Implementation method for correcting reinforcing steel bars

A realization method and steel bar technology, which is applied in the field of steel bar processing, can solve the problems of large size, inconvenient handling, easy to scratch yourself, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

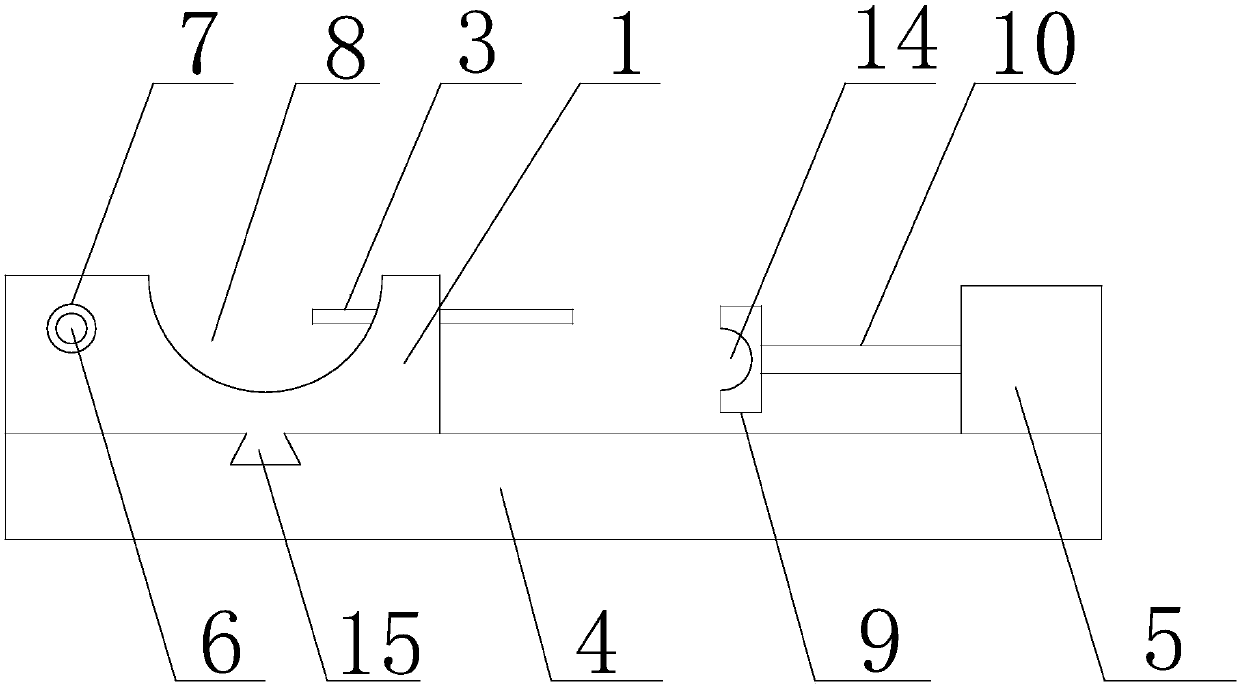

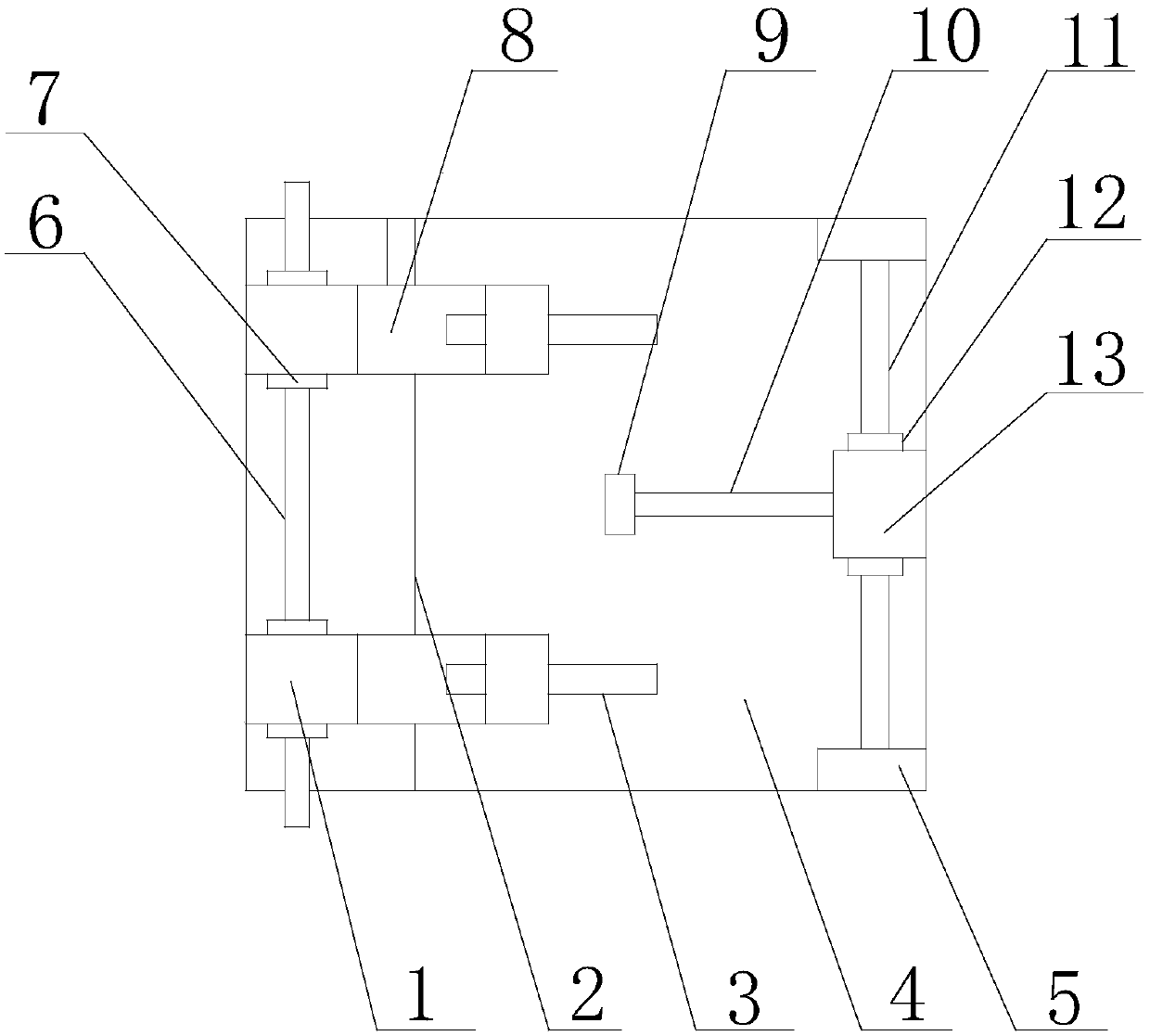

[0022] Such as figure 1 , figure 2 As shown, an implementation method for correcting steel bars in the present invention includes the following steps: firstly place the base 4 horizontally on the construction ground, and then horizontally place the steel bars to be corrected in the grooves 8 of the two support blocks 1 , and make the protruding part of the reinforcing bar face the pressing plate 9, then rotate the movable rod 3, fix the two ends of the reinforcing bar on the support block 1, and finally open the driving mechanism 5, so that the pressing plate 9 moves towards the protruding part of the reinforcing bar, and use the pressing plate 9 to move the The protruding part of the steel bar is straightened.

[0023] Wherein, including base 4, the top of described base 4 is provided with two support blocks 1, and support block 1 can move on base 4, and the top of described support block 1 is provided with arc-shaped groove 8, and described support The sidewall of block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com