Positioning milling tire

A positioning pin and positioning groove technology, applied in the field of mechanical parts processing, can solve problems such as poor positioning accuracy, and achieve the effect of satisfying processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

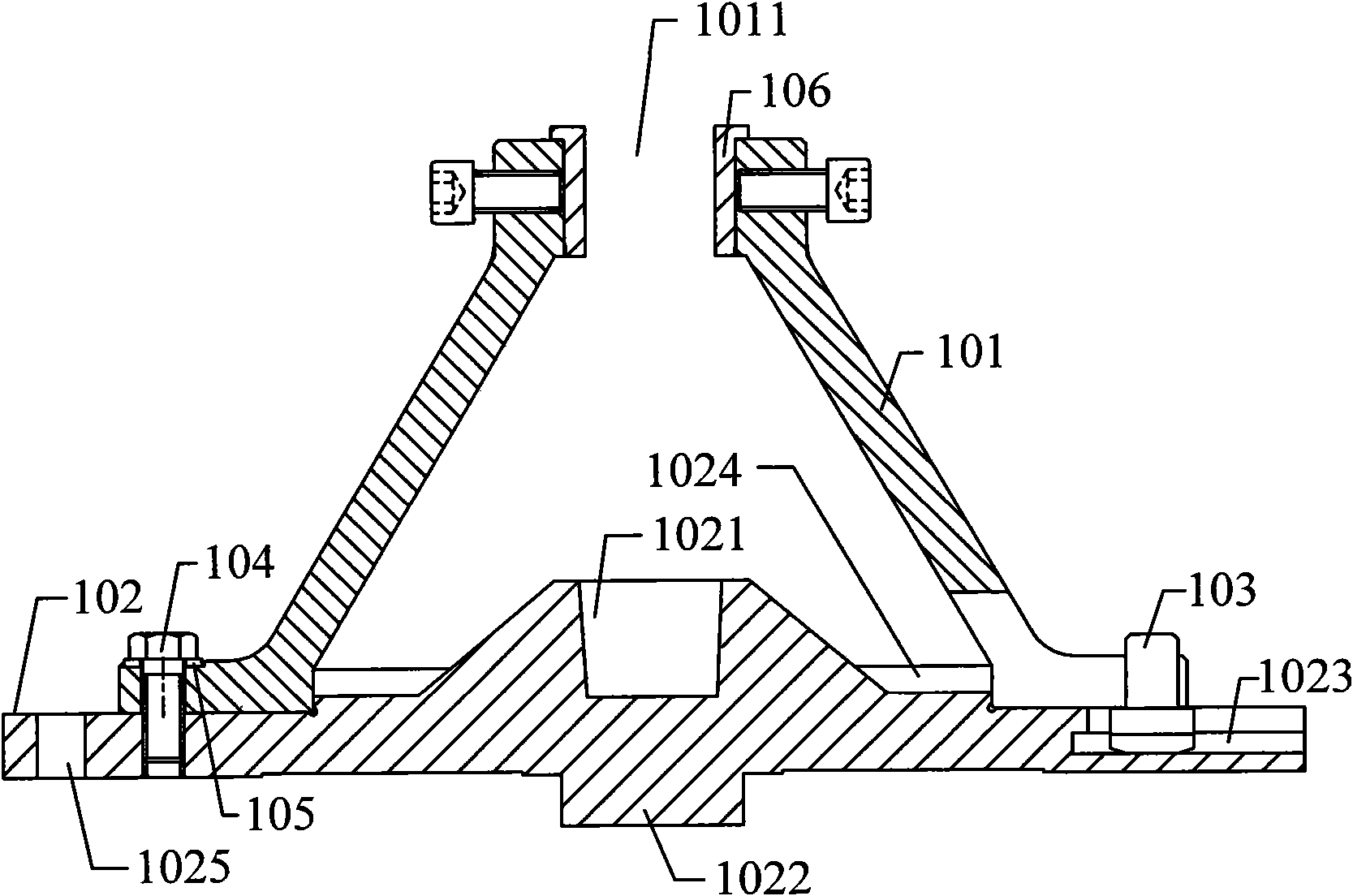

[0017] The positioning milling tire of the present invention is mainly used for positioning and clamping the blank material to assist in milling the blank material to make the connecting rod for the conversion circuit of the transmission box, and to ensure the processing accuracy of the end face spline.

