Universal shot blasting fixture used for shot blasting of root of compressor blade

A technology of shot peening treatment and air compressor, which is applied to the processing device of used abrasives, manufacturing tools, abrasives, etc., can solve the problems of high maintenance cost and poor versatility, and achieve good versatility, improve production efficiency, and reliable clamping tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

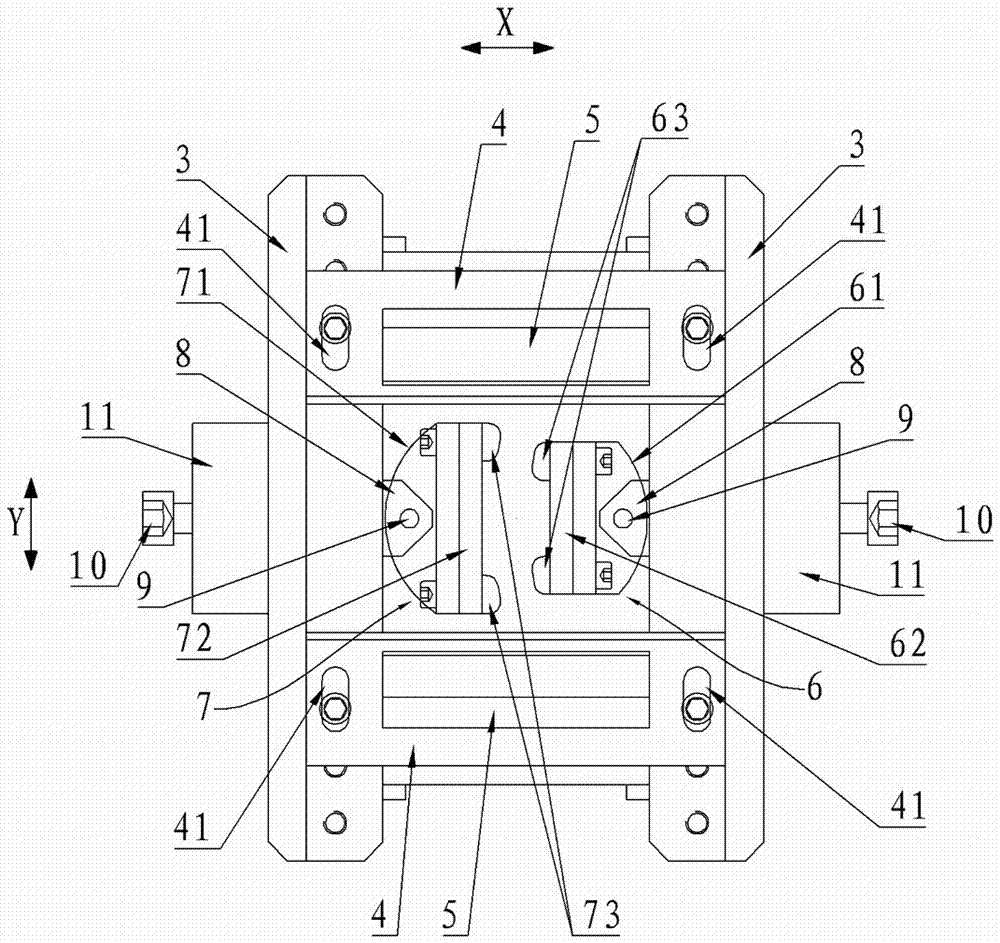

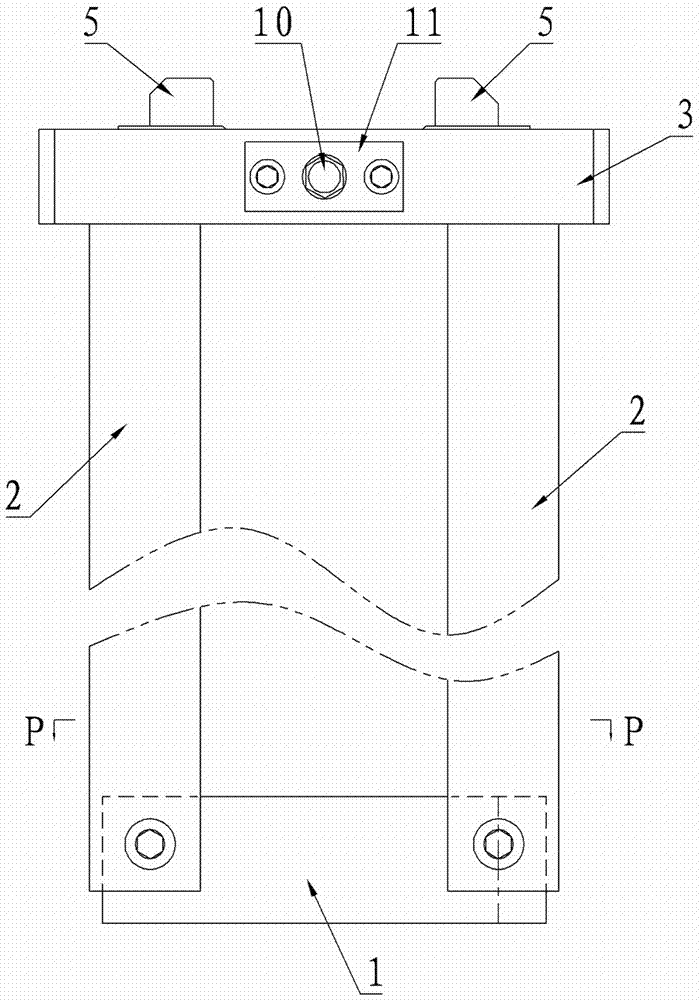

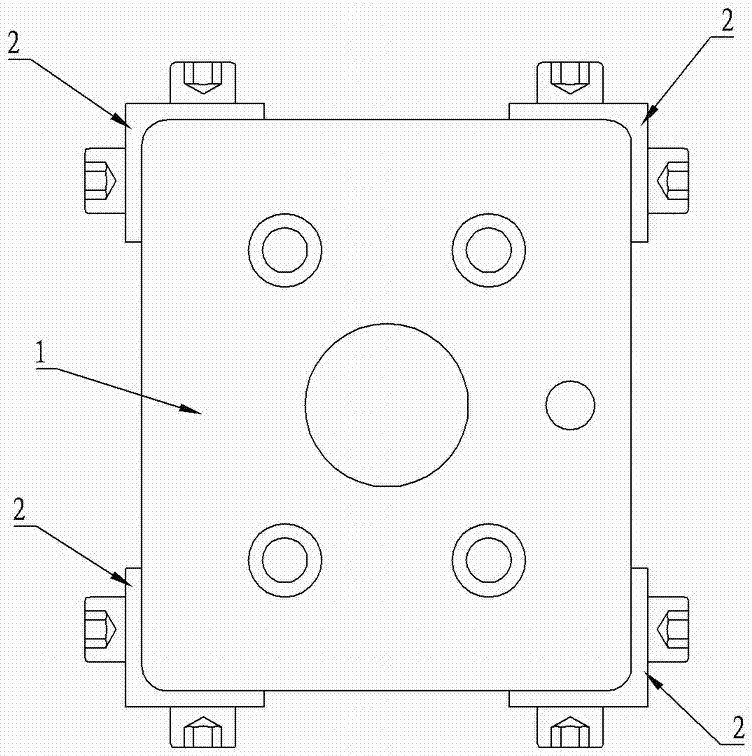

[0024] See figure 1 , figure 2 and image 3 , the general shot peening fixture used for the shot peening of the blade root of the compressor blade of the present invention comprises a base 1, a positioning adjustment component and an adjustable blade profile holding component, and the four corner ends of the base 1 are respectively vertically installed with equal heights The height bracket 2, in this embodiment, the height bracket 2 is an equilateral angle steel, which is installed on the outside of the corner end of the base 1; the positioning adjustment component is supported and installed on the height bracket 2, and the adjustable blade profile clamping component is installed in the positioning On the adjustment assembly; the positioning adjustment assembly includes a positioning guide block 3 and a sliding plate 4. Two positioning guide blocks 3 are installed on the four height brackets 2 in parallel in the lateral direction, and two laterally parallel sliding plates 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com