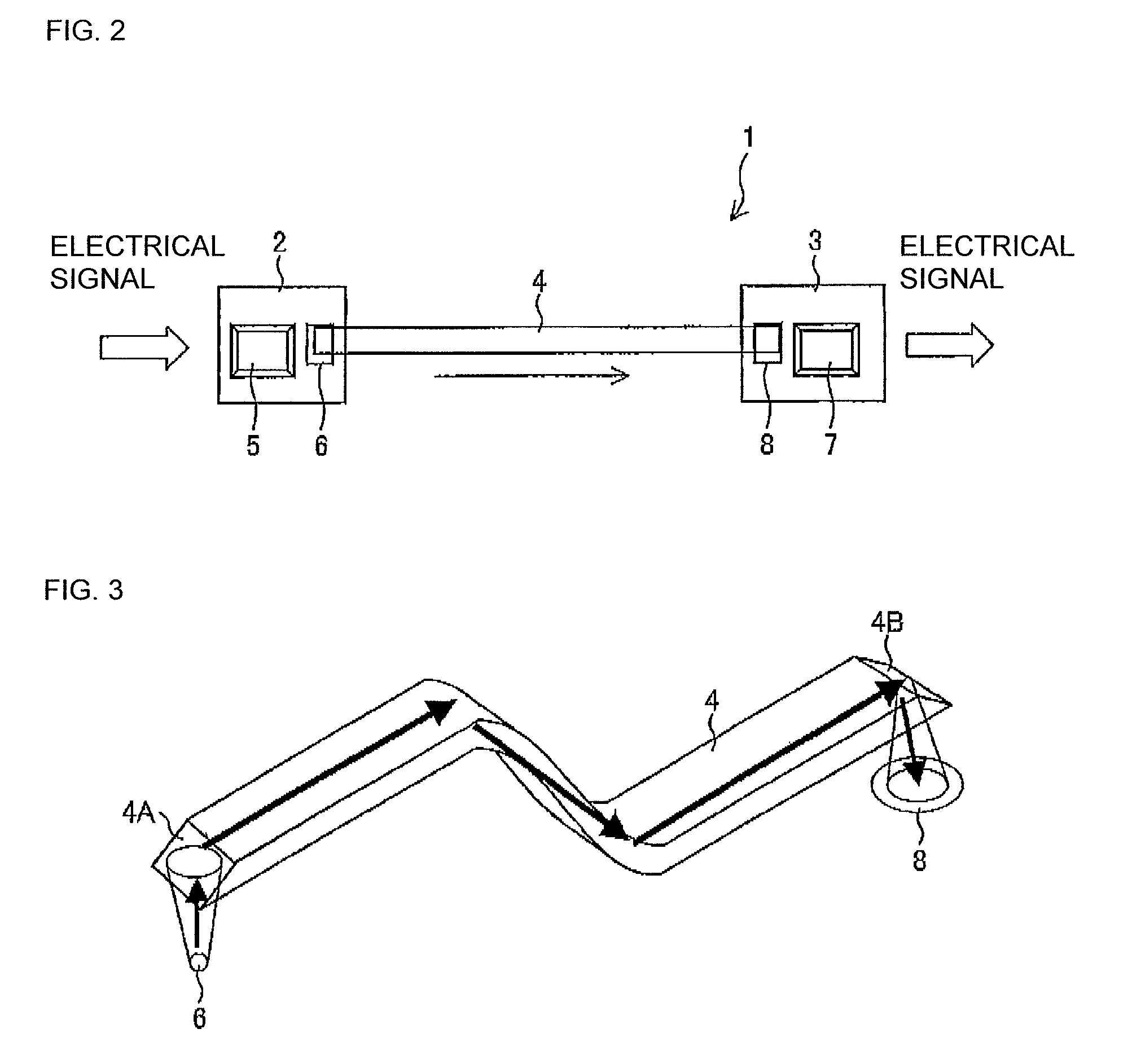

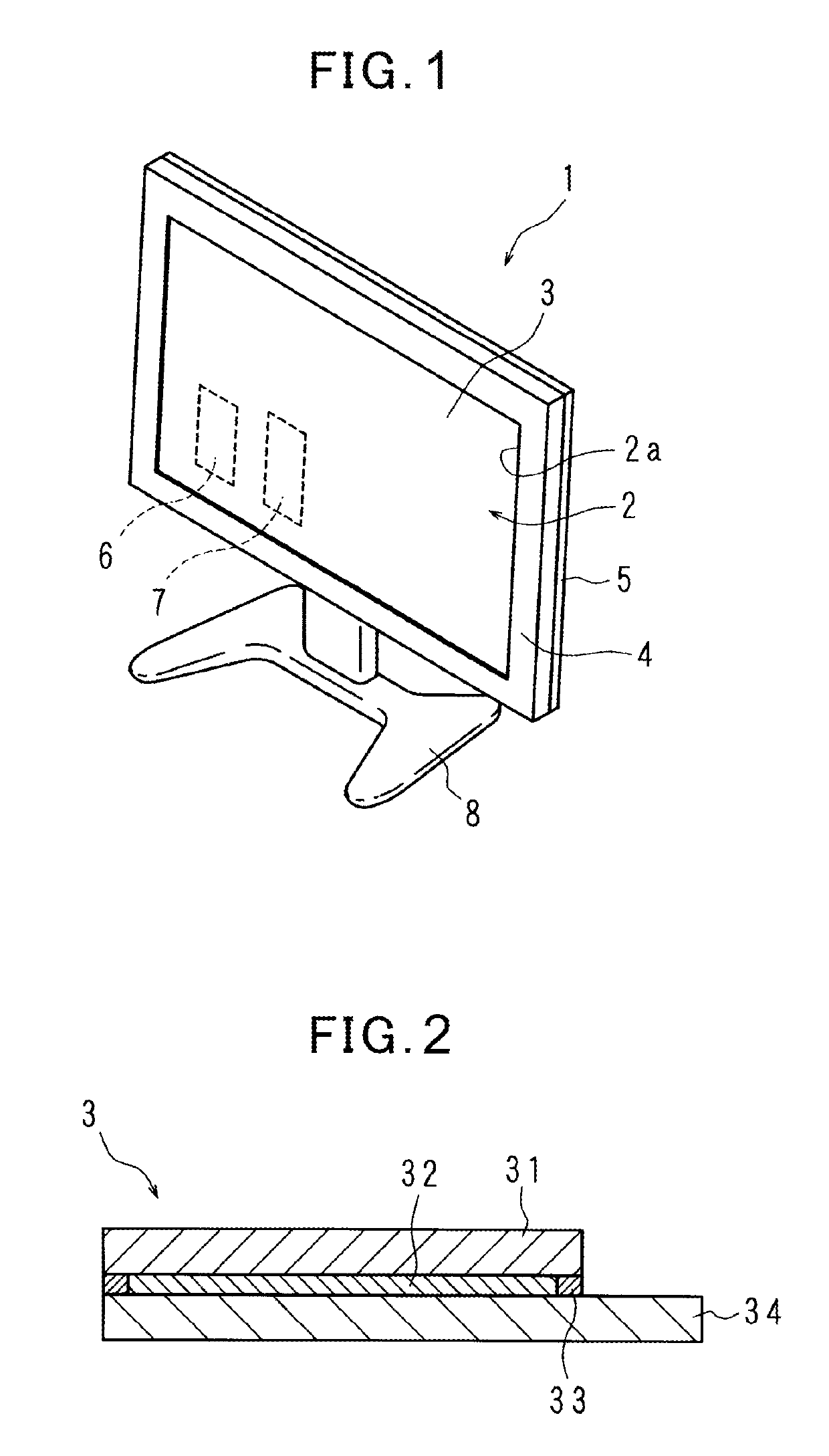

Package manufacturing method, package, optical module and die for integral molding

InactiveUS8218917B2Avoid warpingSatisfy positioning accuracySolid-state devicesSemiconductor/solid-state device manufacturingOptical ModuleShell molding

An integrally molding die for manufacturing a package includes a supporting portion for supporting at least one end including an incident / exit port of a light signal in a light transmission path, and a lead frame for mounting an optical element. The integrally molding die includes a recess for forming the supporting portion, a first projection, which comes into contact with an optical element mounting surface of the lead frame, and a second projection, which comes into contact with a back surface of the optical element mounting surface.

