Patents

Literature

96results about How to "Meet clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

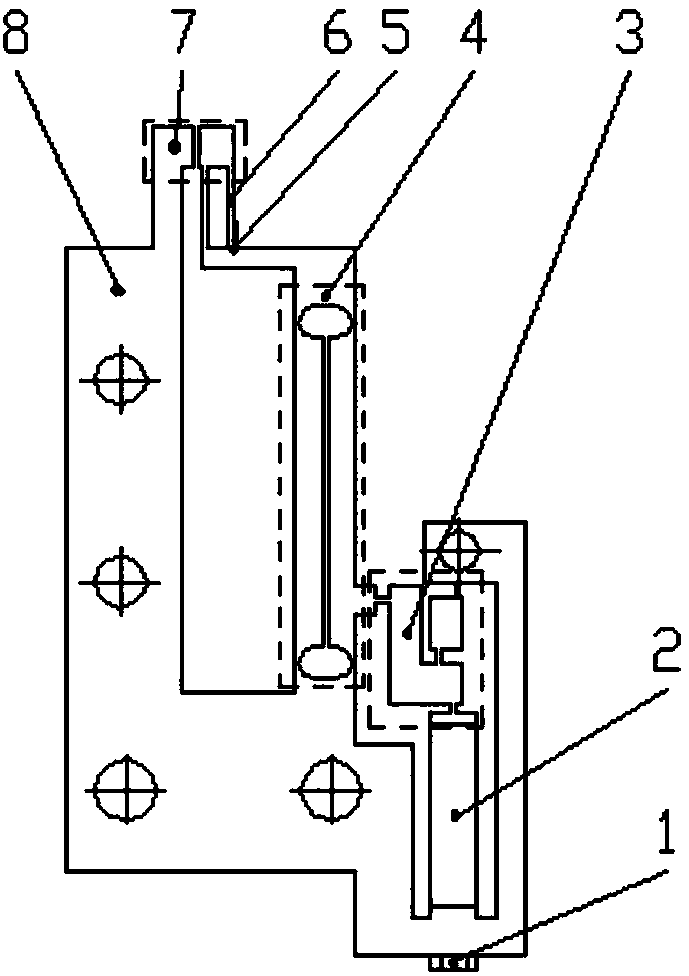

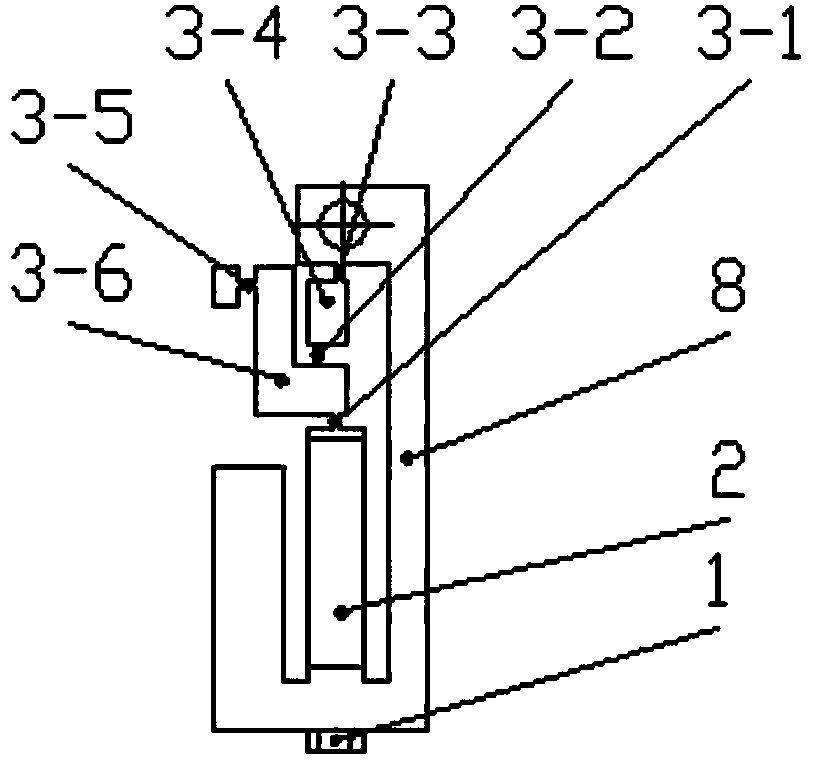

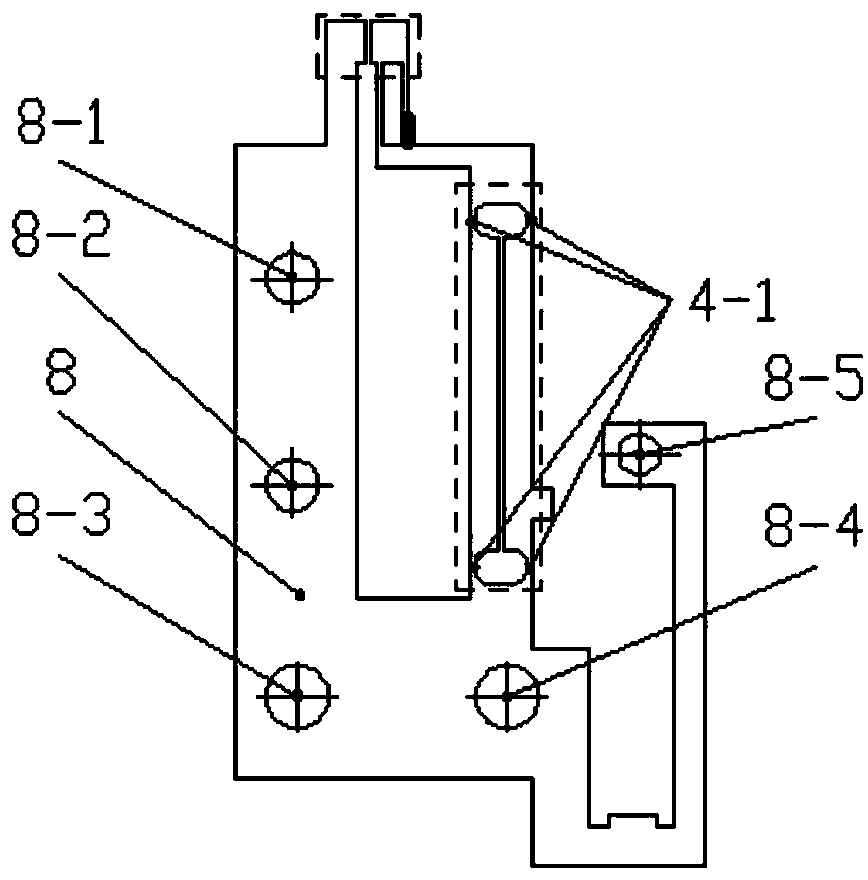

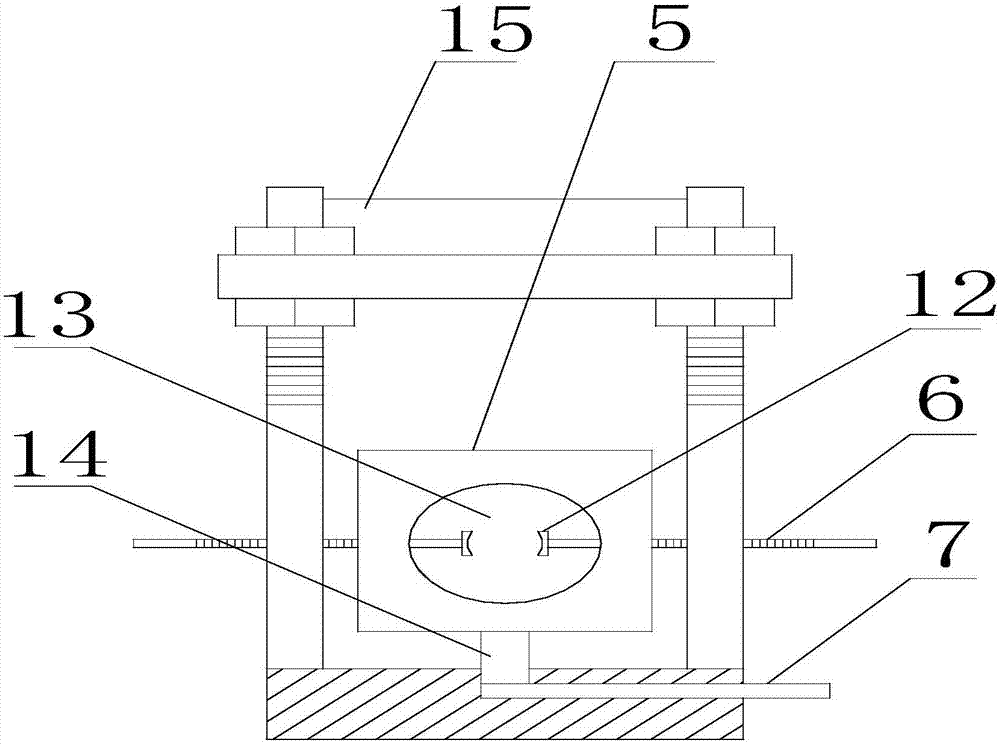

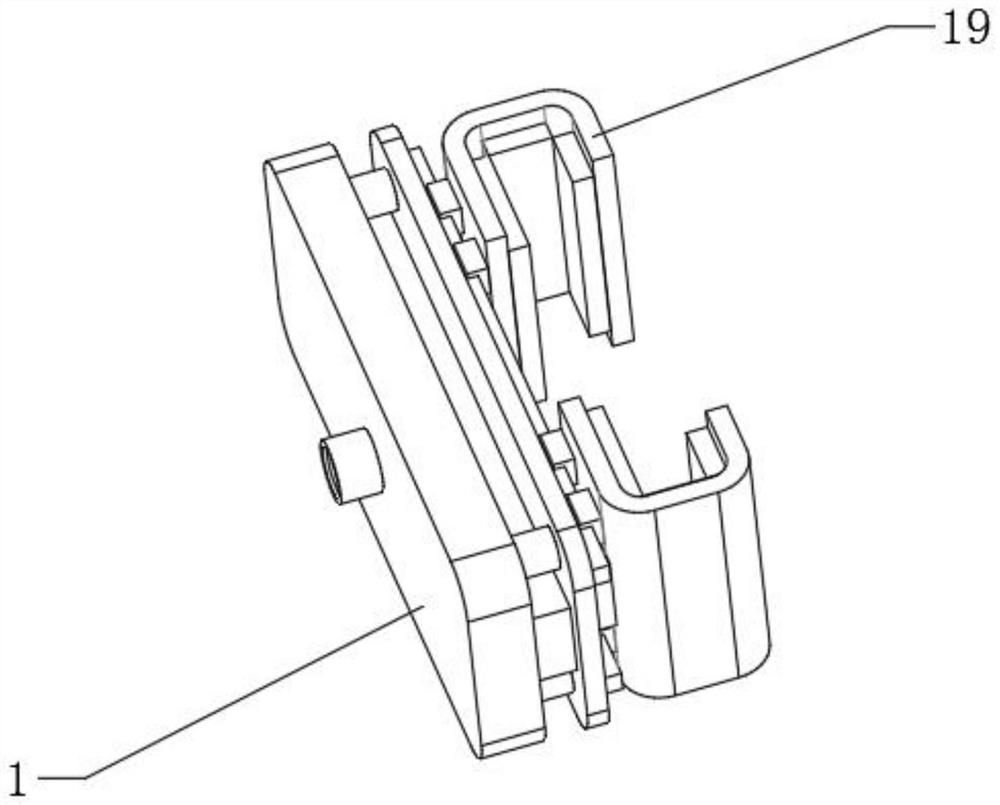

Asymmetric two-stage displacement amplification flexible micro-operation mechanism

ActiveCN108297086ACompact structureStable clampingProgramme-controlled manipulatorMicro-operationNon symmetric

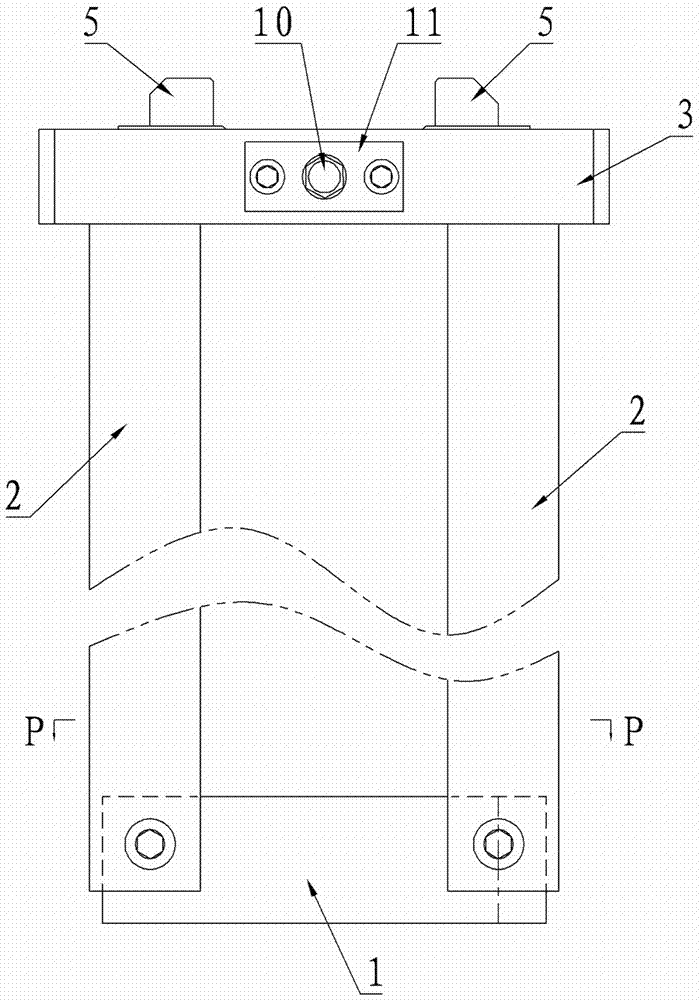

The invention relates to an asymmetric two-stage displacement amplification flexible micro-operation mechanism. The mechanism comprises a base body, a piezoelectric ceramic driver, an SR displacementamplification mechanism, a parallelogram lever amplification mechanism and a pre-tightening bolt, wherein the piezoelectric ceramic driver is installed on the base body through the pre-tightening bolt. The micro-operation mechanism only controls movement of one jaw, and the other jaw is connected with the base body and is fixed to be unmoved; the output end of the piezoelectric ceramic driver is connected with the input end of the SR displacement amplification mechanism through a flexible hinge IV, the SR displacement amplification mechanism is connected with the base body through a flexible hinge I, the output end of the SR displacement amplification mechanism is connected with the input end of the parallelogram lever amplification mechanism through a flexible hinge II, and the output endof the parallelogram lever amplification mechanism is connected with the jaws through a flexible parallel double-plate mechanism; and a metal strain gauge is adhered to the flexible parallel double-plate mechanism. According to the asymmetric two-stage displacement amplification flexible micro-operation mechanism, the asymmetric structure design is adopted, so that the structure of the micro-operation mechanism is compact, stable clamping is realized, and the defects of de-synchronic clamping and instability existing in symmetrical clamping are overcome.

Owner:TIANJIN UNIV

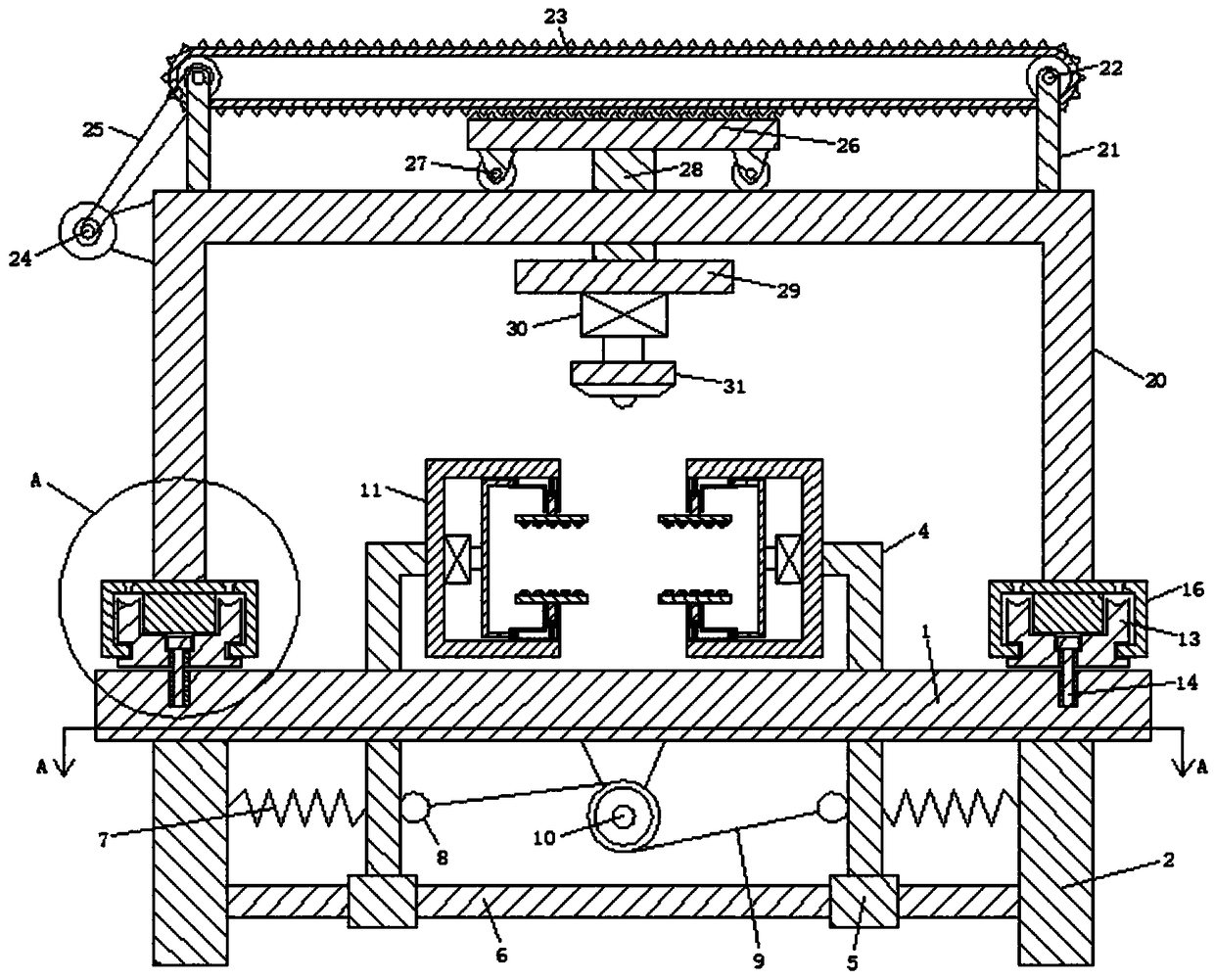

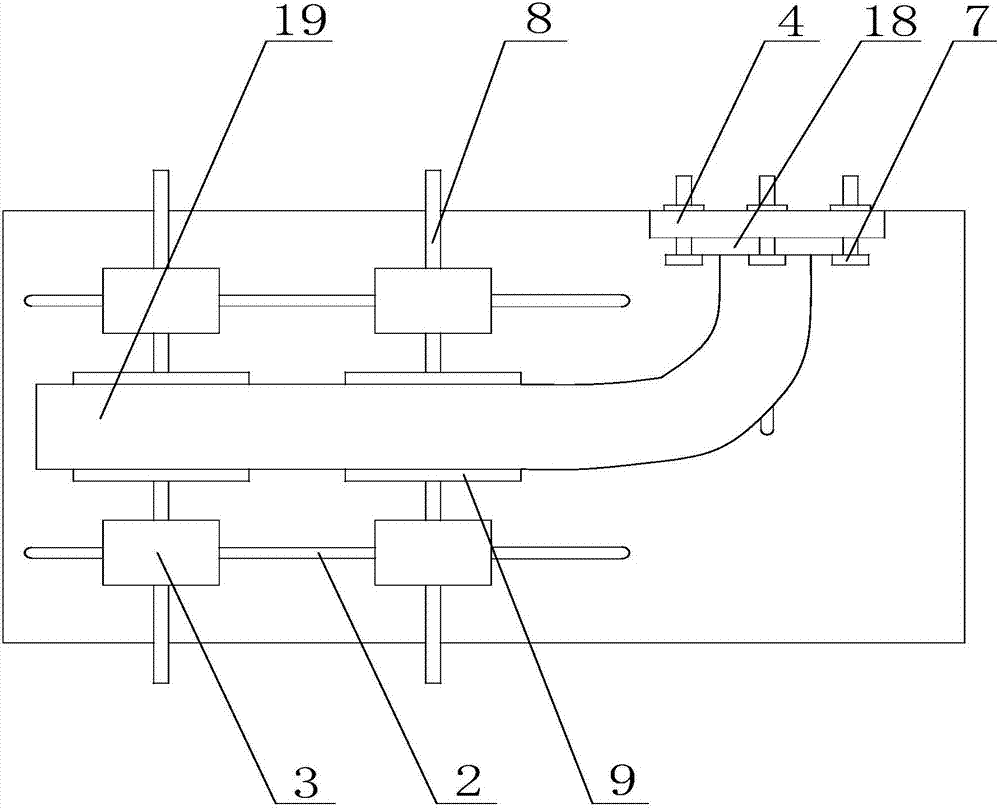

Numerical control plasma cutting machine work station with stable clamping

ActiveCN109158744AAvoid compromising accuracyStable clampingWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlHydraulic cylinder

The invention discloses a numerical control plasma cutting machine work station with stable clamping. The numerical control plasma cutting machine work station with stable clamping comprises a worktable, supporting legs, a sliding groove, a movable block, a limiting pipe, a limiting rod, a first spring, a rope ring, a traction rope, a winding wheel, a clamp, a fixed frame, a hydraulic cylinder, apiston pipe, a piston frame, a first piston, a piston rod, a second piston, a second spring, a clamping plate, a thread hole, a guide rail, a bolt, a guide groove, a sliding block, a guide block, an oil storage groove, an oil adding hole, a cutting frame, a wheel frame, a transmission wheel, a first transmission belt, a motor, a second transmission belt, a transmission block, rollers, a transmission rod, a mounting plate, an air cylinder, a plasma cutting machine and a clamping groove. The work station has the beneficial effects of being stable in clamping, wide in application, high in cuttingefficiency, precise in positioning and the like.

Owner:吴忠市黄河电焊机有限公司

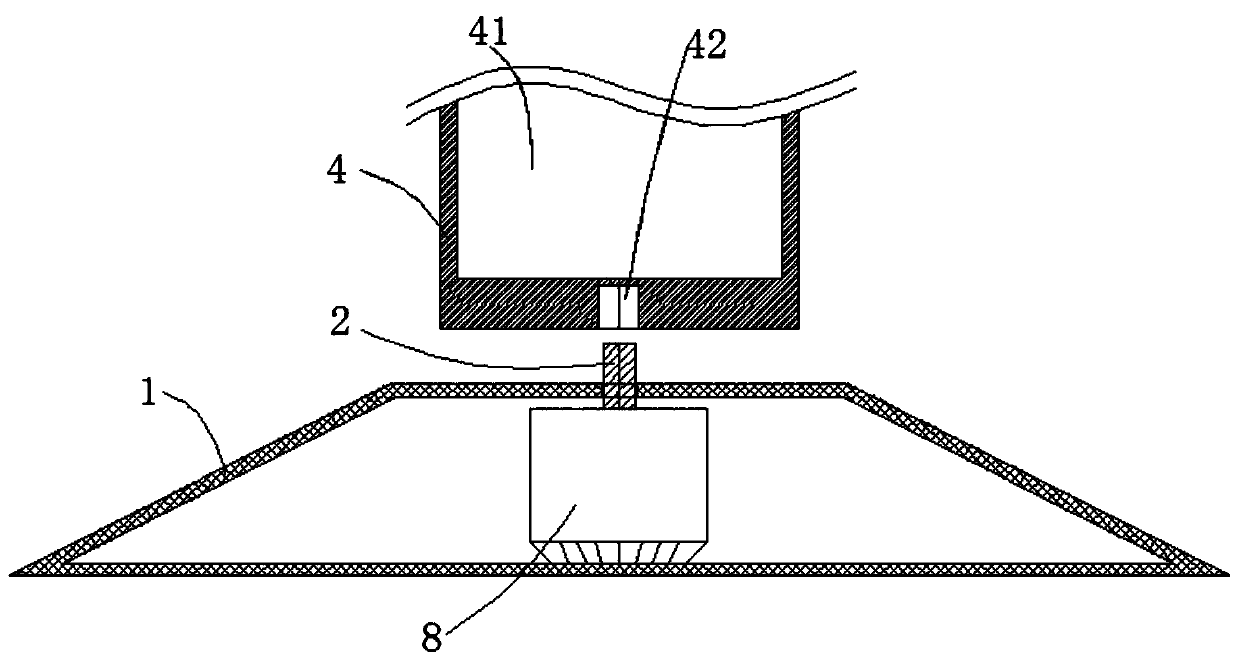

Operating platform capable of realizing quick cleaning of petroleum pipeline machining waste chips

The invention discloses an operating platform capable of realizing quick cleaning of petroleum pipeline machining waste chips. The operating platform comprises a base and a machining table, wherein supporting columns are arranged between the base and the machining table, each supporting column is provided with a first nut and a second nut, and the machining table is located between the first nuts and the second nuts; the machining table is provided with a first through hole, a fixed block, sliding grooves and push plates, the push plates are located in the sliding grooves, and the fixed block is provided with first clamping rods; the base is provided with a groove and a leakage hole, a connecting rod is arranged in the groove, and a supporting platform is arranged at the top of the connecting rod and provided with a second clamping rod and a second through hole; the side wall of the base is further provided with a rotating shaft and a drawer, the drawer communicates with the leakage hole, the rotating shaft is connected with the connecting rod and located in the groove, and when the rotating shaft is rotated, the supporting platform will rotate together with the rotating shaft. The operating platform can meet the requirement for clamping petroleum pipeline bends with different angles, lengths and diameters, and is simple in structure and convenient to operate, and the iron chips on a workbench can be cleaned up and stored in a concentrated mode.

