Total-servo silk-screen printing equipment

A technology of screen printing and equipment, applied in the field of full-servo screen printing equipment, can solve the problems of long time, high production cost, high labor intensity of printing machinery, and achieve the effect of improving surface tension and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

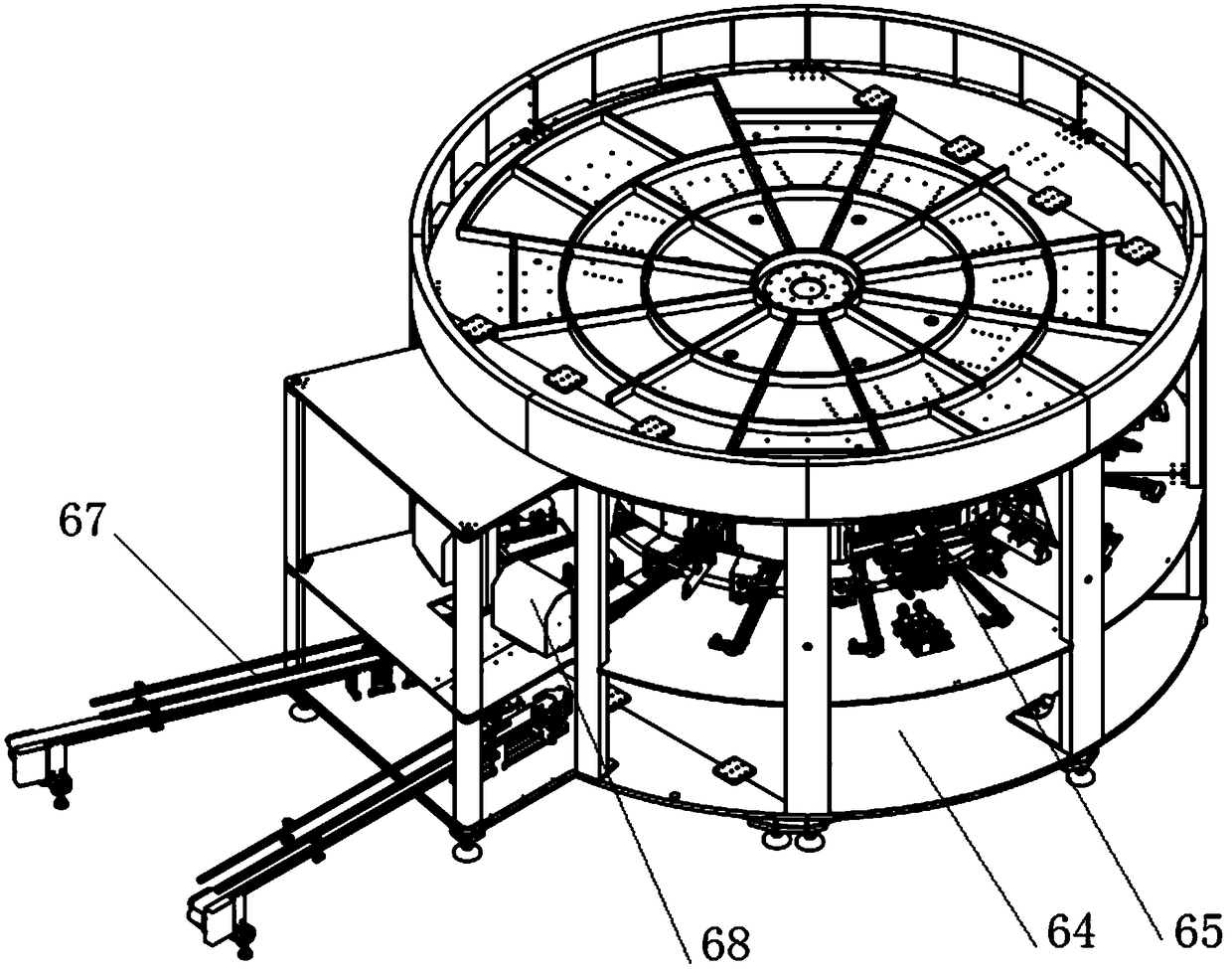

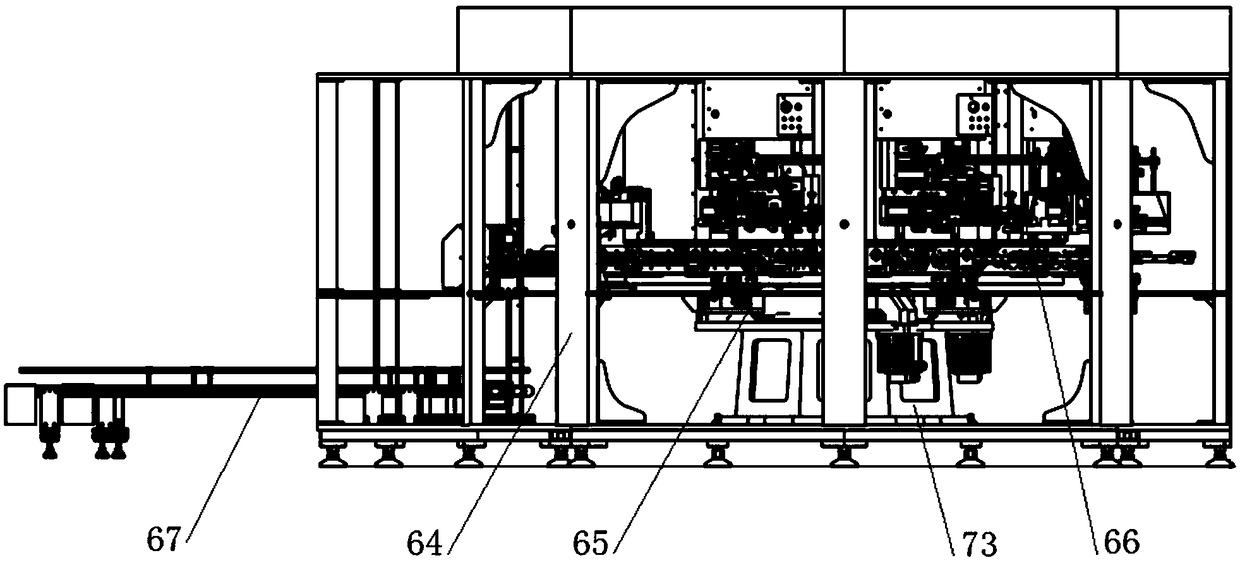

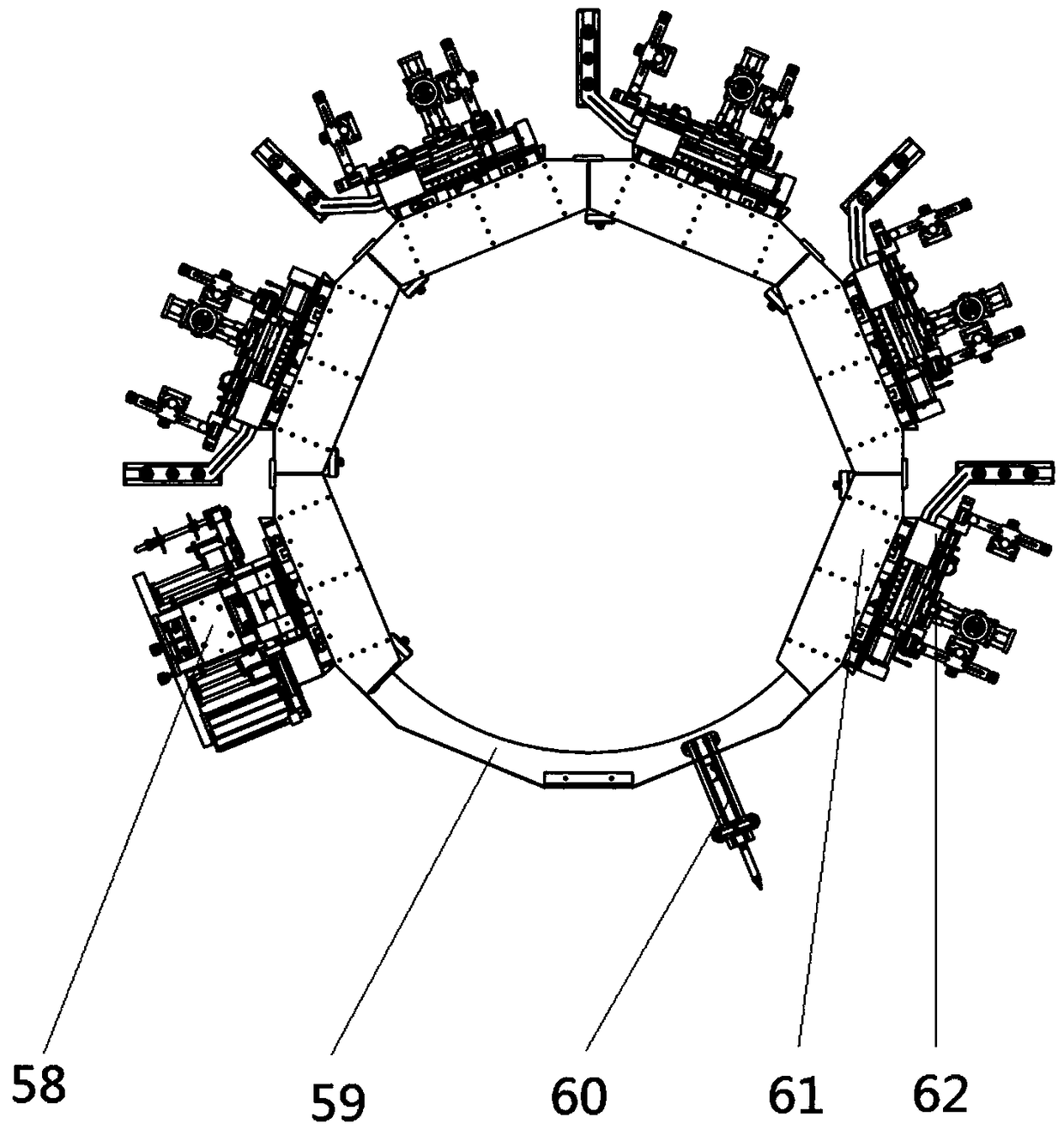

[0071] Such as Figure 1 to Figure 6 As shown, a full-servo screen printing device of the present invention includes a casing 64 , a turntable 65 , a printing assembly 66 and a loading and unloading device. The turntable 65 and the printing assembly 66 are located inside the casing 64 . The casing 64 is a cylindrical structure as a whole, and the interior of the casing 64 is hollow. The casing 64 is divided into an upper layer and a lower layer. And the turntable 65 is located at the bottom of the casing 64, the printing assembly 66 is connected to the top of the turntable 65, the turntable 65 drives the printing assembly 66 to rotate in the casing 64 according to the set direction and rotation angle, and the loading and unloading device is located in the casing 64 Outside, the loading and unloading device is for the turntable 65 to transfer the substrate.

[0072] The printing assembly 66 includes a plurality of printing hanging plates, the printing hanging plates include a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com