Owner:ORMON CORP

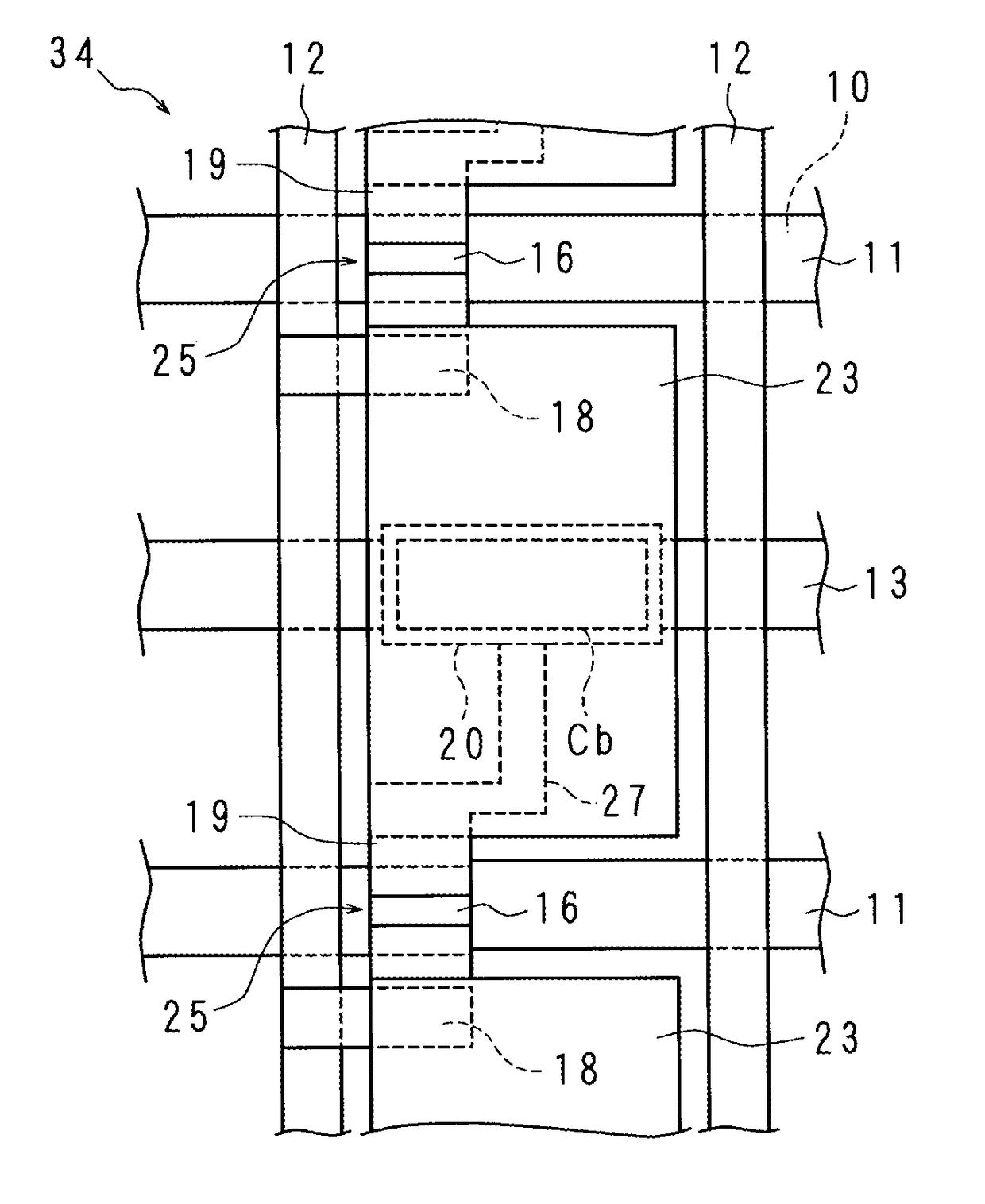

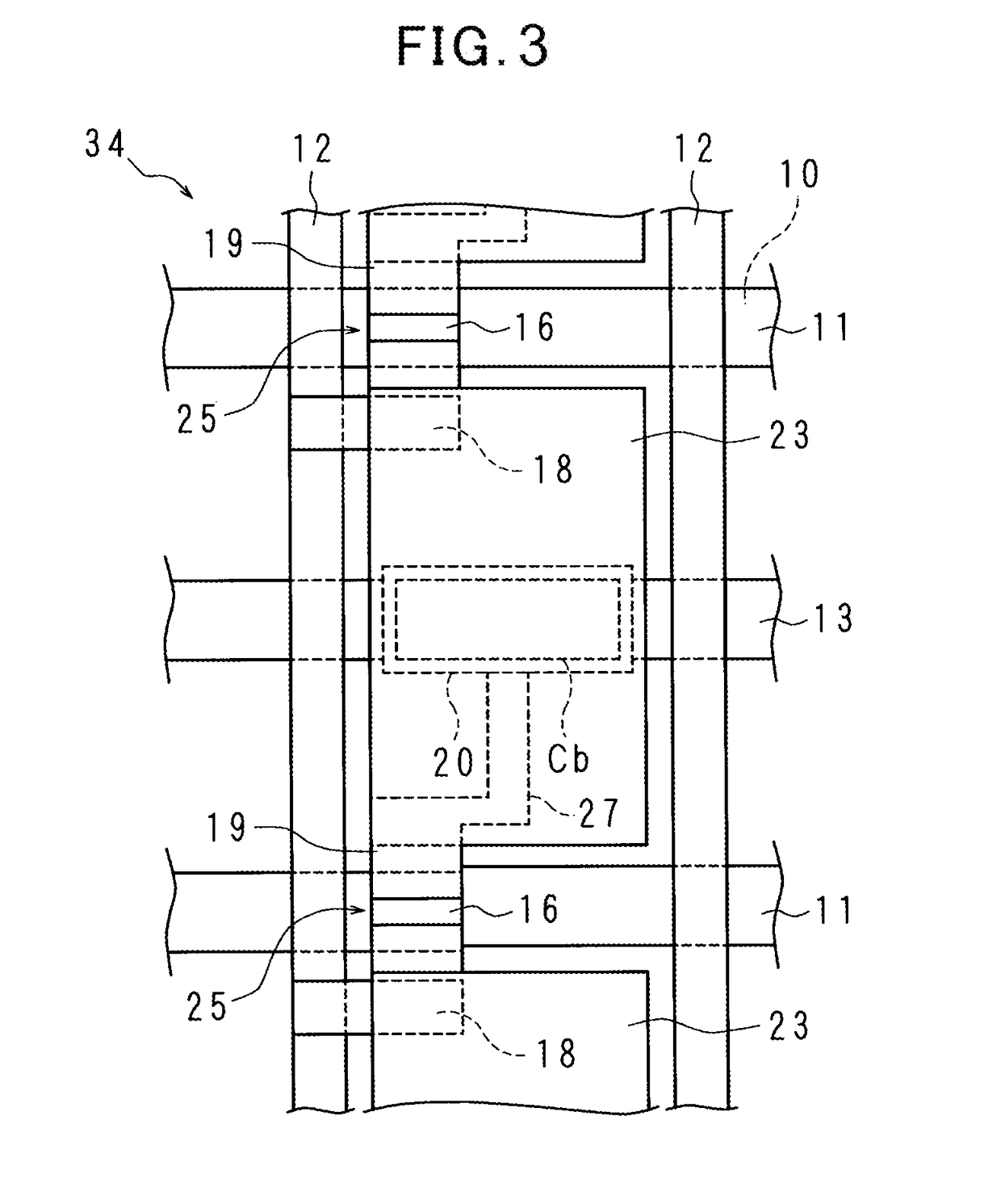

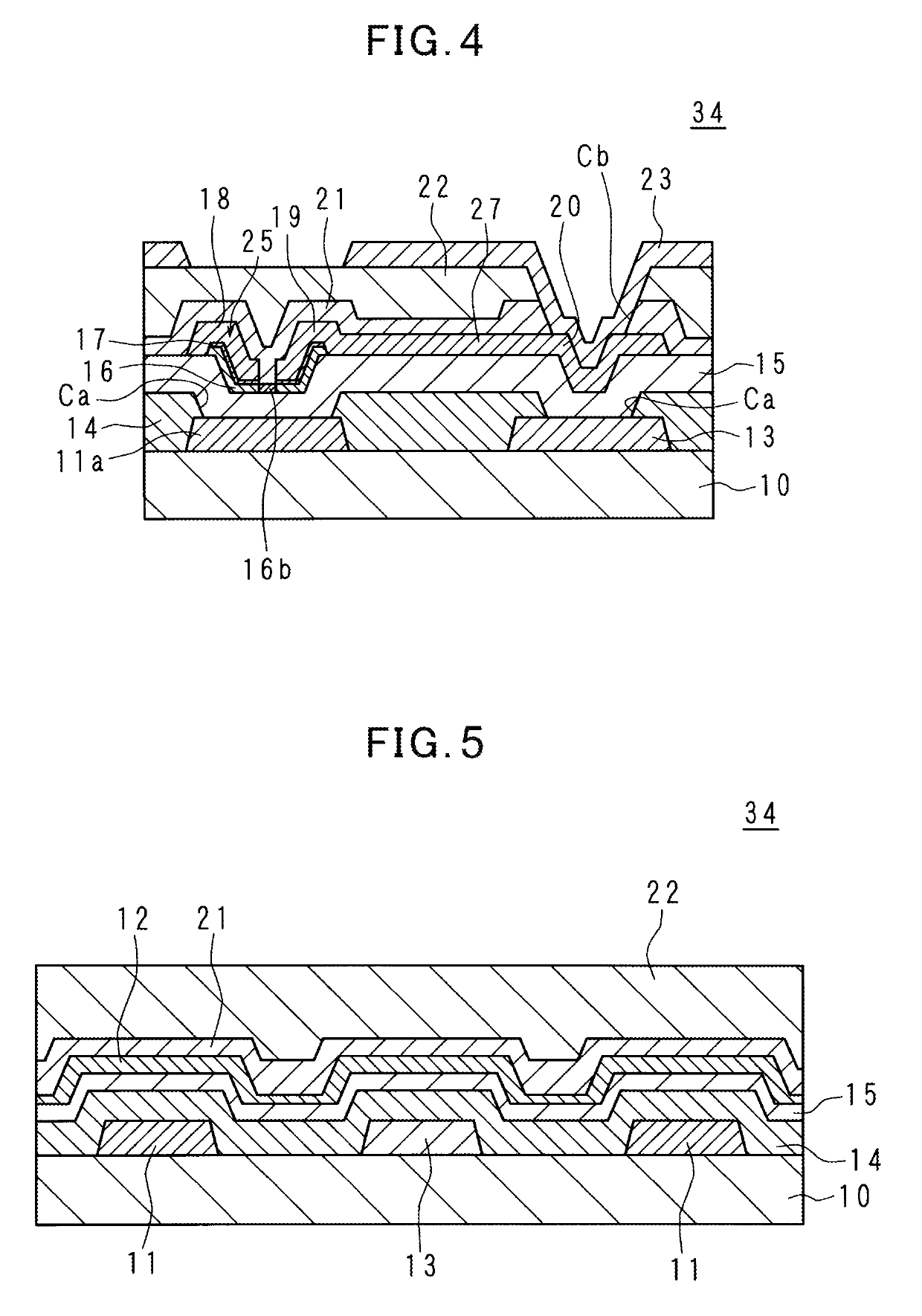

Method for manufacturing thin film transistor substrate

ActiveUS20180248031A1Reduce variationSatisfy positioning accuracyTransistorSolid-state devicesLaser beamsSemiconductor

There is provided a manufacturing method for a thin-film transistor substrate, which enables to excellently perform alignment between an annealed region of a semiconductor film and a mask pattern of a conductive film. The method comprises annealing a semiconductor film being formed on a gate insulation film covering a gate electrode with a laser beam by using a mask, the gate electrode being formed within a thin-film transistor substrate region on a substrate; forming a first alignment mark outside the thin-film transistor substrate region on the substrate, by irradiating the substrate through the mask with the laser beam; patterning the semiconductor film; forming a conductive film on the semiconductor film; positioning a photomask on the basis of the first alignment mark; and forming a source electrode and a drain electrode by patterning the conductive film through the photomask; wherein the first alignment mark is formed while annealing the semiconductor film.

Owner:SAKAI DISPLAY PROD

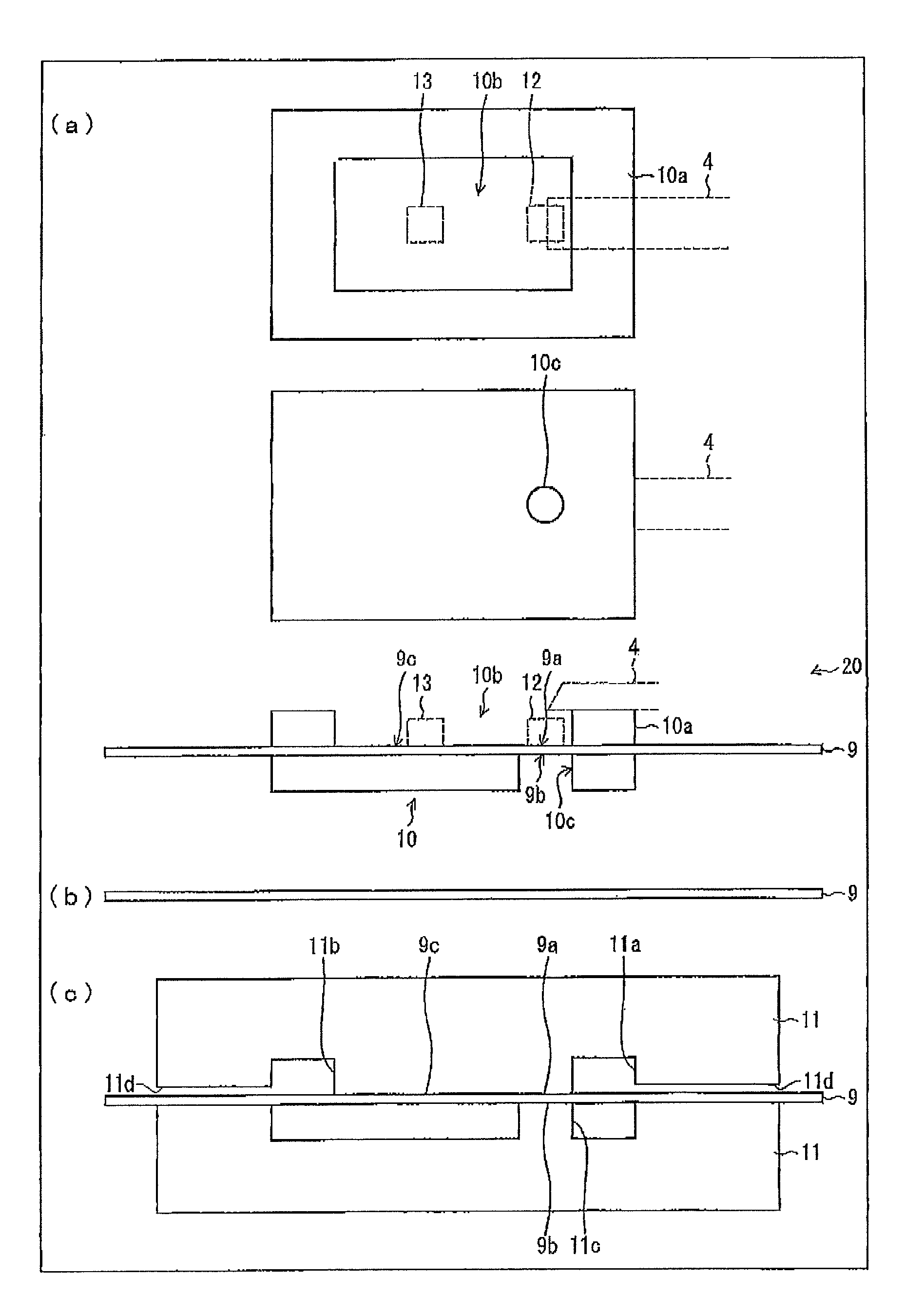

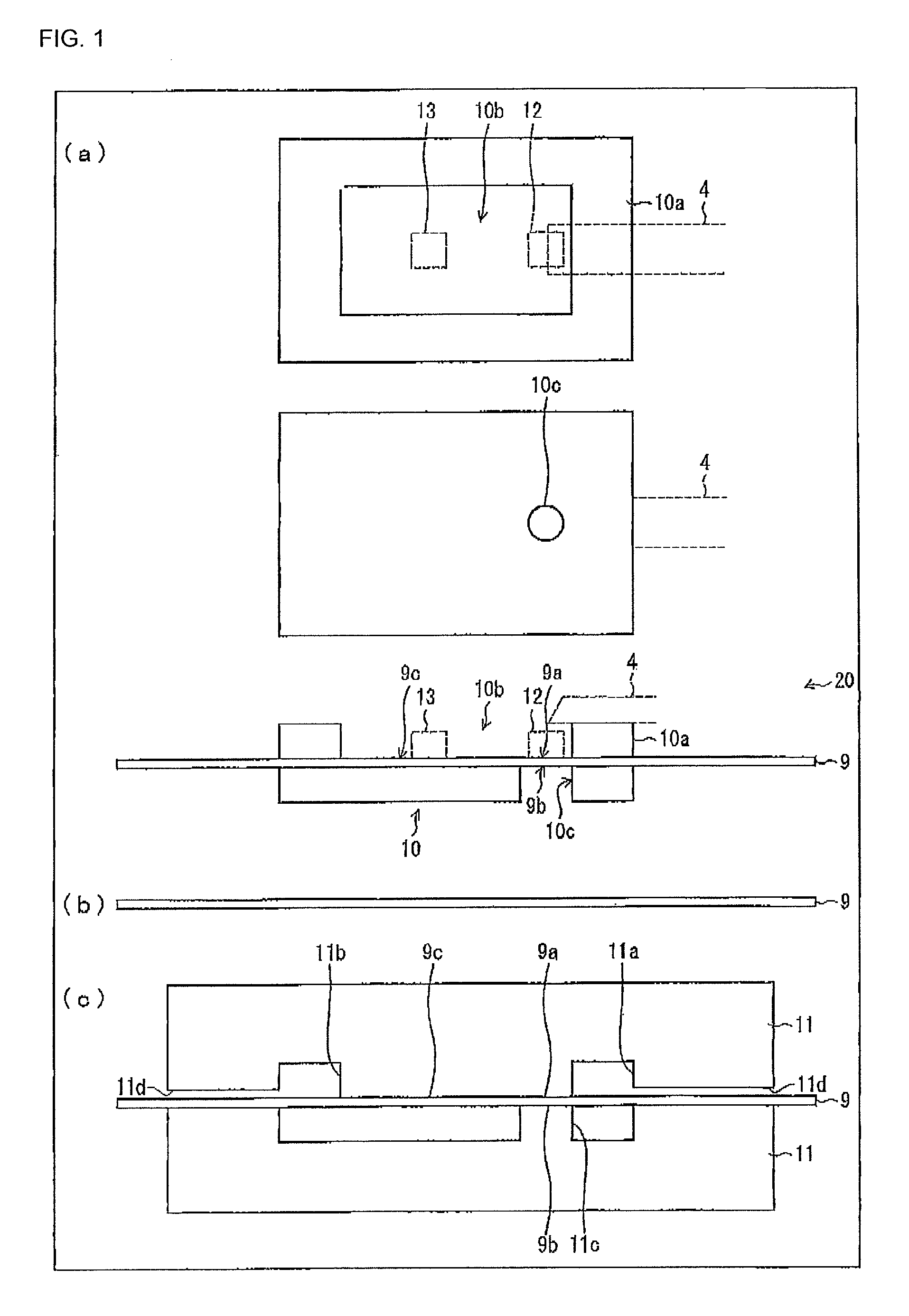

Liquid ejecting head unit and liquid ejecting apparatus

ActiveUS8235501B2Satisfy positioning accuracyImprove accuracyInking apparatusOther printing apparatusLiquid jetLiquid drop

A liquid ejecting head unit includes: a plurality of liquid ejecting heads, each of which has a nozzle array in which nozzles ejecting liquid droplets are arrayed; a base plate to which the plurality of liquid ejecting heads are fixed in a state being positioned at predetermined positions thereof; and positioning pins which are fixed to the base plate and engaged with positioning holes formed in the liquid ejecting heads. Each of the positioning pins is held in a holding hole provided in a fixing plate fixed to the base plate. A reference plate is joined to a surface of each of the fixing plates. Further, in each of the reference plates, there are provided: an insertion hole in which the positioning pin is substantially inscribed; and a minute hole that serves as a reference for positioning the positioning pin to the base plate.