Owner:CHENGDU LAIBAO PETROLEUM EQUIP

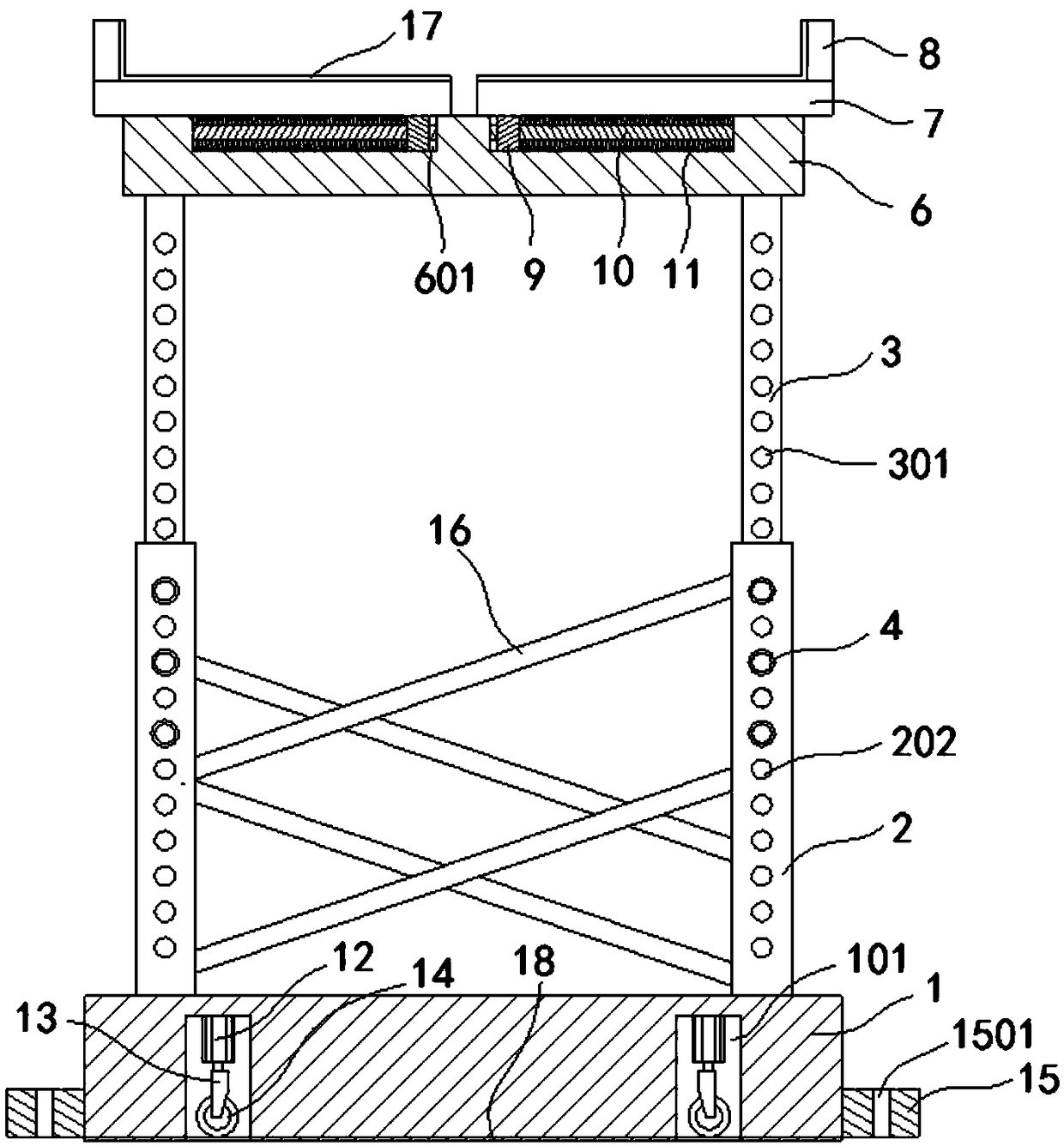

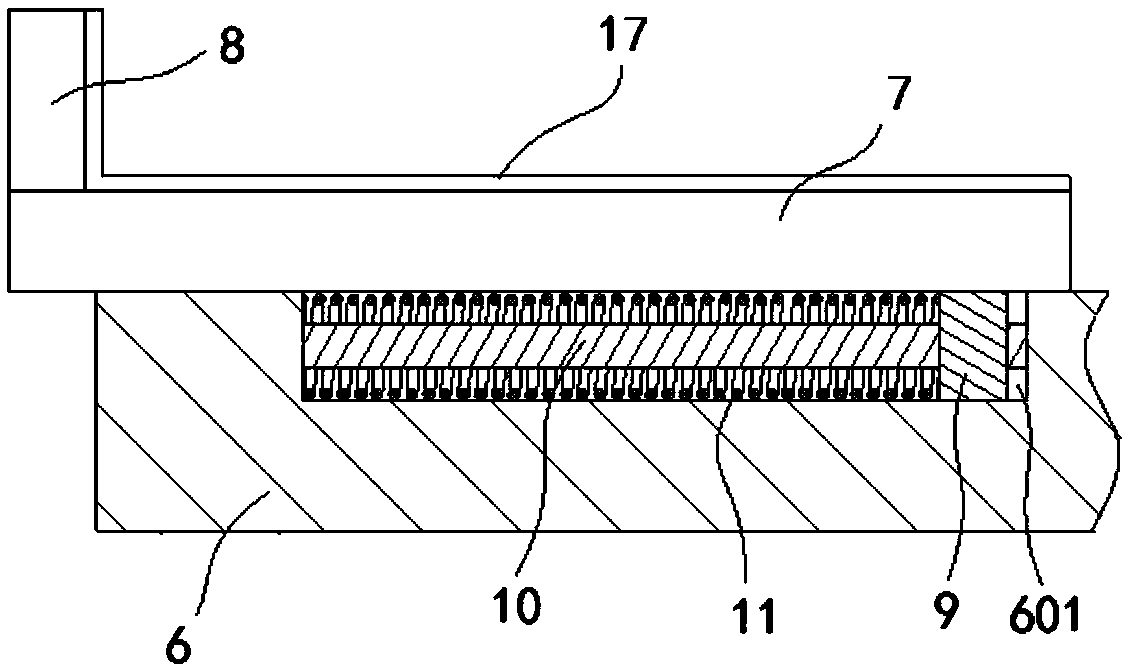

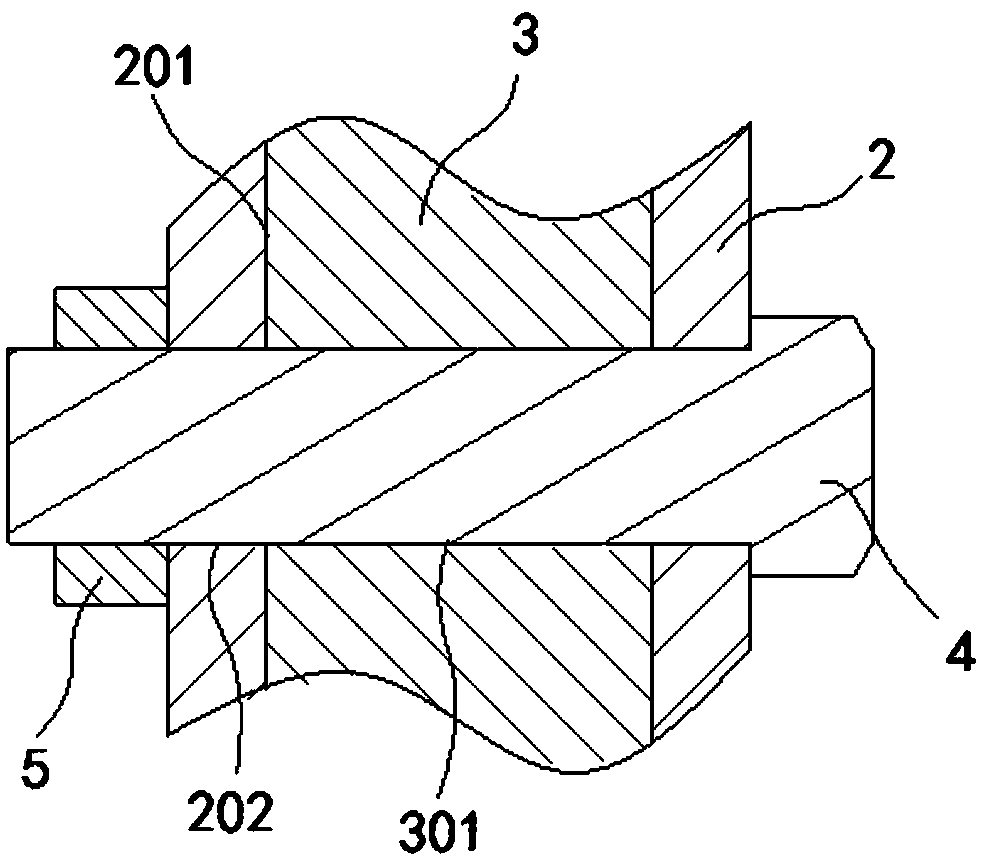

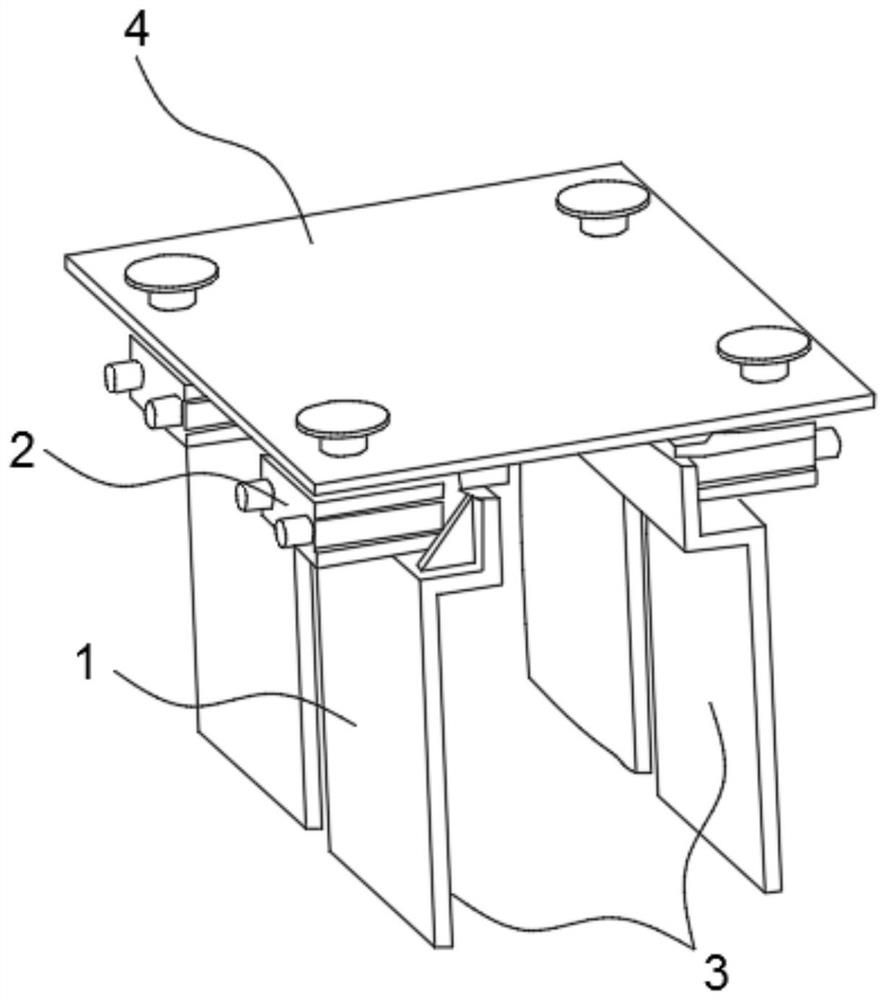

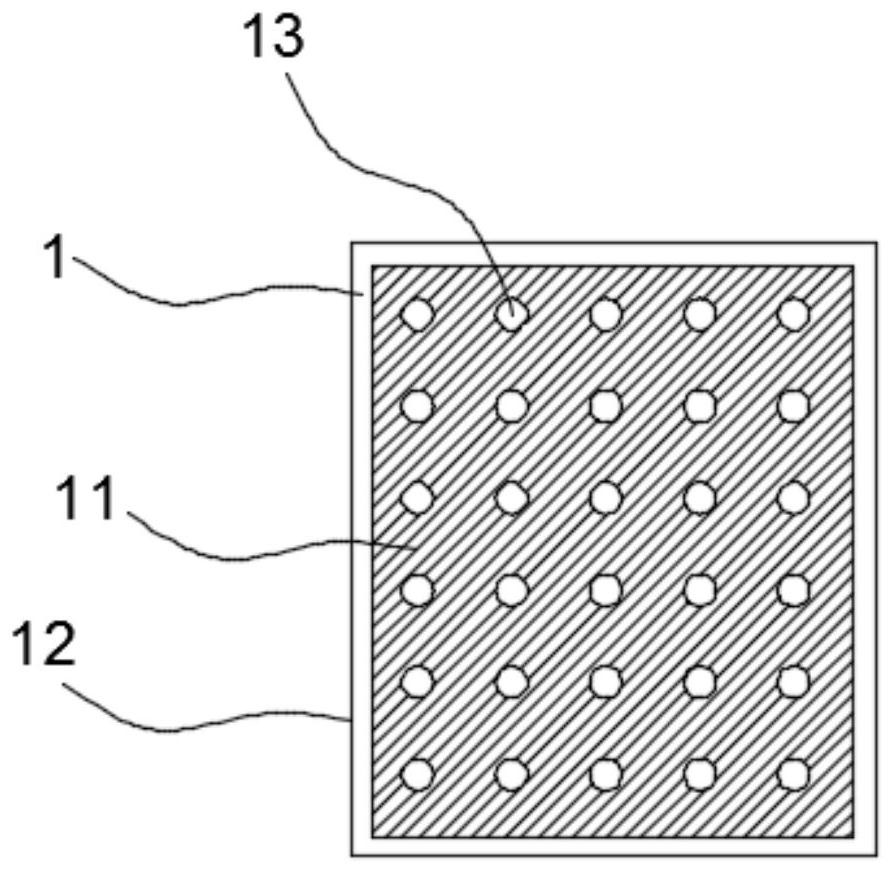

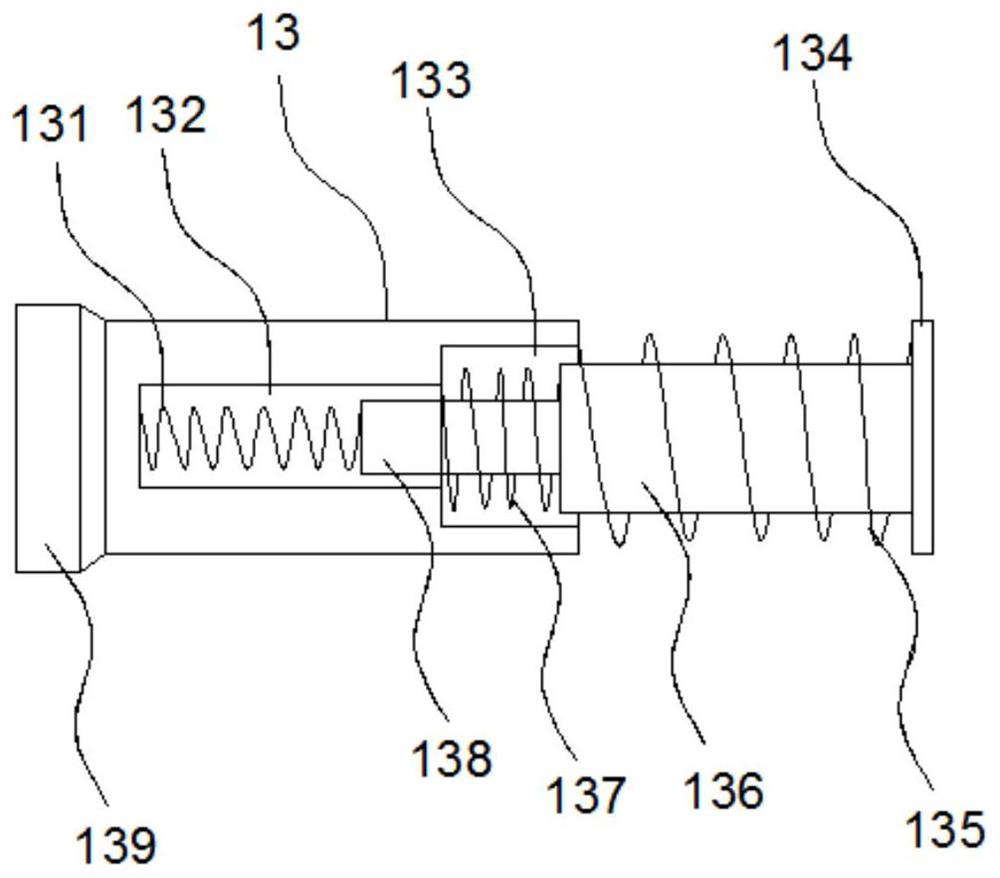

Supporting frame for fabricated building

Owner:绍兴职业技术学院

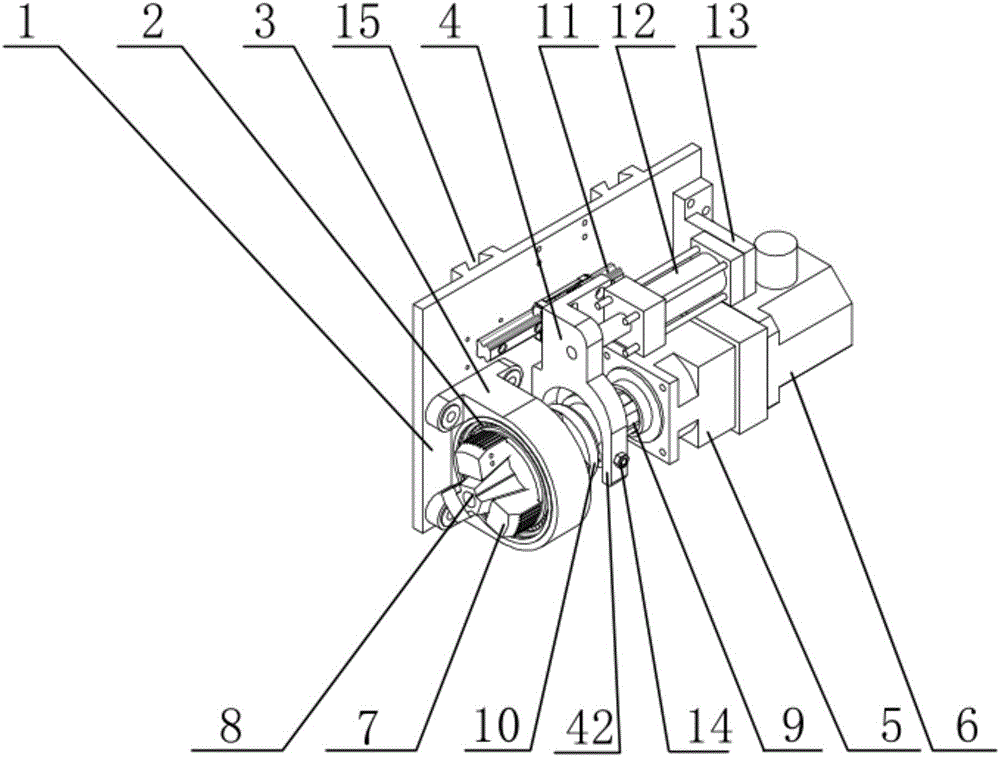

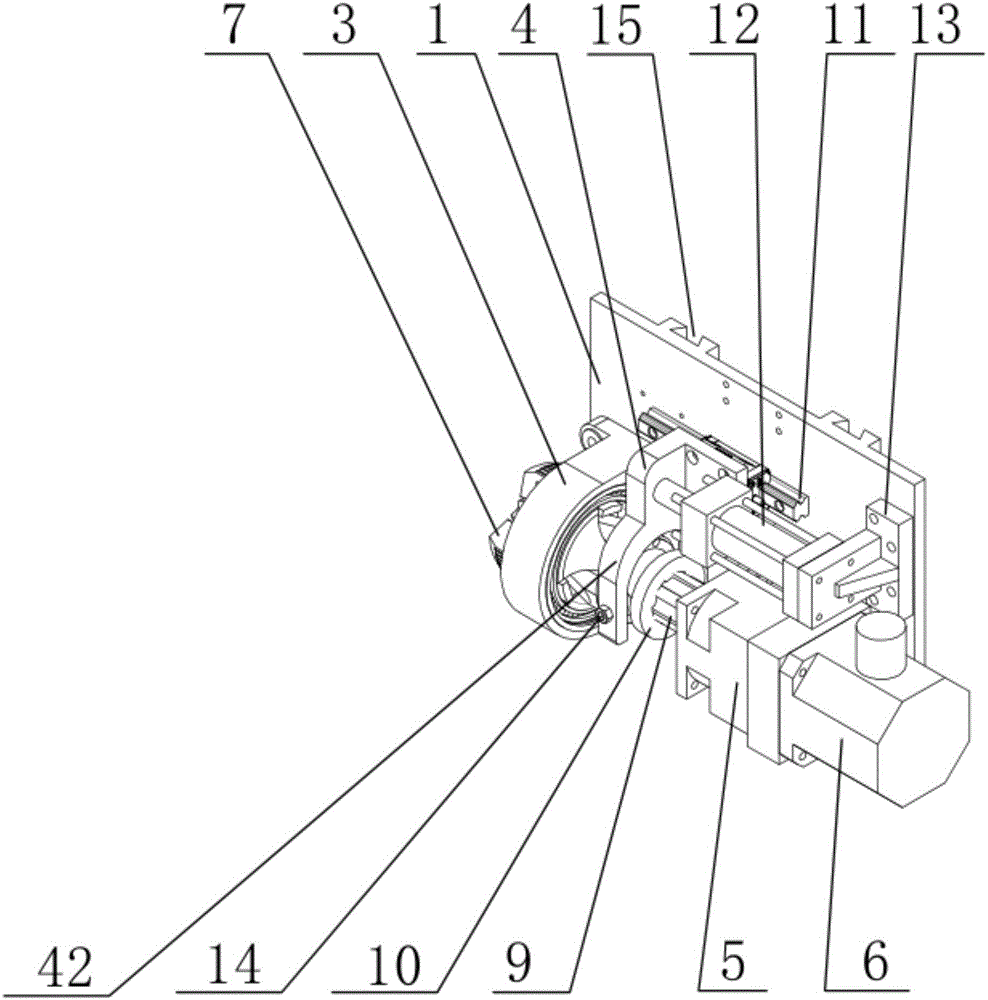

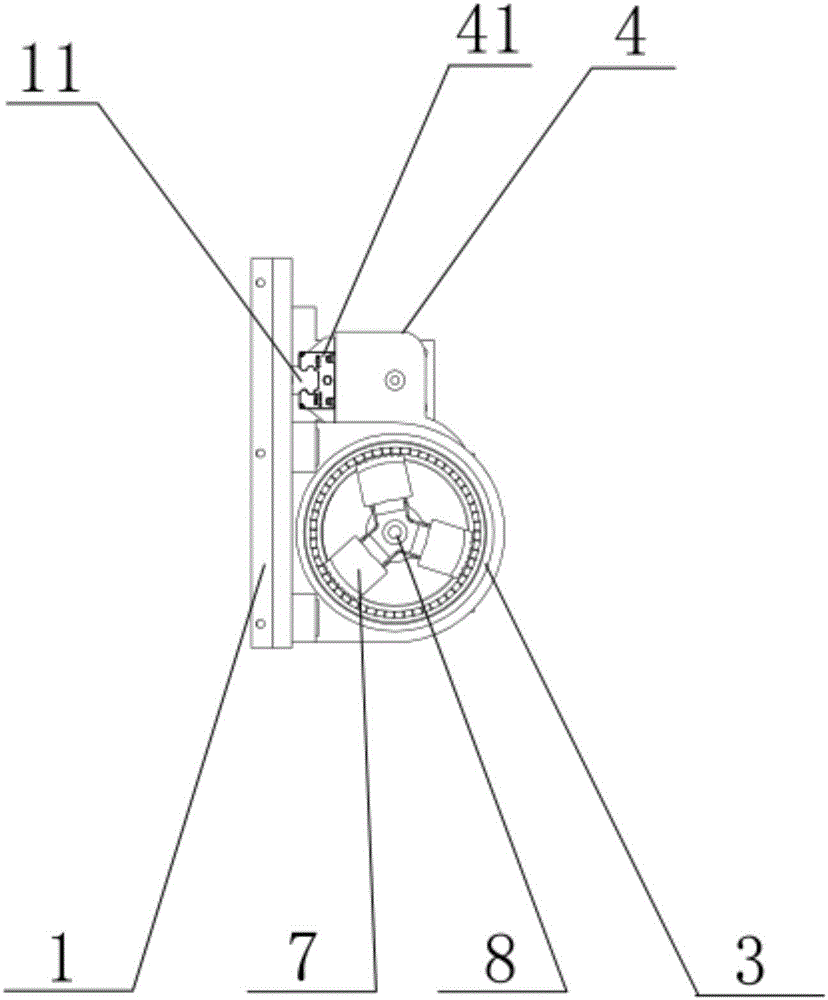

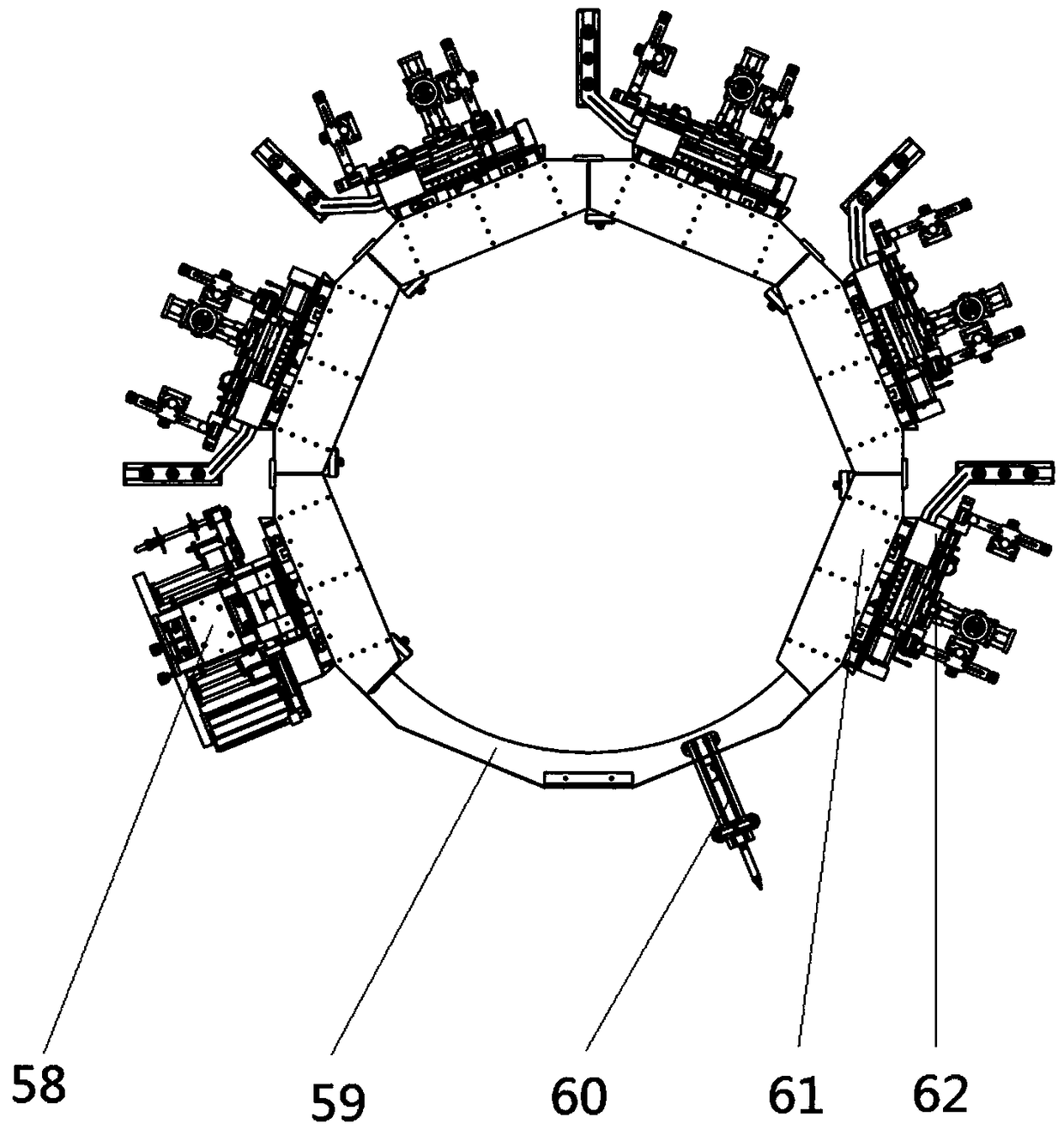

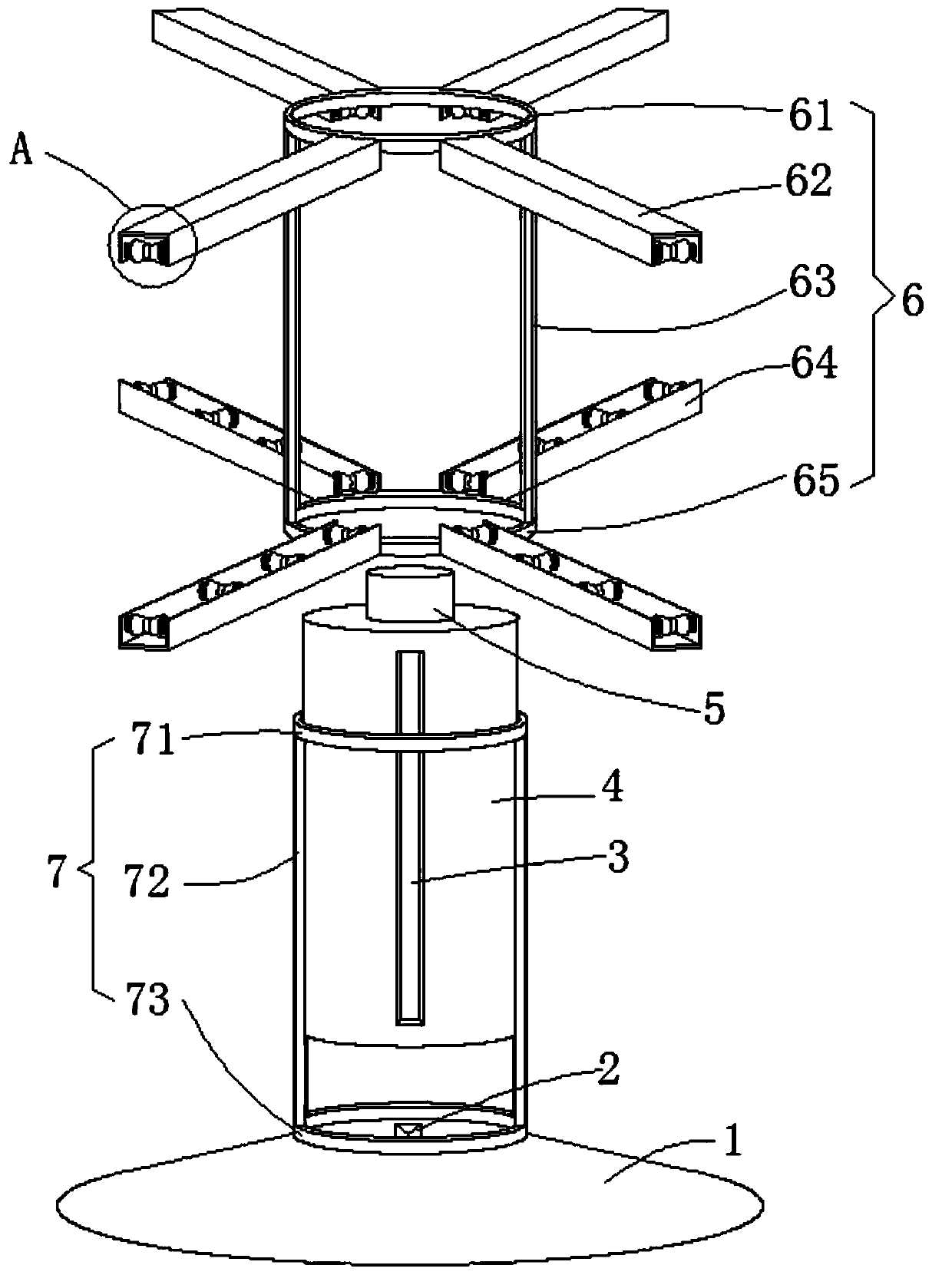

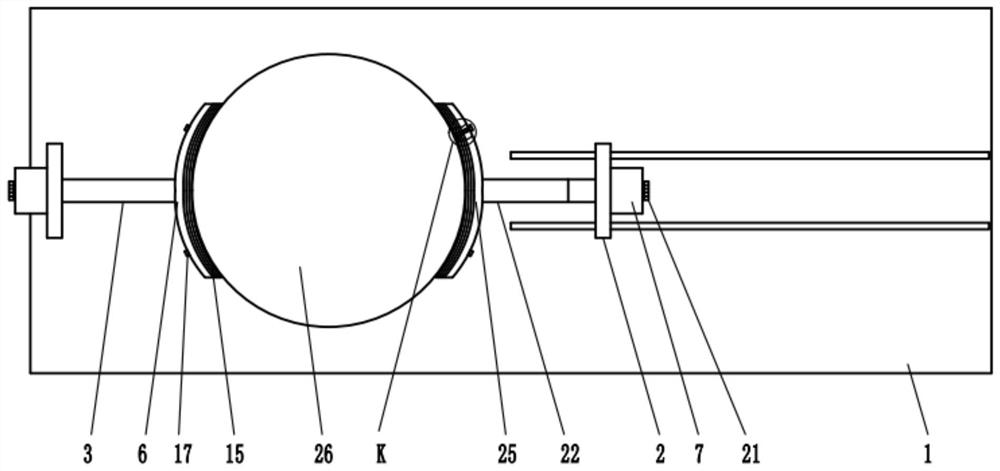

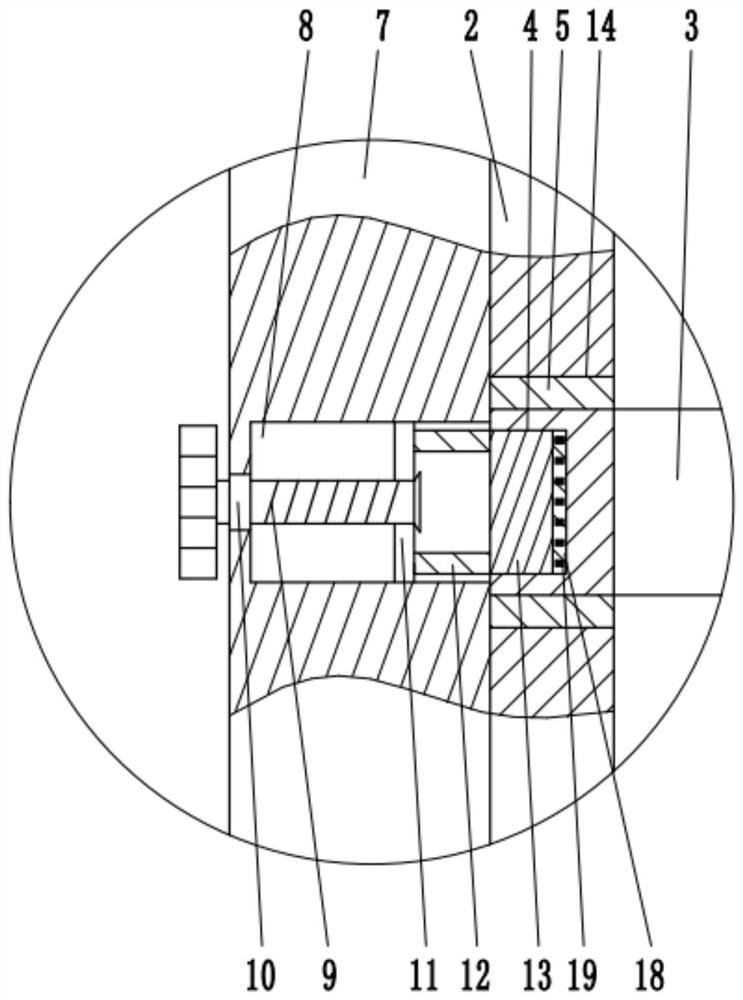

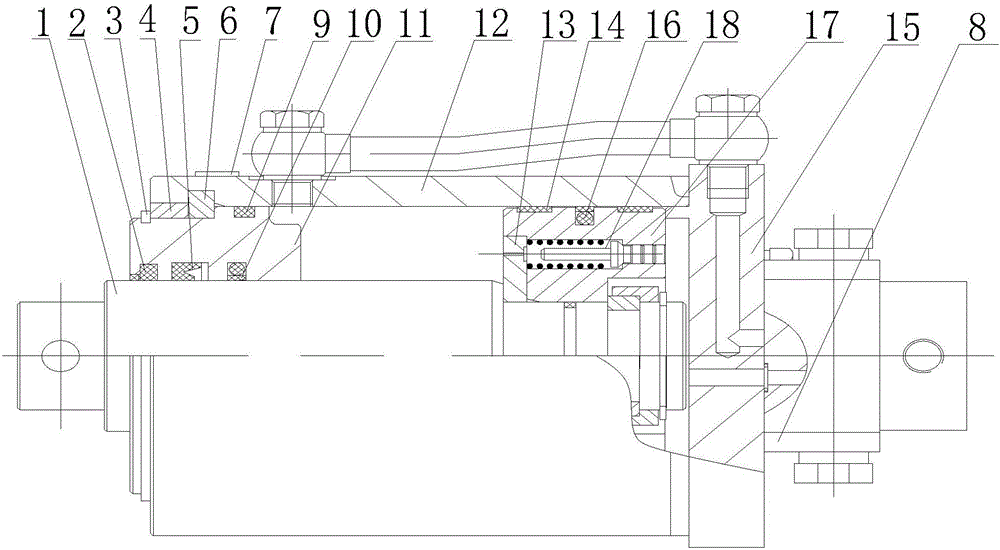

Rotating feeding device capable of achieving clamping from interior of pipe end

InactiveCN106312627AWith concentric rotation functionWith longitudinal feeding functionPrecision positioning equipmentMetal working apparatusReciprocating motionElectric machinery

The invention provides a rotating feeding device capable of achieving clamping from the interior of a pipe end. The device comprises a main shaft, a servo motor, a servo reduction machine, a shifting fork seat, a driving air cylinder, an inner strutting block and an inner strutting triple-jaw, wherein the servo motor is used for driving the main shaft to rotate, and the driving air cylinder is used for driving the shifting fork seat to perform reciprocating motion. The shifting fork seat drives a sliding block to be capable of performing inward-and-outward reciprocating motion in the axial direction of the main shaft while performing inward-and-outward reciprocating motion,. The inner strutting block and the sliding block are arranged on the main shaft from outside to inside and both can perform inward-and-outward reciprocating motion in the axial direction of the main shaft. The inner strutting triple-jaw is in limited-fit connection with a machine base. When performing outward movement in the axial direction of the main shaft, the inner strutting block can drive the inner strutting triple-jaw to perform outward expansion in the axial direction of the main shaft and the radial direction of the machine base, so that the inner strutting triple-jaw props the inner pipe wall, and the effect that the interior of the pipe end is clamped and fixed through the inner strutting triple-jaw is achieved. The rotating feeding device has the beneficial effects of being reasonable in structure, high in machining precision, good in stability, reliable in operation, convenient to adjust and the like.

