Butt welding machine for constructional engineering

A technology for construction engineering and butt welding machines, applied in manufacturing tools, welding equipment, auxiliary welding equipment, etc., can solve the problems of insufficient scope of application, insufficient mobility, low welding efficiency, etc., and achieve fast, convenient, stable and fast welding results. Welding effect, easy cooling and forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

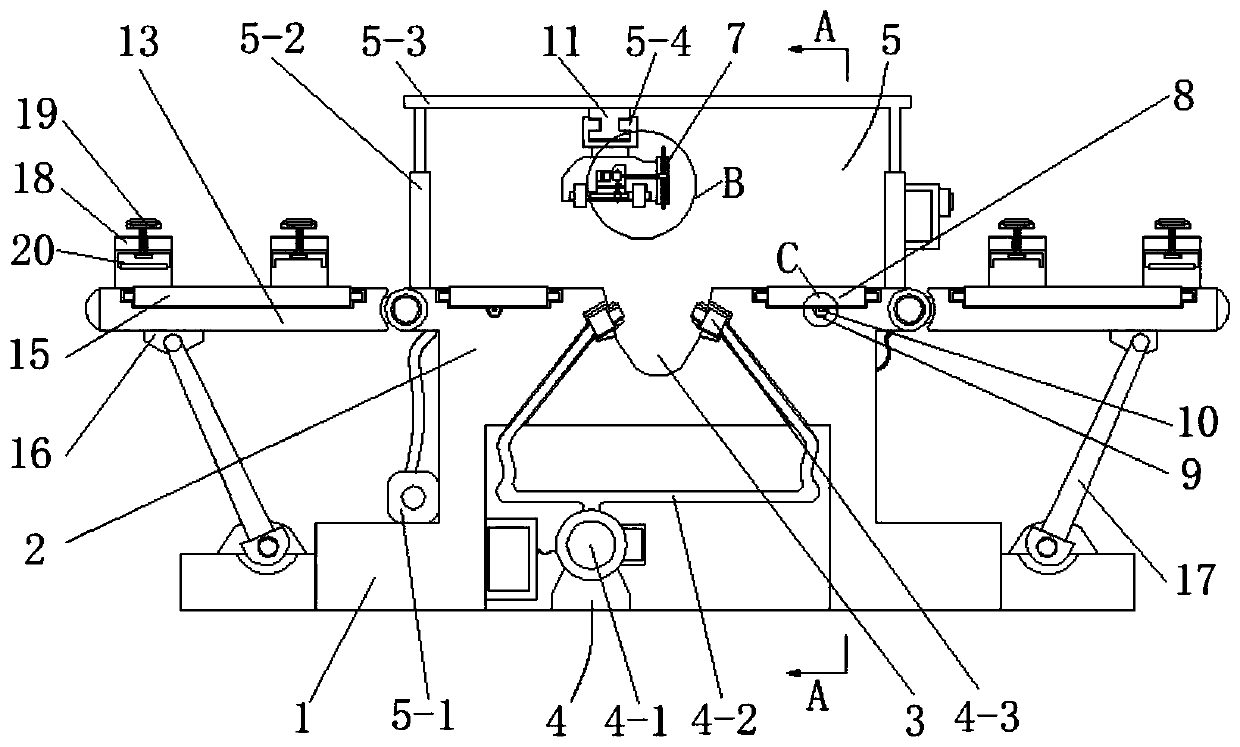

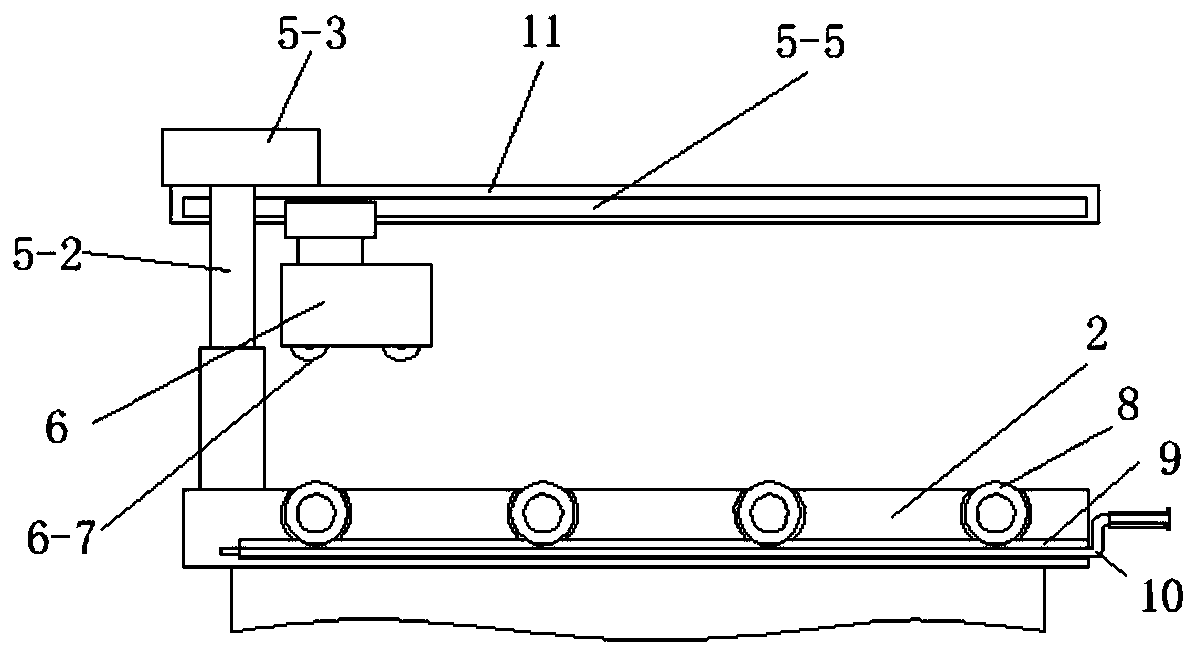

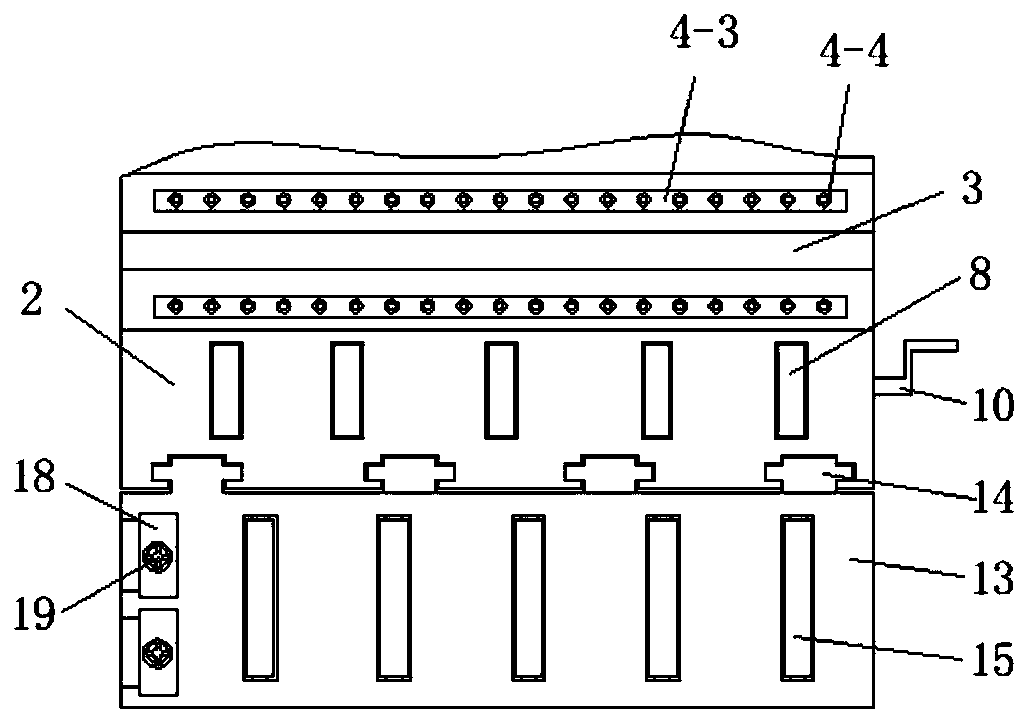

[0022] A kind of butt welding machine for construction engineering of the present embodiment, such as Figure 1 to Figure 6 As shown, it includes a fixed base 1, a placement platform 2, a U-shaped slag collection tank 3, an air source cooling system 4, a hydraulic guide support mechanism 5, a walking trolley 6 and a welding wire drum 7, and the placement platform 2 is placed on the upper part of the fixed base 1. The U-shaped slag collection tank is placed at the center of the placement table, the air source cooling system 4 is placed at the bottom of the U-shaped slag collection tank 3, and communicates with the U-shaped slag collection tank 3, and the hydraulic guide support mechanism 5 is placed on the placement table 2 On the upper part, the walking trolley 6 is clamped on the hydraulic guide support mechanism 5, and can move horizontally and vertically relative to the hydraulic guide support mechanism 5, and the welding wire drum 7 is fixedly connected to the walking troll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com