Owner:SEIKO EPSON CORP

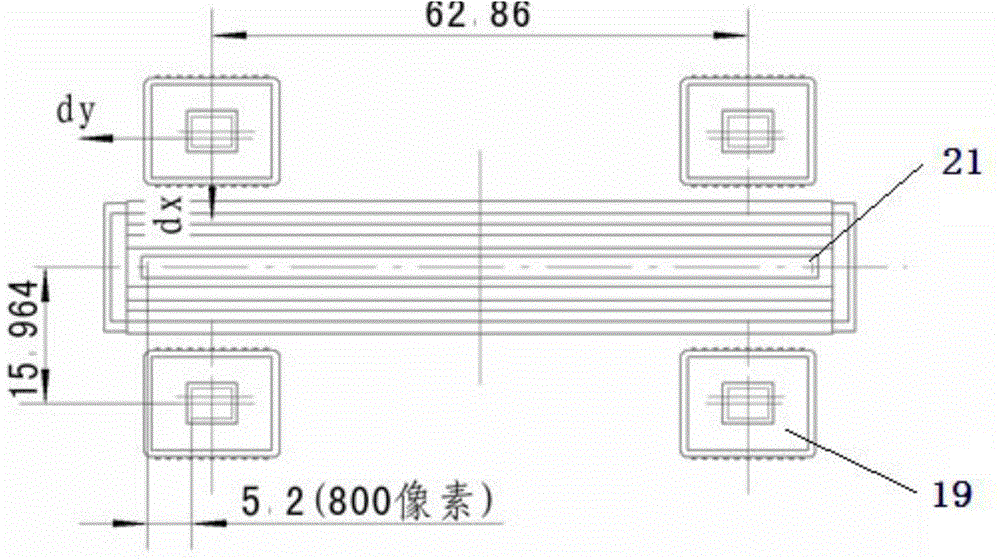

Line-surface-mixed CCD focal plane splicing system for three-dimensional mapping camera

InactiveCN104792315ARealize photogrammetrySatisfy position accuracyPicture taking arrangementsSatelliteImage resolution

The invention discloses a line-surface-mixed CCD focal plane splicing system for a three-dimensional mapping camera and belongs to the technical field of spatial optical remote sensing. The system comprises a splicing microscope, a microscope display device, a focal plane assembly to be spliced, a splicing tool, a two-dimensional adjustment table and a base, wherein the two-dimensional adjustment table is placed on the base; a splicing bracket is placed on the two-dimensional adjustment table; the focal plane assembly to be spliced is placed on the splicing bracket; the splicing microscope and the microscope display device are fixed to the base and are used for observing the focal plane assembly to be spliced. According to the line-surface-mixed CCD focal plane splicing system for the three-dimensional mapping camera, line-surface-mixed CCD focal planes of the three-dimensional mapping camera can be spliced, the position accuracy between a line array CCD and a surface array CCD provided for 5m ground resolution is met, photography measurement without ground control points can be achieved, the requirement on the stability of satellite attitude is reduced, and the mapping accuracy can be improved. The line-surface-mixed CCD focal plane splicing system for the three-dimensional mapping camera plays an important role in the first-generation transmission type three-dimensional Chinese mapping satellite.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

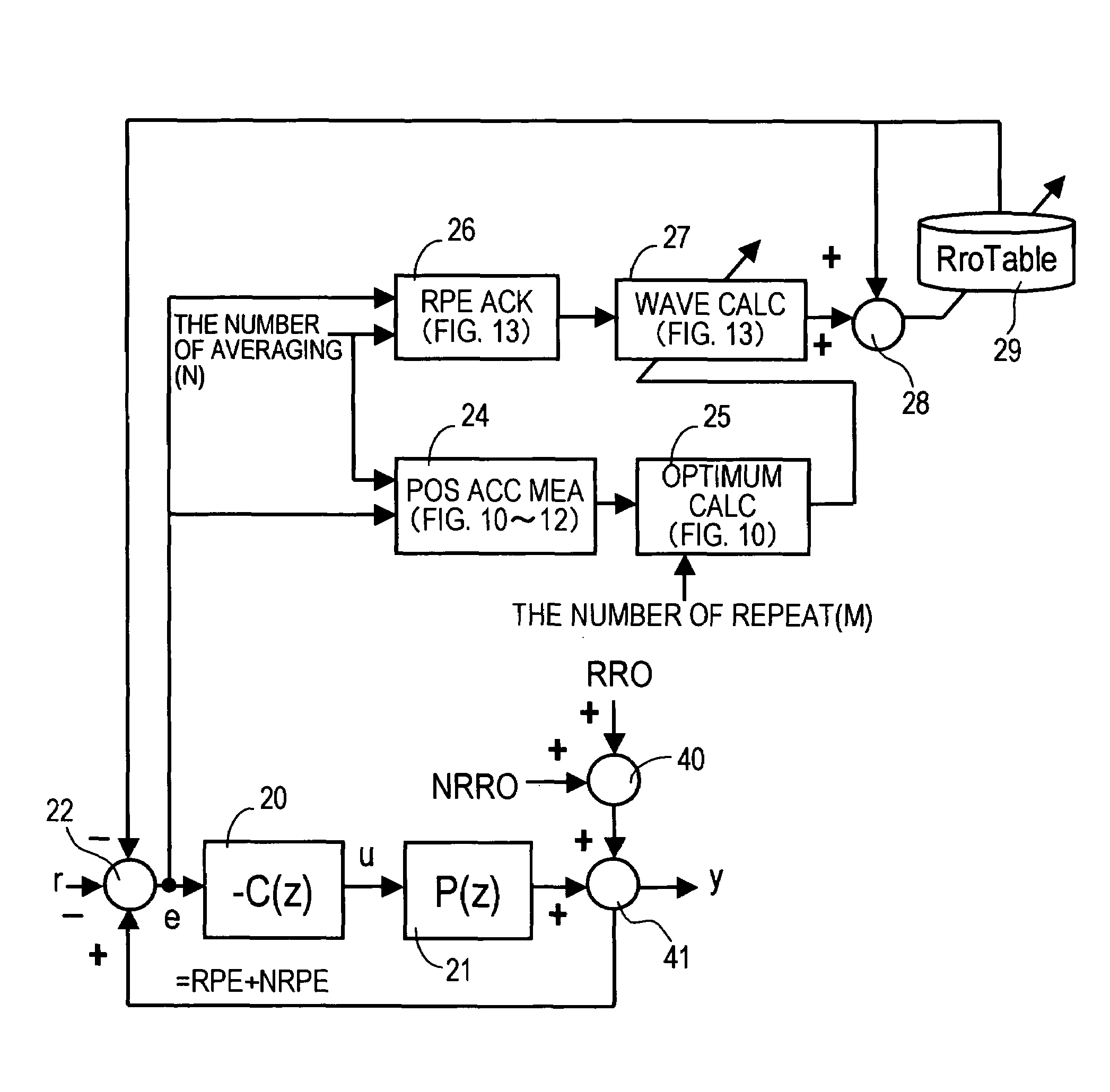

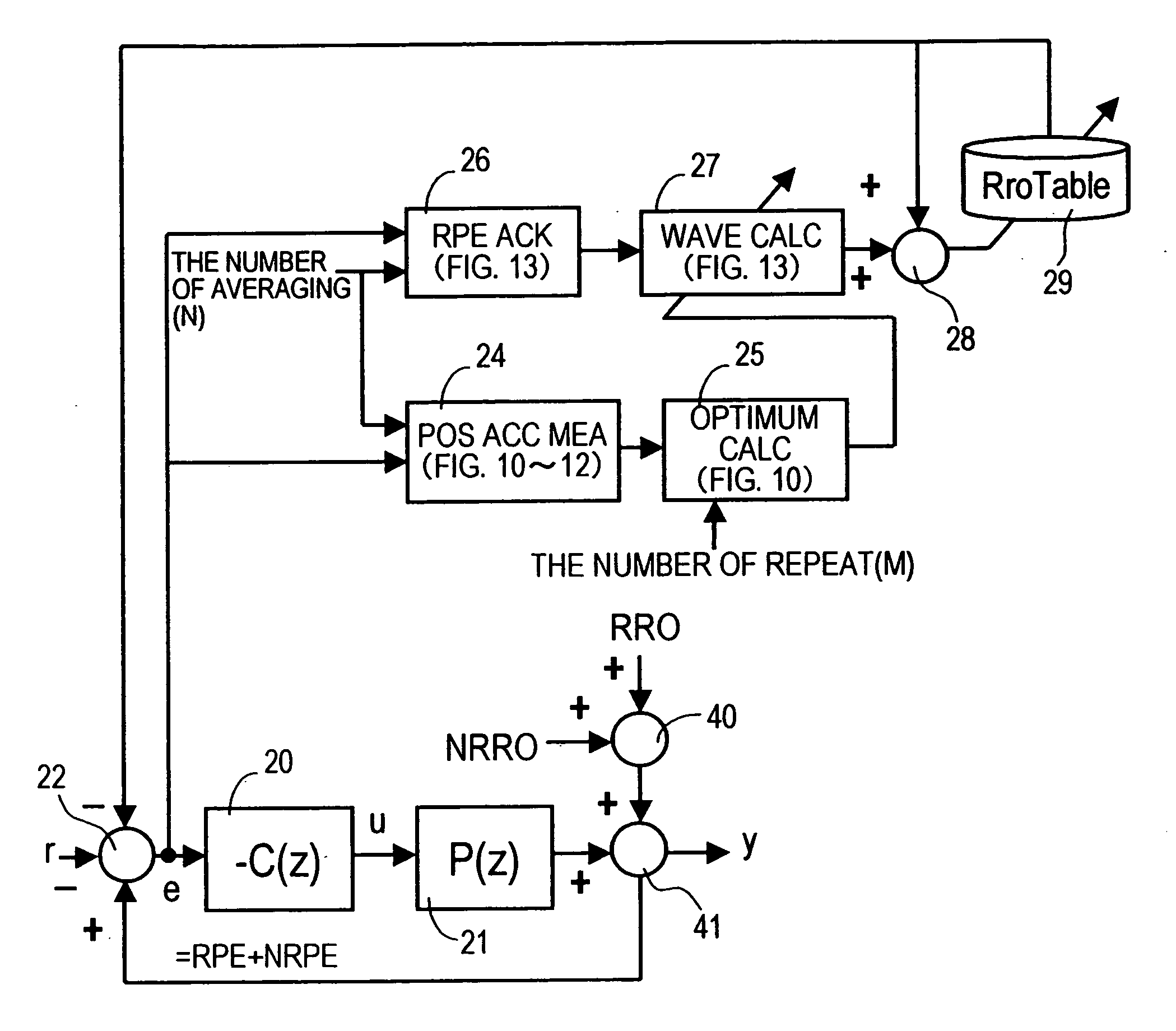

Correction table creation method for head position control, head position control method and disk device

ActiveUS20070008645A1High gainSatisfies the specifications of the positioning accuracy in a short timeTrack finding/aligningRecord information storageComputer scienceHead position

A head position control system control the position of the head by correcting the components synchronizing rotation of the disk from the head control amount, in which an adjusted gain to minimize the components synchronizing rotation after correction is theoretically acquired. An adjusted gain based on the ratio of the magnitude between the components synchronizing rotation of a disk and the components not synchronizing rotation of the disk in the position signals is used. And a gain to minimize RRO after correction can be theoretically determined using an expression to determine RRO after correction. The gain can be determined without depending on experiment, and the value of RRO after correction can be guaranteed, therefore the manufacturing time and the device specifications can be determined.

Owner:KK TOSHIBA

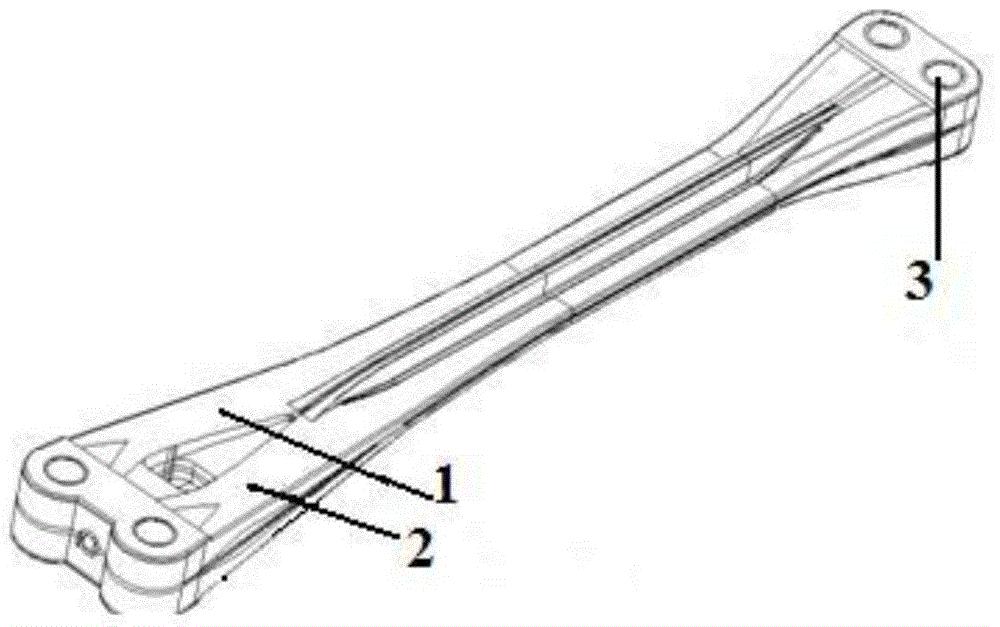

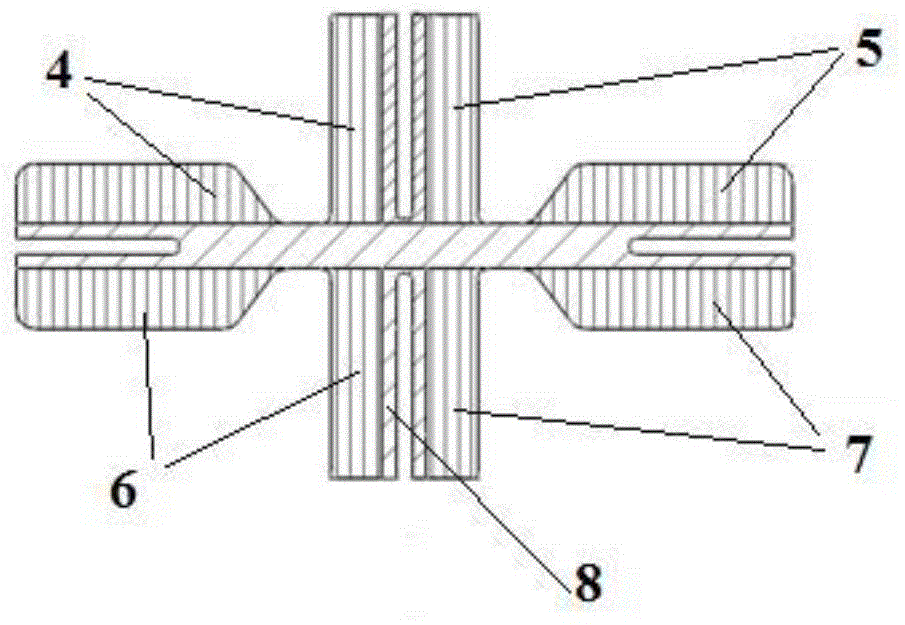

Positioning milling tire

InactiveCN101927435ASolve the technical defect of poor positioning accuracySatisfy positioning accuracyMilling equipment detailsPositioning apparatusEngineeringProcessing accuracy

The invention provides a positioning milling tire. The positioning milling tire comprises a support body, a milling tire seat and a positioning pin, wherein a vertical installation through hole is formed on the top of the support body; an opening for one end of a blank material, which is to be machined into an end face spline, to extend out is formed on one side at the bottom of the support body; the support body is bolted to the top of the milling tire seat; a micro taper hole is formed on the top of the milling tire seat; a boss is formed at the bottom of the milling tire seat; the micro taper hole, the boss and the vertical installation through hole of the support body are coaxial; a T-shaped positioning groove with an outward opening is formed on the lateral part of the milling tire seat; and the positioning pin is arranged in the T-shaped positioning groove. The technical scheme of the invention overcomes the technical defect that the positioning milling tire has poor positioning precision on the blank material which is to be machined into a conversion circuit connecting rod for a transmission case in the prior art, and can assist in machining the conversion circuit connecting rod for the transmission case so as to meet the machining precision of the end face spline of the conversion circuit connecting rod for the transmission case.