Owner:ZHEJIANG KING MAZON MACHINERY

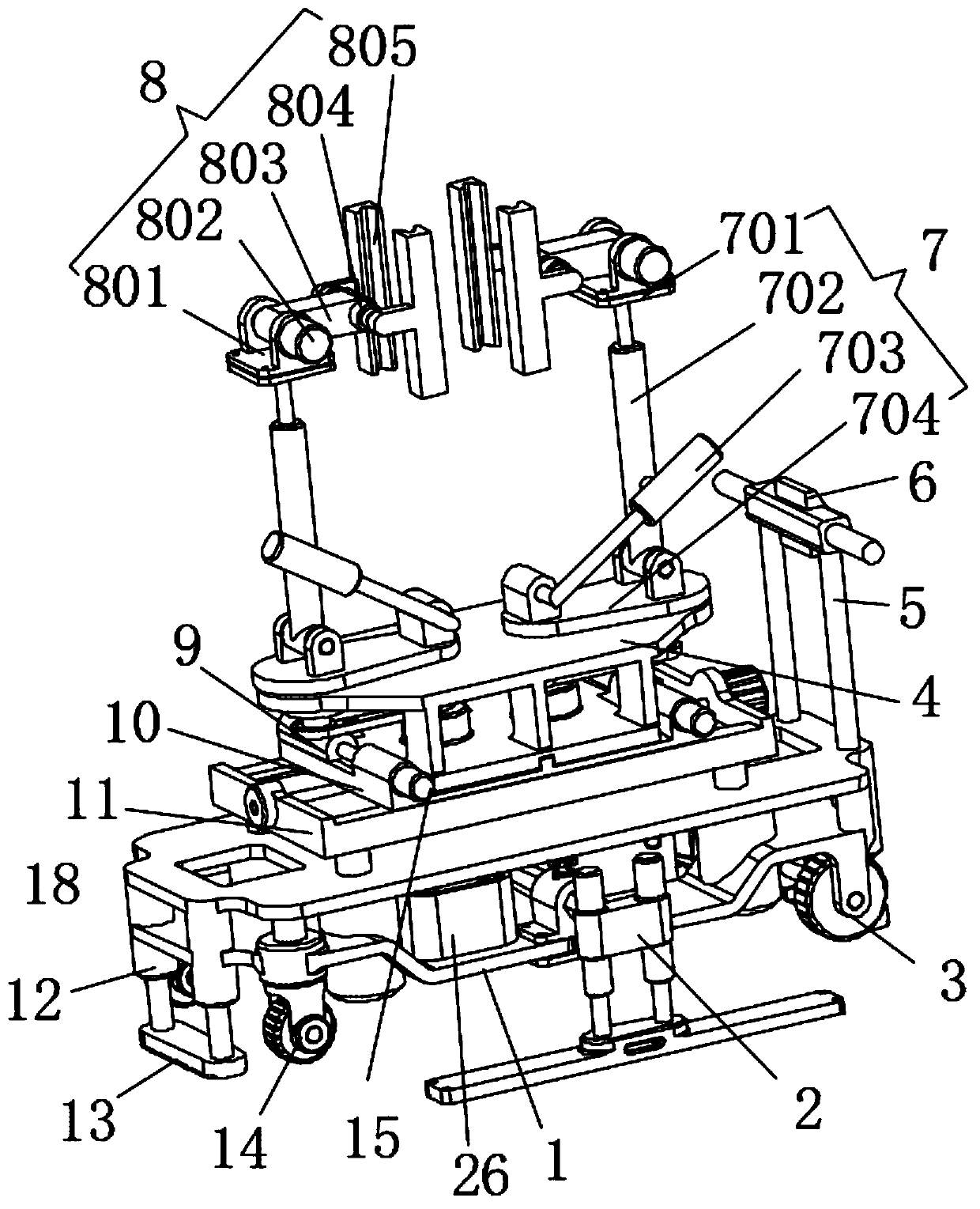

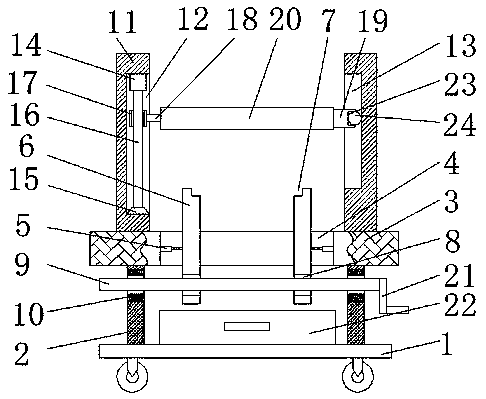

Multifunctional clamping and fixing device for building construction

ActiveCN110374337AImprove construction accuracyHigh utility valueBuilding material handlingMulti degree of freedomArchitectural engineering

The invention relates to the technical field of building equipment, in particular to a multifunctional clamping and fixing device for building construction. The multifunctional clamping and fixing device comprises a base, wherein a built-in power supply is fixedly arranged on the base by a bolt, a support table is fixedly arranged at an upper end of the base by a bolt, a universal wheel is fixedlyarranged at a left side of the base by a bolt, and a roller is fixedly arranged at a right side of the base by a bolt. The multifunctional clamping and fixing device has the beneficial effects that multi-degree of freedom clamping operation can be achieved by an adjustment device and a clamping device, targeted replacement can be performed by the clamping device according to a part needed to be clamped, so that clamping of a plate, a rod, a pipe or parts in other shapes can be effectively met; and moreover, high-accuracy clamping and fixing can be effectively achieved by slight adjustment, traditional handhold operation can be substituted, the construction accuracy can be effectively improved, so that the construction quality is ensured, and the physical consumption of a constructor is reduced.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

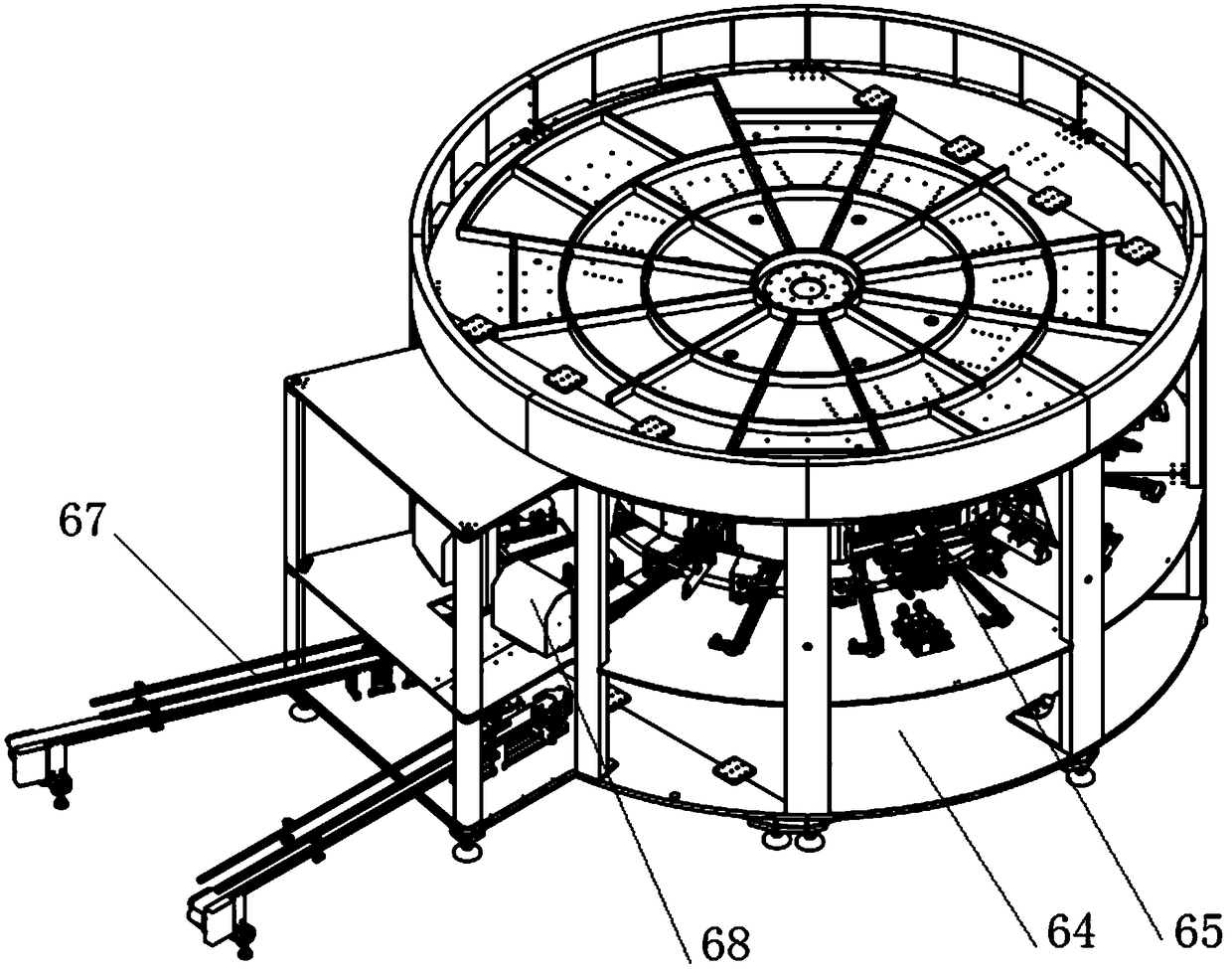

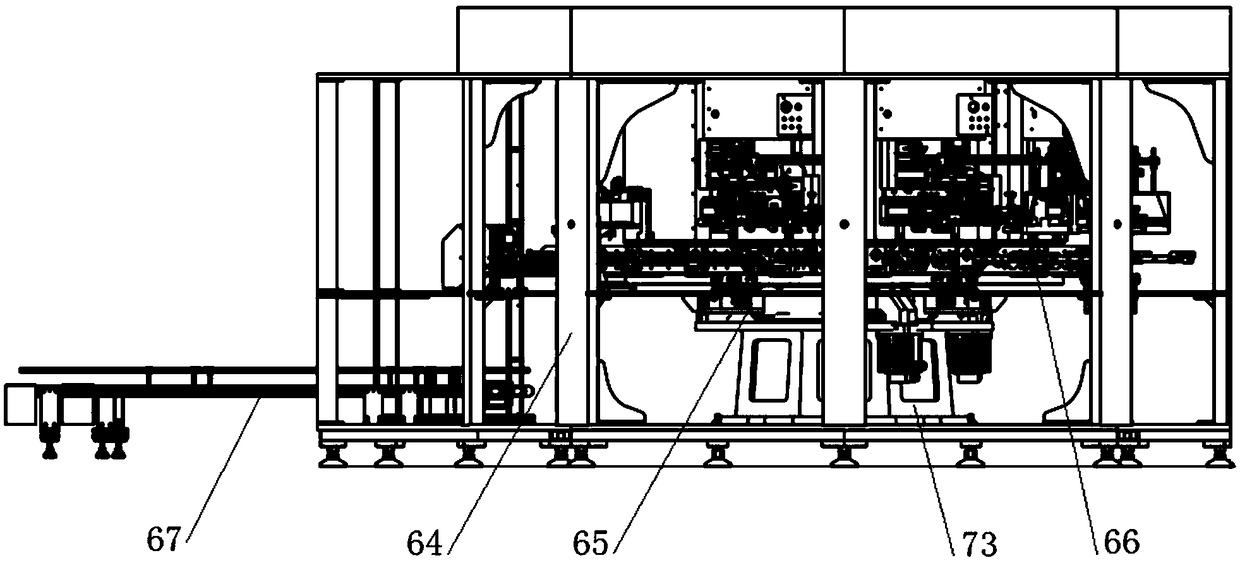

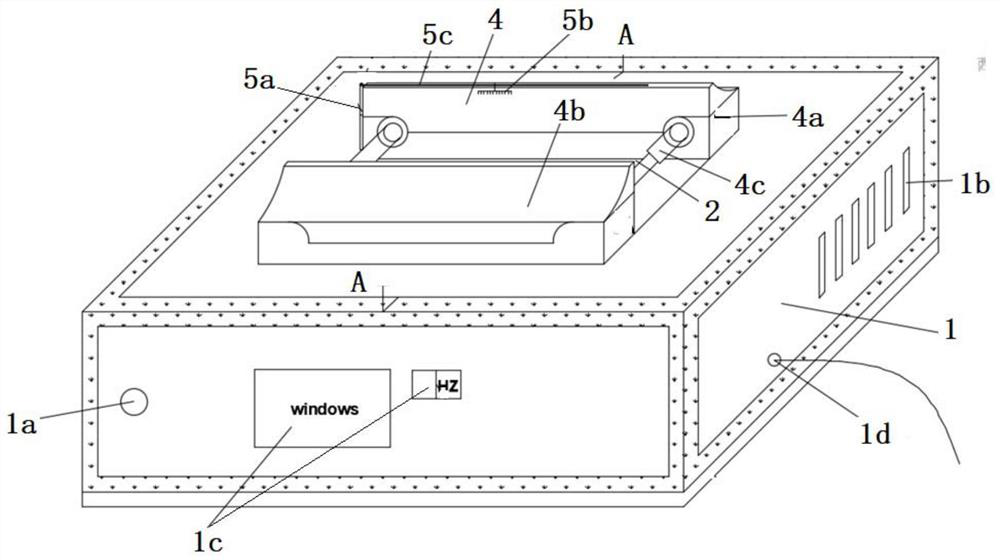

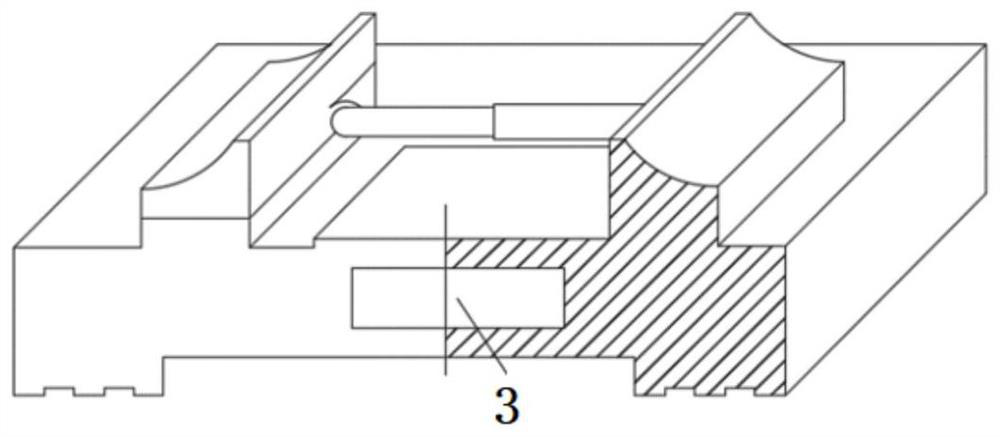

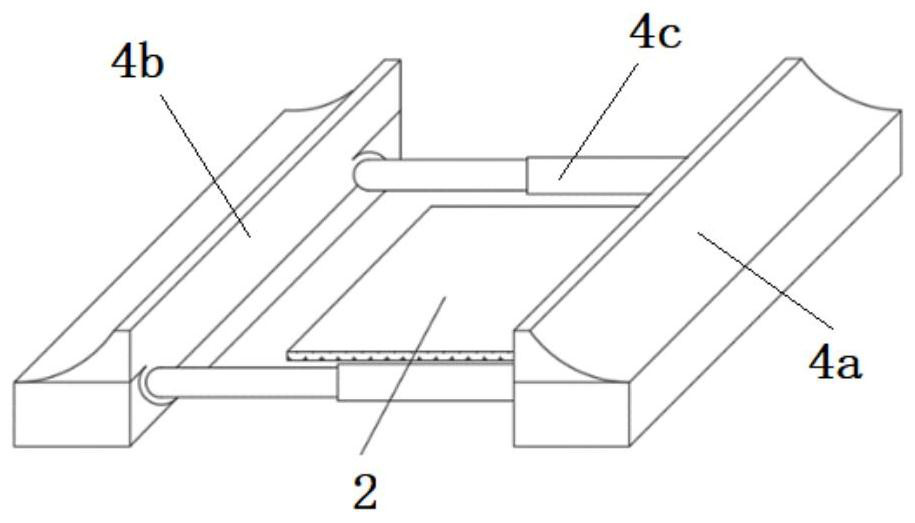

Total-servo silk-screen printing equipment

PendingCN109454980AAccurate printingIncrease surface tensionScreen printersScreen printingCharge and discharge

The invention discloses total-servo silk-screen printing equipment. The total-servo silk-screen printing equipment comprises a housing, a turning plate, a printing assembly and a charging and discharging device; the turning plate and the printing assembly are positioned inside the housing; the printing assembly is connected with the top of the turning plate; the turning plate is used for driving the printing assembly to rotate inside the housing; the charging and discharging device is positioned at the outer side of the housing and is used for conveying a to-be-printed material for the turningplate; the printing assembly comprises a plurality of printing lifting plates; the plurality of printing lifting plates are correspondingly provided with a fire burning component, a gold stamping component and a printing component; the turning plate comprises a base, a rotary disc, an index table and an electric slip ring; the rotary disc is arranged on the base and is rotationally connected witha pedestal; the index table is connected with the bottom of the rotary disc; the charging and discharging device comprises a conveying belt and a clamp; the conveying belt is positioned at the bottomof the housing; the clamp is arranged on the housing and is used for conveying the to-be-printed material to the turning plate.

Owner:SICHUAN XINGDA PACKAGING EQUIP MFG

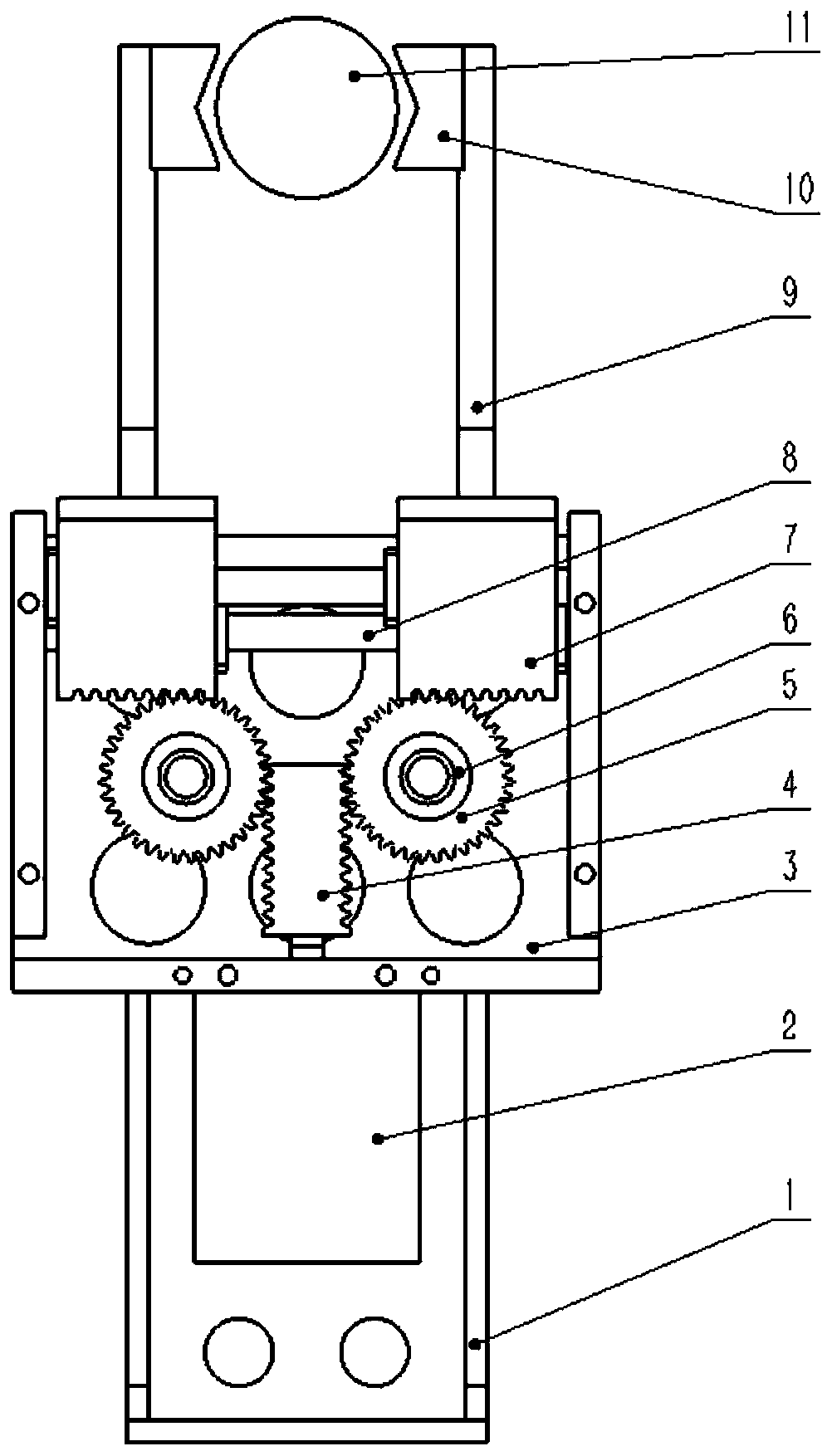

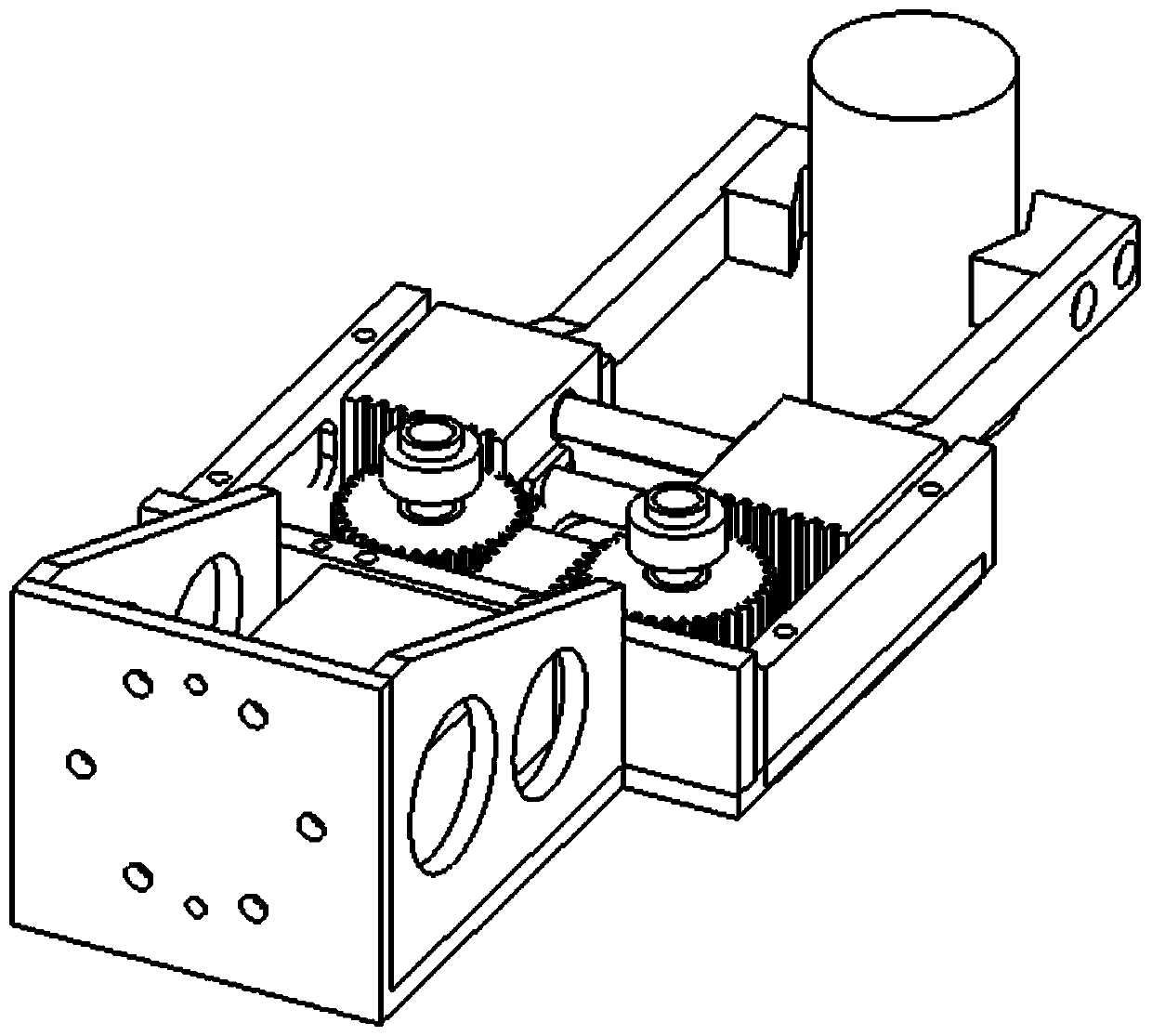

Centering clamping jaw based on gear and rack driving

InactiveCN111331067AKeep the center position unchangedGuaranteed unchangedForging/hammering/pressing machinesReciprocating motionGear wheel

The invention belongs to the field of automatic forging, and particularly relates to a centering clamping jaw based on gear and rack driving. The centering clamping jaw based on gear and rack drivingcomprises an air cylinder, a guide rod, a bearing, a gear, a longitudinal rack, a transverse rack, clamping blocks and a positioning block, wherein the clamping blocks are connected to the transverserack; the transverse rack is arranged on the guide rod in a sleeving manner; the transverse rack and the longitudinal rack are arranged in cooperation with the gear; and the longitudinal rack is connected to the air cylinder. When the longitudinal rack moves upwards, the gear is driven to rotate, the transverse rack is driven to move by the gear, the two clamping blocks move away from each other in opposite directions, and at the moment, the clamping jaw is in the expansion state. When the longitudinal rack moves downwards, the gear is driven to rotate, the transverse rack is driven to move bythe gear, the two clamping blocks move toward each other in opposite directions, and at the moment, the clamping jaw is in the clamping state. The clamping jaw is used for converting the reciprocating motion of a power mechanism into the reciprocating motion of the clamping blocks through the gear and rack driving; the positioning block is used for ensuring that the center of a clamped workpieceis always in the same position; and the direct effect of the high temperature environment and a release agent on the air cylinder is avoided.

