Large-sized H-shaped steel drilling die

A technology for H-shaped steel and drilling molds, which is applied in the direction of drilling molds for workpieces, etc. It can solve the problem that the coaxiality of the upper and lower holes of H-shaped steel is difficult to meet the accuracy requirements, and the upper and lower flanges cannot be drilled, etc. problems, to achieve the effect of improving operating efficiency, meeting processing requirements, and meeting end face positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

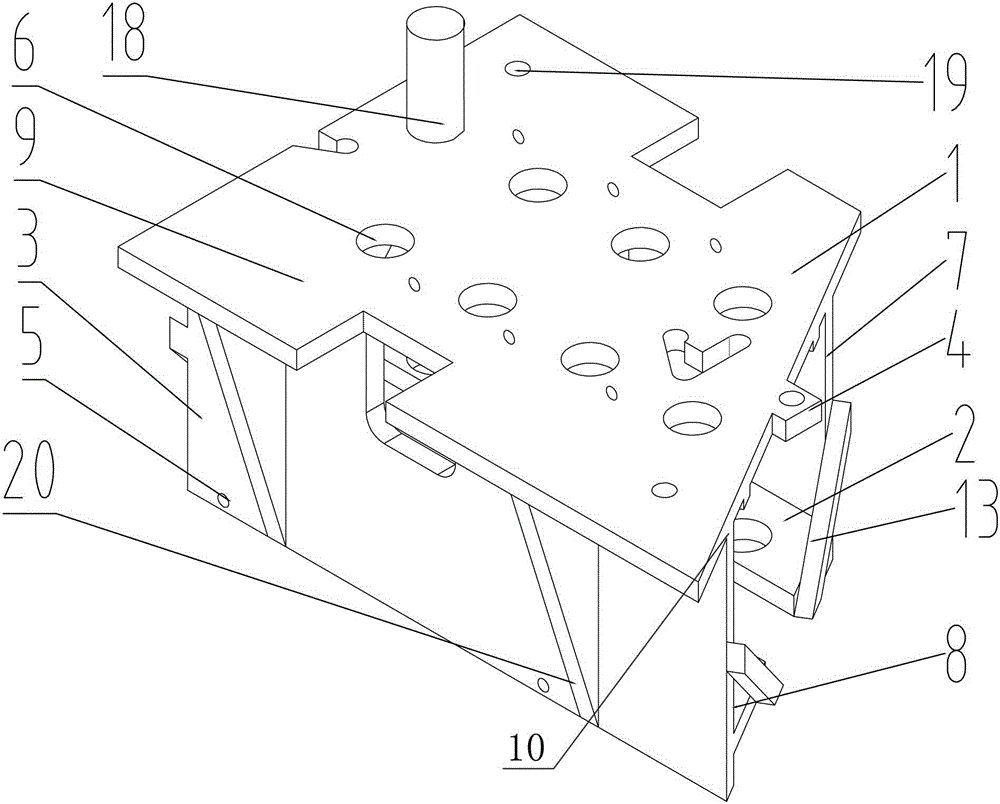

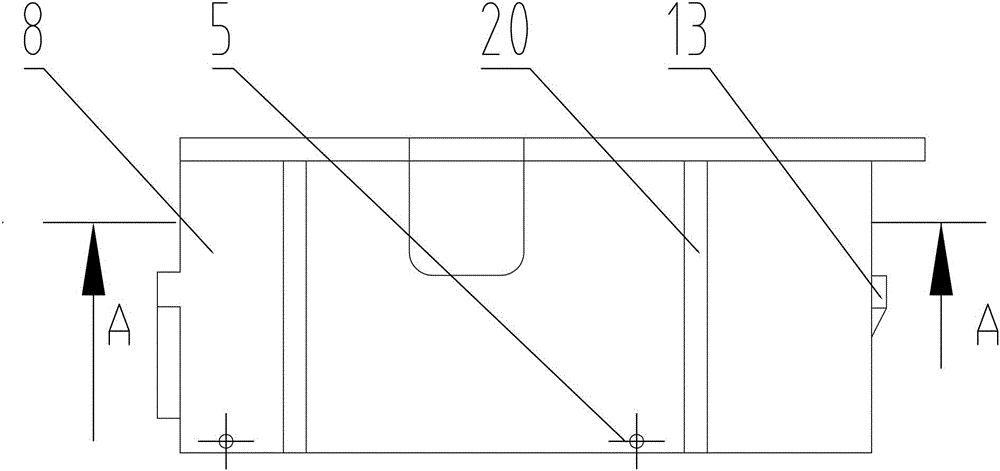

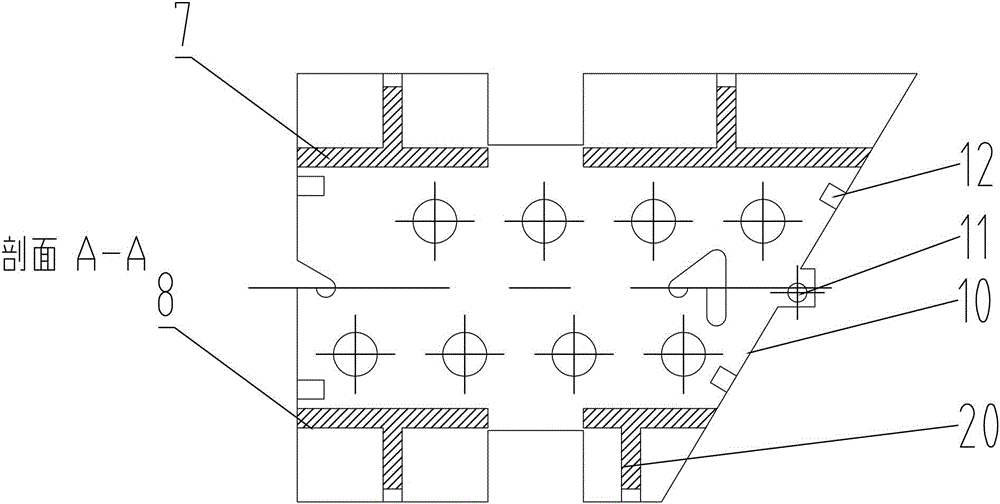

[0024] Such as figure 1 As shown, a large-scale H-shaped steel drilling mold includes an upper positioning template 1, a lower positioning template 2, a support plate 3, a positioning assembly 4 and an adjusting bolt 5, and the upper positioning template 1 and the lower positioning template 2 are equipped with A plurality of positioning holes 6, the size and quantity of the positioning holes 6 are the same as the size and quantity of the holes that the H-shaped steel needs to process, and the coordinate positions of the positioning holes 6 are the same as the coordinate positions of the H-shaped steel holes; the support plate 3 includes a left support Plate 7 and right support plate 8, upper positioning formwork 1 is fixedly connected with lower positioning formwork 2 by left support plate 7, right support plate 8 and forms formwork main body 9; The shaped steel is positioned, and the adjusting bolts 5 are evenly distributed on the upper positioning template 1, the lower posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com