Motor test platform

A test bench and engine technology, which can be used in engine testing, machine/structural component testing, measuring devices, etc., to solve problems such as collisions between pre-installed platforms and engines, potential safety hazards, and inconvenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

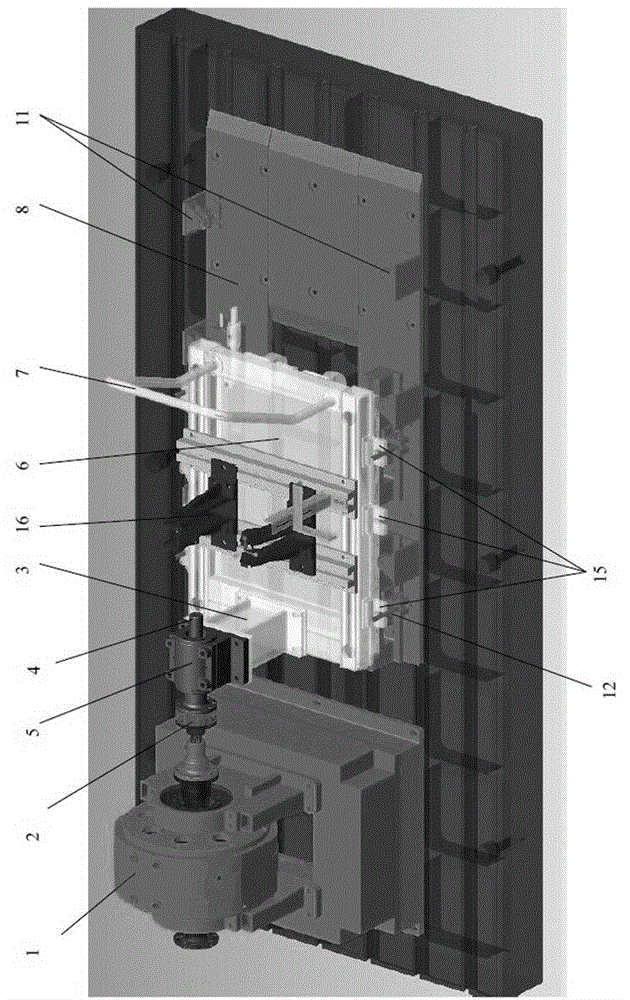

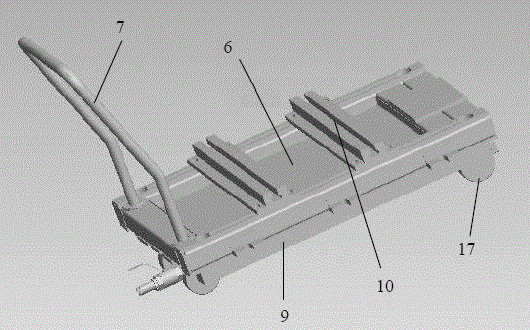

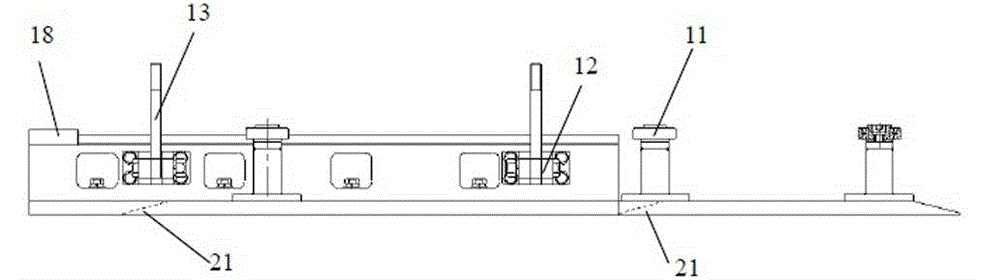

[0024] An example of an engine test bench of the present invention is Figure 1~Figure 7 As shown, it includes a V-shaped guide rail 19 and a plane guide rail 20 extending forward and backward along the docking direction as a docking guide rail, and has a platform guide rail adapted to the docking guide rail so as to be able to guide and move on the docking guide rail. Mobile platform 6, mobile platform The rear end of 6 is provided with cart handle 7, and cart handle 7 forms cart jointly with mobile platform 6, wheel 23, as figure 2 shown. The engine test bench includes a base 8, on which V-shaped guide rails 19 and plane guide rails 20 are arranged; two pairs of roller support frames are arranged at the bottom of the mobile platform 6 along the front and rear directions, and rollers 17 are rotated on the roller support frames, and a front side The axial spacing of the pair of rollers is greater than the axial spacing of the pair of rollers on the rear side. The base 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com