Owner:JARI AUTOMATION CO LTD CHINA

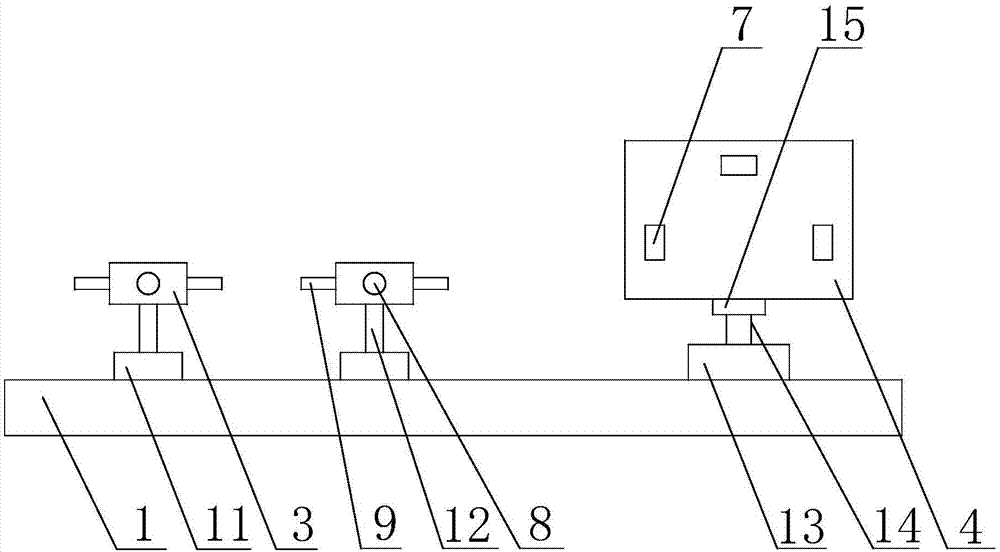

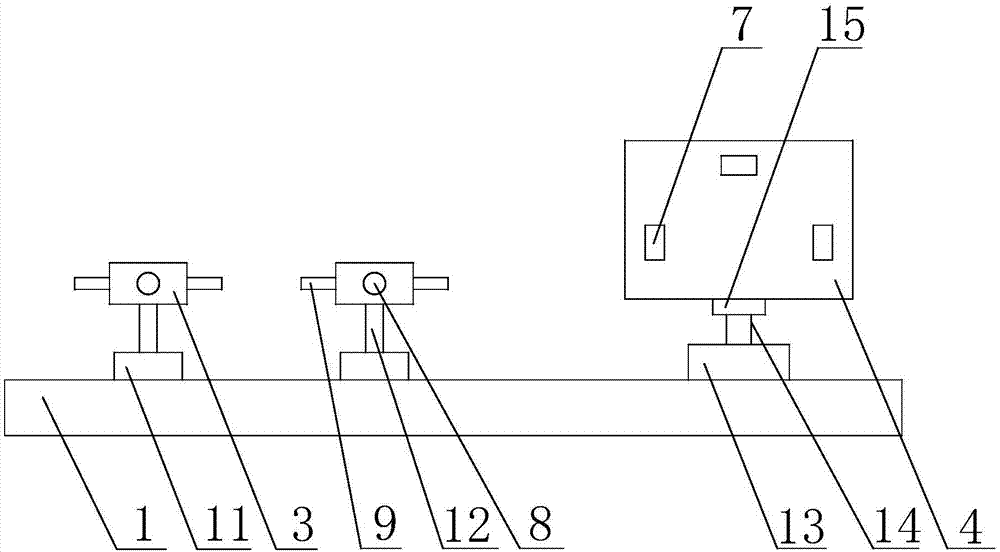

Grinding equipment for front beam in rear floor front beam assembly and working method of grinding equipment

ActiveCN113618580AImprove efficiencyImprove feeding efficiencyGrinding drivesGrinding machinesMechanical engineeringGrinding process

The invention discloses grinding equipment for a front beam in a rear floor front beam assembly and a working method of the grinding equipment. The grinding equipment comprises a grinding chamber, wherein limiting mechanisms are installed on the two side walls of the grinding chamber correspondingly; a lifting cylinder is installed at the top of the outer wall of the grinding chamber; the end of a piston rod of the lifting cylinder is connected with a grinding mechanism; a jacking cylinder is installed at the bottom of the outer wall of the grinding chamber; the end of a piston rod of the jacking cylinder is connected with a conveying mechanism; and chip extraction mechanisms are installed on the outer walls of the two sides of the grinding chamber correspondingly. Through the arrangement of the conveying mechanism, the front beam in the rear floor front beam assembly can be conveyed, meanwhile, the front beam in the rear floor front beam assembly can be fed to the position between two rotating plates, the feeding efficiency is high, and through the arrangement of the chip extraction mechanisms, after feeding of the front beam in the rear floor front beam assembly is completed, two collecting boxes can automatically descend to the position below the front beam in the rear floor front beam assembly, and waste chips in the grinding process are efficiently collected.

Owner:合肥至信机械制造有限公司

Automatic mincing type medicine cutting device

ActiveCN110883834AAdapt to slicing operationsMeet clampingMetal working apparatusMedicinal herbsEngineering

The invention relates to pharmaceutical equipment, and aims at providing an automatic mincing type medicine cutting device which is high in efficiency and high in universality. The device comprises arack, and a feeding mechanism, a conveying mechanism and a cutting mechanism are sequentially arranged on the upper surface of the rack from left to right. The conveying mechanism comprises two sets of clamping assemblies symmetrically arranged at the front side and the rear side of the rack. Each clamping assembly comprises a first fixed plate arranged at the position, close to the edge, of the rack, the first fixed plate extends in the length direction of the rack, U-shaped groove plates are arranged on the inner side of the first fixed plate side by side, openings of the U-shaped groove plates face inwards, and a plurality of conveying rollers are arranged in the U-shaped groove plates side by side. According to the invention, the device can be qualified for clamping and slicing variousmedicinal materials with different sizes, and is high in universality, compact and reasonable in layout and small in size.

Owner:绵阳一康制药有限公司

Marking mechanism based on bend for cutting arc-shaped petroleum pipeline

InactiveCN106881707ASave human effortImprove work efficiencyOther workshop equipmentPetroleumSteel rope

The invention discloses a marking mechanism based on a bend for cutting an arc-shaped petroleum pipeline. The marking mechanism comprises a left cutting device and a right cutting device; the top of the left cutting device and the top of the right cutting device are each provided with a connecting rod, each connecting rod is provided with a movable rod, and the movable rods of the left cutting device and the right cutting device are connected through hinges; the left cutting device and the right cutting device each comprise a first clamp and a second clamp, a rotation element is arranged between each first clamp and the corresponding second clamp, bosses are arranged at the tail ends of the first clamp and the second clamp and are provided with screws, arc-shaped sliding grooves are formed in the first clamps and the second clamps, movable blocks are arranged in the sliding grooves and provided with steel ropes, and the steel ropes are located in the sliding grooves; and handles are arranged at the tail ends of the steel ropes, and the steel ropes of the left cutting device and the right cutting device are connected through the handles. By means of the marking mechanism, marking of the arc-shaped petroleum pipeline can be carried out, two cutting lines can be cut at a time, the labor is saved, and meanwhile, the working efficiency is improved.

Owner:CHENGDU DAMO PETROLEUM TECH CO LTD

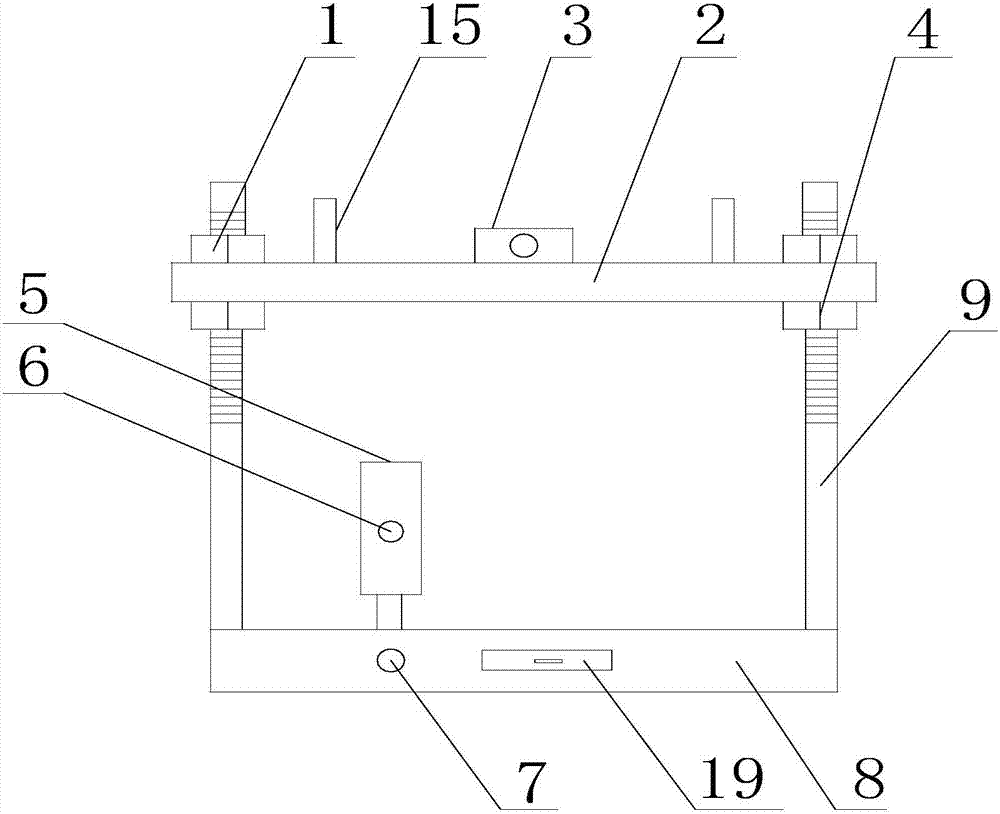

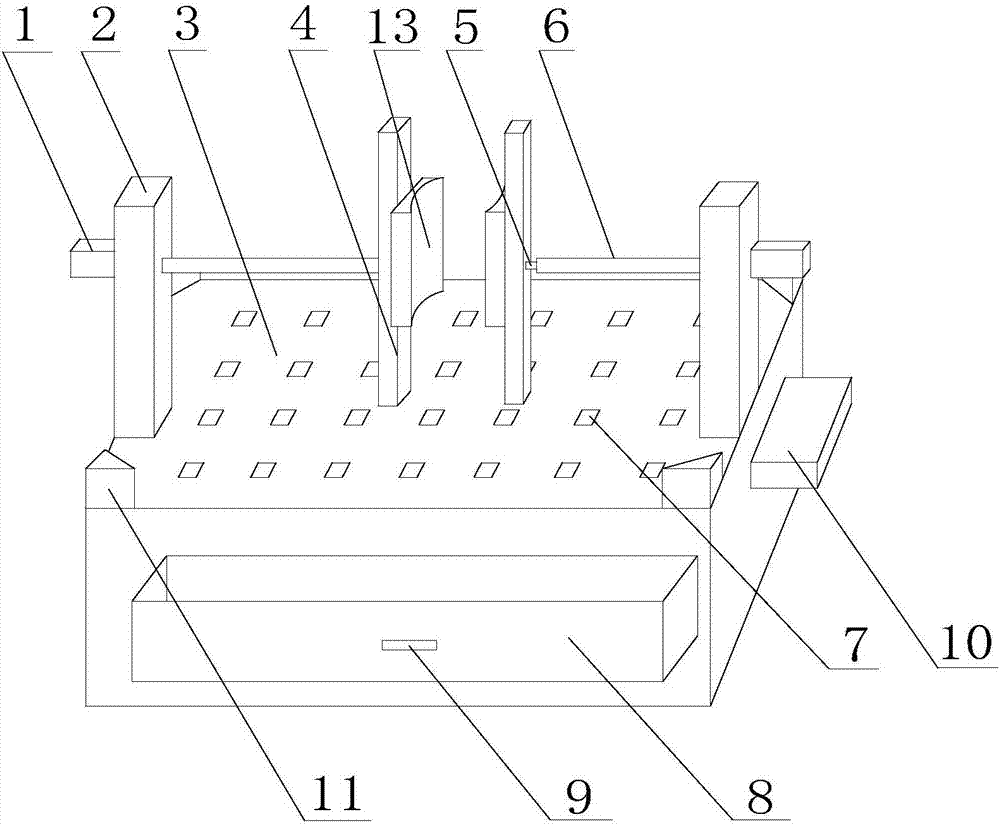

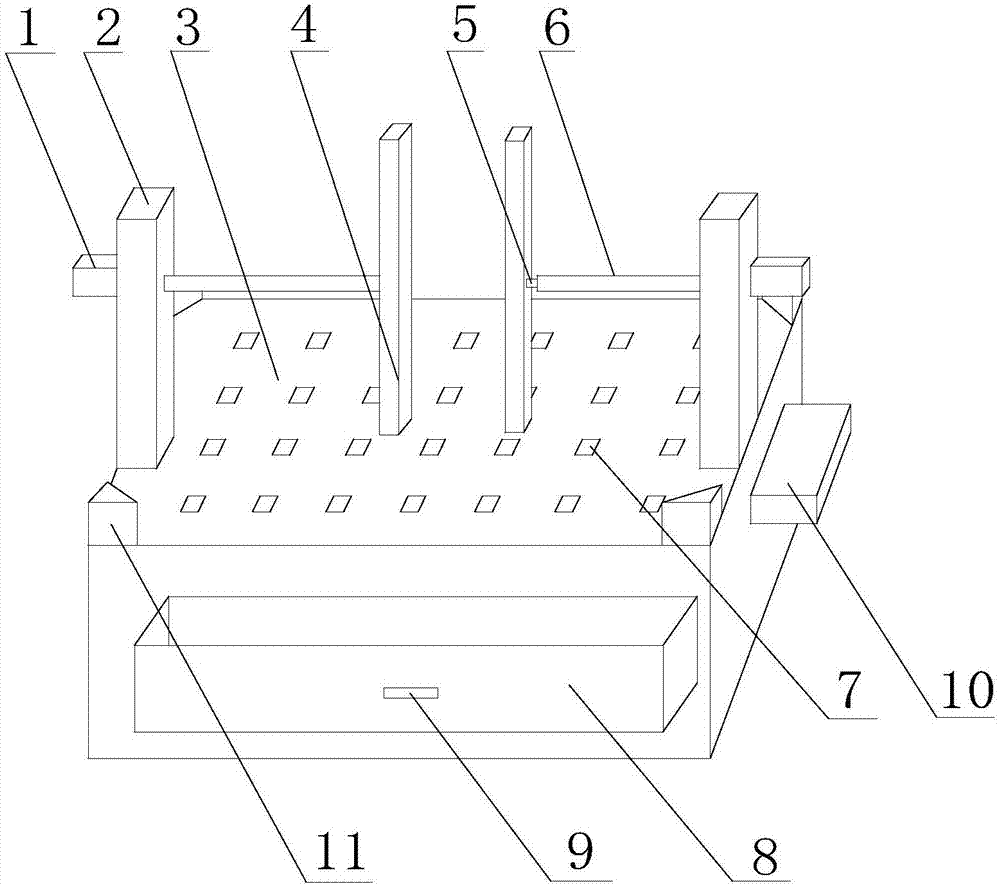

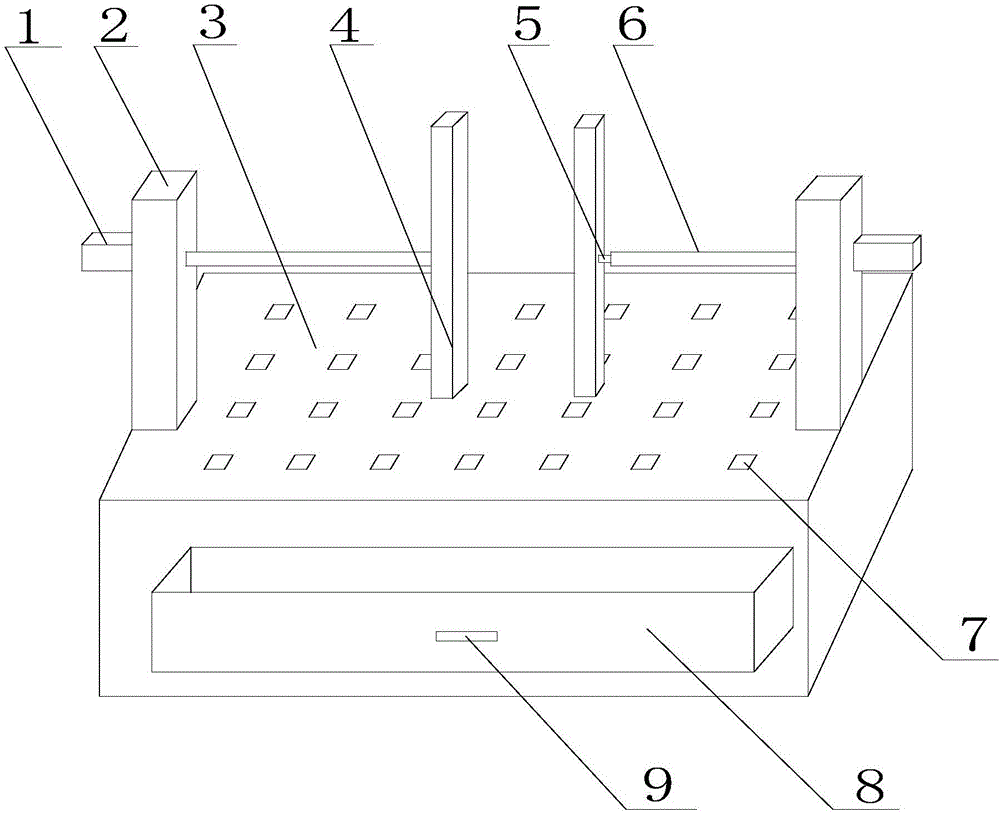

Clamping mechanism suitable for clamping flat surface or curved surface

InactiveCN106914774AAvoid scratchesMeet clampingPositioning apparatusMaintainance and safety accessoriesDrive shaftEngineering

The invention discloses a clamping mechanism suitable for clamping a flat surface or a curved surface. The clamping mechanism comprises a workbench, wherein two support columns are arranged at the top of the workbench and a plurality of leakage holes are formed in the top of the workbench; a drive mechanism is arranged on the support columns; a drive shaft of the drive mechanism is inserted into the support columns in a penetrating manner; a connection rod is arranged at the tail ends of the support columns; one end of the connection rod is connected with the drive shaft, and a movable shaft is arranged at the other end of the connection rod; a first clamping block is arranged on the movable shaft; a thread hole is formed in the first clamping block; a screw is arranged in the thread hole; a second fixing block is arranged on the screw; fixing blocks are arranged at the four corners of the top of the workbench; an air blowing pipe is arranged on each fixing block; an air blower and a drawer are further arranged on the side surface of the workbench; the drawer is manufactured from a magnetic material, and the inside of the drawer communicates with the leakage holes; and the air blower is connected with the air blowing pipes. The clamping mechanism disclosed by the invention is capable of fixing a workpiece with the flat surface or the curved surface, and capable of uniformly recovering and storing the chippings generated during a machining process, thereby preventing the chippings from scratching operating personnel.

Owner:LUZHOU YUANCHENG ENG MACHINERY CO LTD

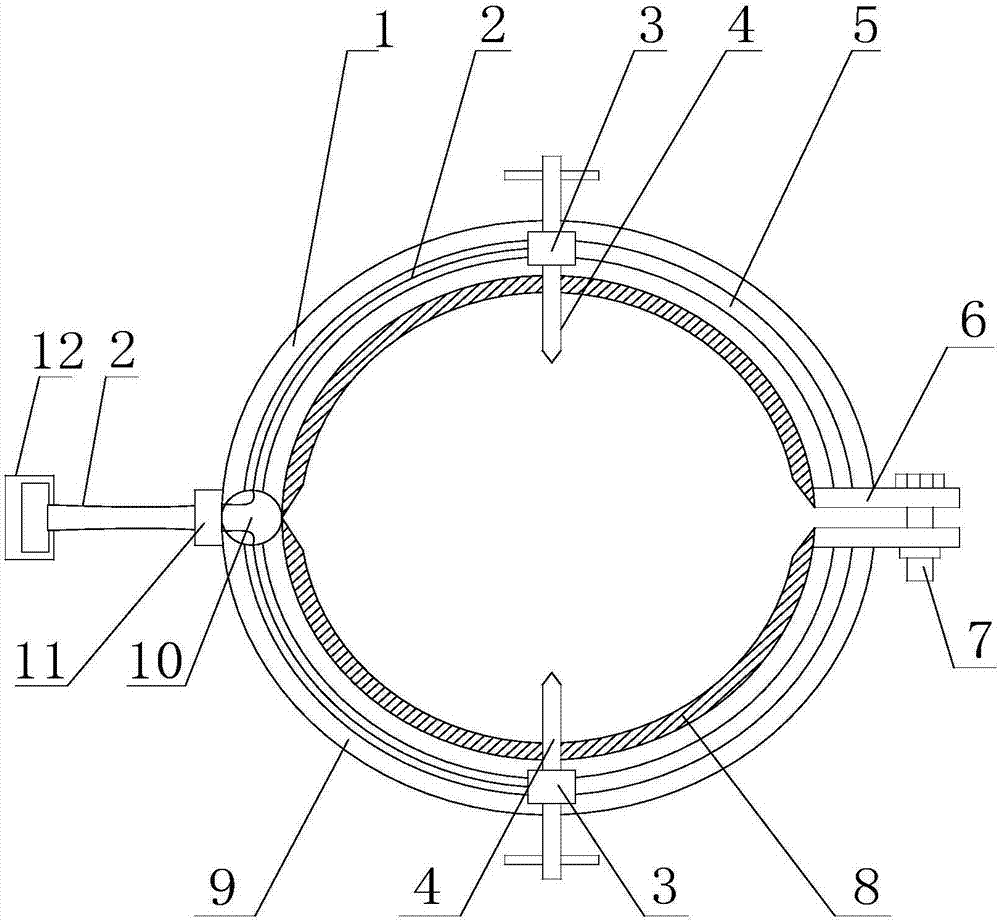

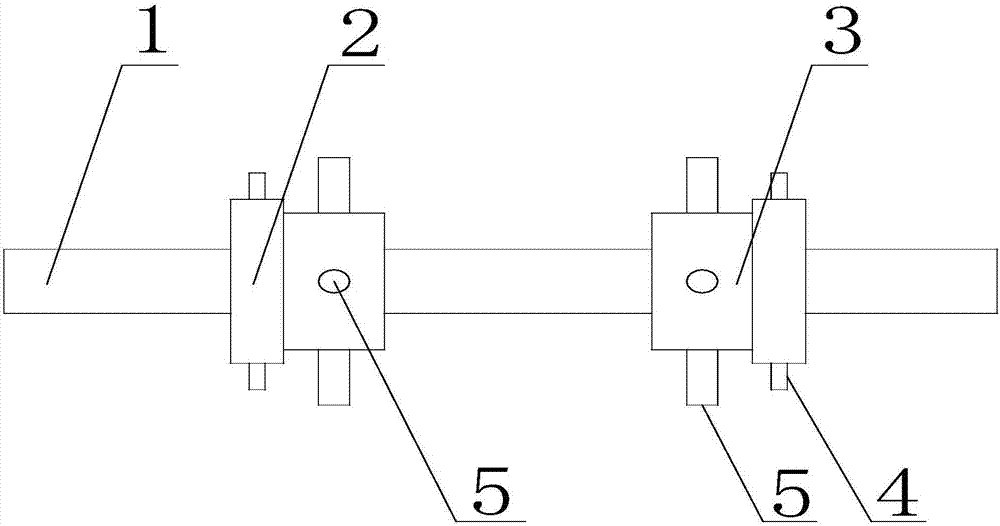

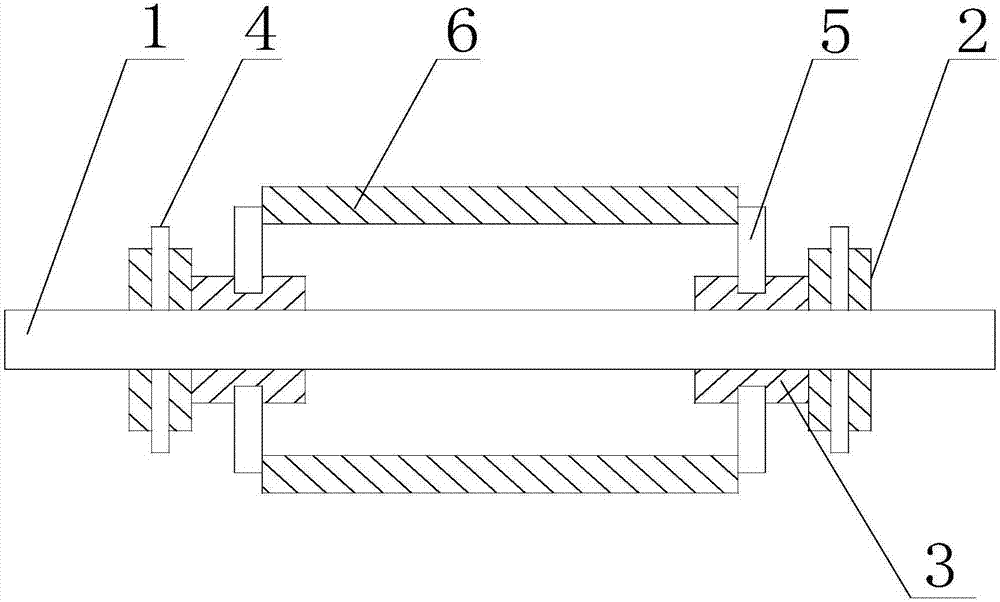

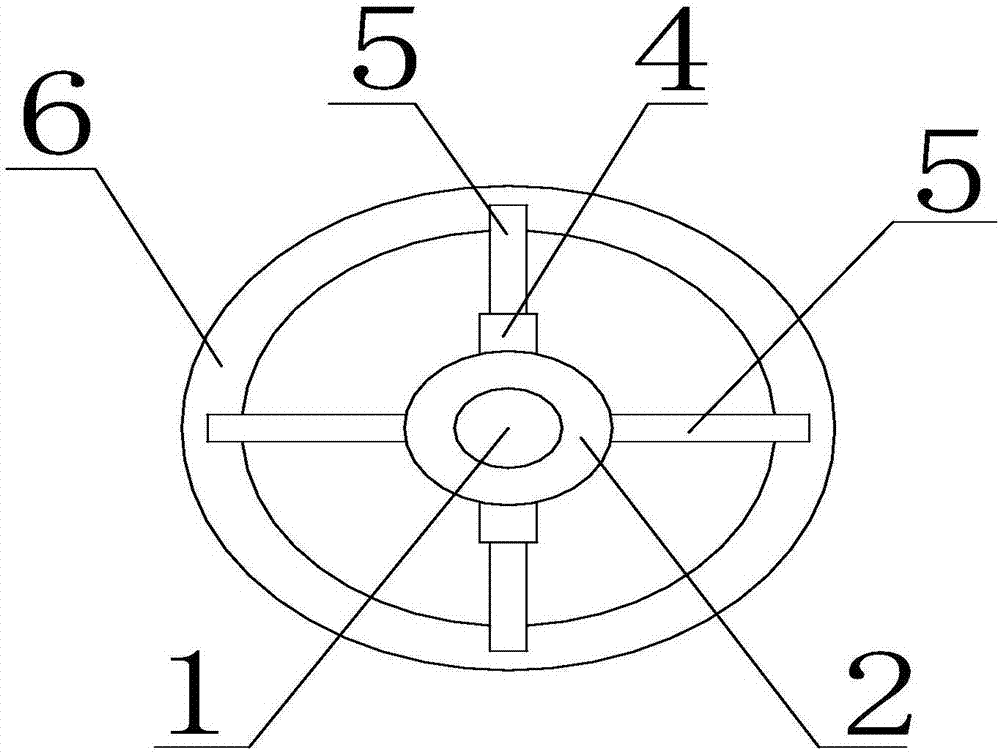

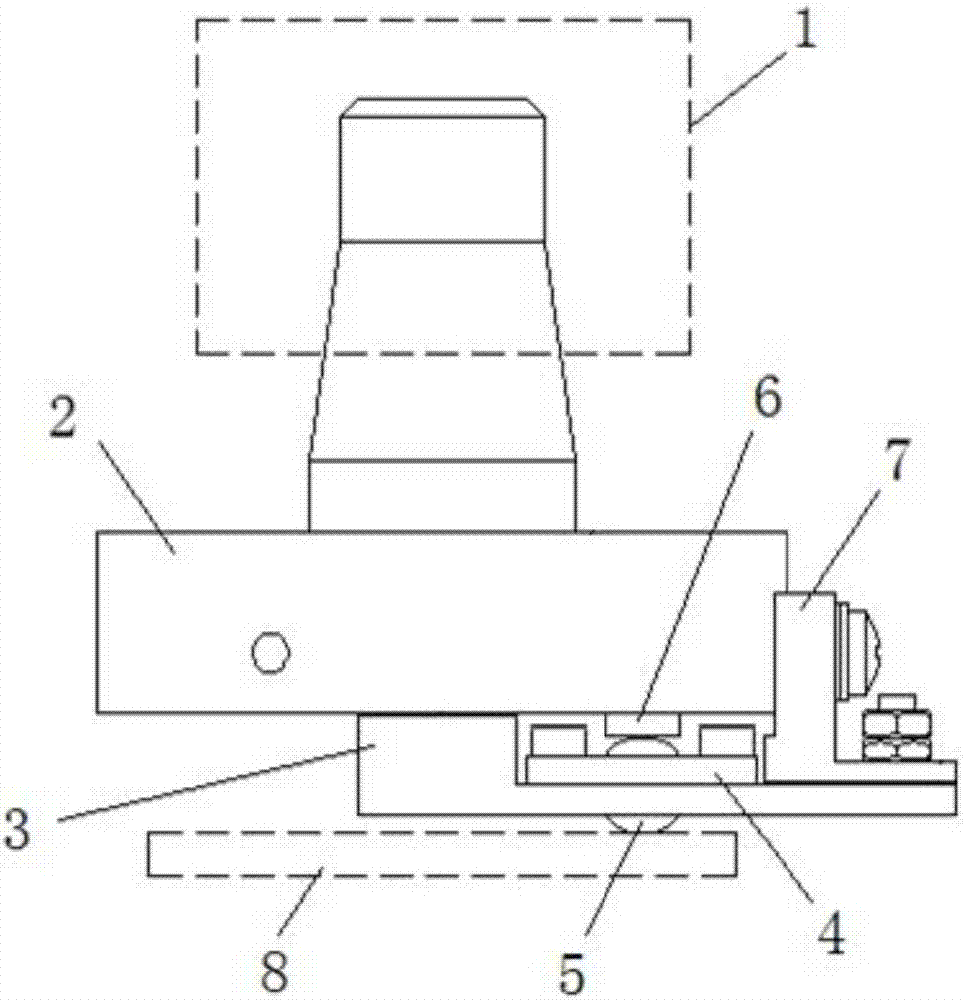

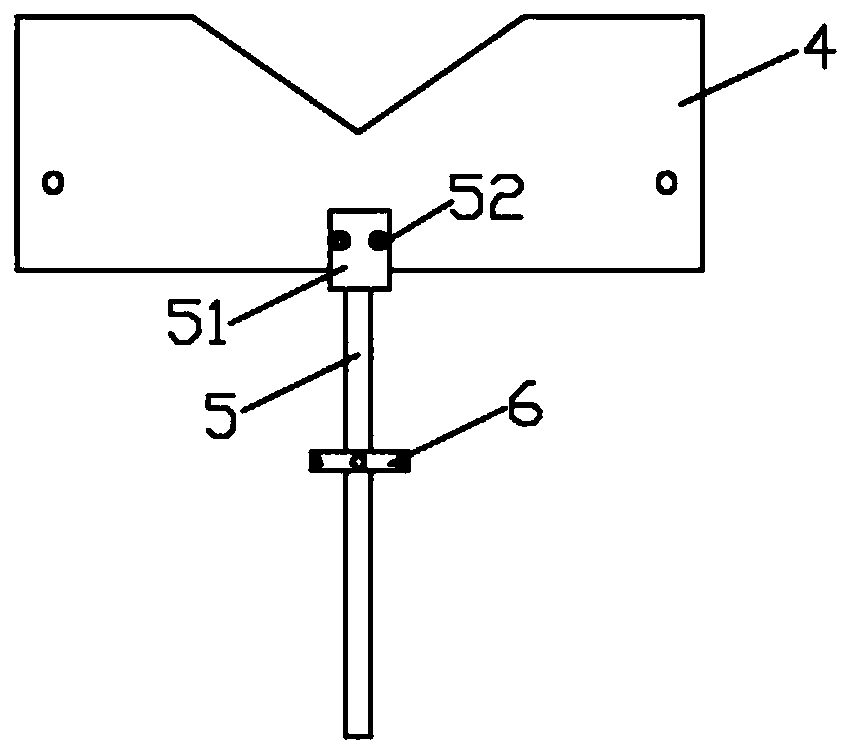

Fixing mechanism for external circle grinding of sleeve-like mechanical components

InactiveCN107052918AAvoid inconsistent depth of cutThe spacing can be adjusted arbitrarilyRevolution surface grinding machinesGrinding work supportsMechanical componentsEngineering

The invention discloses a fixing mechanism for cylindrical grinding of sleeve mechanical parts, which includes a shaft rod, a positioning block and a clamping block are arranged on the shaft rod, two adjusting rods are arranged on the positioning block, and the adjusting rod connects with the positioning block through a screw thread. Connection, used to fix the positioning block on the shaft rod, there are several baffles on the clamping block, the baffles are connected with the clamping block through threads, and the baffles are used to block the side of the sleeve parts between the two clamping blocks The height of the baffle can be adjusted by rotating the baffle to meet the clamping of sleeve parts with different diameters. The invention is simple in structure, easy to operate, can ensure that the outer circle of the sleeve workpiece is coaxial with the shaft, improves the cutting accuracy, and can hold multiple sleeve workpieces at the same time, satisfying the simultaneous processing of multiple sleeve workpieces, and improving the accuracy of sleeve workpieces. production efficiency.