Owner:CRRC BEIJING ERQI LOCOMOTIVE CO LTD

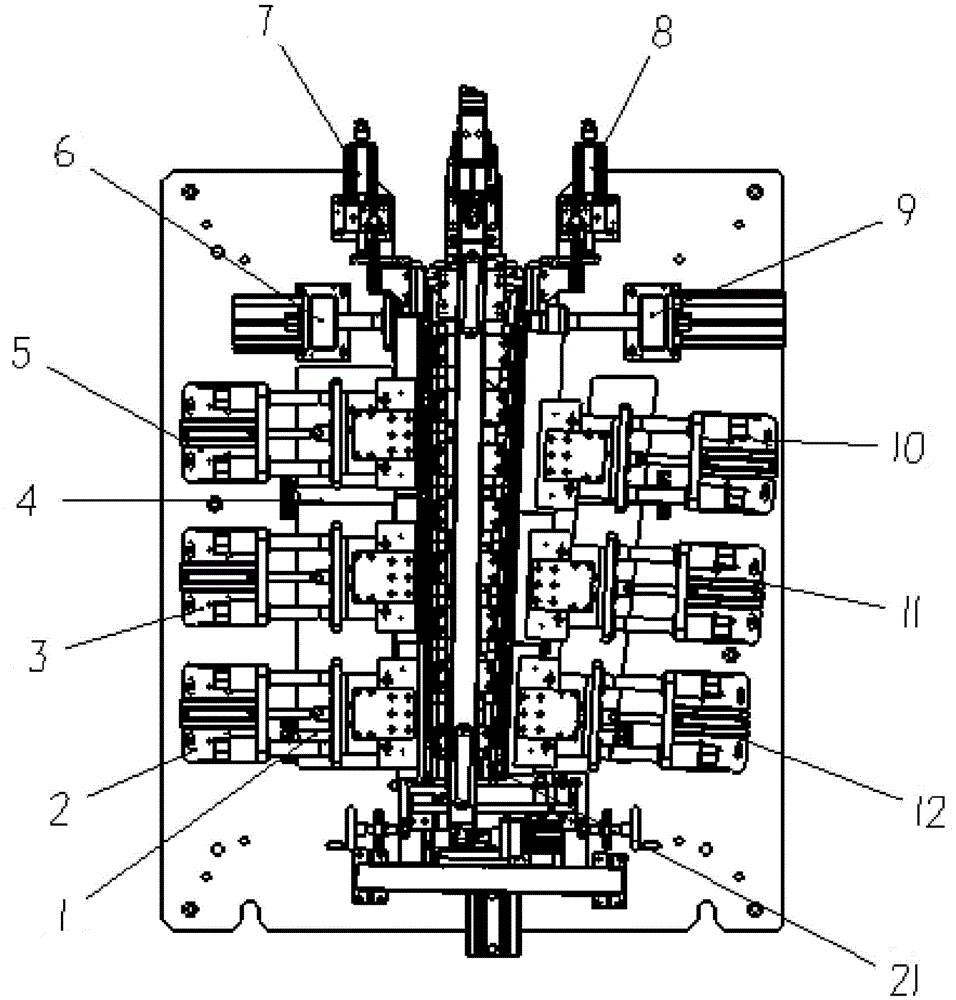

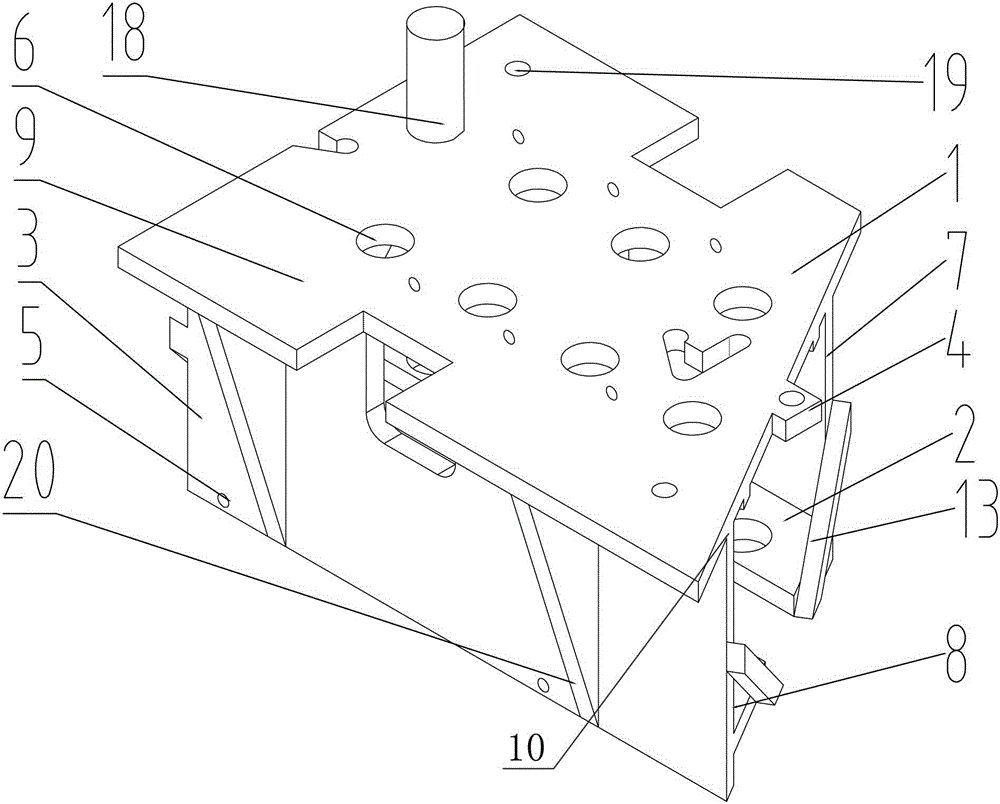

Tool clamp used for robot automatic welding

ActiveCN105598621AEasy to operateSatisfy positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled

The invention discloses a tool clamp used for robot automatic welding. The tool clamp comprises a separation plate tab positioning assembly (14), shaft hole positioning assemblies (6, 9), plane plate compression assemblies (2, 3, 5), curved plate compression assemblies (10, 11, 12), side wall plate compression assemblies (7, 8), a transverse beam assembly (13), back air protective jacking mechanisms (15, 16), jacking compression mechanisms (18, 19, 20), a middle separation frame assembling component (17) and auxiliary supports (1, 4), wherein the plane plate compression assemblies (2, 3, 5) and the curved plate compression assemblies (10, 11, 12) are located on the two sides of the middle part of the transverse beam assembly (13) respectively; the side wall plate compression assemblies (7, 8) are distributed on the two sides of the front end part of the transverse beam assembly (13); the shaft hole positioning assemblies (6, 9) are further distributed on the two sides of the front end part of the transverse beam assembly (13); and the separation plate tab positioning assembly (14) is distributed at the tail part of the transverse beam assembly (13). The invention provides an automatic welding tool which is simple to operate and efficient, aiming at certain complicated thin-wall welding parts; and the requirements on tool positioning precision and clamping efficiency by robot automatic welding are met.

Owner:JIANGXI HONGDU AVIATION IND GRP

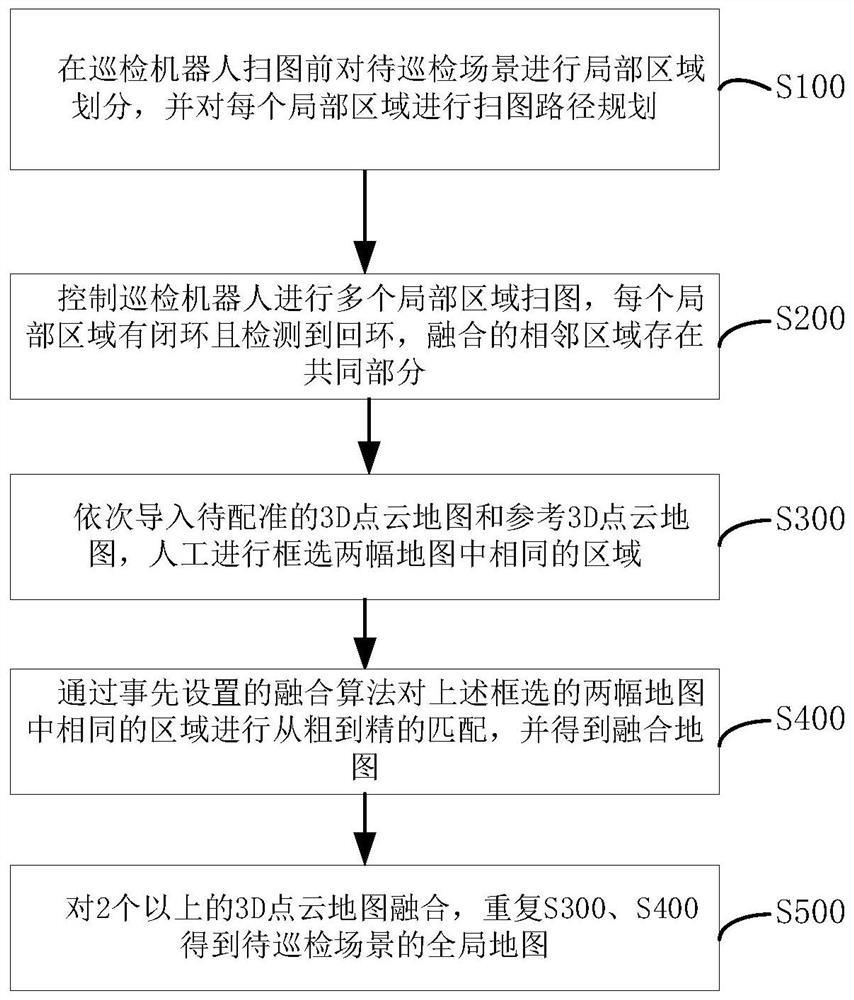

3D point cloud map fusion method and system for transformer substation inspection robot

ActiveCN112183285ASatisfy positioning accuracyExact fusion matrixImage enhancementImage analysisPoint cloudEngineering

The invention discloses a 3D point cloud map fusion method and system for a transformer substation inspection robot, and the method comprises the following steps: carrying out the local region division of a to-be-inspected scene before the scanning of the inspection robot, and carrying out the scanning path planning of each local region; controlling the inspection robot to scan images of multiplelocal areas, each local area having a closed loop and detecting a loop, and the fused adjacent areas having a common part; sequentially importing a 3D point cloud map to be registered and a reference3D point cloud map, and manually selecting the same areas in the two maps; and carrying out coarse-to-fine matching on the same areas in the two selected maps through a preset fusion algorithm, and obtaining a fused map. According to the 3D point cloud map fusion method of the transformer substation inspection robot, the risk of global optimization failure can be avoided, multi-local 3D point cloud map high-precision fusion of a transformer substation scene of 100,000 levels or above is achieved, and the requirements for positioning and navigation of the inspection robot are met.