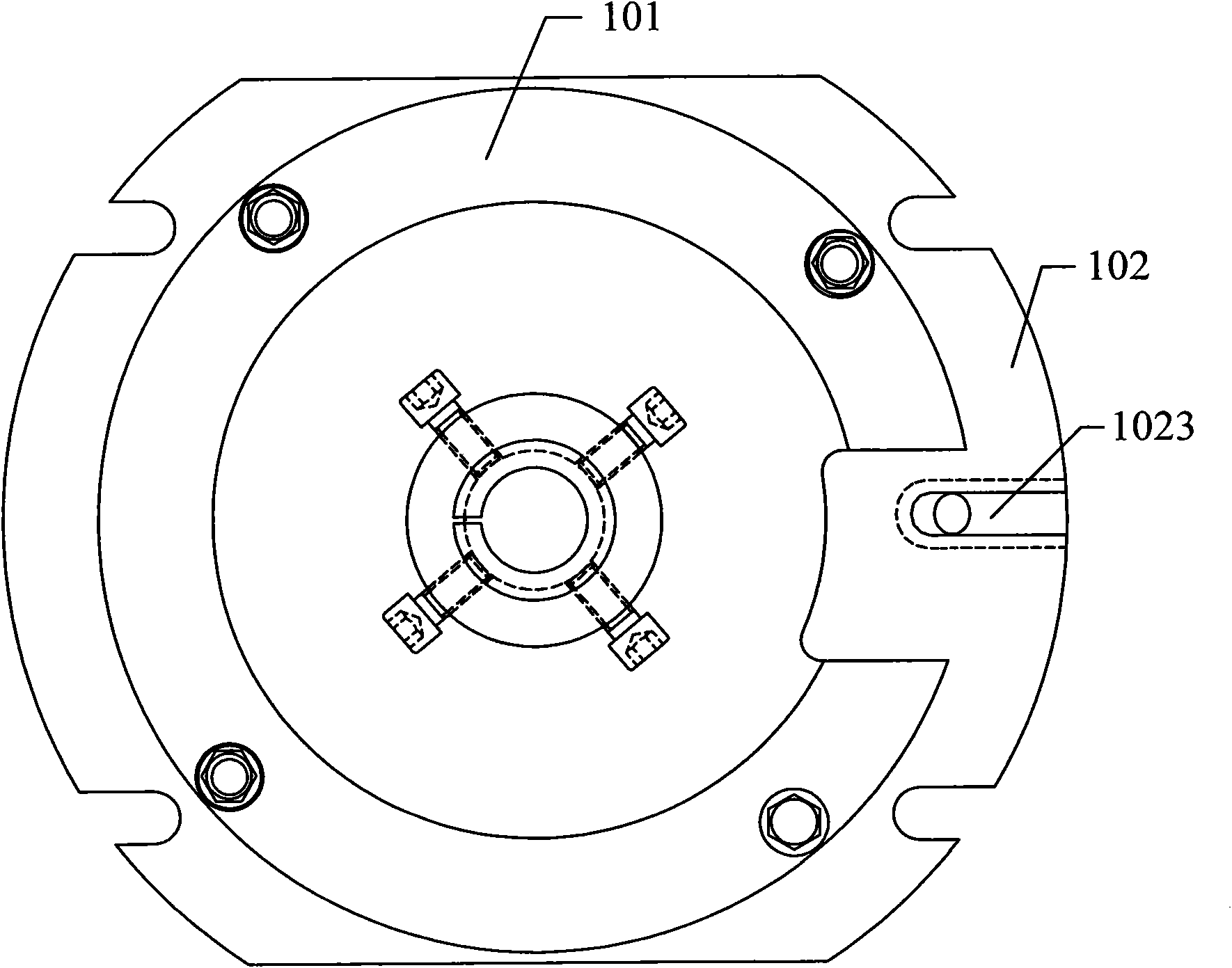

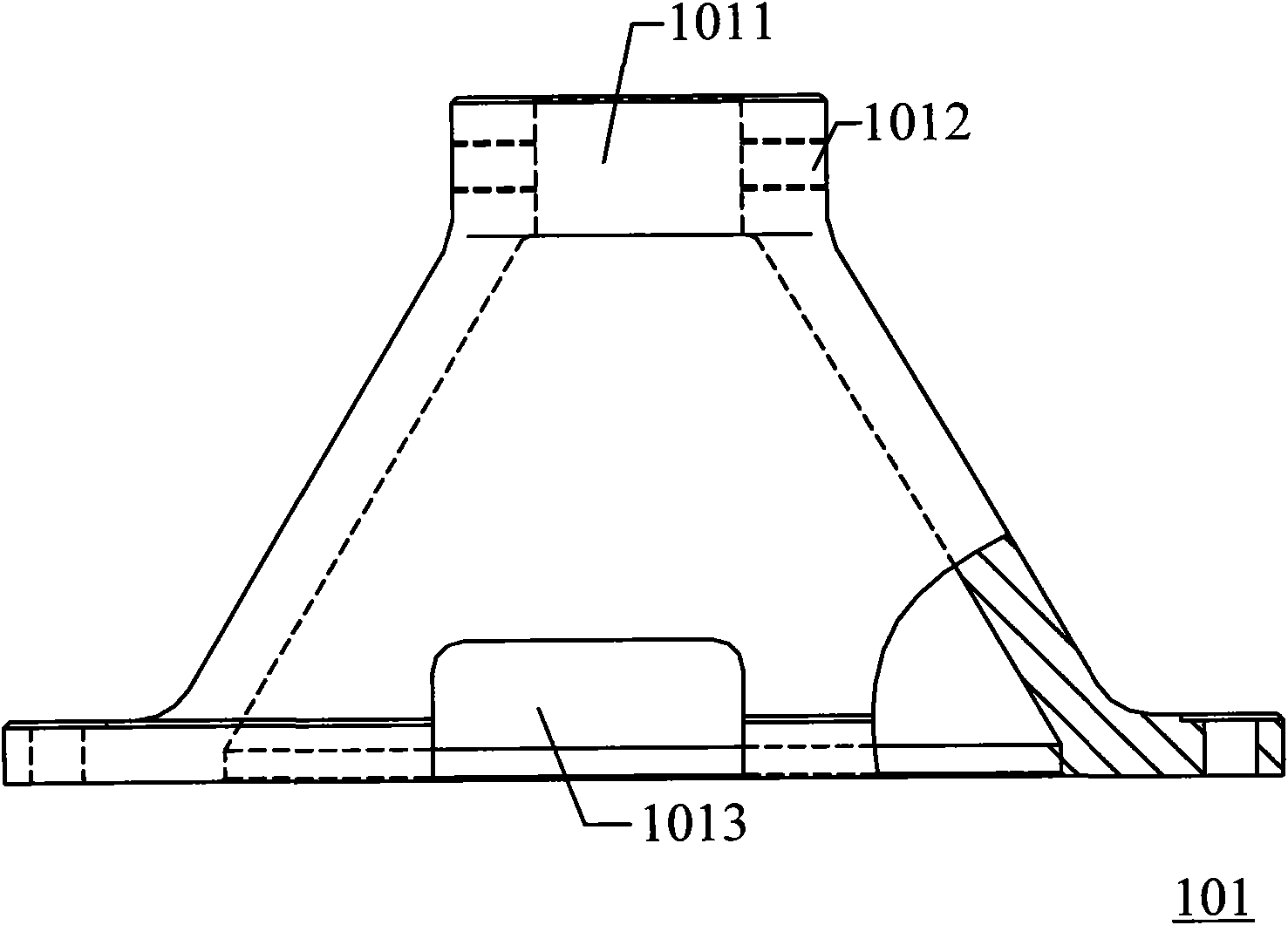

[0018] figure 1 It is a side sectional view of the positioning milling tire of the present invention. figure 2 It is the top view of the positioning milling tire of the present invention. image 3 It is a side view half-sectional view of the support body in the positioning milling tire of the present invention. Figure 4 It is a top view of the supporting body in the positioning milling tire of the present invention. Figure 5 Side view of the milling seat in the positioning milling tire for the present invention. Figure 6 It is the top view of the milling seat in the positioning milling tire of the present invention. to combine Figure 1 to Figure 6 As shown, the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com