Owner:绵竹市凯瑞机械加工有限公司

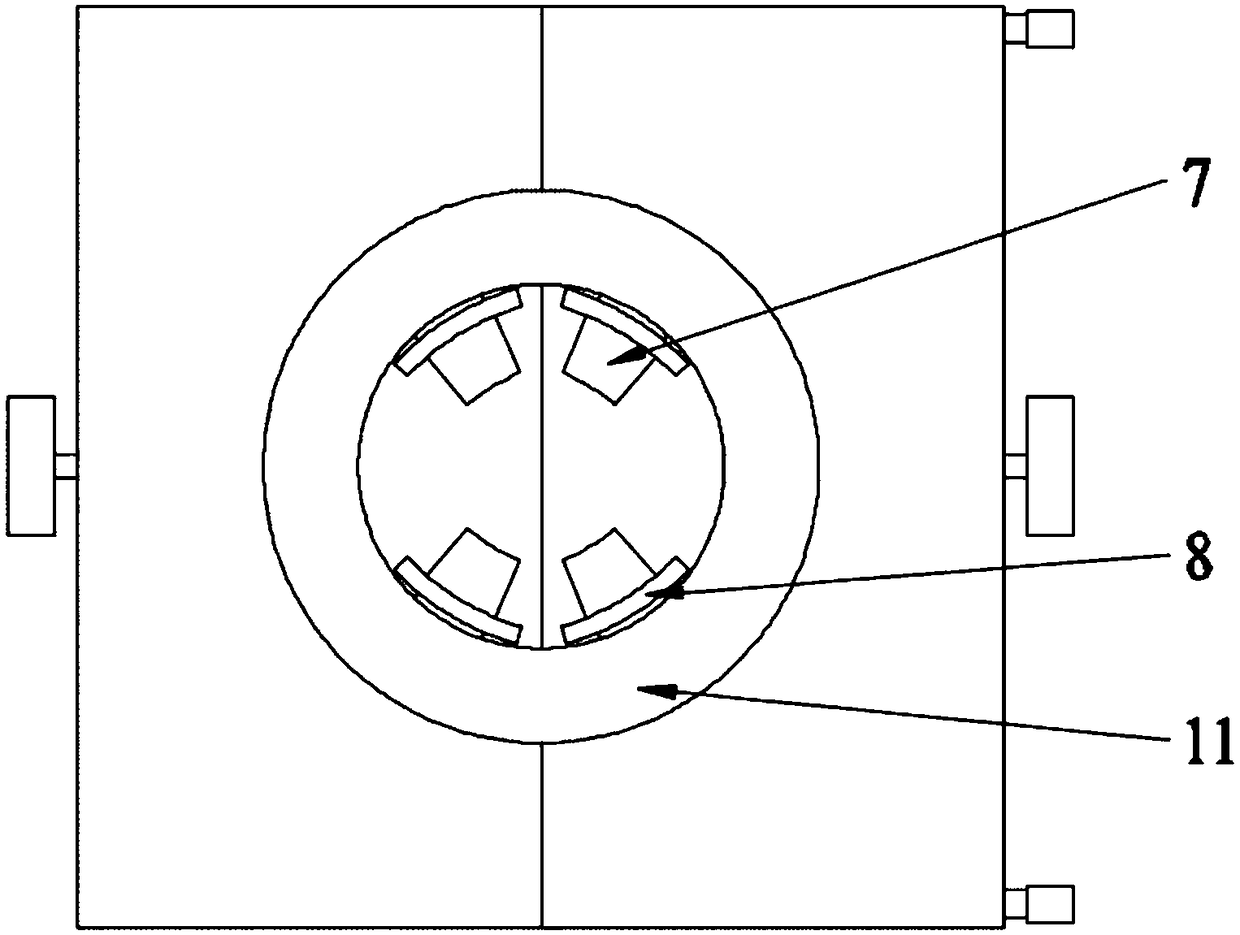

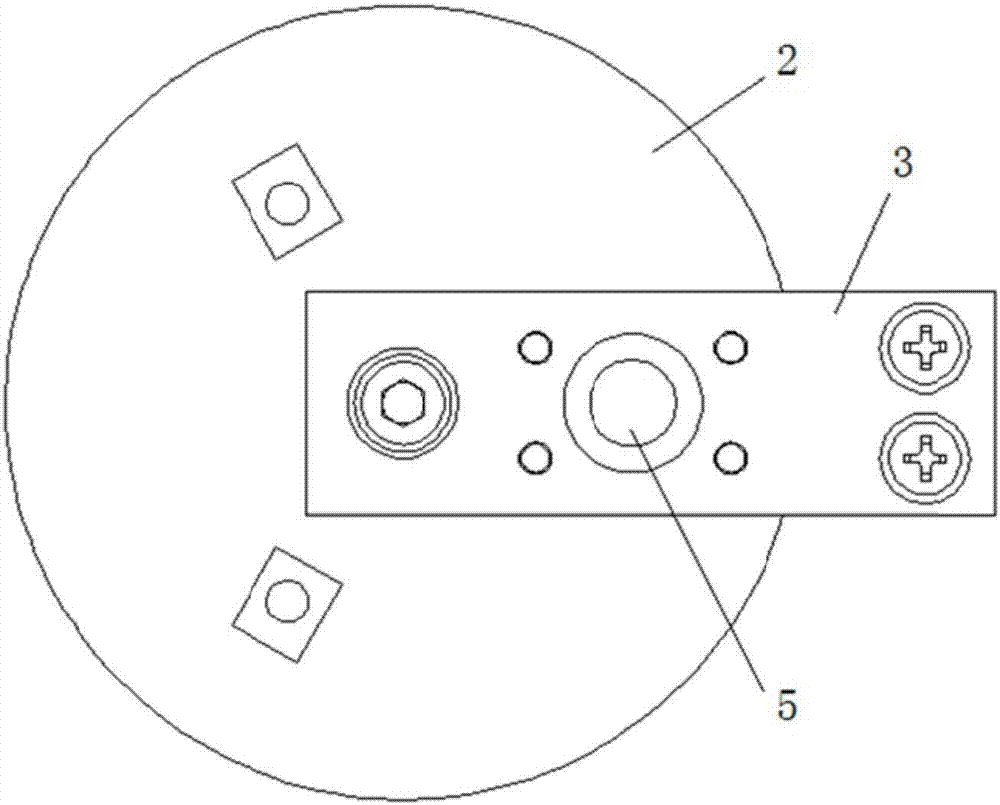

Work fixture for cylindrical optical element

The invention discloses a work fixture for a cylindrical optical element. A clamping and fixing structure is formed by utilizing a fixed bottom plate structure and a clamping device; a through hole isformed in the middle of the fixed bottom plate structure; multiple clamping claws are uniformly and fixedly arranged on the inner wall of the through hole of the fixed bottom plate structure and canmove along the direction perpendicular to the inner wall of the through hole, so that a workpiece is clamped; the multiple clamping claws move inwards or outwards along one center so as to fix the optical element, so that the optical element is uniformly stressed, the stability on clamping the optical element is improved, and the clamping claws are prevented from getting loose; and through a locking mechanism, during the detection process of the optical element, the occurrence of the phenomenon that the optical element is inaccurate in centering so as to influence processing or detecting due to the poor stability of the clamping claws and the dead weight of the optical element is avoided.

Owner:XI AN JIAOTONG UNIV

Drying device for furniture production

InactiveCN110411168AAchieve dryingAffect qualityDrying gas arrangementsPretreated surfacesBraced frameFixed frame

The invention discloses a drying device for furniture production. The drying device for the furniture production comprises a base, a supporting frame and a fixed frame; a rotary motor is arranged in the center of an inner cavity of the base; the rotary motor is connected with an air supply cylinder through an auxiliary rotary shaft, and the air supply cylinder is inserted between an inner cavity of a first annular supporting frame and an inner cavity of a second annular supporting frame in the vertical direction in a sliding mode; a plurality of first U-shaped limiting plates are welded on theouter wall of a first annular fixed frame in the radial direction; a plurality of second U-shaped limiting plates are welded on the outer wall of a second annular fixed frame in the radial direction;a plurality of guide wheels are respectively and rotatably arranged on the left side and the right side of inner cavities of each first U-shaped limiting plate and the corresponding second U-shaped limiting plate through rotary shafts; and the fixed frame is connected to the outer walls of the first annular supporting frame and the second annular supporting frame of the supporting frame through the first annular fixed frame and the second annular fixed frame in a sliding mode. According to the drying device for furniture production, furniture production boards can be conveniently dried, the painted boards can also be subjected to alternate hot air drying treatment, and the oil paint bulging caused by overhigh temperature and the influence of the quality of the painted boards are prevented.

Owner:SHENZHEN POLYTECHNIC

Special fixture for numerical control machining center

InactiveCN111958270ASimple structureEasy to operateWork clamping meansPositioning apparatusNumerical controlStructural engineering

The invention discloses a special fixture for a numerical control machining center. The special fixture comprises a fixing plate, wherein a clamping assembly is arranged at the bottom of the fixing plate; the clamping assembly comprises two clamping plates vertically and oppositely arranged; one end of each clamping plate is slidably connected with the fixing plate through a guide structure; the two clamping plates can move towards each other along the guide structures; a plurality of clamping parts are uniformly distributed on the opposite sides of the two clamping plates, wherein each clamping part comprises a fixing seat, and the fixing seats are fixed to the clamping plates; one surfaces, away from the clamping plates, of the fixing seats are connected with contact parts; a multi-stagebuffer structure is arranged between each contact part and the corresponding fixing seat; the bottom of the fixing plate is further provided with a plurality of telescopic devices; and the telescopicends of the telescopic devices are connected with one sides, opposite to each other, of the two clamping plates. The special fixture is simple in structure and convenient to operate, can clamp workpieces of different shapes on the premise of ensuring stable clamping, avoids clamping damage on the surfaces of the workpieces, and is worth popularizing.

Owner:JIANGSU SECURITY TECH CARRER ACADEMY

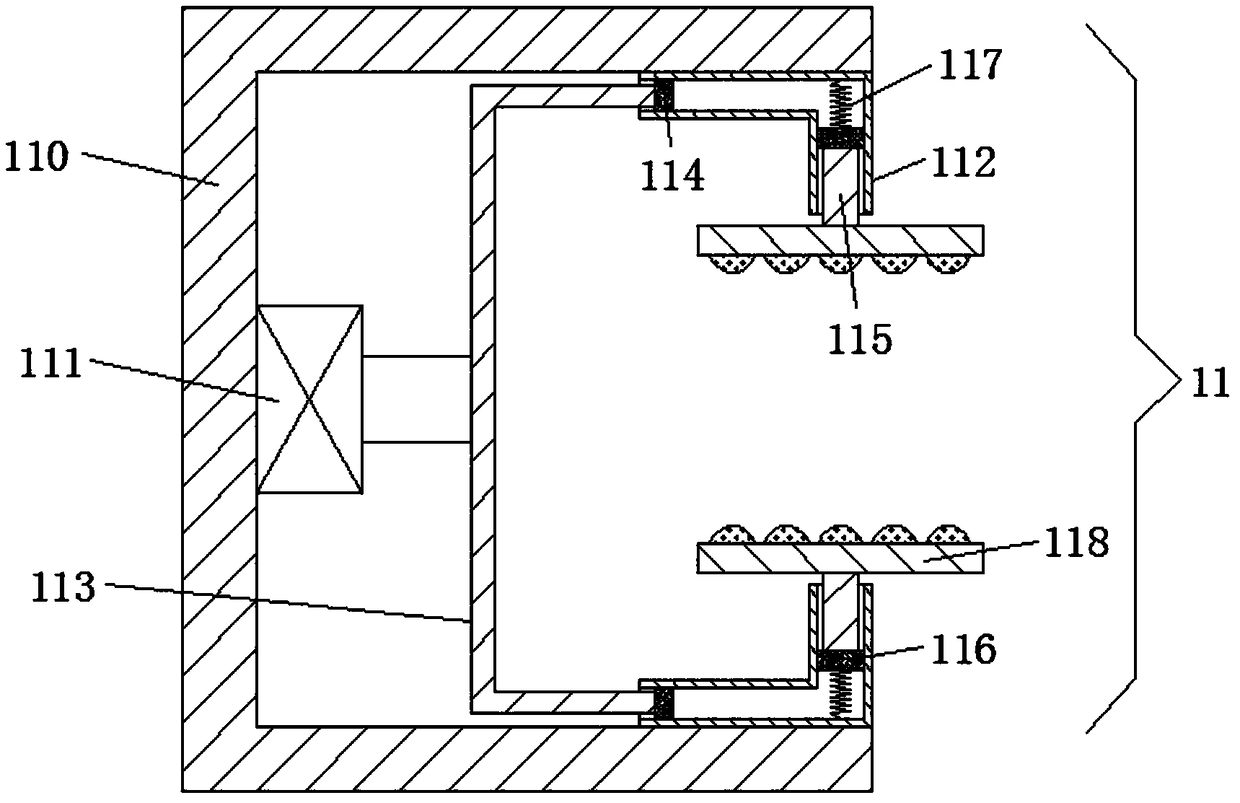

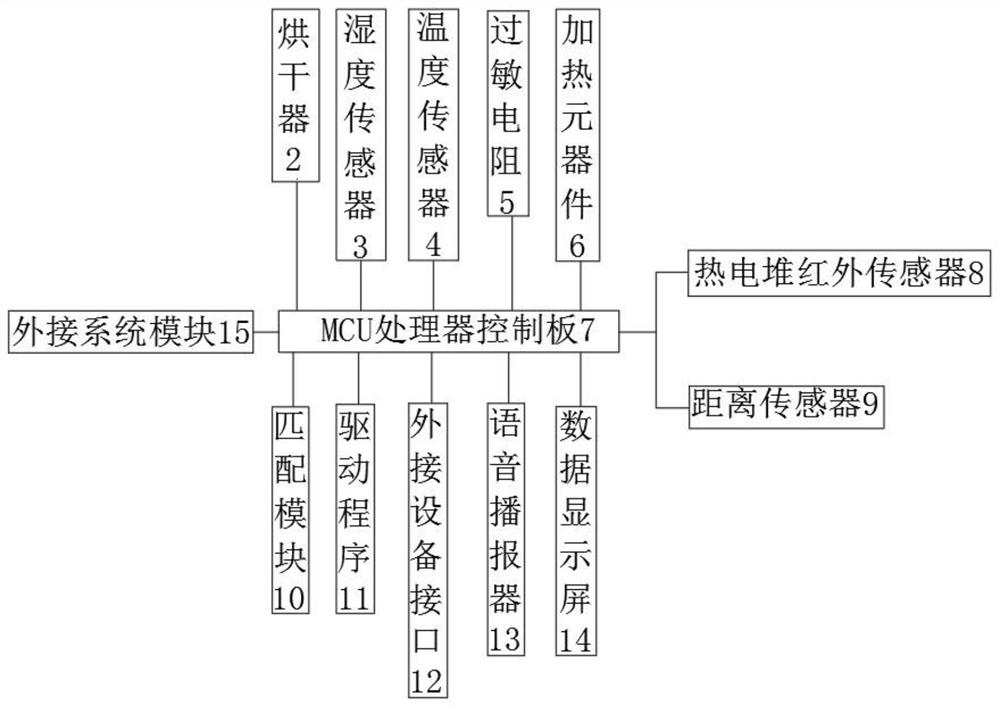

Infrared temperature measurement module based on thermopile

InactiveCN112097922AReduce distractionsAccurate calculationPyrometry using electric radation detectorsBody temperature measurementThermopile

The invention discloses an infrared temperature measurement module based on a thermopile, and relates to the technical field of body temperature measurement. The invention aims to solve the problem that temperature measurement is greatly influenced by the distance. The module specifically comprises a core assembly and a placement assembly; the core assembly comprises a device box and an MCU processor control panel; and a thermopile infrared sensing chip, a distance sensing module, a high-precision NTC chip, a matching module and an external equipment interface are electrically installed on theouter wall of the top of the MCU processor control panel, wherein the thermopile infrared sensing chip is electrically connected with a thermopile infrared sensor, and the distance sensing module iselectrically connected with a distance sensor; and a driving module is arranged in the MCU processor control panel and comprises a temperature calculation program and an environment compensation program. The matching module can perform zooming-in or zooming-out processing on the human body temperature measured in a centimeter range, and is matched with an environment compensation program and a temperature calculation program, so that the measured temperature error is smaller than 0.1 DEG C.

Owner:深圳铯敏发科技有限公司

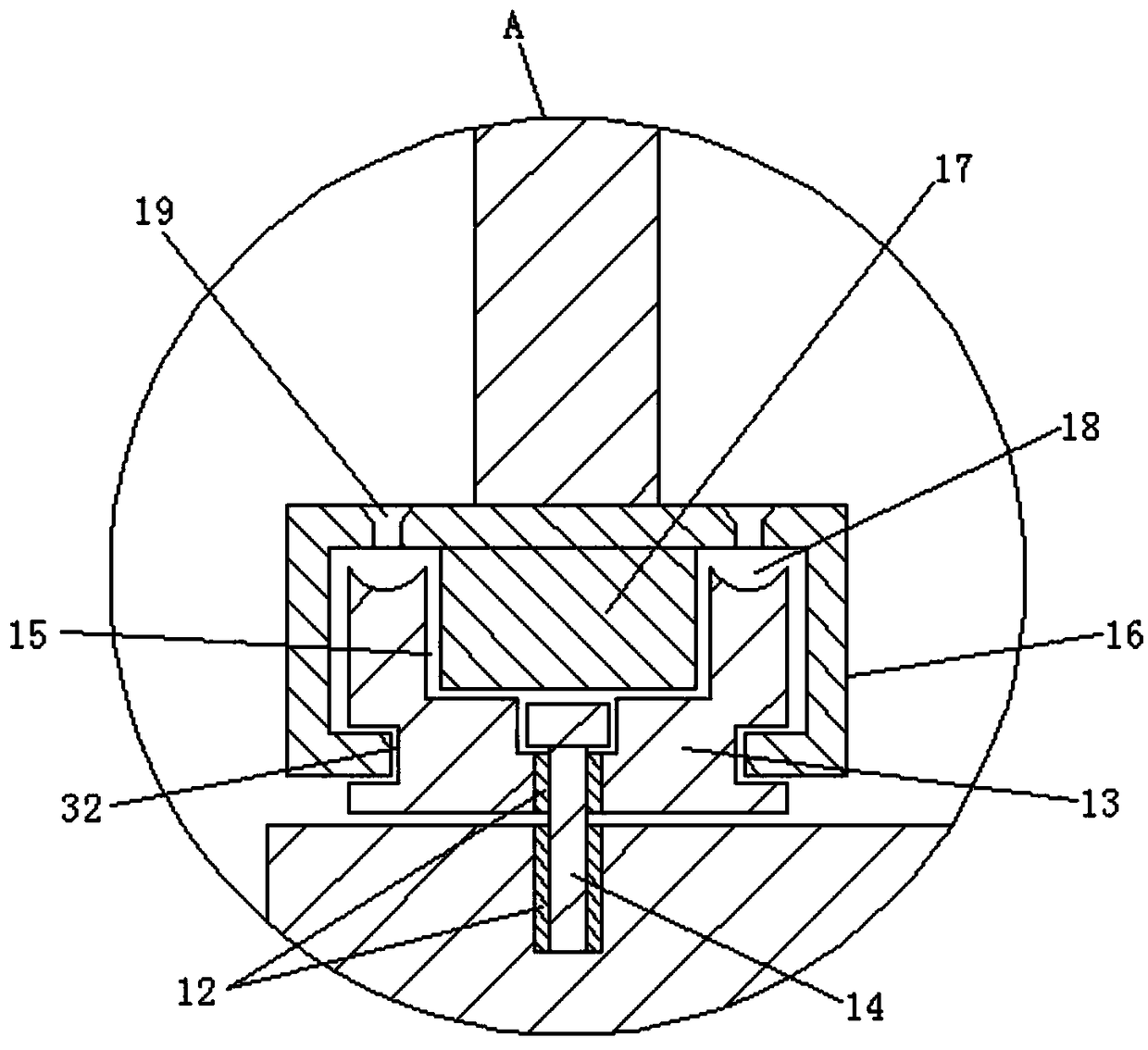

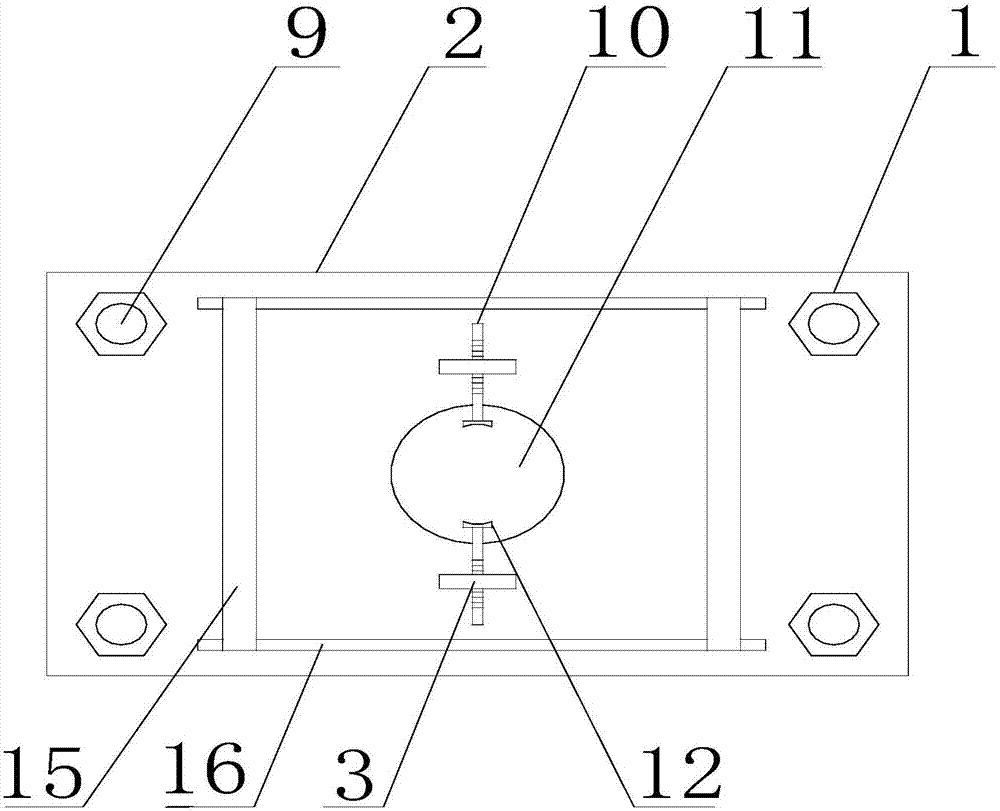

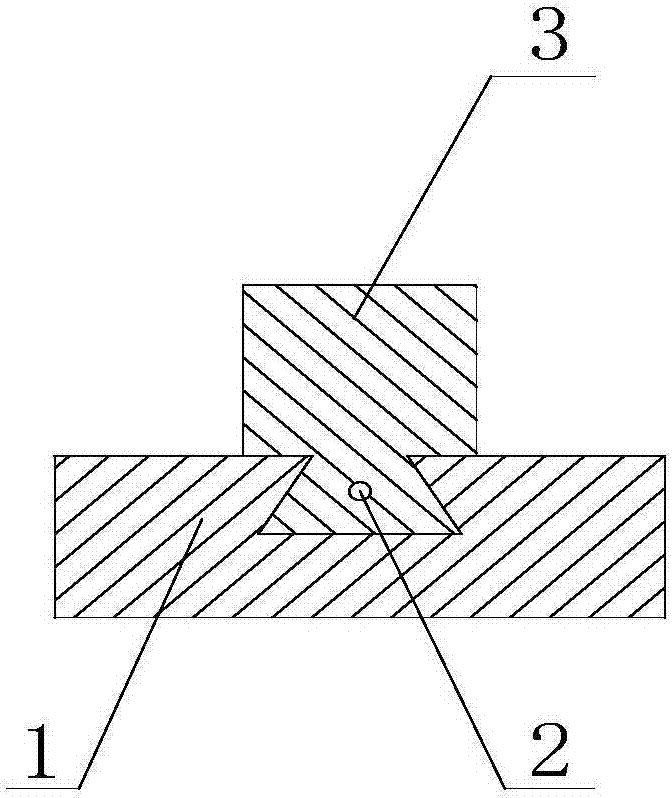

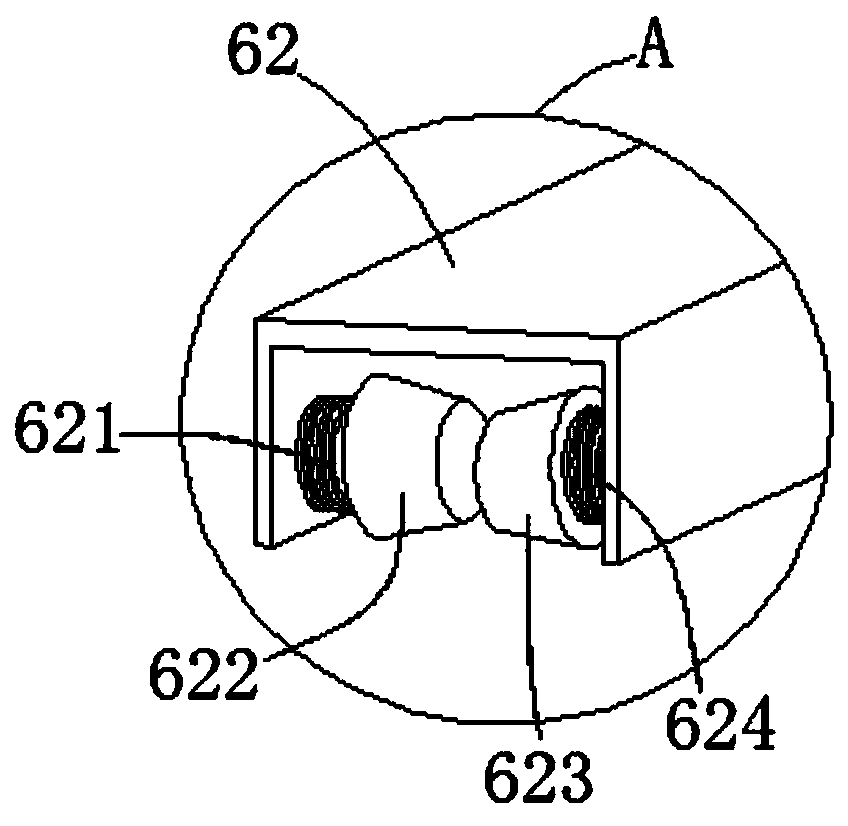

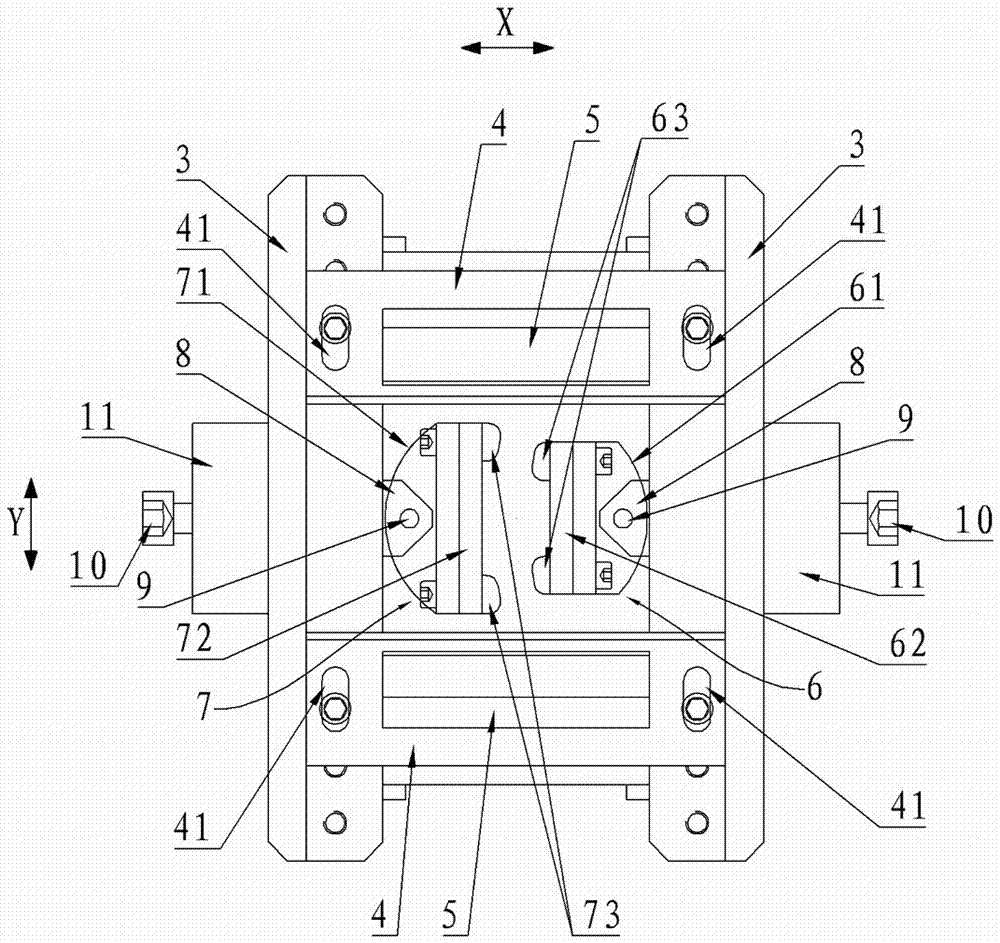

Fixture device for rolling-sliding mixed friction test, and use method of fixture device

ActiveCN106872262AMeet clampingCompact structureInvestigating abrasion/wear resistanceMixed statesAxial distance

The invention provides a fixture device for a rolling-sliding mixed friction test, and a use method of the fixture device. A set of block-ball-tray assembling device is formed by a pin sample, a ceramic ball sample and a tray sample; the radial size of the ceramic ball sample is adjusted by adjusting the aperture of a center hole of a bushing and adjusting the extending length of the pin sample, and the axial distance of the ceramic ball sample is adjusted by adjusting the distance between a support seat and the lower surface of a fixture head, so that the requirement of clamping ceramic ball samples with different diameters in a certain diameter range can be met. The fixture device is compact in structure, and has good applicability for the research of tribology behavior of materials in a rolling-sliding mixed state.