Owner:HEFEI CSG SMART ROBOT TECH CO LTD +2

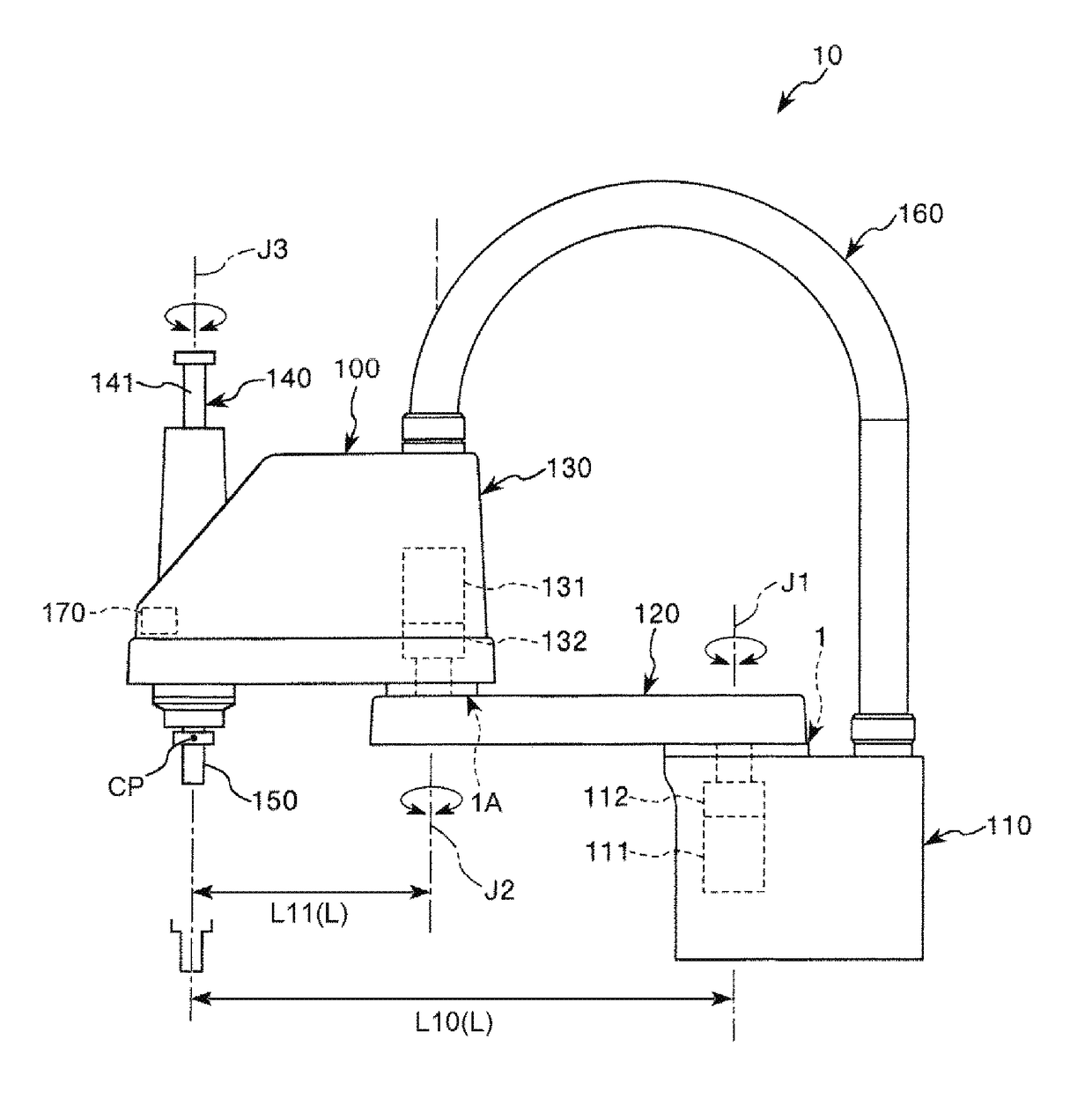

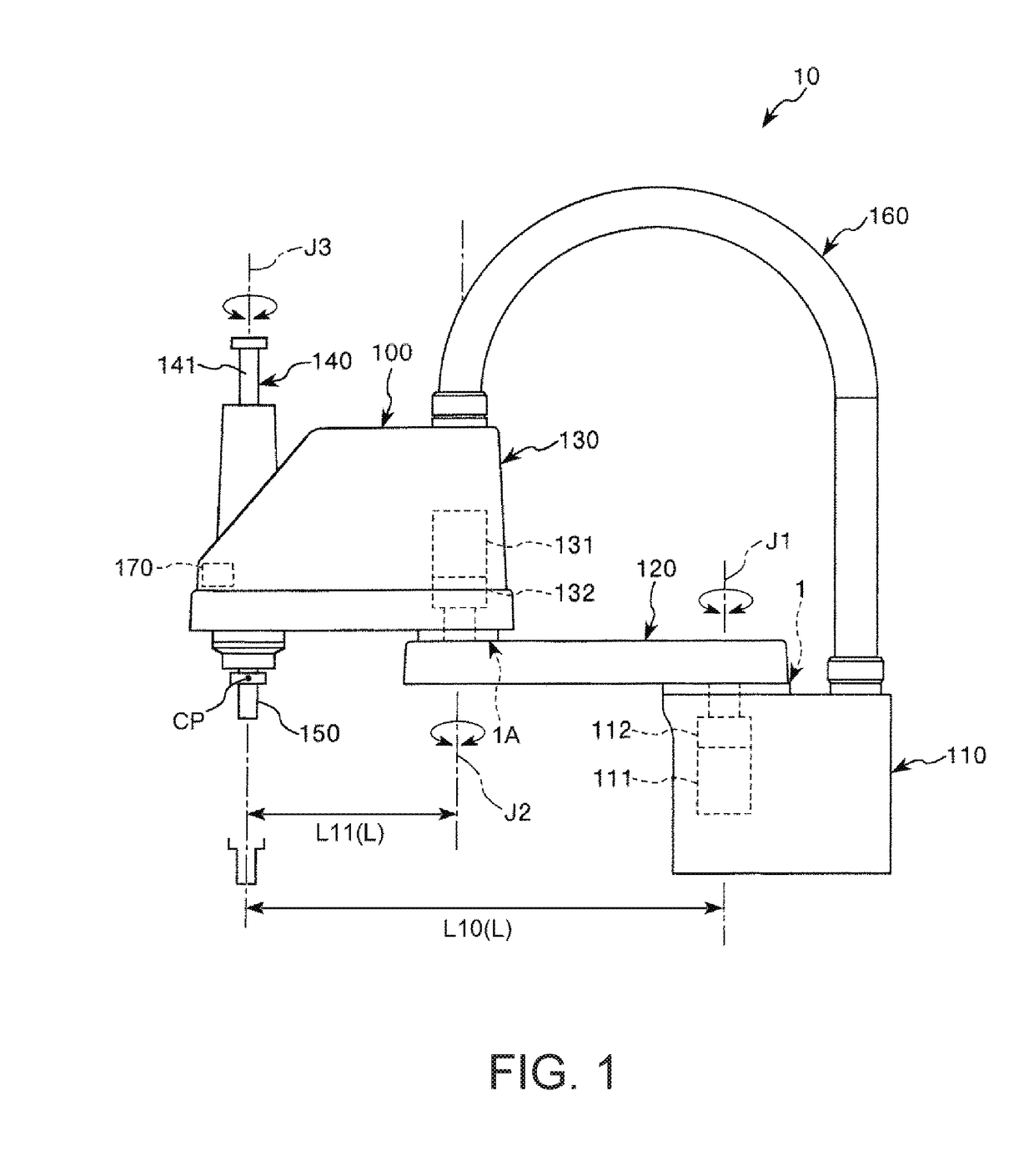

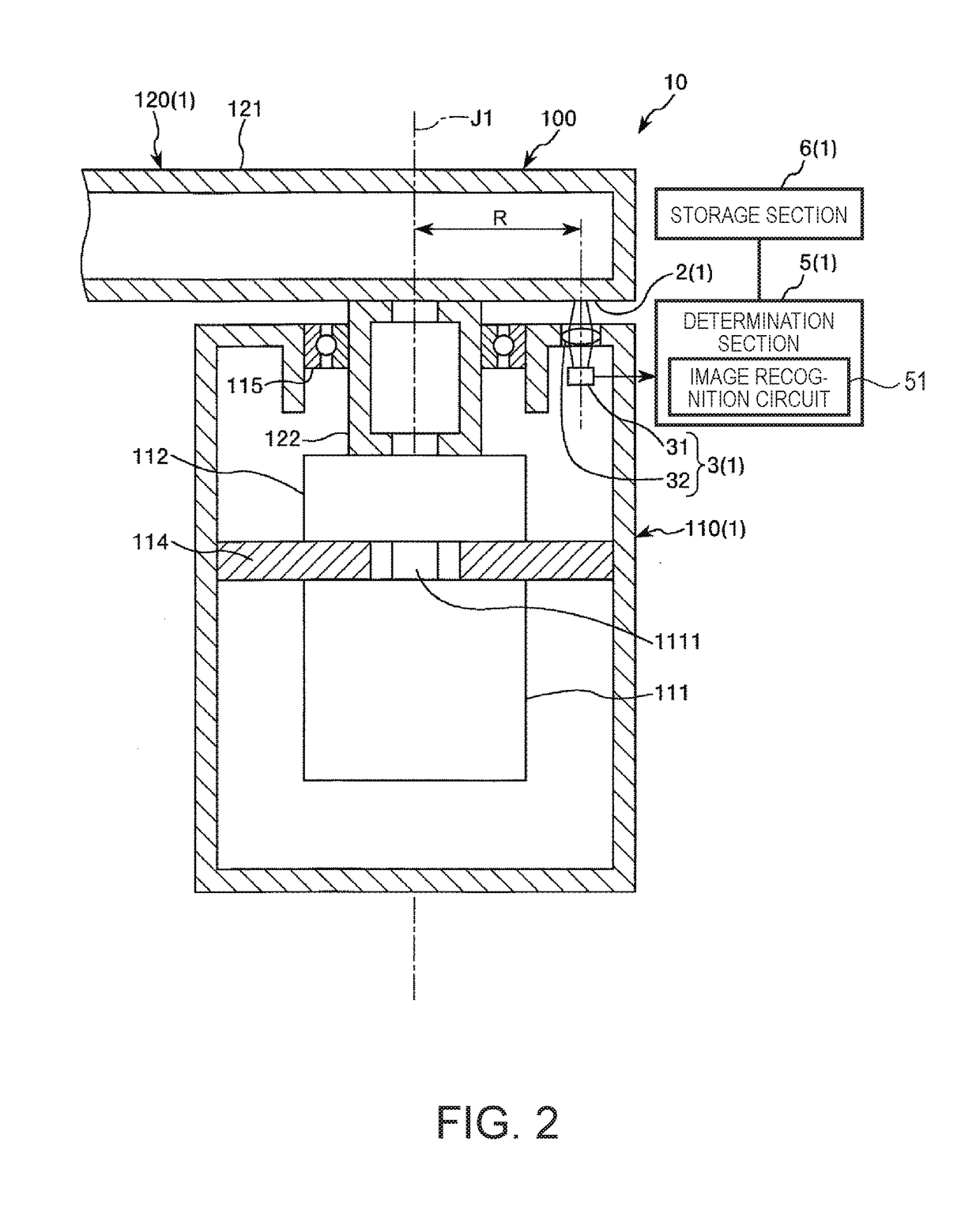

Robot

ActiveUS20180207805A1Reduce vibrationImprove accuracyProgramme-controlled manipulatorRobotField sizeTemplate matching

A robot includes: a base; a robot arm rotatably provided around a rotation axis relative to the base; a mark which rotates in accordance with rotation of the robot arm; a capturing element which captures the mark; a memory which stores a reference image therein; and a determination section which determines a rotation state of the robot arm by template matching by subpixel estimation using the reference image and an image captured by the capturing element, in which a relationship of 2R / B≤L / X≤100R / B is satisfied when a viewing field size per one pixel of the capturing element is B, a distance between the rotation axis and the center of the mark is R, the maximum distance between the rotation axis and a tip of the robot arm is L, and repetition positioning accuracy of the tip of the robot arm is X.

Owner:SEIKO EPSON CORP

High-speed flexible label dispensing device

The invention discloses a high-speed flexible label dispensing device. The high-speed flexible label dispensing device comprises a rack and further comprises a label box mechanism, a label taking mechanism and a label feeding mechanism which are mounted on the rack. The label box mechanism comprises a label box and further comprises a linear guide way, an upper limiting mechanism, lower limiting rods, a label pressing block, a label supporting plate and a blowing spray nozzle which are mounted on the label box. The label taking mechanism comprises a rotary air cylinder, a vacuum sucker and a label taking air cylinder. The label feeding mechanism comprises a label guiding platform and a label push air cylinder. A blowing spray nozzle structure is disposed at a label taking opening of the label box of the label dispensing device, parallel air flow is blown out to destroy vacuum among labels and separate the labels when one of the labels is taken out, and therefore the effect that only one label is taken out during label taking is guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

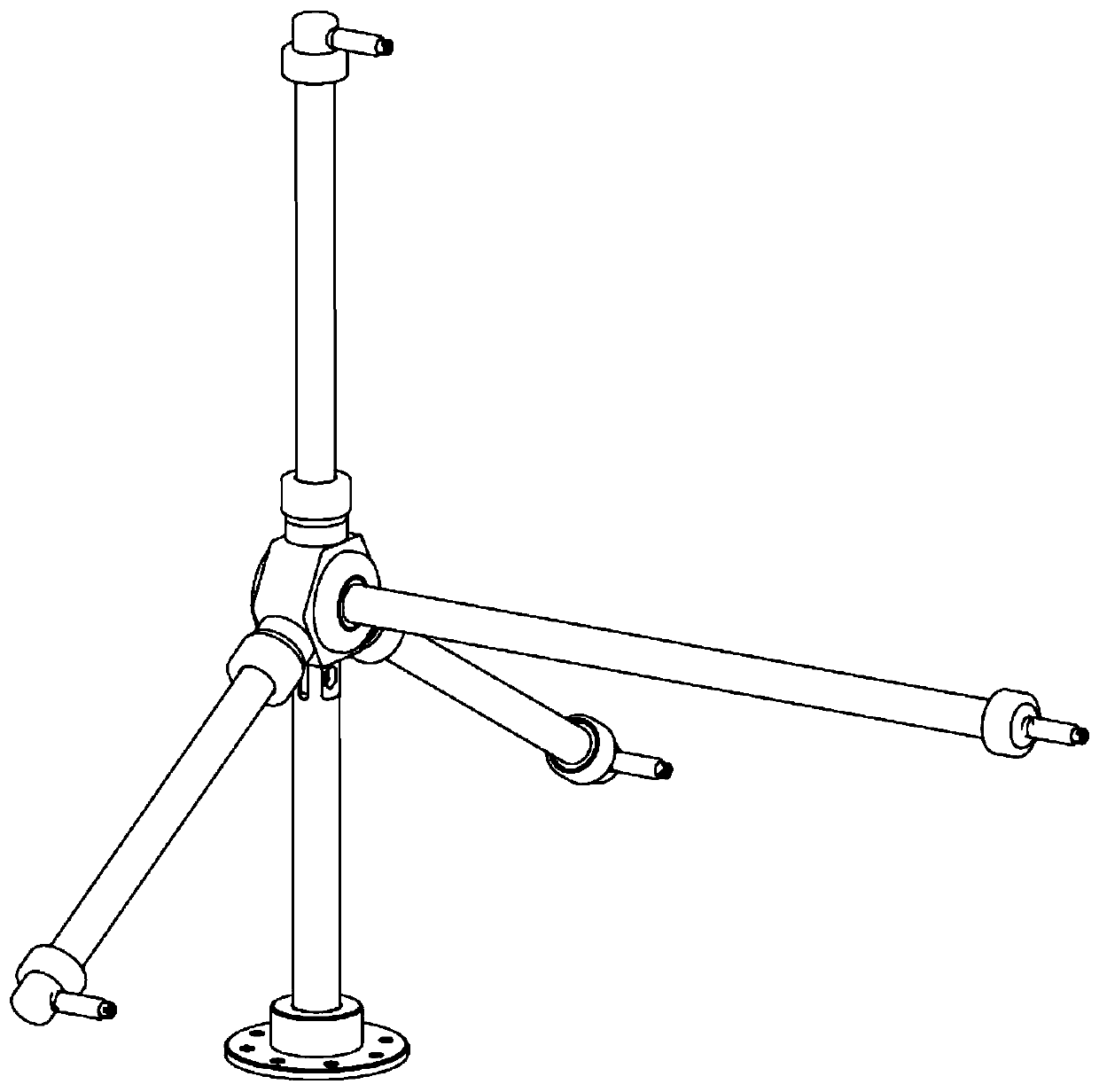

Underwater positioning device and underwater positioning method

The invention discloses an underwater positioning device and an underwater positioning method. The device comprises a plurality of fish finders which comprise one main fish finder and at least two slave fish finders, wherein each fish finder is used for measuring the distance from the fish finder to an underwater target; at least three connecting rods, wherein each connecting rod is used for connecting two adjacent fish finders, and the main fish finder and the slave fish finders are connected by the connecting rods to form noncollinear distribution; and a control unit which obtains the coordinates of the underwater object according to the distances measured by all fish finders and the coordinates of the fish finders. The device can obtain the correct position of the underwater target quickly and conveniently through at least three fish finders which are in noncollinear distribution, thereby achieving the precise locating of the underwater target through the conventional equipment. Thedevice is low in cost, is portable, and is flexible and convenient for application and maintenance.

Owner:SHENZHEN ZHENDI INFORMATION TECH CO LTD

Method for manufacturing thin film transistor substrate

InactiveUS10396207B2Satisfy positioning accuracyExcellently perform alignmentTransistorSolid-state devicesLaser beamsSemiconductor

There is provided a manufacturing method for a thin-film transistor substrate, which enables to excellently perform alignment between an annealed region of a semiconductor film and a mask pattern of a conductive film. The method comprises annealing a semiconductor film being formed on a gate insulation film covering a gate electrode with a laser beam by using a mask, the gate electrode being formed within a thin-film transistor substrate region on a substrate; forming a first alignment mark outside the thin-film transistor substrate region on the substrate, by irradiating the substrate through the mask with the laser beam; patterning the semiconductor film; forming a conductive film on the semiconductor film; positioning a photomask on the basis of the first alignment mark; and forming a source electrode and a drain electrode by patterning the conductive film through the photomask; wherein the first alignment mark is formed while annealing the semiconductor film.

Owner:SAKAI DISPLAY PROD

Correction table creation method for head position control, head position control method and disk device

ActiveUS20060056100A1Guaranteed valueHigh gainTrack finding/aligningRecord information storageComputer scienceHead position

A head position control system control the position of the head by correcting the components synchronizing rotation of the disk from the head control amount, in which an adjusted gain to minimize the components synchronizing rotation after correction is theoretically acquired. An adjusted gain based on the ratio of the magnitude between the components synchronizing rotation of a disk and the components not synchronizing rotation of the disk in the position signals is used. And a gain to minimize RRO after correction can be theoretically determined using an expression to determine RRO after correction. The gain can be determined without depending on experiment, and the value of RRO after correction can be guaranteed, therefore the manufacturing time and the device specifications can be determined.

