Machining operating table facilitating recycling of sweeps

A technology of mechanical processing and operating table, which is applied in the direction of metal processing equipment, metal processing machine parts, manufacturing tools, etc., and can solve problems such as affecting processing work, inability to fix mechanical parts, and cuts by operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

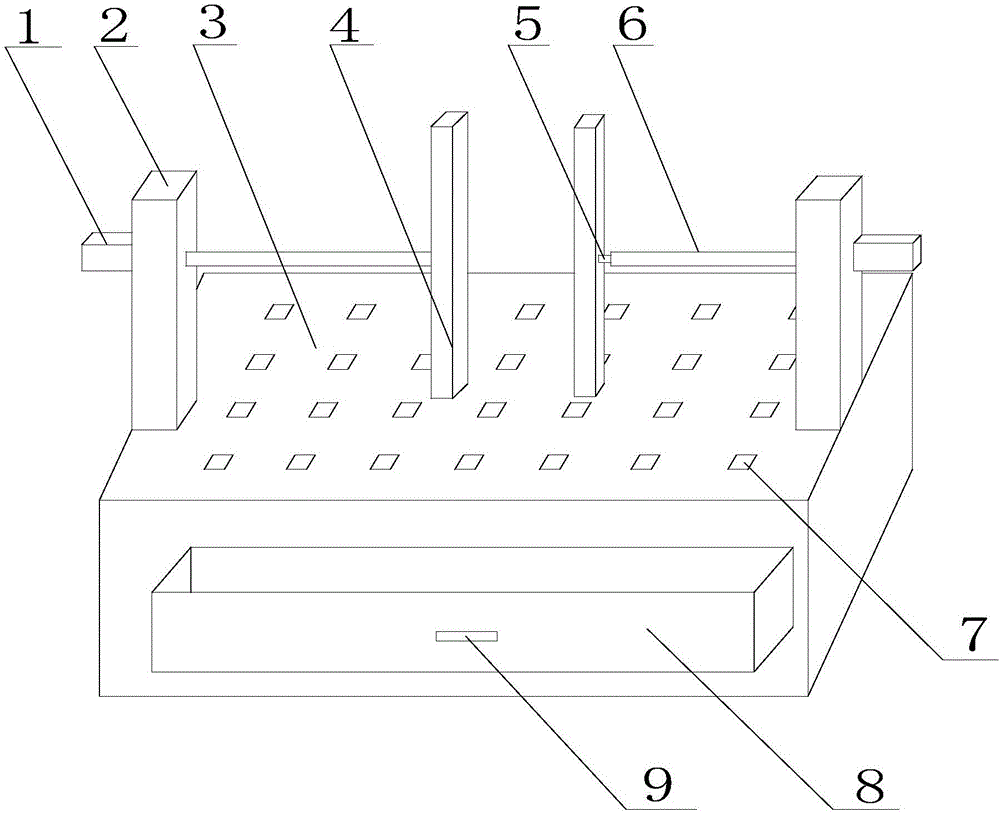

[0020] like figure 1 As shown, the present invention facilitates the recycling of waste chips, including a rectangular workbench 3. The top of the workbench 3 is provided with two support columns 2, and the two support columns 2 are respectively located on both sides of the axis of the workbench 3. , the support column 2 is in the shape of a cuboid and has a length of 60 cm. A drive mechanism 1 is provided on the side wall of the support column 2. The drive mechanism 1 includes a drive shaft. The drive mechanism 1 is preferably a hydraulic cylinder, and the drive shaft is a piston rod in the hydraulic cylinder. , the driving shaft crosses on the support column 2, and the end of the driving shaft is provided with a connecting rod 6. Under the action of the driving mechanism 1, the driving shaft can drive the connecting rod 6 to move in the horizontal direction, and one end of the connecting rod 6 is connected to the driving Shaft connection, movable shaft 5 on the other end, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com