Owner:SHAANXI UNIV OF SCI & TECH

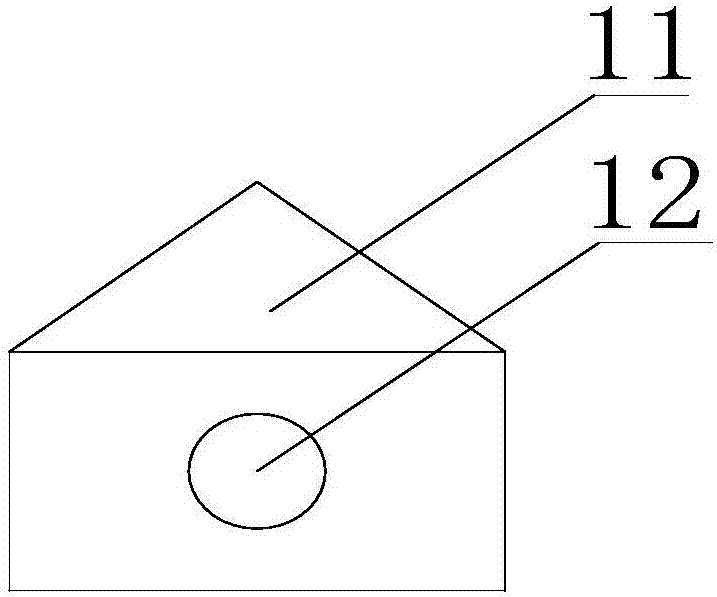

Machining operating table facilitating recycling of sweeps

InactiveCN106826257AAvoid scratchesAchieve clampingWork clamping meansLarge fixed membersDrive shaftMachining process

The invention discloses a machining operating table facilitating recycling of sweeps. The machining operating table comprises a working table. The top of the operating table is provided with two supporting columns and a plurality of leakage holes, the supporting columns are provided with driving mechanisms, driving shafts of the driving mechanisms penetrate the supporting columns, the tail end of each supporting column is provided with a connecting rod, one end of the connecting rod is connected with the driving shaft, the other end of the connecting rod is provided with a movable shaft, the movable shaft is provided with a clamping block, the clamping block can rotate around the movable shaft, the side of the working table is further provided with a drawer that can be pulled open, the drawer is made of a magnetic material, and the inside of the drawer is communicated with the leakage holes. According to the machining operating table, a to-be-machined part can be fixed to the working table, the contact area between a clamping component and the part is increased, and the part is protected from damage; the sweeps generated in the machining process can be uniformly recycled and restored, and the sweeps are prevented from scraping an operator.

Owner:LUZHOU YUANCHENG ENG MACHINERY CO LTD

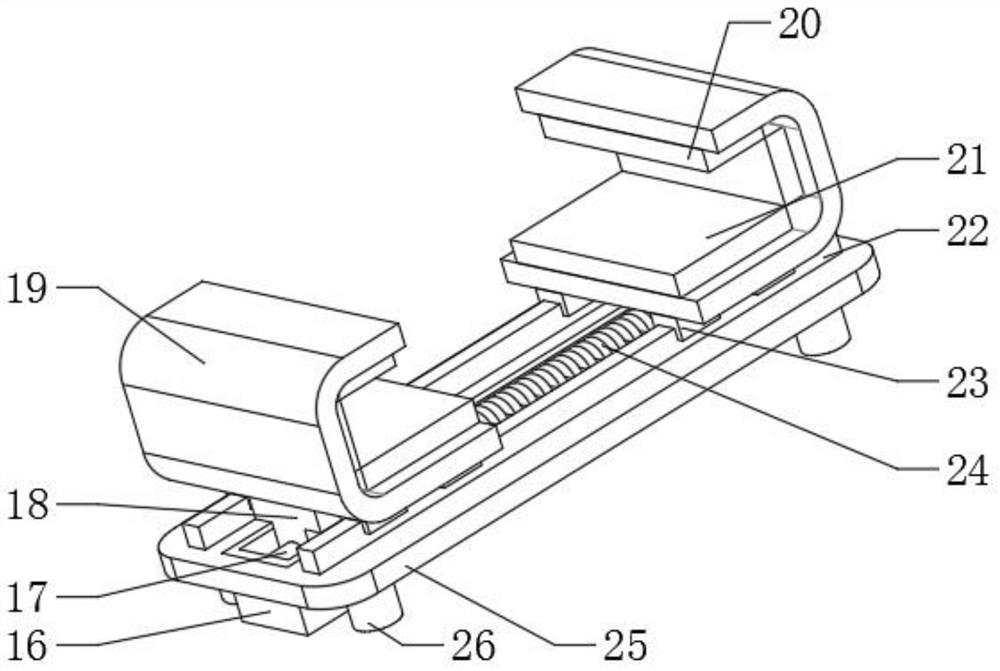

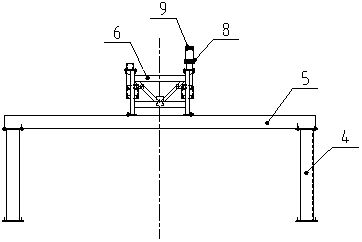

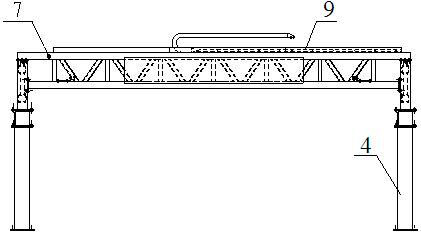

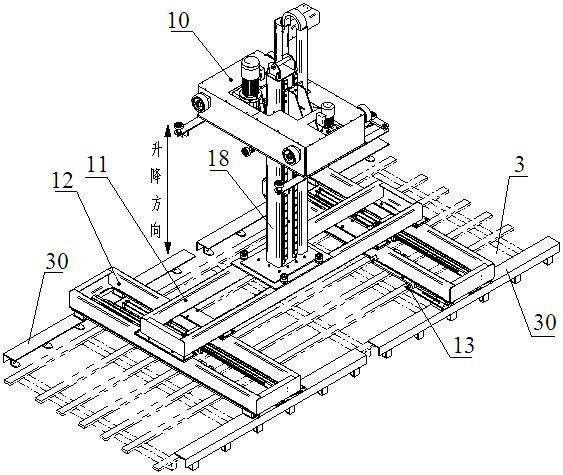

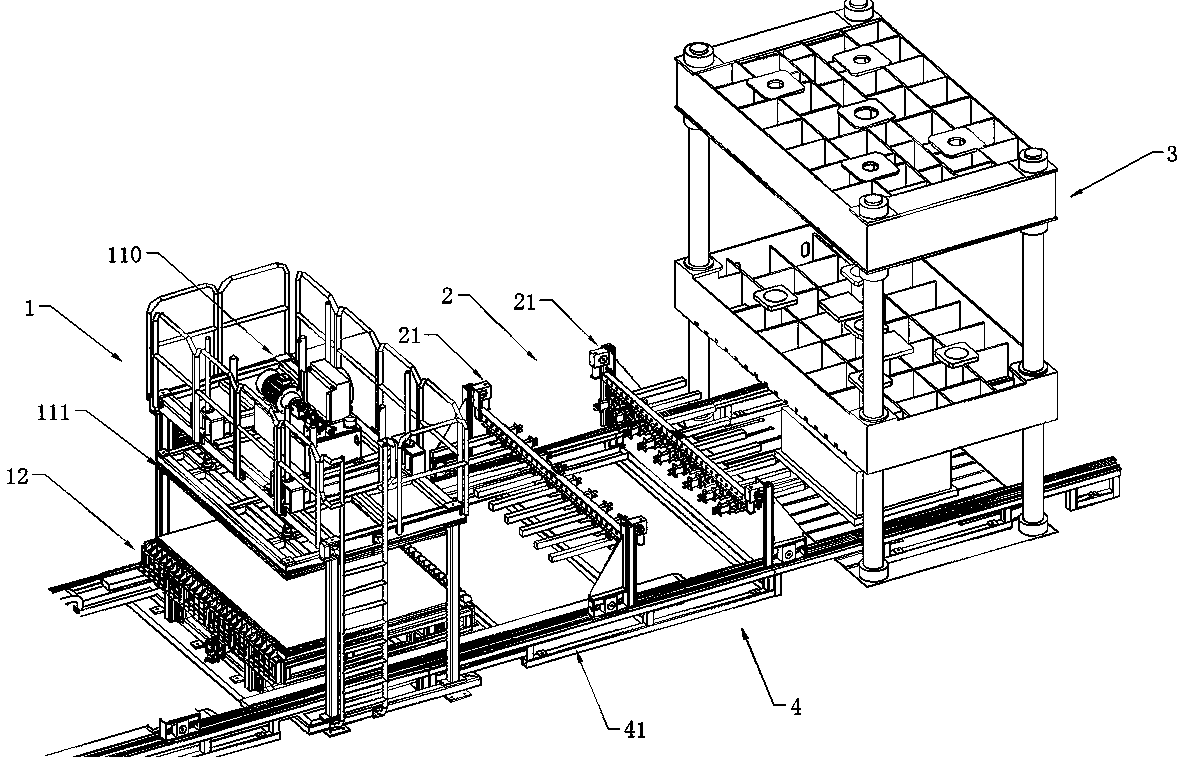

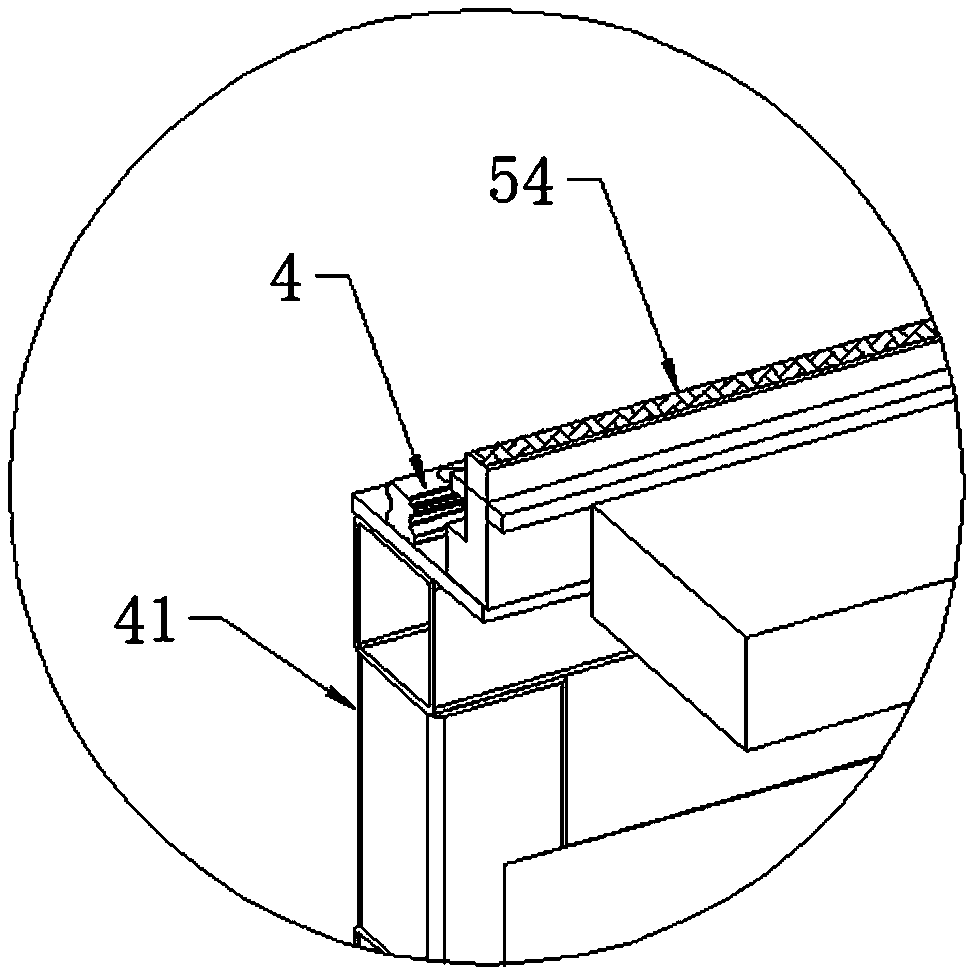

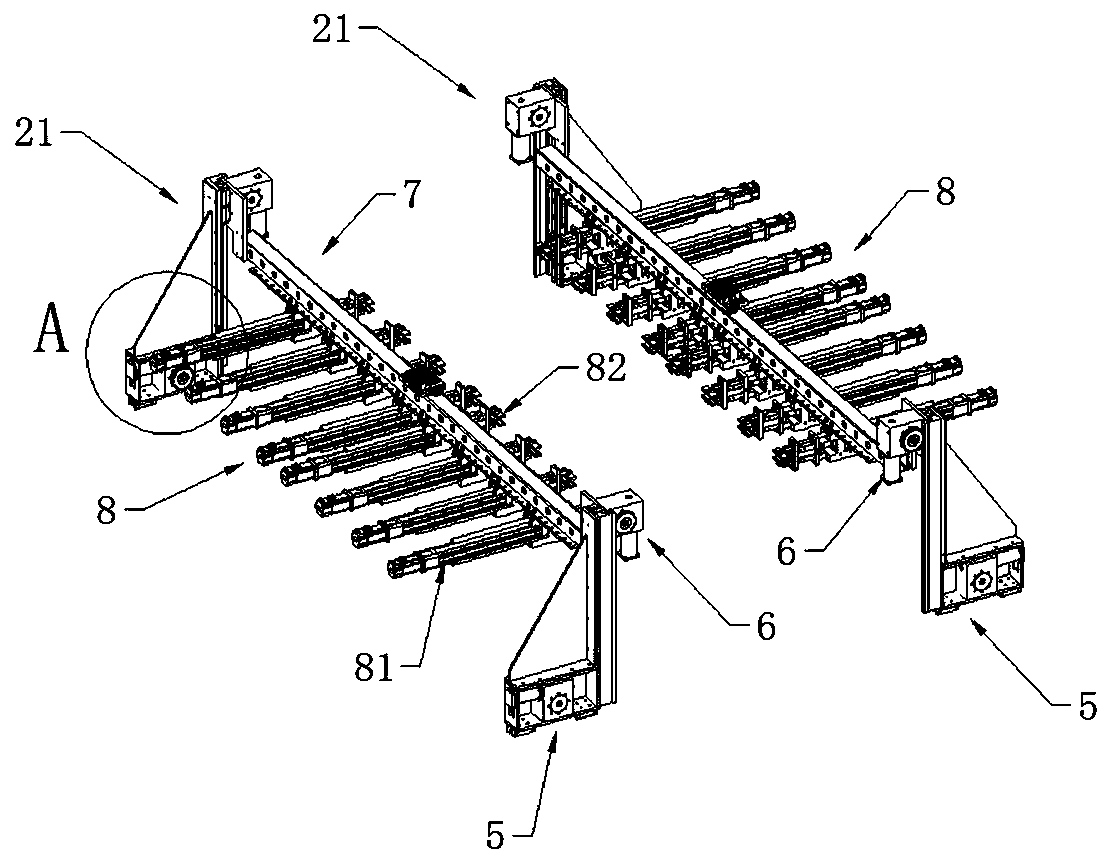

Multi-layer net-shaped wood pallet feeding device and method

PendingCN111762583AEasy to transportEasy to hang outConveyorsStacking articlesAgricultural engineeringStructural engineering

The invention provides a multi-layer net-shaped wood pallet feeding device and method. The multi-layer net-shaped wood pallet feeding device comprises a gap bridge assembly and a transverse moving assembly; the transverse moving assembly is arranged on the gap bridge assembly and is in sliding connection with the gap bridge assembly, and wood pallets are clamped by the transverse moving assembly and can be driven by the transverse moving assembly to move up and down and transversely; and a portal structure is provided by stand columns and cross beams, so that upstream wood pallet conveying equipment can convey the wood pallets conveniently; a small frame and a large frame form a walking channel of the transverse moving assembly, the opening degree of the upper portion of the walking channel is larger than the width of the upper portion of the transverse moving assembly, and hoisting-out during mounting and dismounting is facilitated; the number of clamping units can be increased by arranging a cross beam assembly, so that clamping of different numbers of wood pallets is achieved, the opening degrees of two manipulators are adjusted through an air cylinder, the wood pallets of different widths can be clamped, and the requirement for clamping the wood pallets of different shapes is met. The device saves the labor cost, compared with manual carrying and forklift conveying, according to the technical scheme, the device and the method greatly reduce the labor intensity of field workers; operation is easy and convenient, and efficiency is high.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Special processing device for arc-shaped solid wood line

InactiveCN109227780AAdjustable distanceAvoid destructionProfiling/shaping machinesSolid woodEngineering

The invention discloses a special processing device for an arc-shaped solid wood line. The special processing device comprises a base, wherein support plates are symmetrically and fixedly connected tothe upper end of the base, a worktable is commonly fixedly connected to the upper ends of the two support plates, movable holes are formed in the worktable between the two support plates along the horizontal direction, telescopic rods are fixedly connected to the movable holes close to the side walls of the support plates, clamp plates are fixedly connected to the other ends of the two telescopicrods, bearing openings are formed in the opposite side walls of the upper ends of the two clamp plates, and threaded holes are formed in the plate walls, far from one ends of the bearing openings, ofthe two clamp plates. By arranging a fixed clamp, the wood line is unlikely to slide when being subjected to repeated rolling cutting and rolling caving, so that the roll-cut surface is not damaged,and the special processing device can meet the requirements on the clamping of wood lines with different sizes and the processing of wood lines with different thickness.

Owner:柳州市品尚木业有限公司

Multi-functional clamp for mechanical manufacturing

InactiveCN112025584ARealize processingMeet clampingWork holdersManufacturing engineeringMachine building

The invention relates to the technical field of workpiece machining, and discloses a multi-functional clamp for mechanical manufacturing. The multi-functional clamp comprises a bottom plate, two sideplates, a fixed connecting rod, a telescopic rod, a fixed plate, a threaded rod, a movable plate, a sleeve and a clamping block, the bottom plate is fixed on an operating table, the two side plates are perpendicular to the bottom plate and are respectively provided with a first through hole, and the fixed connecting rod is parallel to the bottom plate; and the telescopic rod and the fixed connecting rod are symmetrically arranged, the fixed plate is fixedly connected to the outer side walls of the two side plates, the threaded rod is hinged to the fixed plate through a third bearing, the movable plate is in threaded connection with the periphery of the threaded rod, the sleeve sleeves the periphery of the threaded rod, and the clamping block is fixedly connected to the second end of the sleeve and is located on the inner side of the threaded rod all the time and matched with a first groove in size. Fixing of the position of a part to be machined is realized by clamping the clamping block into a clamping groove, machining of multiple machining faces is achieved, and for the to-be-machined parts with different widths, the to-be-machined parts with various sizes can be clamped by adjusting the distance between a first clamping part and a second clamping part.