Owner:KK TOSHIBA

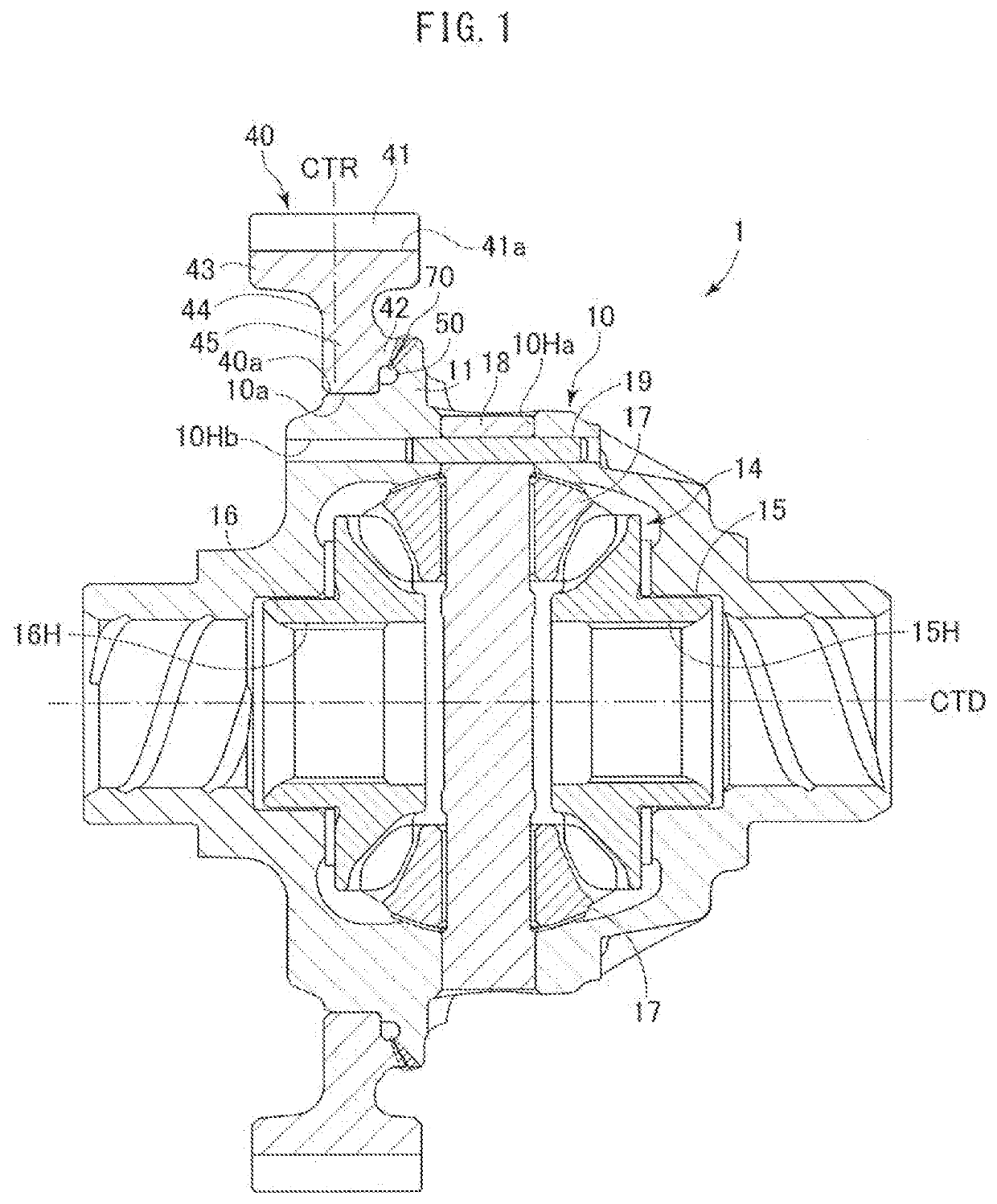

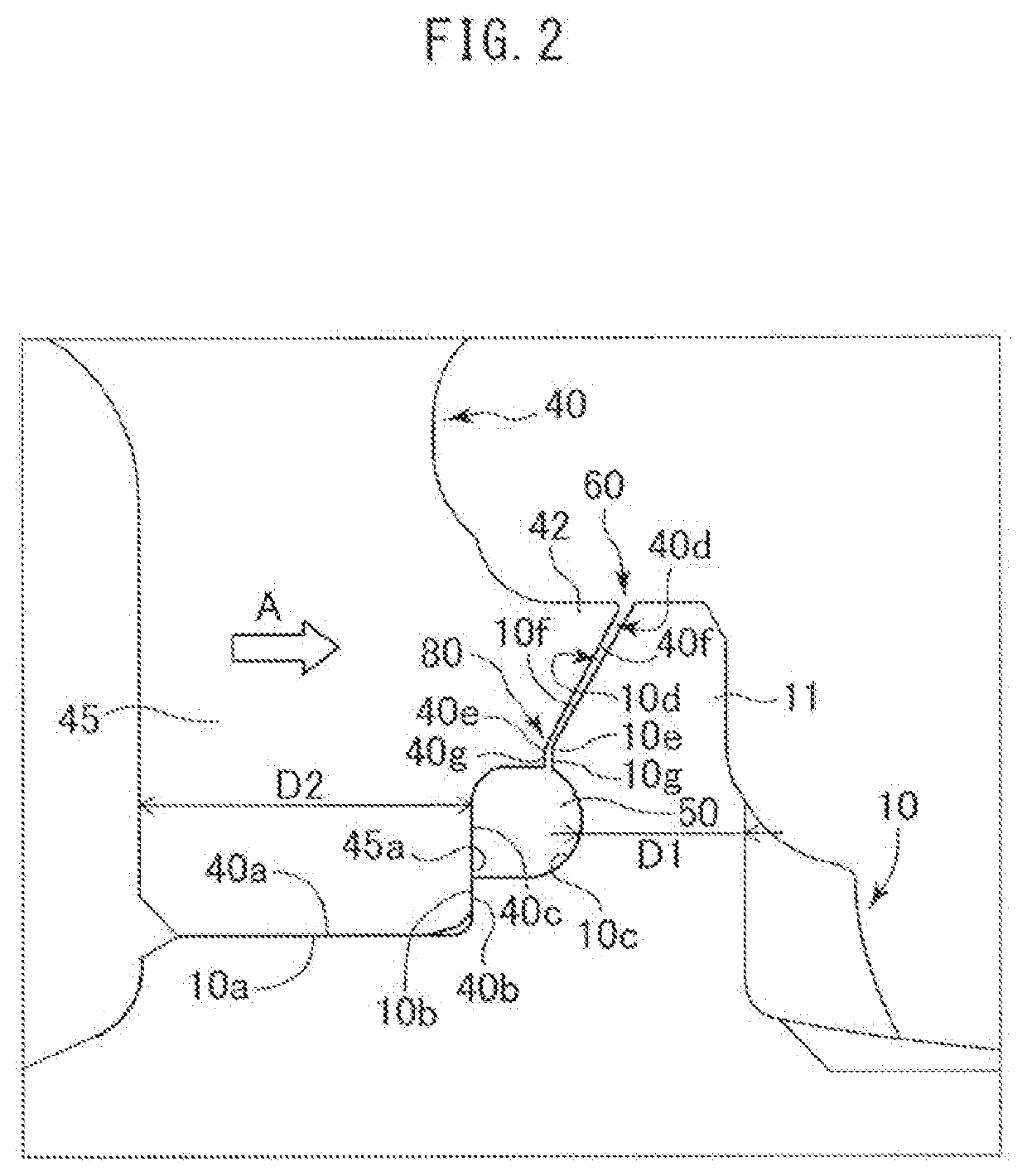

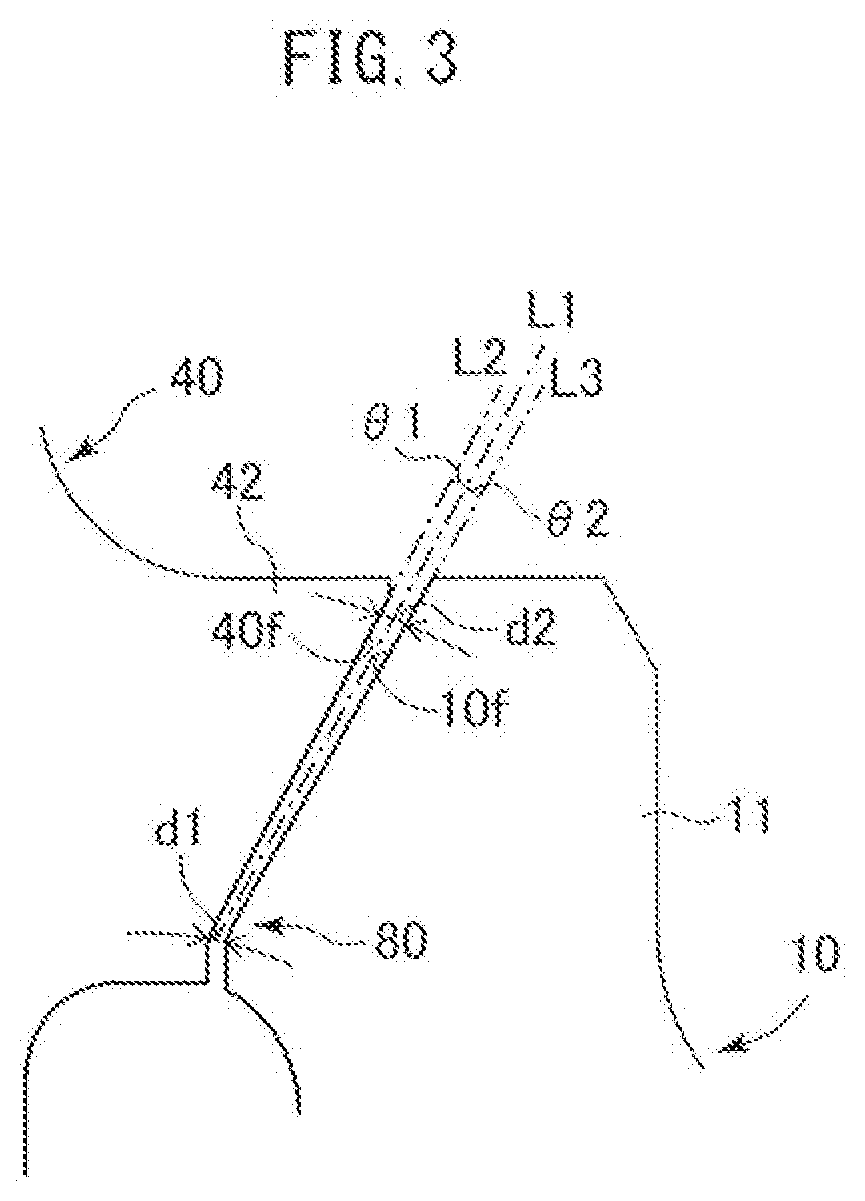

Differential device

ActiveUS20220196131A1Avoid noiseSuppress the differential ring gearGear vibration/noise dampingDifferential gearingsCouplingEngineering

A differential device includes a differential case (10) that has a flange portion (11) and a differential ring gear (40) that has a tooth portion, a fixed and supported portion (45), and a coupling portion. The differential case (10) has a first abutting surface (10a) and a restricting portion (10b). The differential ring gear (40) has a second abutting surface (40a) and an abutting portion (40b). A welding portion that is formed by welding the flange portion (11) of the differential case (10) and the fixed and supported portion (45) of the differential ring gear (40) is disposed at a position that is different from an abutting part between the first abutting surface (10a) and the second abutting surface (40a) and an abutting part between the restricting portion (10b) and the abutting portion (40b).

Owner:AISIN CORP

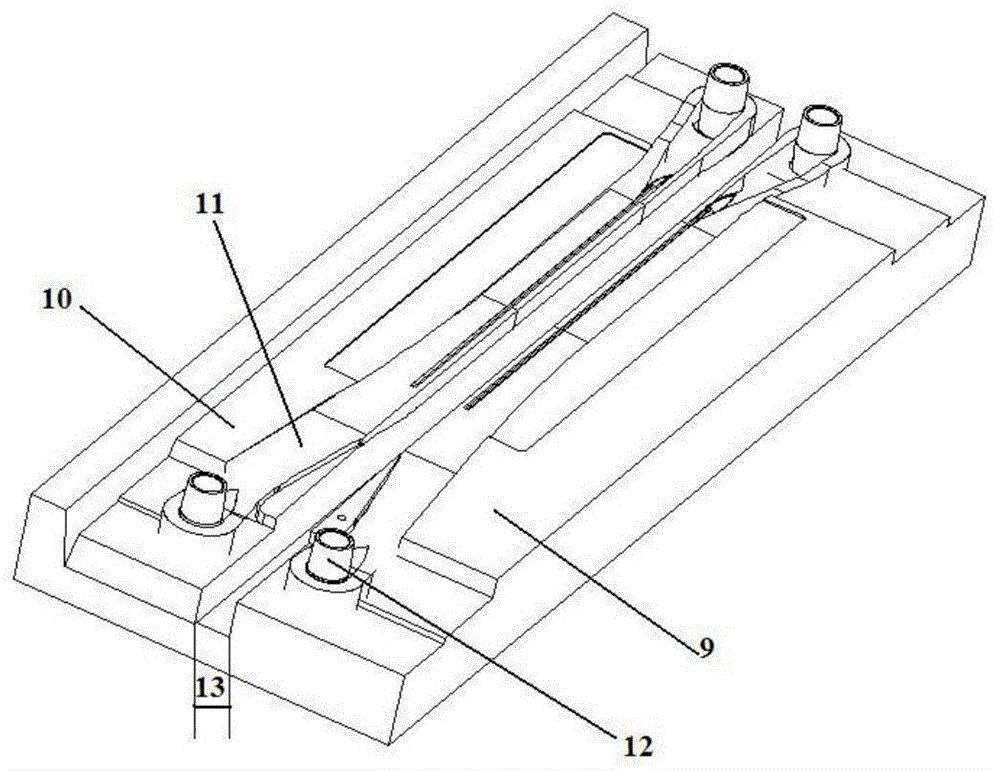

Partitioned paving molding die and method for multi-bundle and multi-positioning girder belts

InactiveCN104669650ASolve the problem of insufficient operating spaceAvoid messy yarnRelative motionMechanical engineering

The invention belongs to a composite molding technology, and particularly relates to a paving molding die and a method for composite parts composed of multi-bundle and multi-positioning girder belts. The die is designed and manufactured in a partitioned mode, a lower die is divided into a main die body and a movable block by taking a symmetric position of girder belts at the front and rear edges of a flexible beam as a die parting surface, and the movable block can move for 0-40 mm away from the main die body so as to dorm a paving space; and a sliding chute is arranged at the joint of the bottom of the movable block and the main die body, so that the relative motion between the movable block and the main die body is performed along a fixed trajectory. The main die body and the movable block are respectively provided with a positioning pin for two bushes at the inner and outer ends, and the positioning pins are used as benchmarks for the winding and positioning of the girder belts. According to the invention, the winding and paving of multi-bundle and multi-positioning girder belts are completed in a partitioned die body form, thereby solving the problem that an operating space between two bundles of girder belts is insufficient, and avoiding the defects of raveling and corrugation of girder belts, and the like caused by the insufficiency of operating spaces.

