Fixing mechanism for external circle grinding of sleeve-like mechanical components

A technology of mechanical parts and cylindrical grinding, which is applied in the field of machine parts processing devices, can solve problems such as inconsistent angles, low production efficiency, and different degrees of cylindrical grinding of workpieces, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

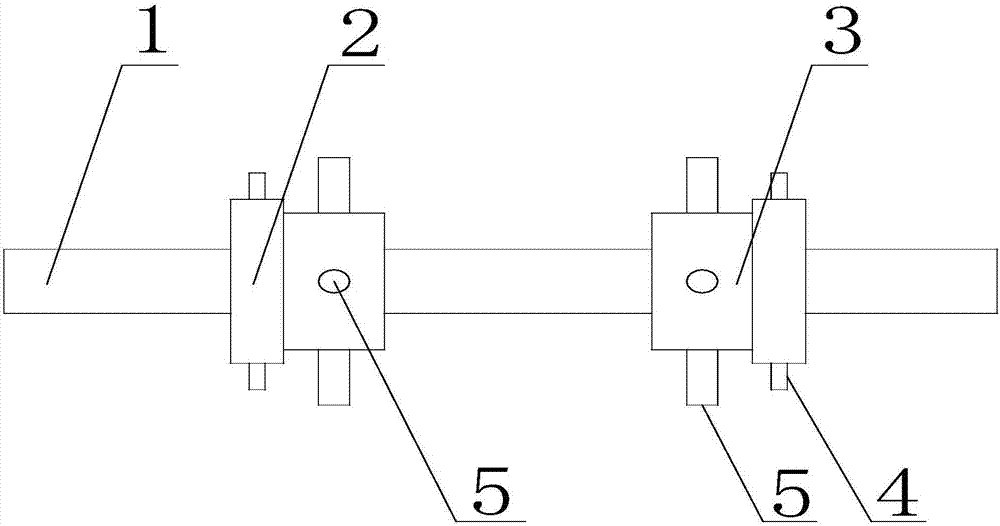

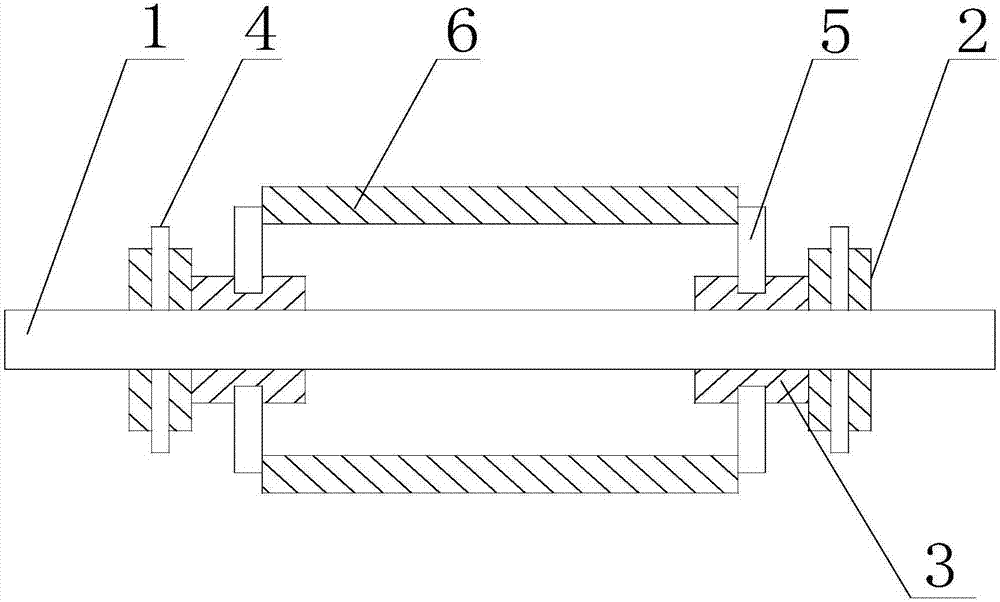

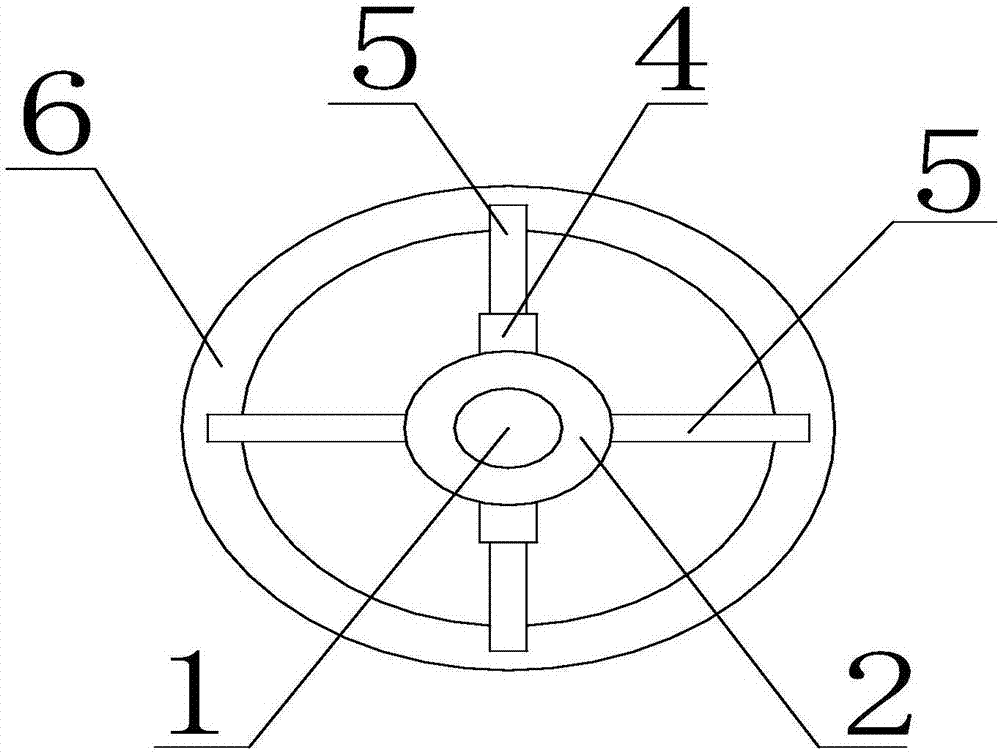

[0022] Such as Figure 1 to Figure 3 As shown, the fixing mechanism for the cylindrical grinding of sleeve mechanical parts of the present invention includes a shaft 1, which can be clamped by a three-jaw chuck, and the shaft 1 is provided with two clamping blocks 3, two The clamping blocks 3 are all hollow cylindrical shapes, that is, the two bottom surfaces of the clamping block 3 are provided with circular holes, and the circular holes on the two bottom surfaces communicate with each other, the clamping blocks 3 are sleeved on the shaft rod 1, and can Freely move on the shaft 1 to adjust the distance between the two clamping blocks 3 to meet the clamping of sleeve workpieces 6 of different lengths. The circumferential surface of the clamping block 3 is provided with four blind Holes, four blind holes are evenly distributed on the circumferential surface of the clamping block 3, a baffle 5 is arranged in the four blind holes, the baffle 5 is connected with the blind hole on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com