Ultrasonic drilling device

A drilling device and ultrasonic technology, applied in the ultrasonic field, can solve the problems of low drilling accuracy, high energy consumption, large heat generation, etc., and achieve the effects of fast processing speed, good processing quality and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

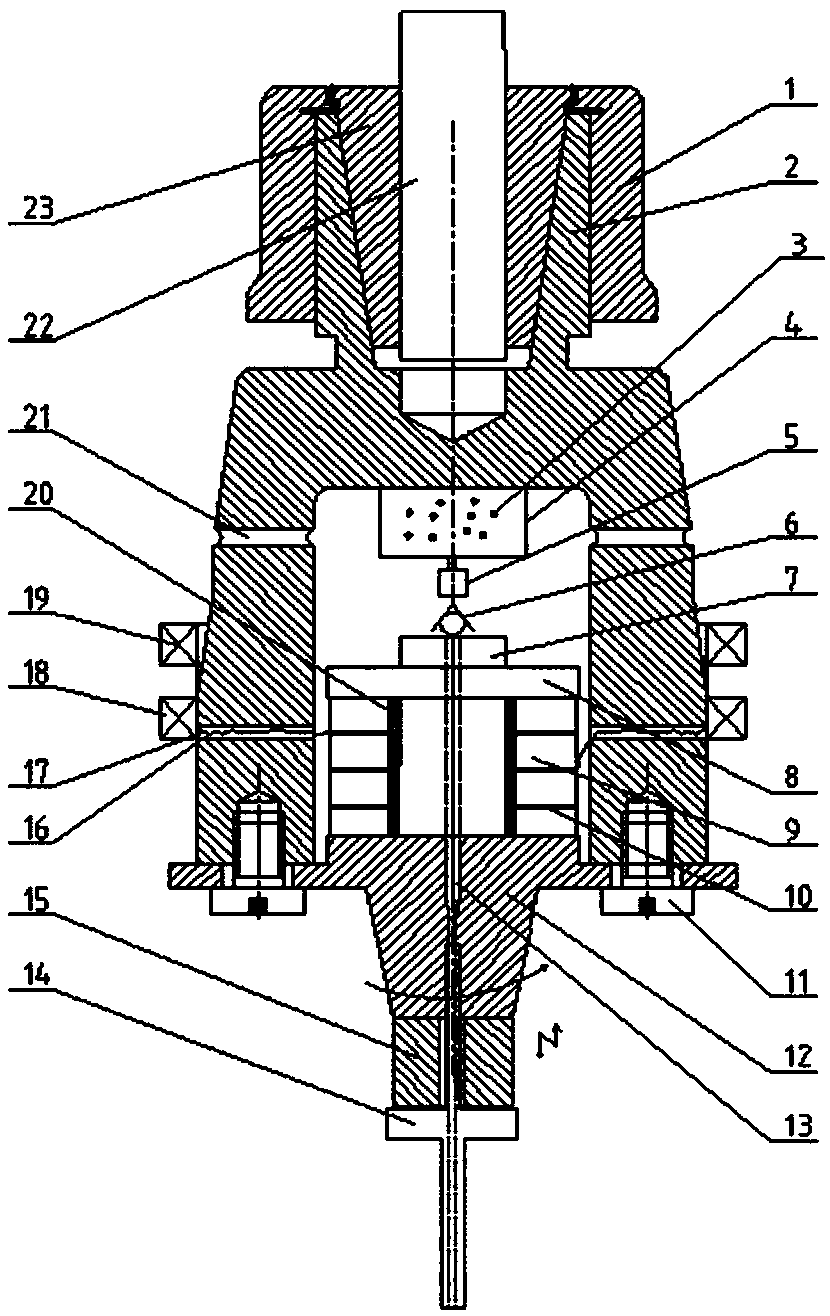

[0030] like figure 1 The shown ultrasonic drilling device is mainly composed of a sleeve cup 2, an induction coil group, a cooling system, a transducer, a horn 12 and a drill rod 14, and the top of the sleeve cup 2 is connected to the machine tool spindle 22 by a clamping mechanism. Connected, the lower part of the sleeve cup 2 is open, and the outer wall of the sleeve cup 2 is wound with an induction coil group matched with the transducer; the cooling system and the transducer are arranged in the open end of the sleeve cup 2; the transducer The driving end of the horn is connected with the input end of the horn 12, and the horn 12 is fixed on the opening end face of the sleeve cup 2 through the connecting bolt 12, and the output end of the horn 12 is connected with the upper end of the drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com