Owner:CHANGHE AIRCRAFT INDUSTRIES CORPORATION

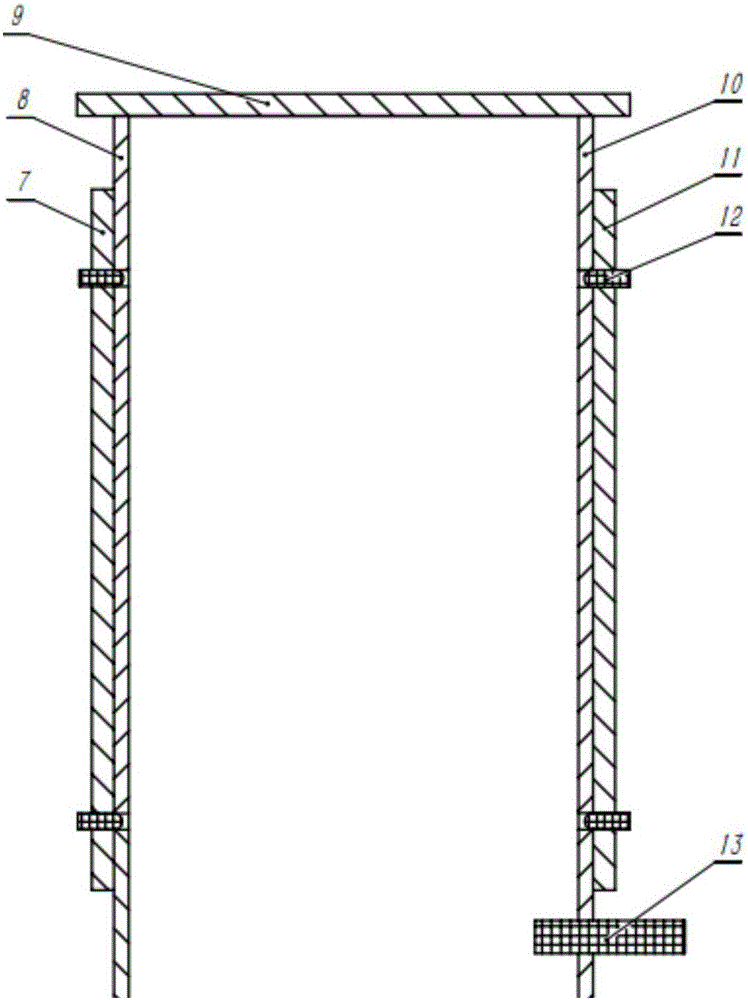

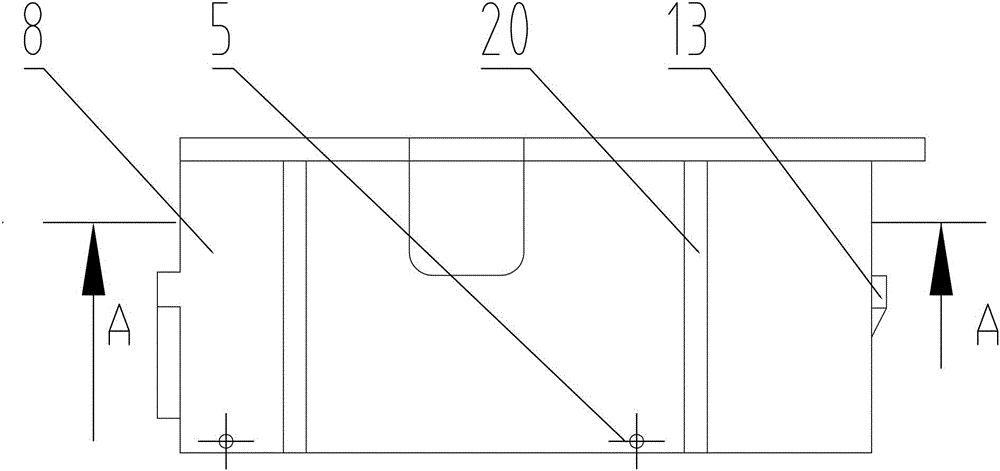

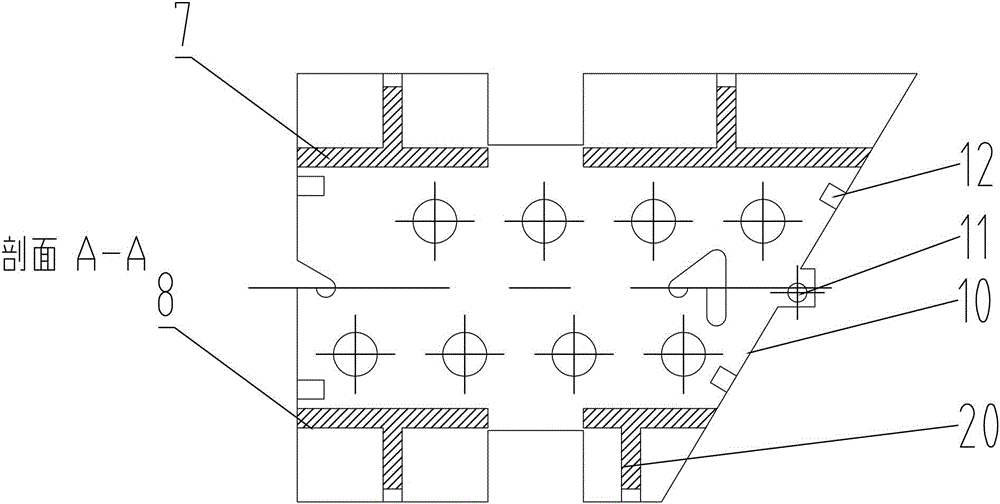

Large-sized H-shaped steel drilling die

ActiveCN105171058ASatisfy position accuracyGuaranteed coaxiality requirementsDrill jigsArchitectural engineeringFlange

A large-sized H-shaped steel drilling die comprises an upper positioning template, a lower positioning template, a support plate, a positioning assembly and adjusting bolts, wherein a plurality of positioning holes are formed in the upper positioning template and the lower positioning template; the positioning holes are the same as holes to be processed in H-shaped steel in size, quantity and position; the support plate comprises a left support plate and a right support plate; the upper positioning template is fixedly connected with the lower positioning template through the left support plate and the right support plate to form a template body; the positioning assembly is arranged at one end of the template body; the adjusting bolts are uniformly distributed on the upper positioning template, the lower positioning template and the support plate. According to the large-sized H-shaped steel drilling die, the upper positioning template, the lower positioning template, the support plate and the positioning assembly are arranged, so that holes in an upper flange plate and a lower flange plate of the H-shaped steel can be subjected to drilling at the same time; therefore, the requirement of holes in the upper flange plate and the lower flange plate for coaxiality is met, and the position precision of all the holes in the flange plates is guaranteed.

Owner:YICHANG JIANGXIA MARINE MACHINERY

Adjusting positioner for radiation device

InactiveUS7942576B2Easy to adjust the positionAccuracy adjustableX-ray/infra-red processesHandling using diaphragms/collimetersDetentX-ray

Owner:TSINGHUA UNIV +1

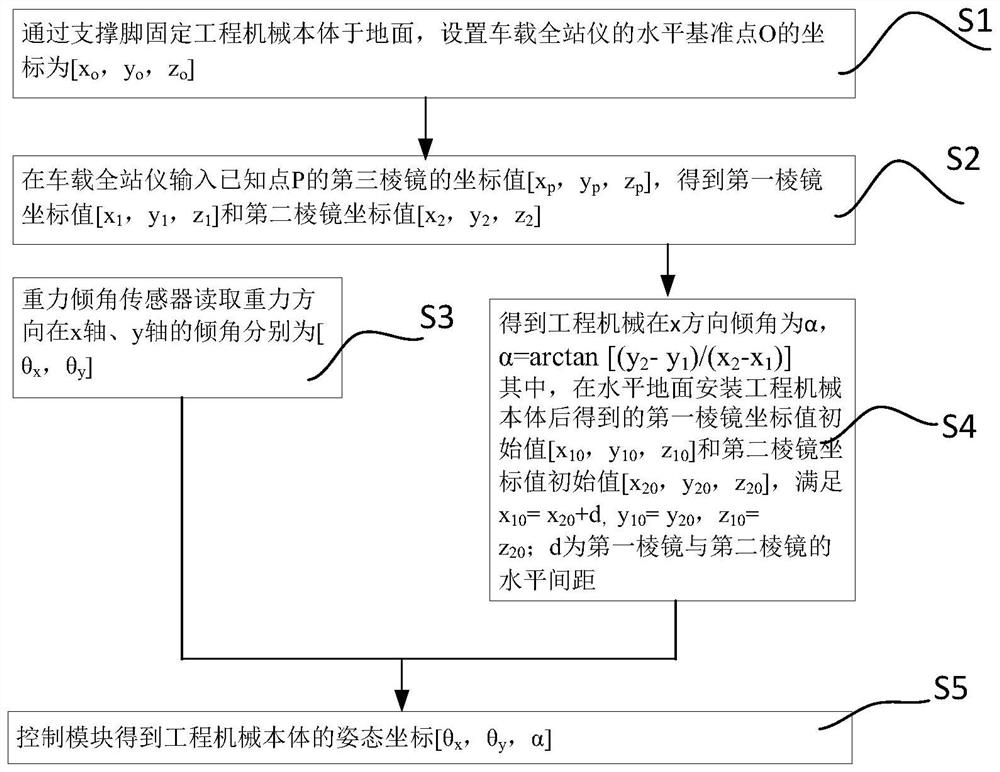

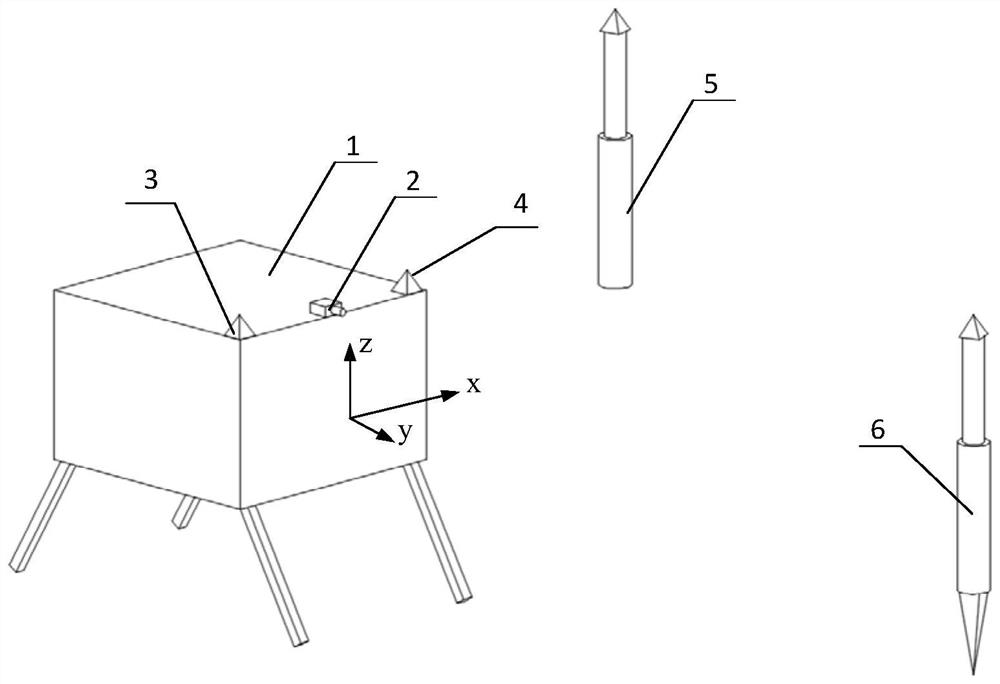

Method and system for determining attitude position of mine engineering machinery

ActiveCN113048972AAccurate calculationEasy to operateNavigational calculation instrumentsIn vehicleTotal station

The invention relates to the technical field of intelligent equipment, and provides a mine engineering machinery attitude position determination method and system.The method comprises the steps that a vehicle-mounted total station, a first prism, a second prism and a third prism of a reference station known point P are fixedly arranged on an engineering machinery body; when the coordinate of the horizontal reference point O of the vehicle-mounted total station and the coordinate value of the third prism of the known point P are set, and the inclination angles of the gravity direction on the x-axis and the y-axis are read in combination with a gravity inclination angle sensor, the operation is simple, the precision is high, and the method and the system can meet the positioning precision of engineering machinery especially working in a mine under the environment of severe working conditions; after the engineering machinery is violently vibrated in the mine operation process, the posture and the position of the engineering machinery body can be rapidly adjusted, and for high-precision positioning operation such as positioning blast holes, the efficiency and the safety of the whole operation can be improved.