Owner:JIANGSU SECURITY TECH CARRER ACADEMY

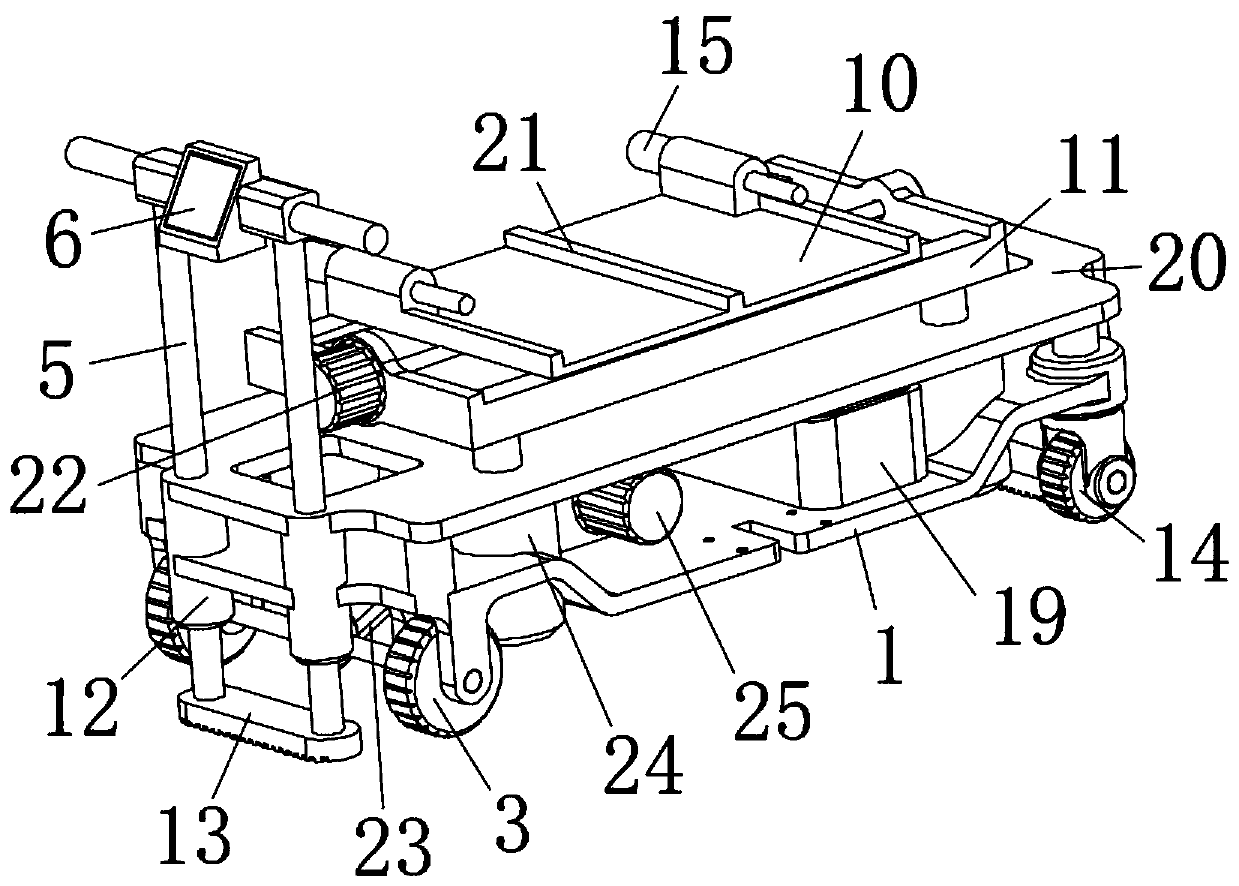

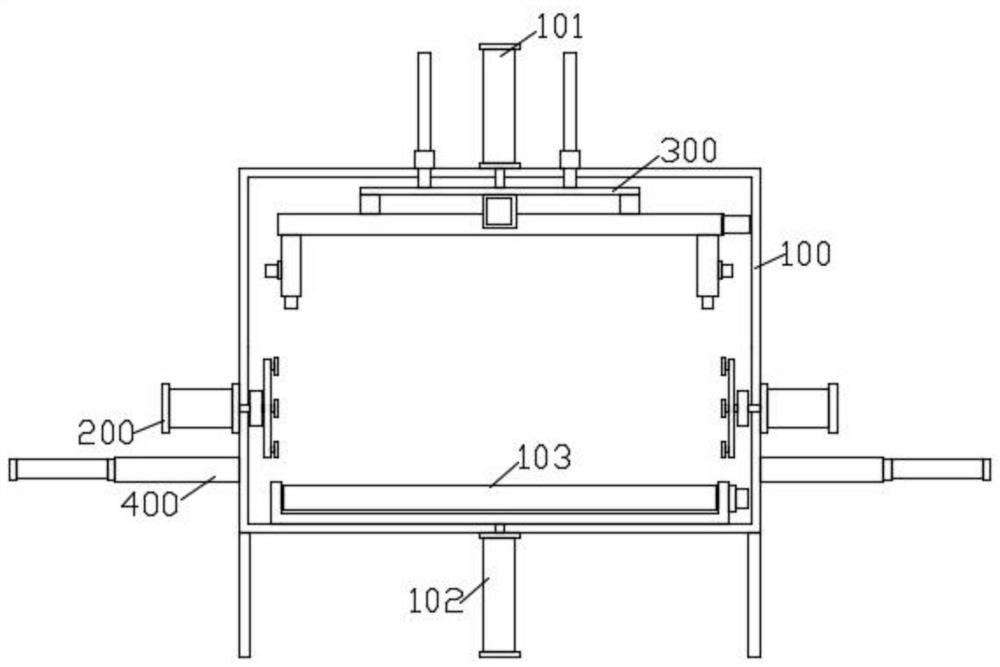

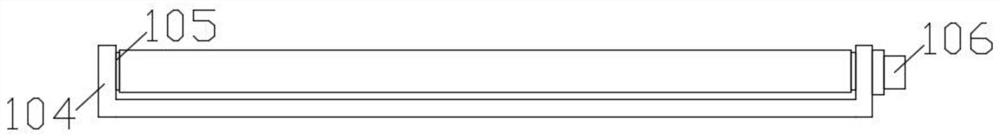

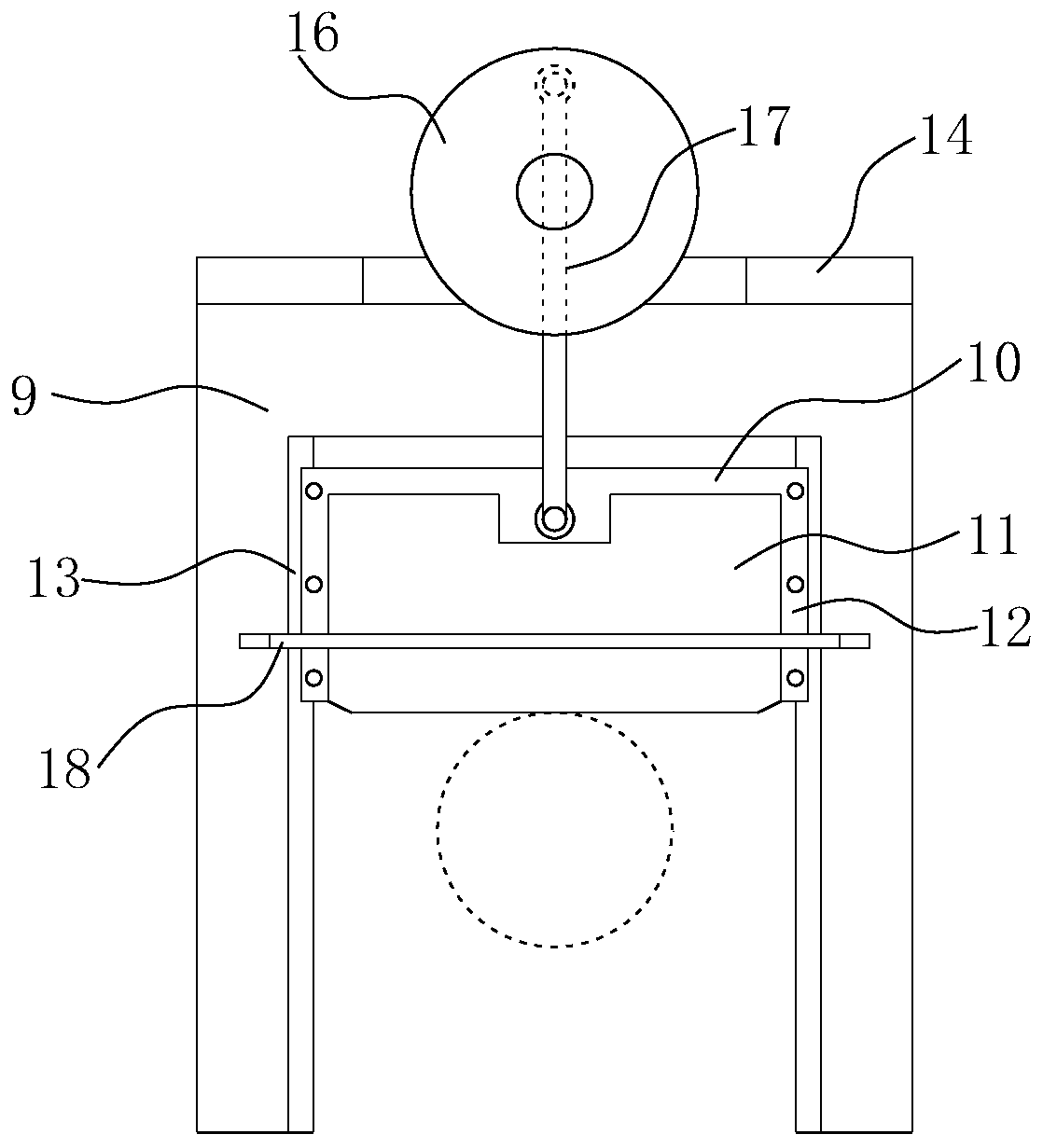

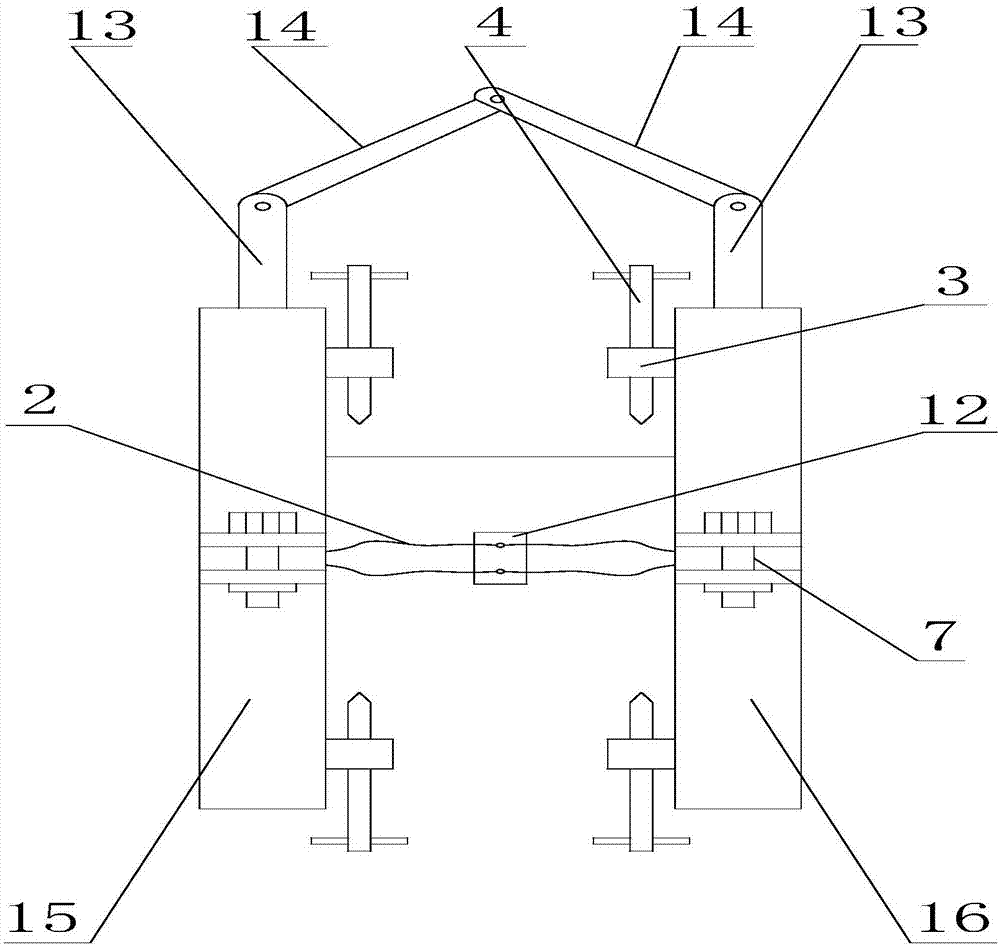

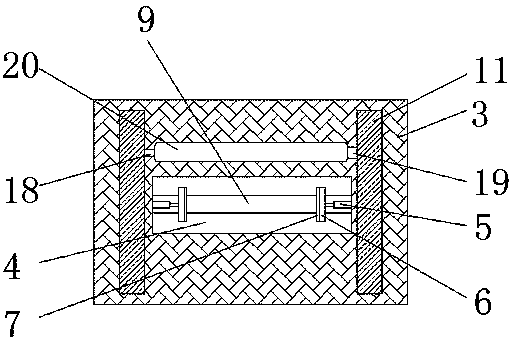

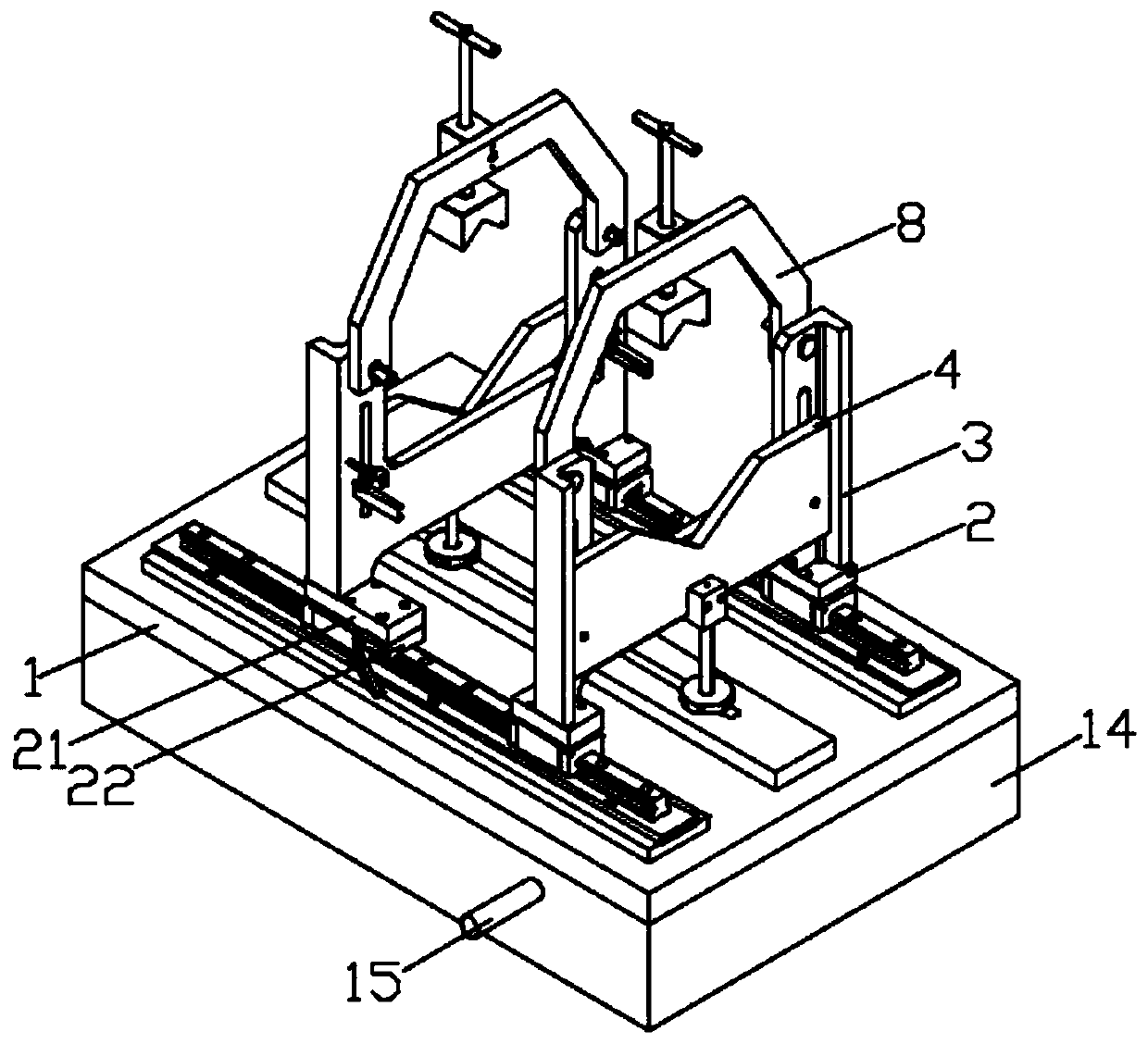

Fiber preforming line forming clamping device and method

The invention discloses a fiber preforming line forming clamping device and method. The device comprise a heating table press, a clamping device body and a preforming press which are sequentially arranged according to the advancing direction of fibers to be formed; the clamping device body slides on two parallel clamping hand guide rails and conveys fiber cloth heated by the heating table press tothe preforming press; and the clamping device is composed of two gantry clamping hand mechanisms which are arranged back and forth and independently perform linear motion. Each gantry clamping hand mechanism comprises two advancing and retreating mechanisms, lifting mechanisms, a cross rod mechanism and a clamping tool which respectively move along the clamping hand guide rails, wherein the advancing and retreating mechanisms are connected with the lifting mechanisms; the cross rod mechanism stretches over the clamping hand guide rails; the two ends of the cross rod mechanism are separately connected with the lifting mechanisms; the clamping tool comprises a plurality of clamping units; and each clamping unit maintains position closed loop or tension closed loop control over the fiber cloth in the pressing process of the preforming press.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

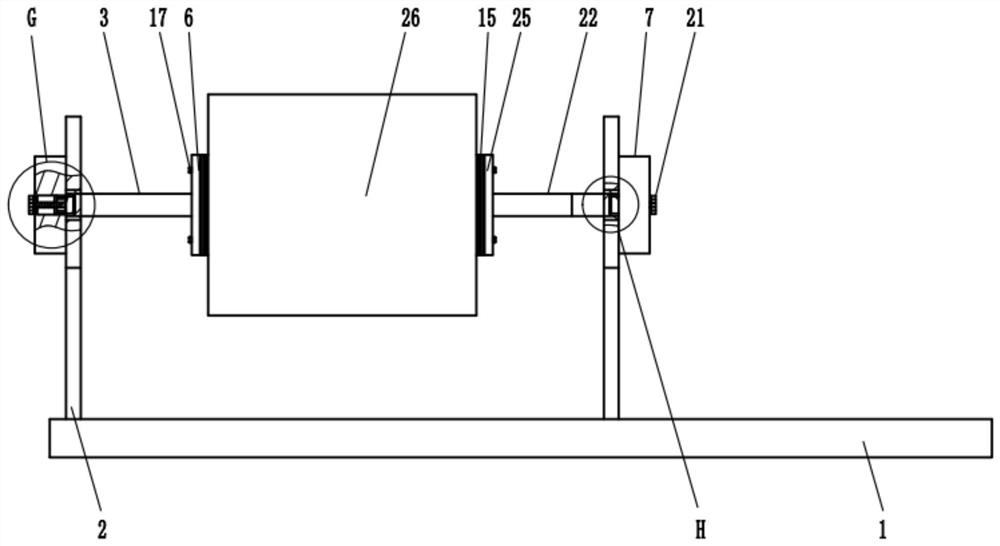

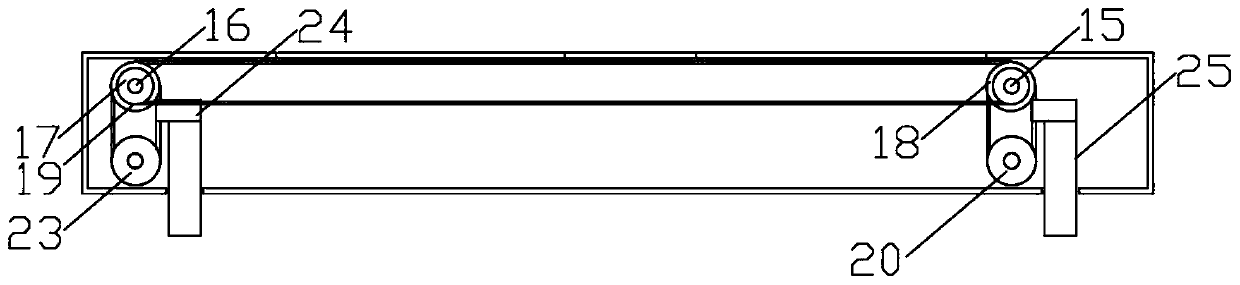

Generator set assembly stand and use method thereof

The invention discloses a generator set assembly stand and a use method thereof. The generator set assembly stand includes a stand body, two movable frames are slidably arranged on the stand body, a mounting plate is installed at the top of each movable frame, and a screw rod seat is installed on each mounting plate. The screw rod seats are rotatably connected with second screw rods, and limitingblocks are installed at the bottoms of the second screw rods. By rotating a first driving rod, the first driving rod drives a second driving rod to rotate through a pulley, while a first rod sleeve onthe first driving rod drives a third rod sleeve to rotate through a transmission belt, a second rod sleeve on the second driving rod drives a fourth rod sleeve to rotate through a transmission belt,and then a supporting column is driven to lift and lower by a clamp block to complete the height adjustment of the stand body; and through the structure, the height adjustment of the generator set assembly stand is more convenient, operators with different heights can use conveniently, the requirements of different heights can be met, and the technical problem of inconvenient adjustment of the height of the generator set assembly stand in the prior art is solved.

Owner:HEFEI CALSIION ELECTRIC POWER SYST

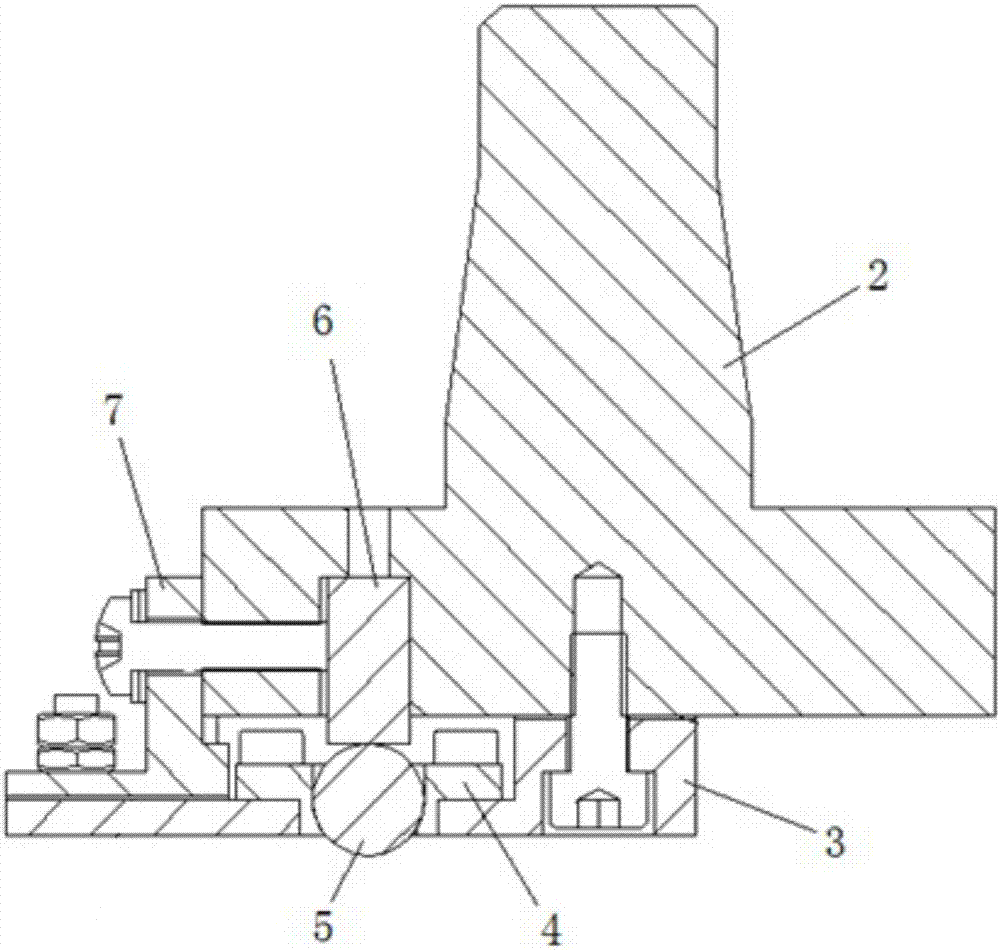

Hydraulic structure for controlling and clamping drill bit of drilling machine

InactiveCN106762939AMeet clampingReduced size spaceEngine sealsFluid-pressure actuatorsCast ironDrill bit

The invention discloses a hydraulic structure for controlling and clamping a drill bit of a drilling machine. The hydraulic structure comprises a cylinder, a cylinder bottom, a piston and a piston rod, wherein the cylinder is connected with the cylinder bottom in a welding mode to form a rodless cavity. Compared with a pull rod type hydraulic cylinder, the hydraulic structure not only has the advantages of being small in space necessary for screws and screw nuts, simple in structure, small in size, light in weight and the like, but also is capable of solving the problem of cylinder bottom leakage caused by aging of sealing parts at the cylinder bottom or other reasons; as an overlapped hydraulic control one-way valve is arranged on the outer wall of the cylinder bottom, pressure can be maintained when the drill bit is clamped by using the hydraulic cylinder; the piston is provided with a pressure control valve, so that the piston rod can be controlled to move, and furthermore the clamping force of the hydraulic cylinder for clamping a cutter can be controlled; the hydraulic cylinder works frequently, generally works in outdoor working environments, and repairing and maintenance conditions are poor, so that the stability of a moveable hydraulic cylinder needs to be improved; as a guide sleeve is made of high-strength cast iron, quality accidents can be avoided.

Owner:泸州长江液压密封件有限公司

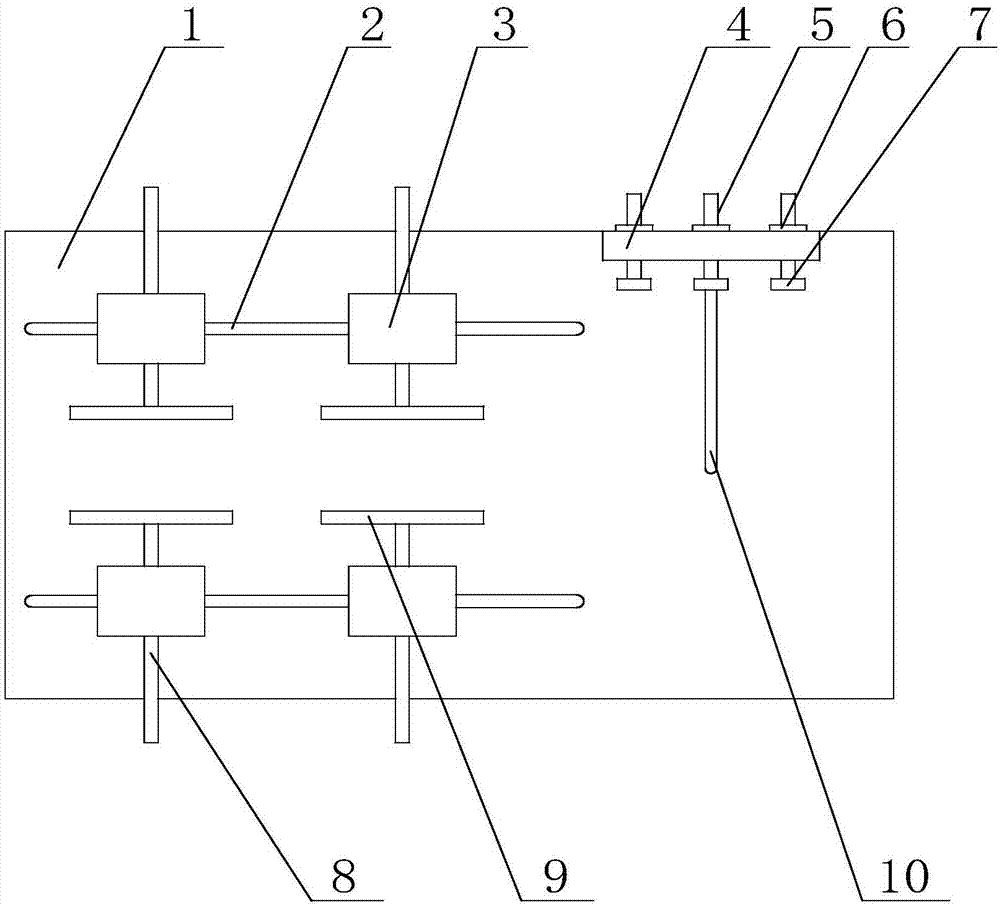

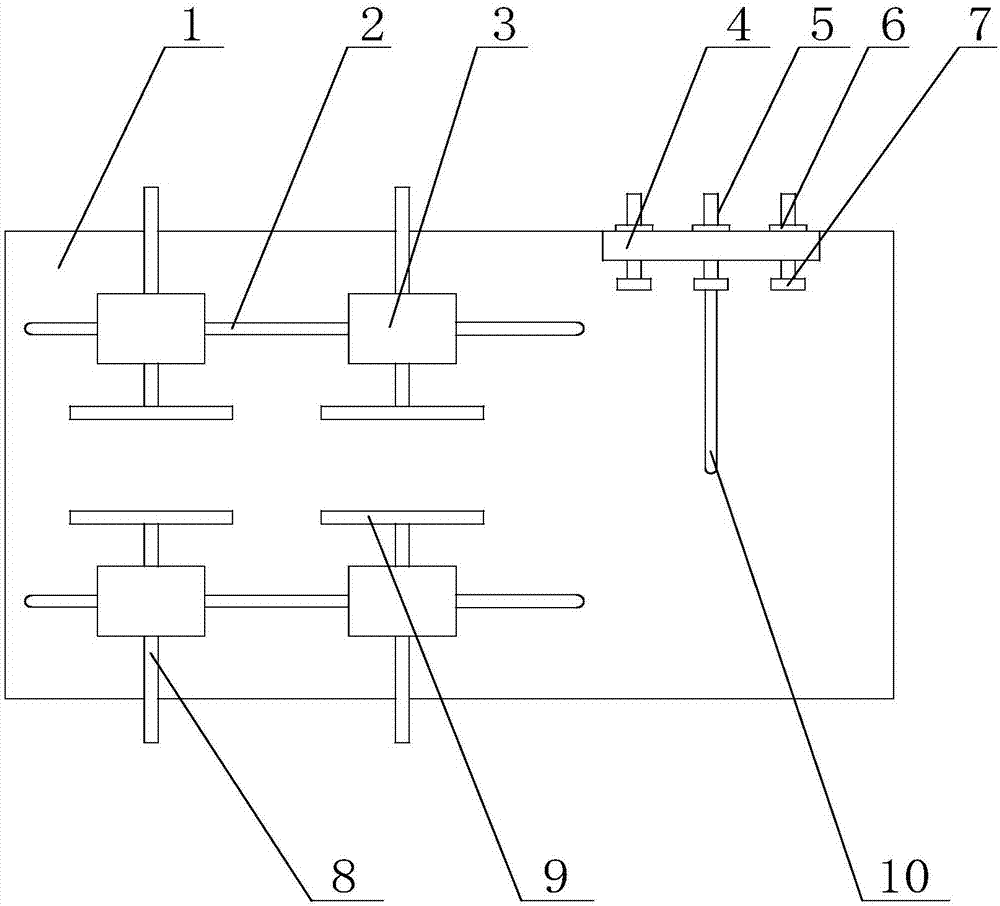

Positioning mechanism for improving welding efficiency for exhaust manifold and flange

InactiveCN107414385AImprove welding efficiencyFor quick alignmentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a positioning mechanism for improving the welding efficiency for an exhaust manifold and a flange. The positioning mechanism for improving the welding efficiency for the exhaust manifold and the flange comprises a base. A plurality of first driving mechanisms are arranged at the top of the base, and the first driving mechanisms can move on the base. Each first driving mechanism comprises a first driving shaft, wherein a clamping plate used for clamping the exhaust manifold is arranged at the top of the first driving shaft. A second driving mechanism is further arranged at the top of the base and can move on the base. The second driving mechanism comprises a second driving shaft, wherein a side table is arranged at the top of the second driving shaft, and the side table can rotate around the second driving shaft; and limiting plates used for clamping the flange are arranged on the side table. By adoption of the poisoning mechanism for improving the welding efficiency for the exhaust manifold and the flange, exhaust manifolds in different shapes can be clamped, and the weld portions of the flange and the exhaust manifold can be aligned conveniently.

Owner:CHENGDU LINGCHUAN SPECIAL IND

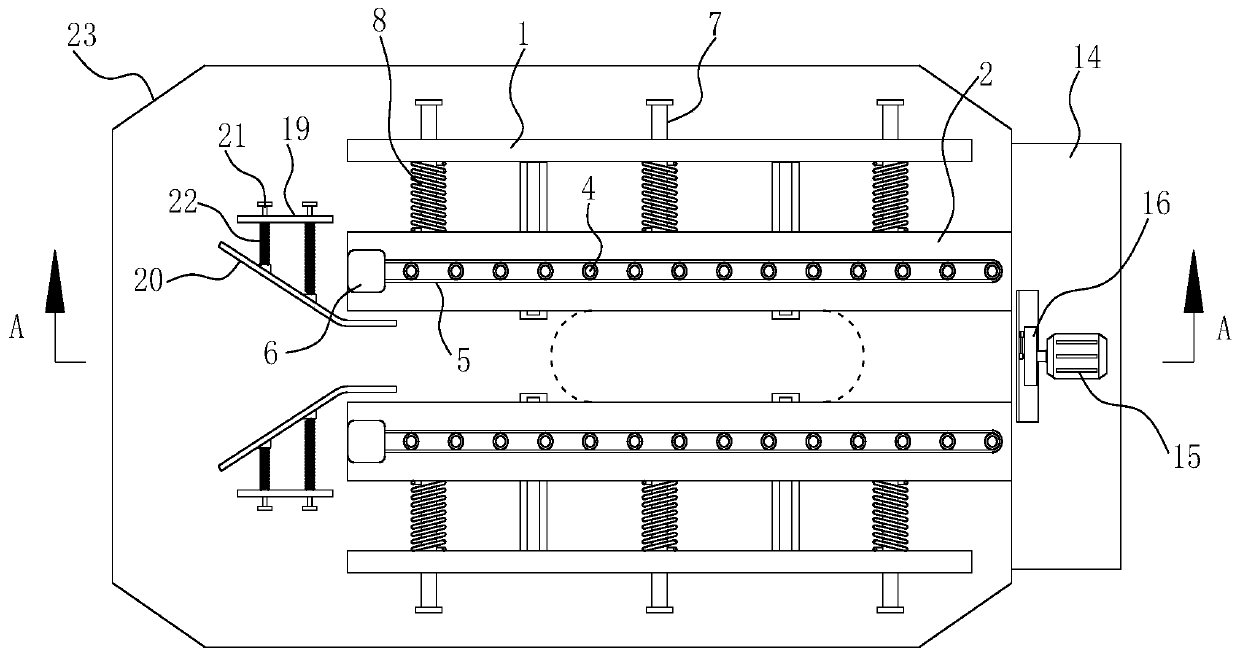

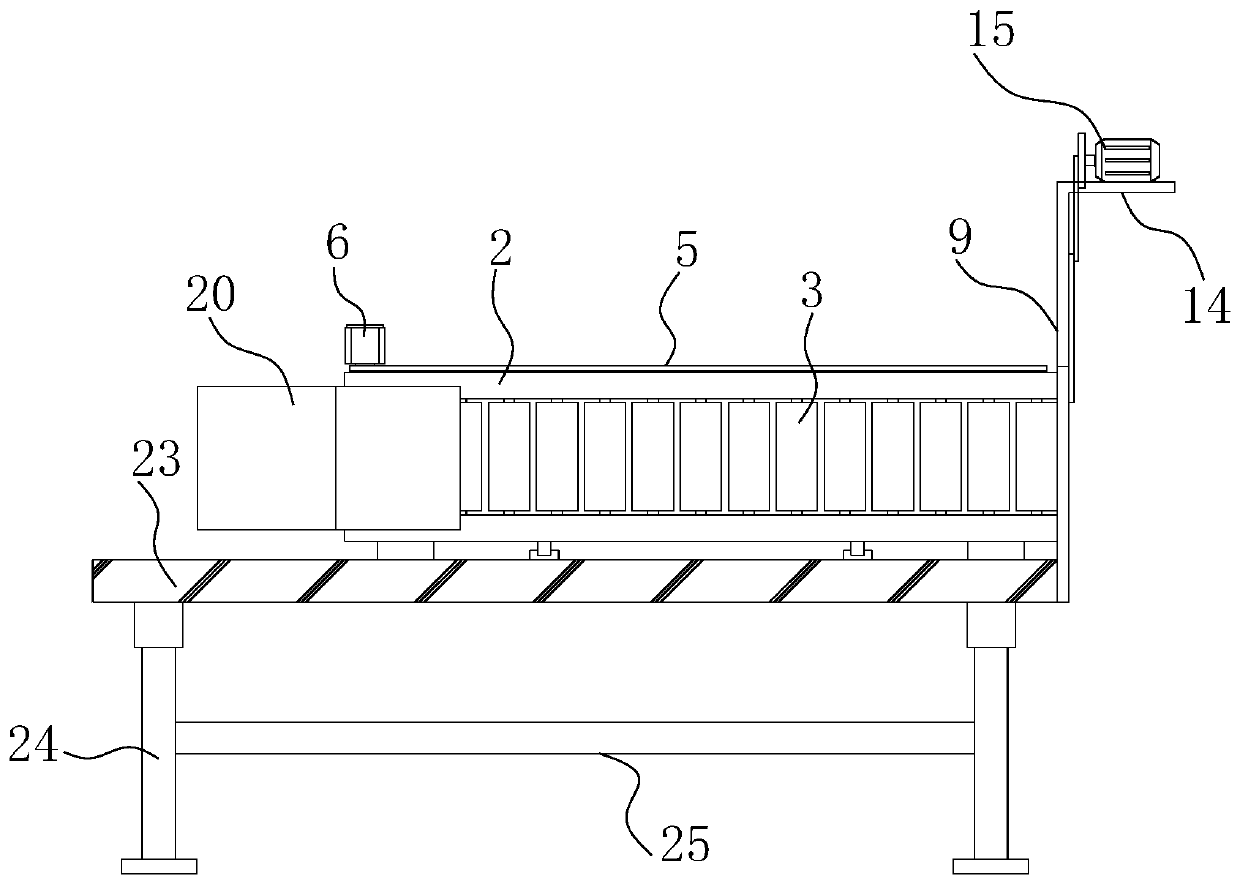

Automatic type concrete test block vibrator

ActiveCN111823356APrevent regenerationImprove performanceAuxillary shaping apparatusElectric machineryStructural engineering

The invention discloses an automatic type concrete test block vibrator. The automatic type concrete test block vibrator comprises a box body, a vibrating panel, a vibrating motor, a mould clamp assembly and a bubble eliminating mechanism, wherein the mould clamp assembly comprises a fixed mould clamp, a movable mould clamp and a suspension type hydraulic support column; the bubble eliminating mechanism comprises a hydraulic stand column, a bubble needle disc and a horizontal rod; gas blowing holes are formed in the bubble needle disc; a bubble needle which is vertically downwards is inserted between adjacent gas blowing holes; the upper end of the bubble needle disc can slide in a transverse slot of a horizontal rod, and can be locked and fixed on any position; the bubble needle on the bubble needle disc just can quickly coat a concrete test block in a test block mould. Without manual assistance, the automatic type concrete test block vibrator can quickly clear bubbles separated out ona concrete surface, so that the concrete test block can be ensured to meet later-stage test requirements better.