Owner:衢州海西电子科技有限公司

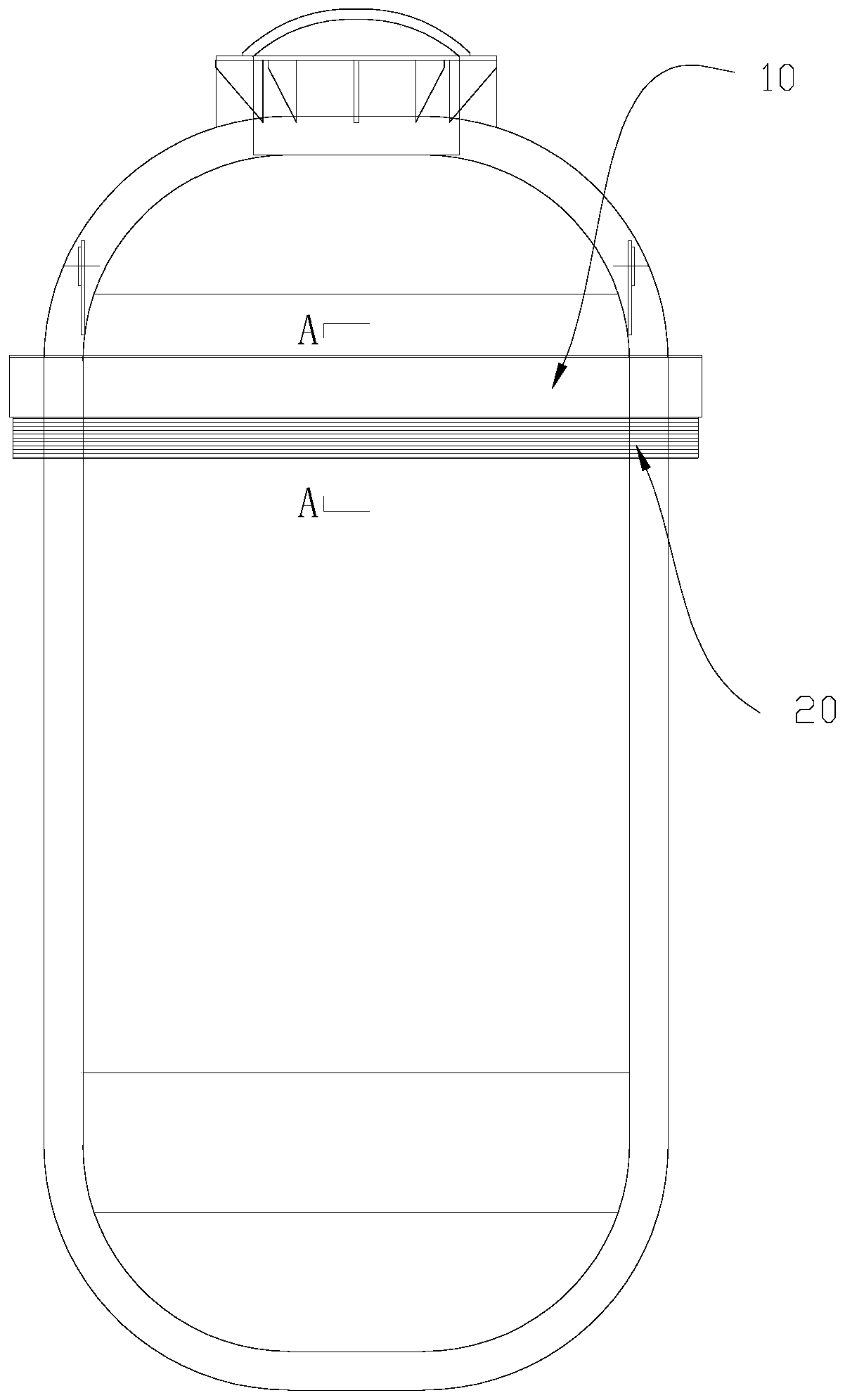

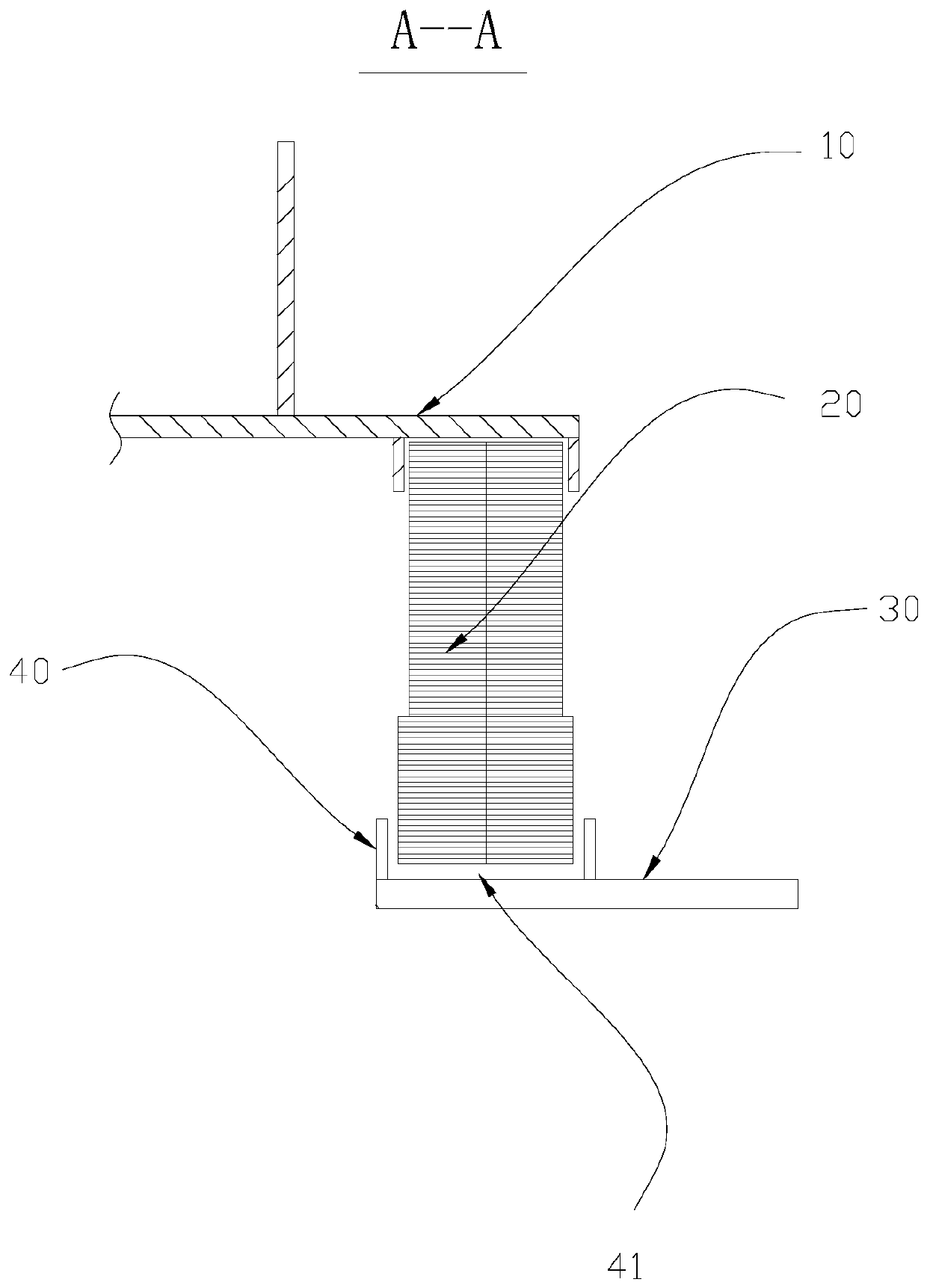

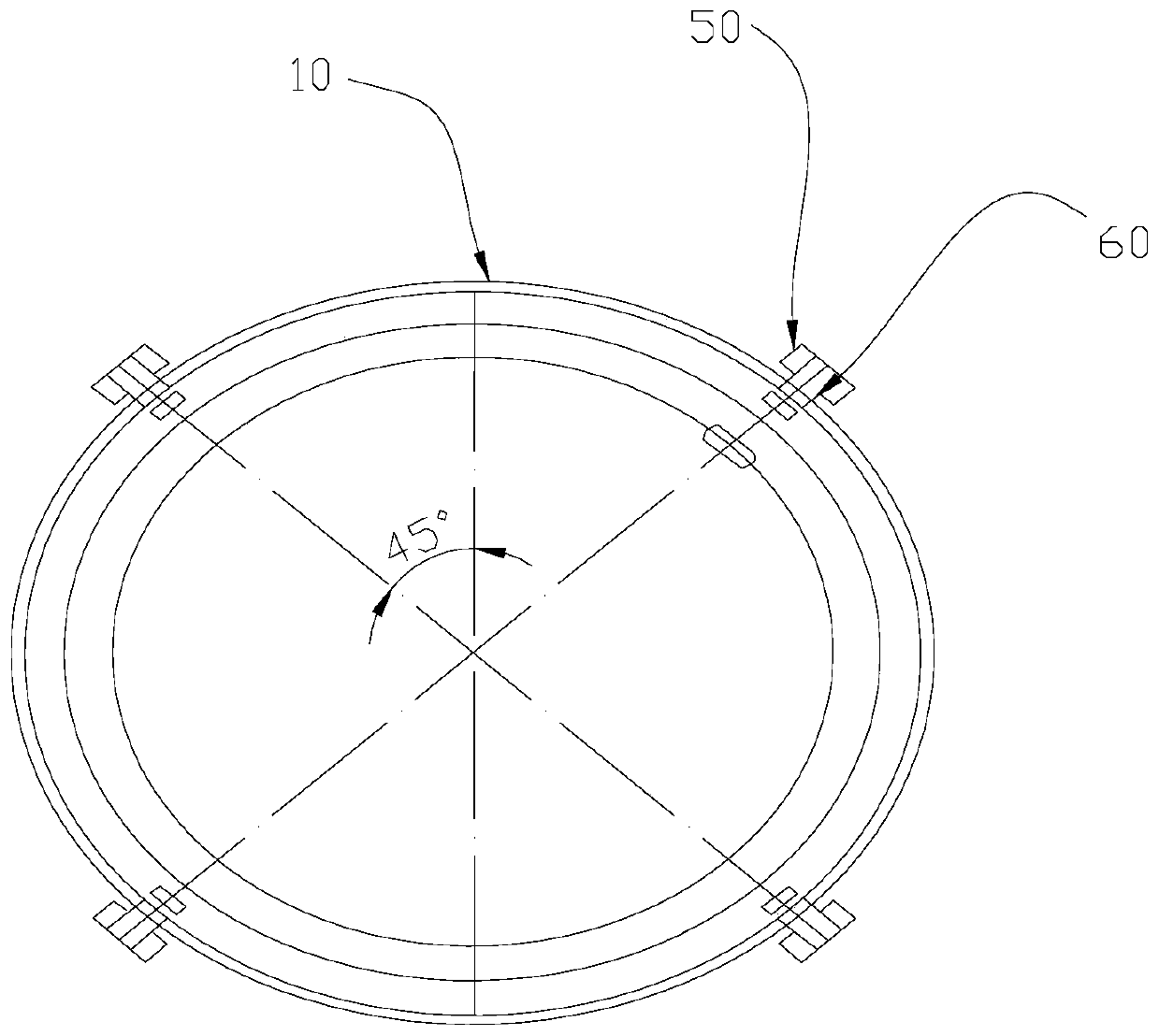

Positioning method of tank body

The invention discloses a positioning method of a tank body. According to the method, the measurement data of a wood block structure and a structural groove are matched and adjusted, the structural groove on a hull structure is arranged according to the installation data of the wood block structure, a 45-degree positioning line of the tank body and a 45-degree positioning line of the hull structure are drawn and matched so that the tank body can be quickly and accurately positioned on the hull structure, the positioning precision requirement is met, the positioning time is shortened, and the situation that the tank body is damaged due to the fact that the wood block structure collides with the hull structure is avoided. The method is used in the technical field of ship construction.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

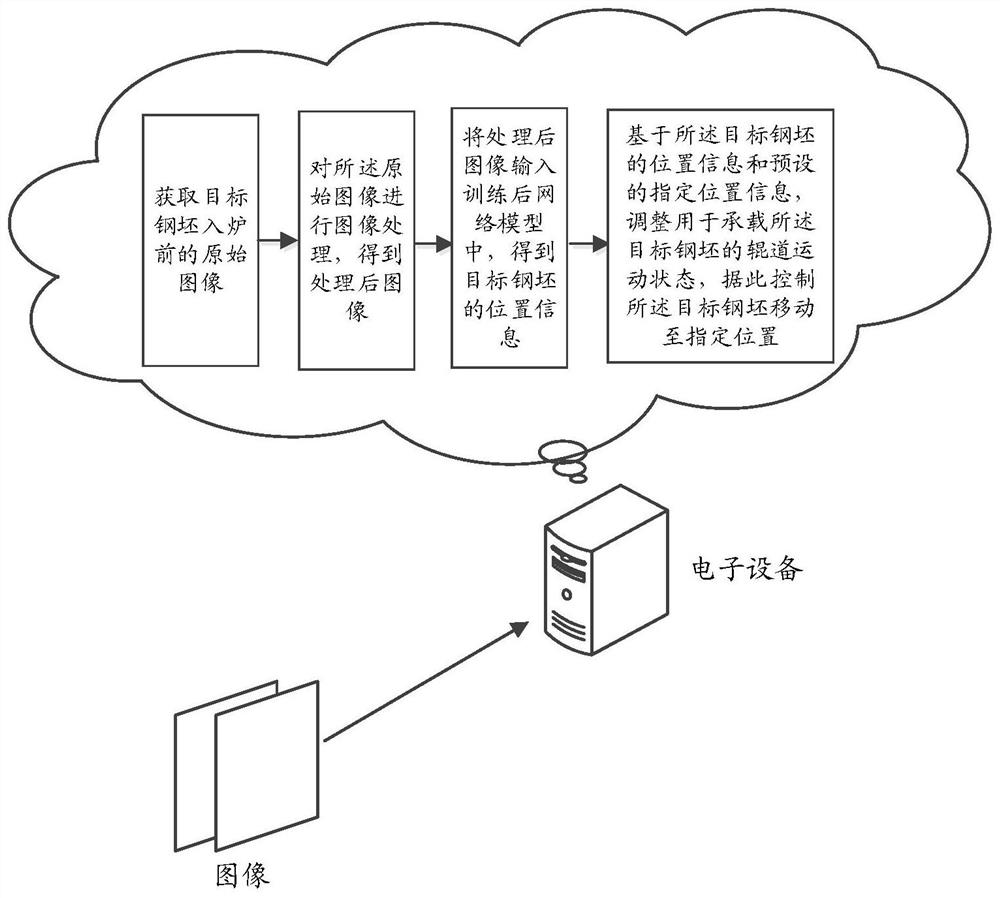

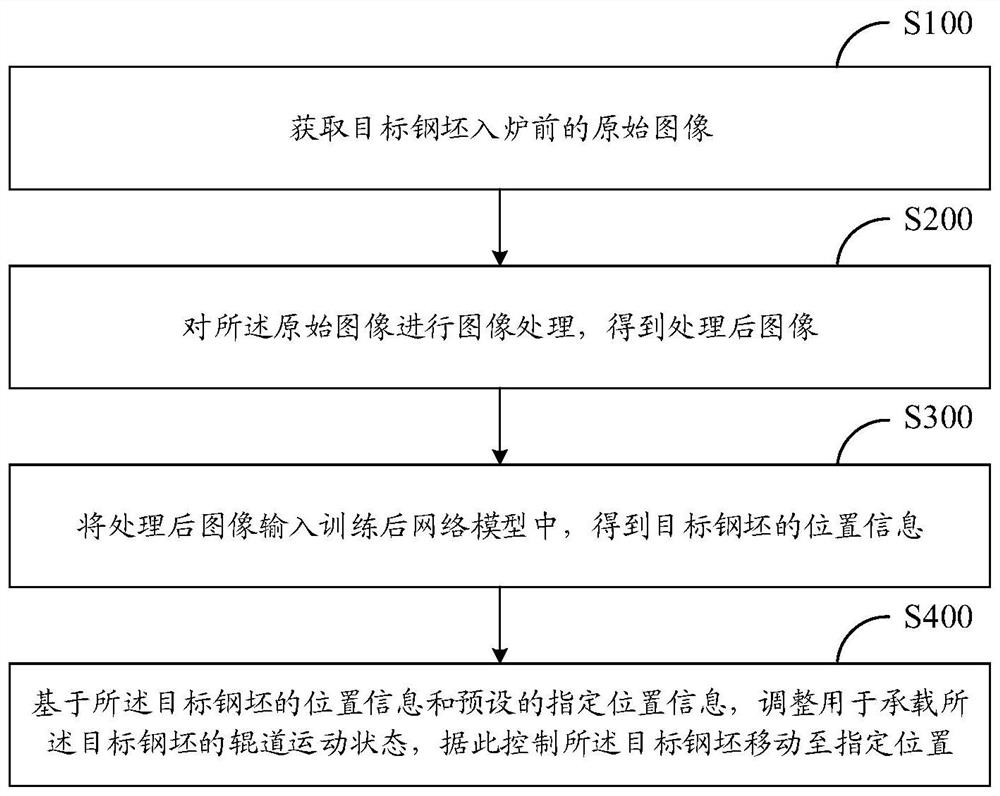

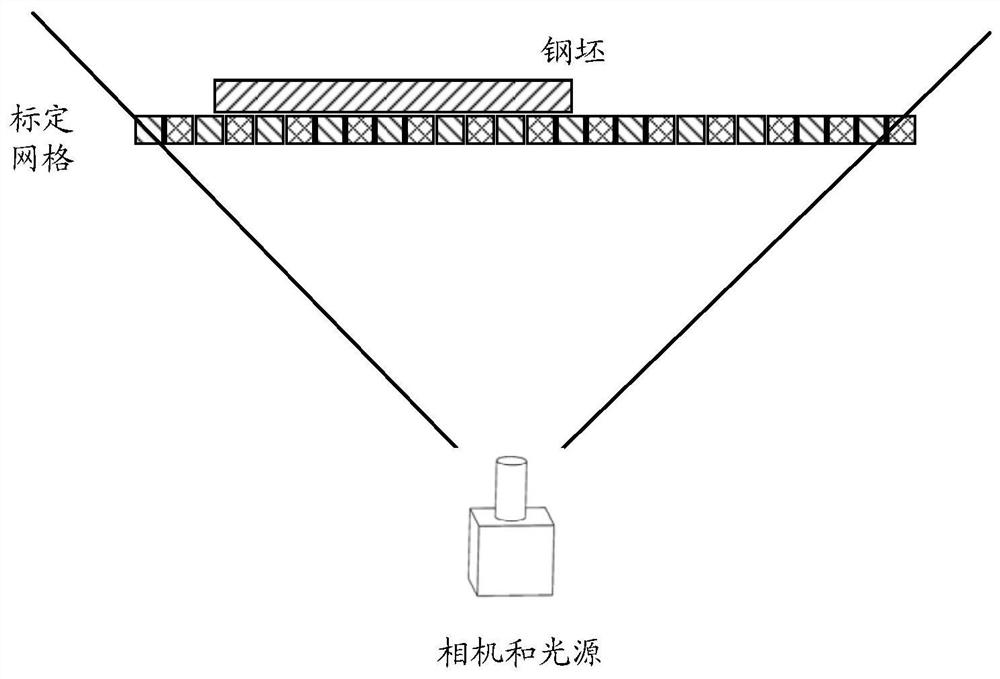

Positioning control method and device before billet charging, electronic equipment and computer readable storage medium

PendingCN113989219AEasy to learnExpand the receptive fieldImage enhancementImage analysisImaging processingMachine vision

The invention discloses a positioning control method and device before billet charging, electronic equipment and a computer readable storage medium. The method of the embodiment of the invention comprises: obtaining an original image of a target steel billet before the target steel billet enters a furnace; performing image processing on the original image to obtain a processed image; inputting the processed image into a trained network model to obtain the position information of the target steel billet; and based on the position information of the target steel billet and preset designated position information, adjusting the motion state of a roller bed used for bearing the target steel billet, and accordingly controlling the target steel billet to move to a designated position. According to the scheme, machine vision and a deep learning technology are utilized to realize automatic positioning of steel billets with different sizes before the steel billets are fed into the furnace, and the effect of accurate positioning is achieved.

Owner:策立科技(南京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com