Owner:SHANDONG UNIV OF SCI & TECH

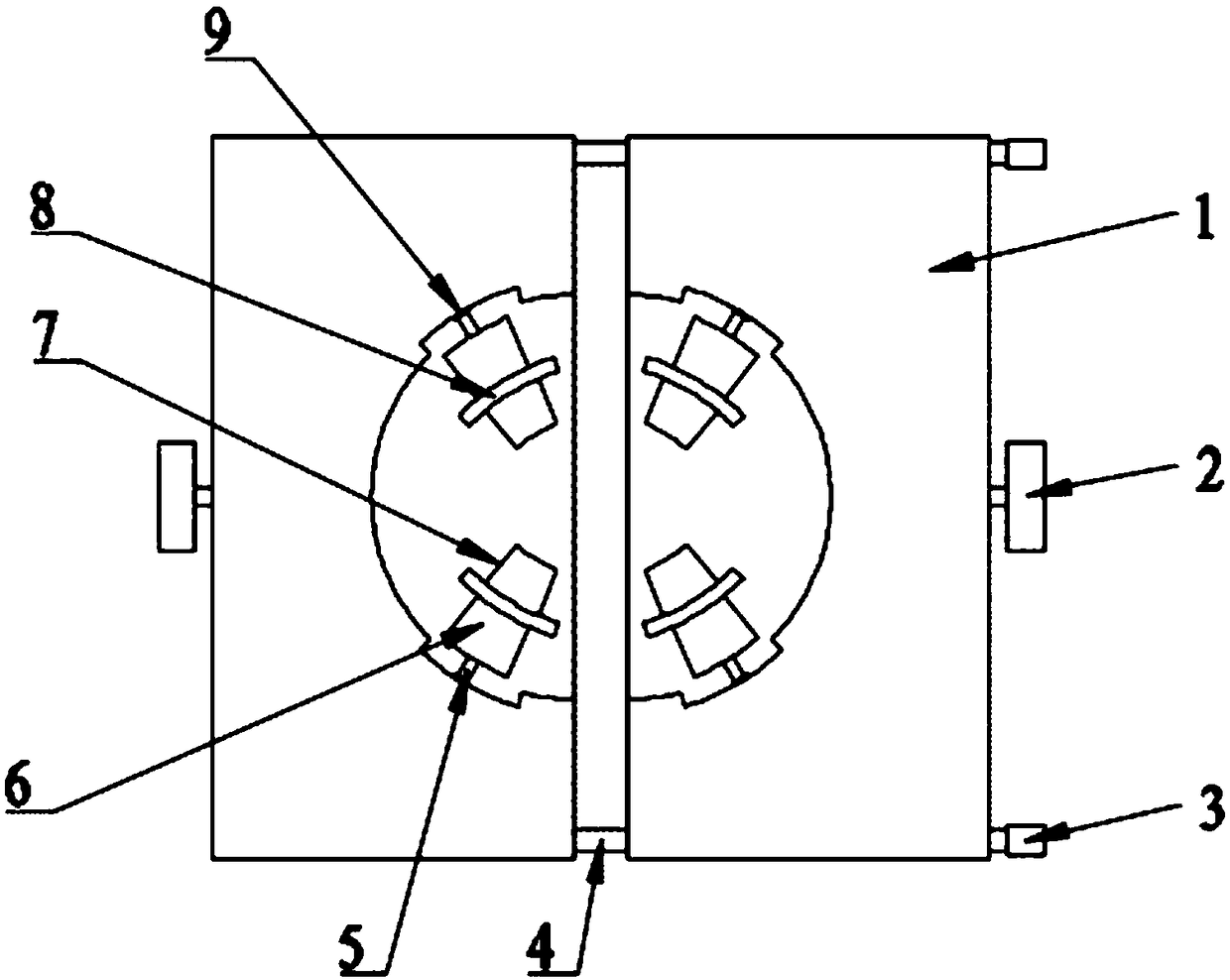

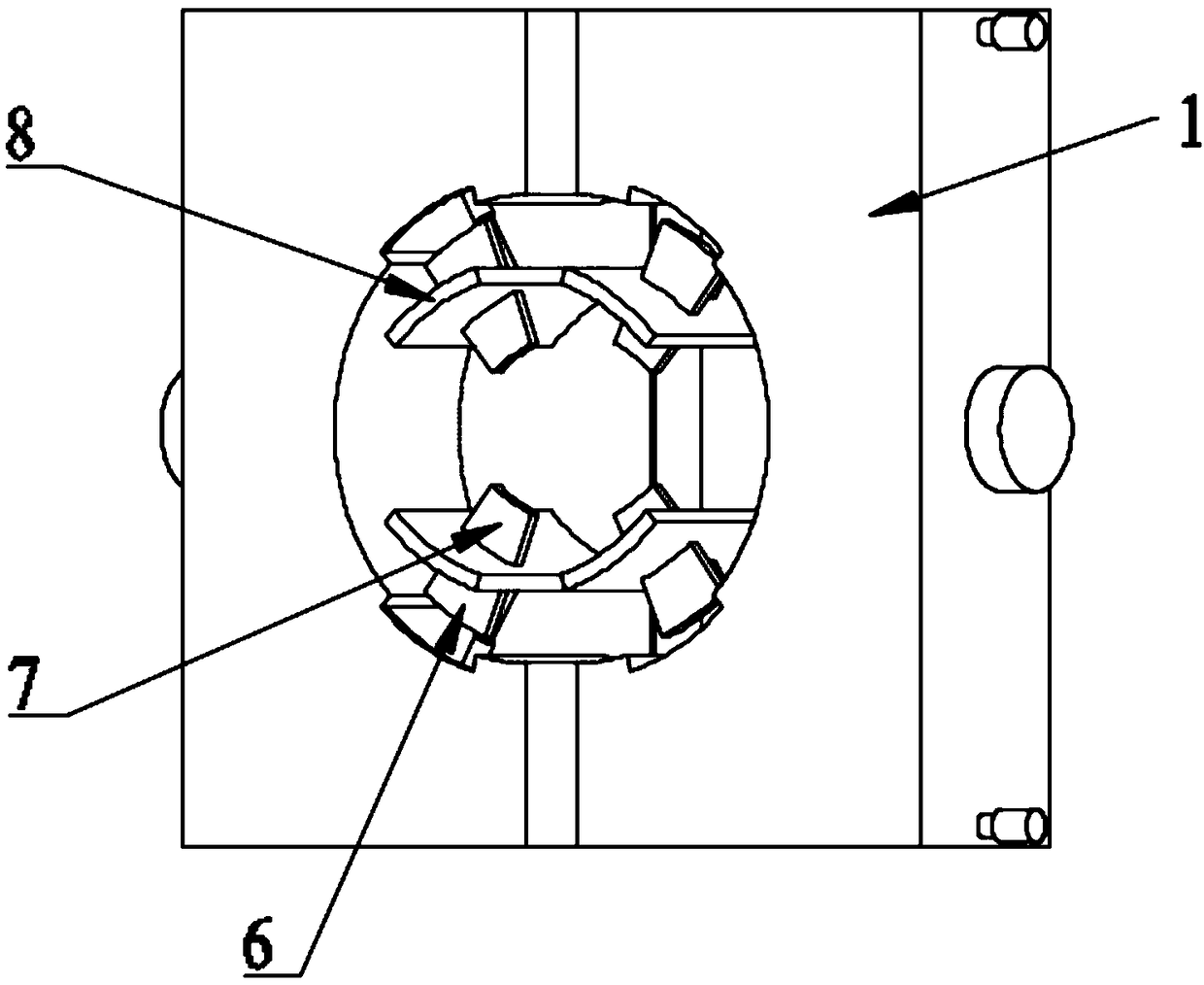

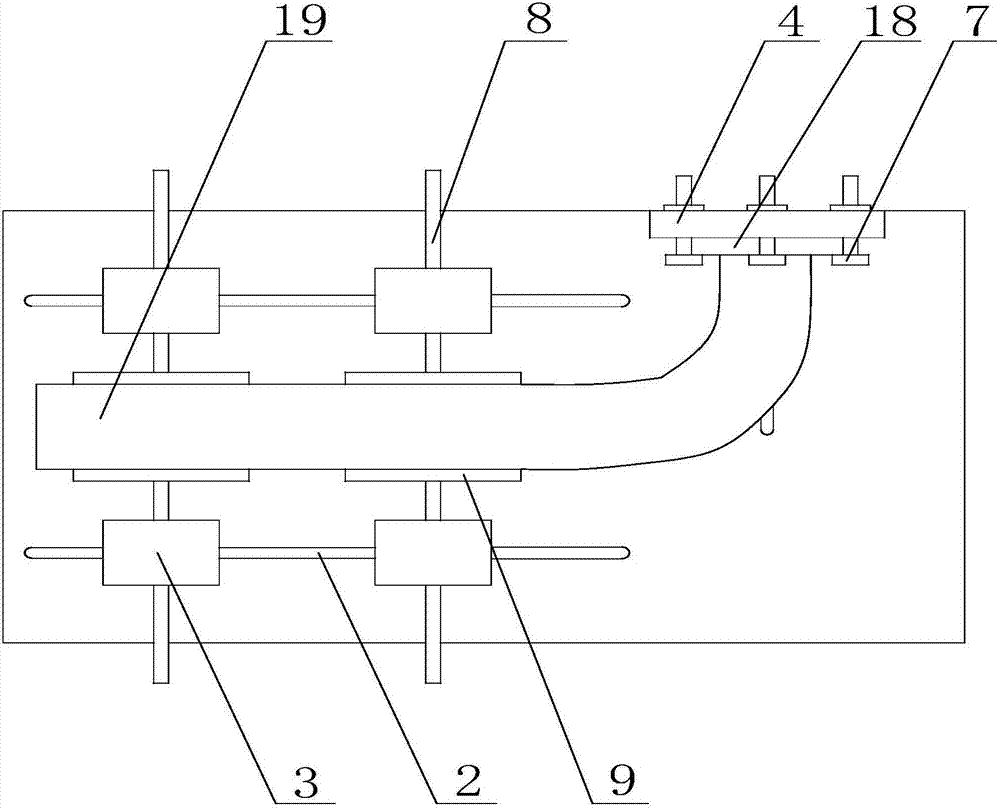

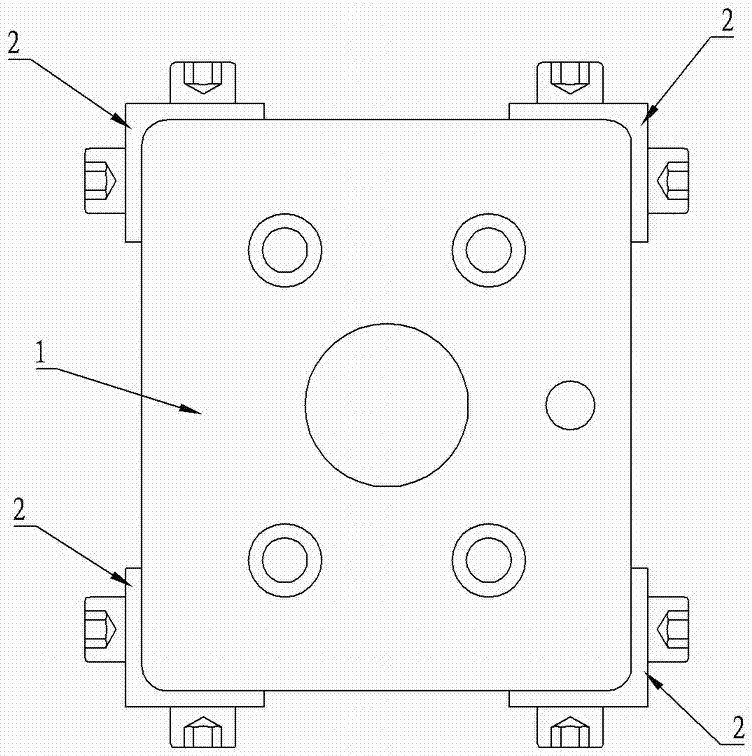

Universal shot blasting fixture used for shot blasting of root of compressor blade

ActiveCN105437087AMeet clampingMeet clamping requirementsAbrasive machine appurtenancesSlide plateCompressor blade

The invention provides a universal shot blasting fixture used for shot blasting of the root of a compressor blade. The universal shot blasting fixture aims at solving the problem of high jig manufacture and maintenance cost due to poor universality of an existing shot blasting fixture of the compressor blade and comprises a base, a positioning and adjusting component and an adjustable blade profile enclasping component, wherein height supports with equal heights are respectively vertically arranged at four corner ends of the base, the positioning and adjusting component is supported on the height supports, the adjustable blade profile enclasping component is arranged on the positioning and adjusting component; the positioning and adjusting component comprises positioning guide blocks and sliding plates, the two positioning guide blocks are arranged on the height supports in parallel along the longitudinal direction and are connected through the two horizontally parallel sliding plates, and the sliding plates can move along the positioning guide blocks to achieve adjustment; and a blade inner arc pressing device and a blade back arc pressing device of the adjustable blade profile enclasping component are respectively oppositely arranged at the horizontal inner sides of the two positioning guide blocks with adjustable angles.

Owner:WUXI TURBINE BLADE

Welding method of exhaust manifold and connection component

InactiveCN107538156AMeet clampingAdjust the height arbitrarilyWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftEngineering

The invention discloses a welding method of an exhaust manifold and a connection component. The welding method of the exhaust manifold and the connection component comprises the following steps that firstly, a base is horizontally placed, a flange to be welded is placed on the side face of a side platform, the edge of the flange is clamped through limiting plates, and the flange is fixed to the side platform through fixing rings; secondly, one side of the exhaust manifold to be welded is placed between fixing blocks, a second drive mechanism is moved along a second sliding groove, the height of the side platform is adjusted at the same time, and the welding portion of the flange and the welding portion of the exhaust manifold are made to be located at the same height; and thirdly, the flange is rotated around a second drive shaft, it is guaranteed that the welding face of the flange is in contact with the welding face of the exhaust manifold, the exhaust manifold is kept fixed, movablerods are sequentially adjusted to enable clamp plates to fix the exhaust manifold, when the exhaust manifold is fixed, the heights of the clamp plates are adjusted through first drive mechanisms, meanwhile the intervals between the clamp plates are adjusted through first sliding grooves, the clamping force on the exhaust manifold is increased, and when the exhaust manifold is well fixed, the exhaust manifold and the flange are welded.

Owner:CHENGDU LINGCHUAN SPECIAL IND

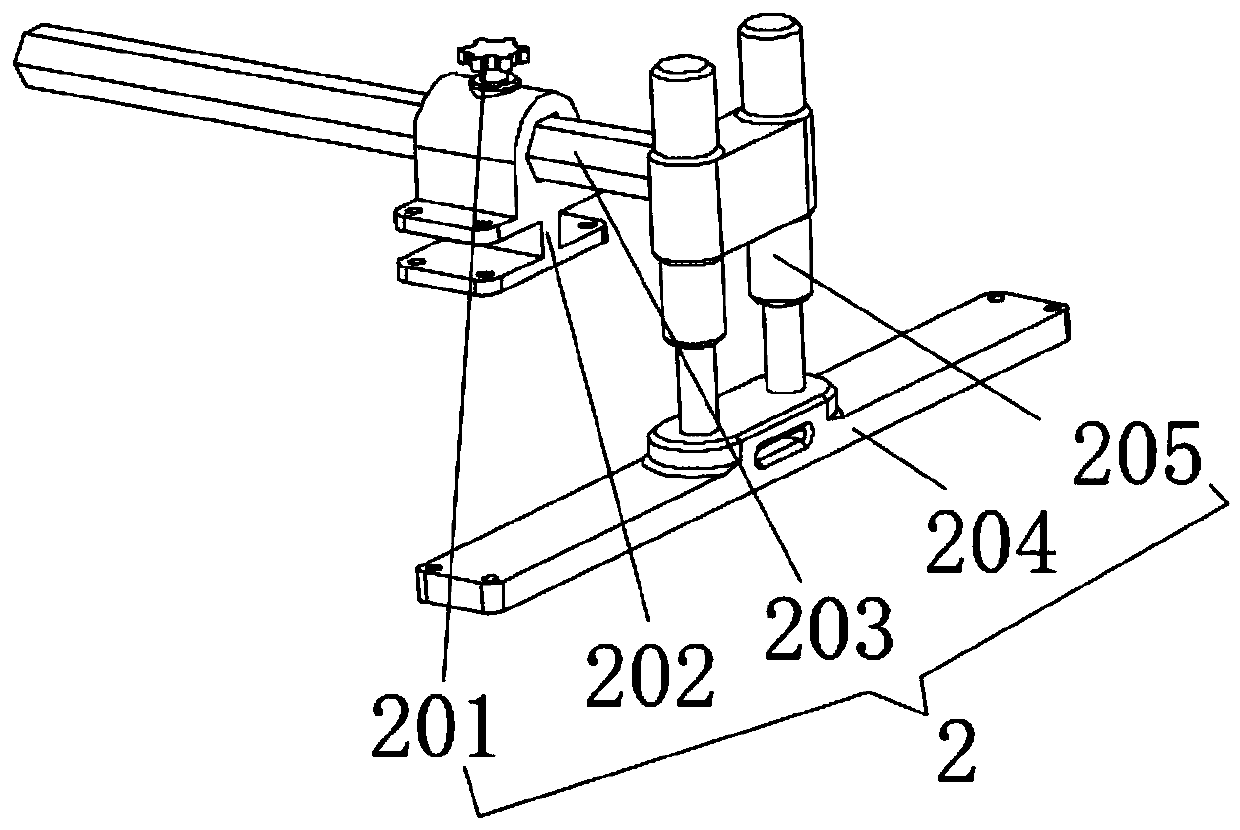

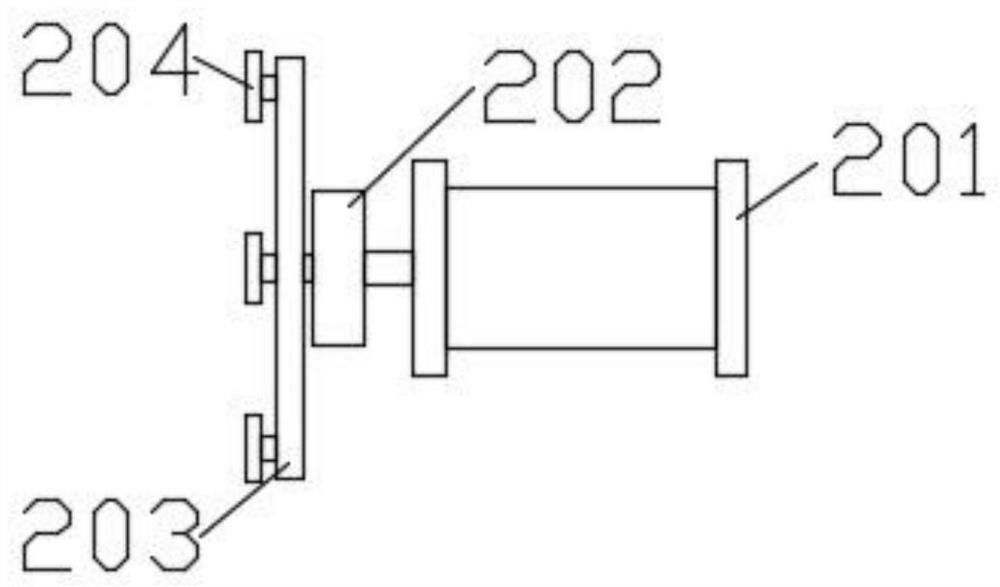

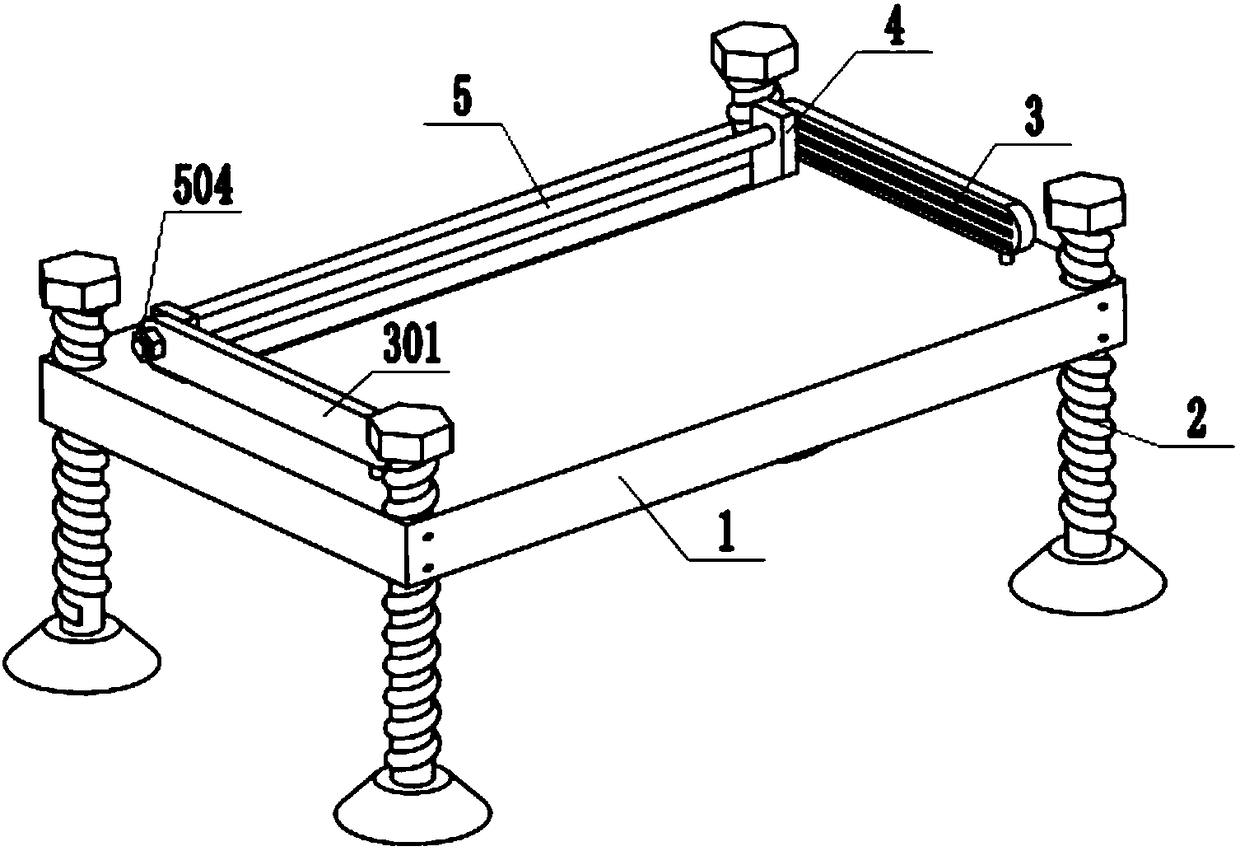

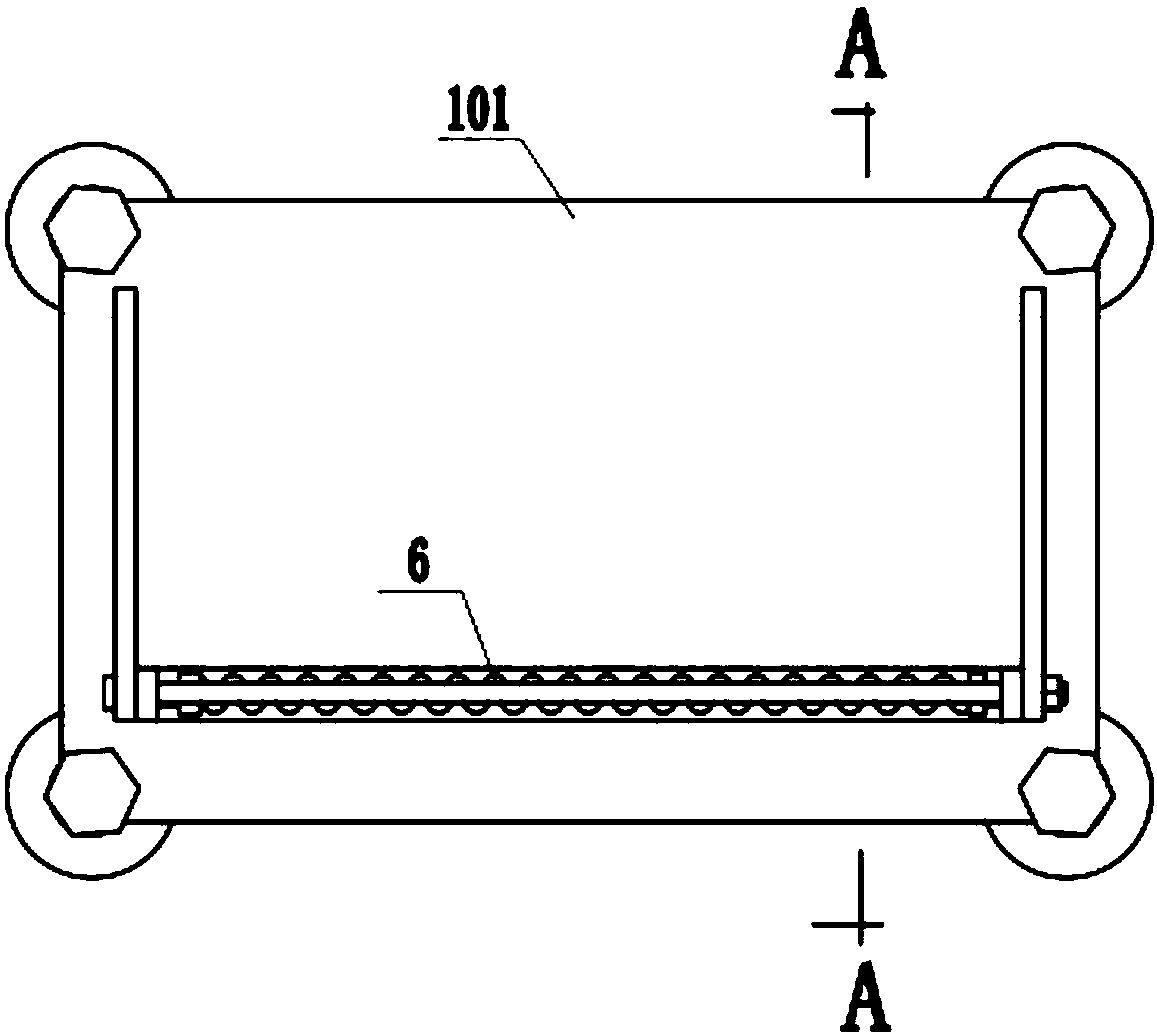

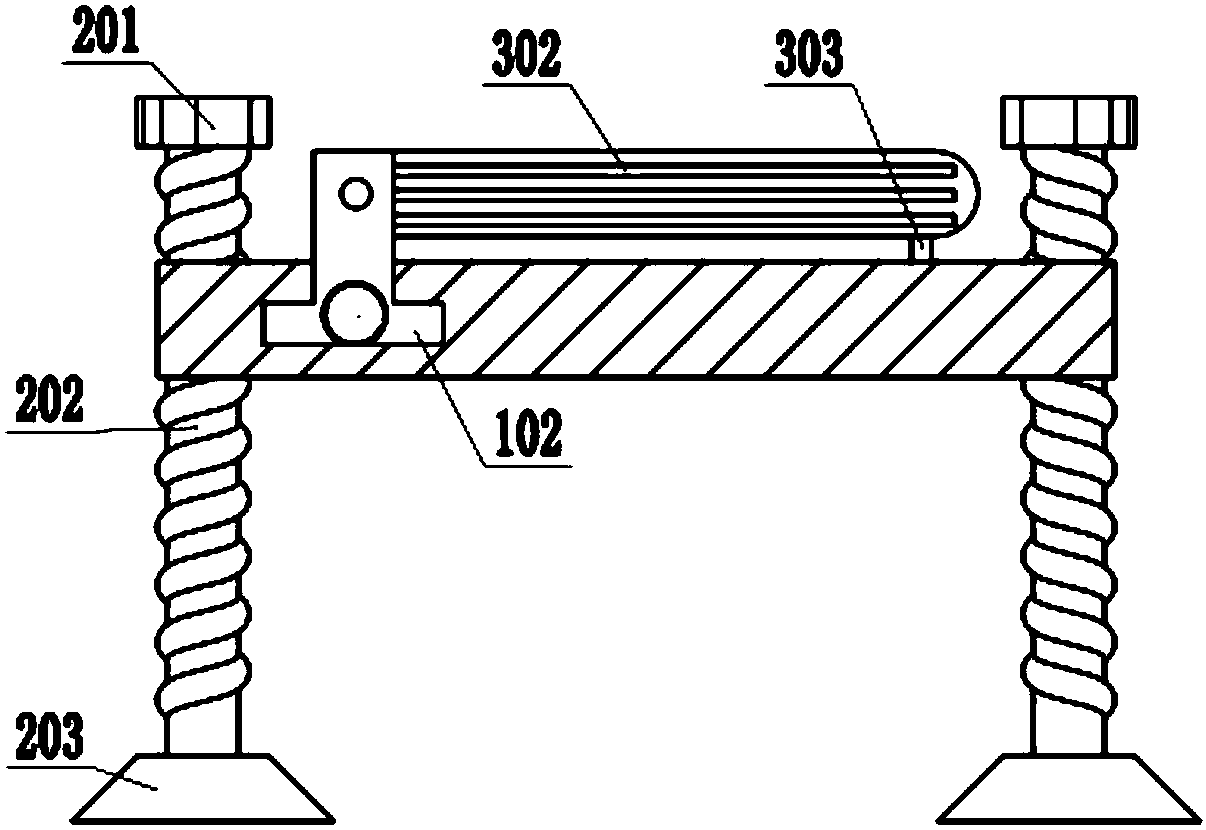

Installation method and application method of electronic component assembly support

InactiveCN108495480AEasy to installAchieve clampingPrinted circuit assemblingElectrical componentsEngineeringElectronic component

The invention discloses an installation method of an electronic component assembly support. The installation method comprises the steps of S1, clamping a circuit board by a clamping plate 3; S2, rotating an angle of the circuit board, and fixing the circuit board by a nut 504; and S3, adjusting a height of each support leg 2 according to the height and the working demand, and fixing a base 1 by asuction disc 203.

Owner:冯水军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com