Steel bar straightening equipment for electric power construction

A technology of electric power construction and steel bar, which is applied in the field of steel bar processing, can solve the problems of inconvenient handling, easy scratching, inconvenient installation of straightening machines, etc., and achieves the effect of easy correction and improved correction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

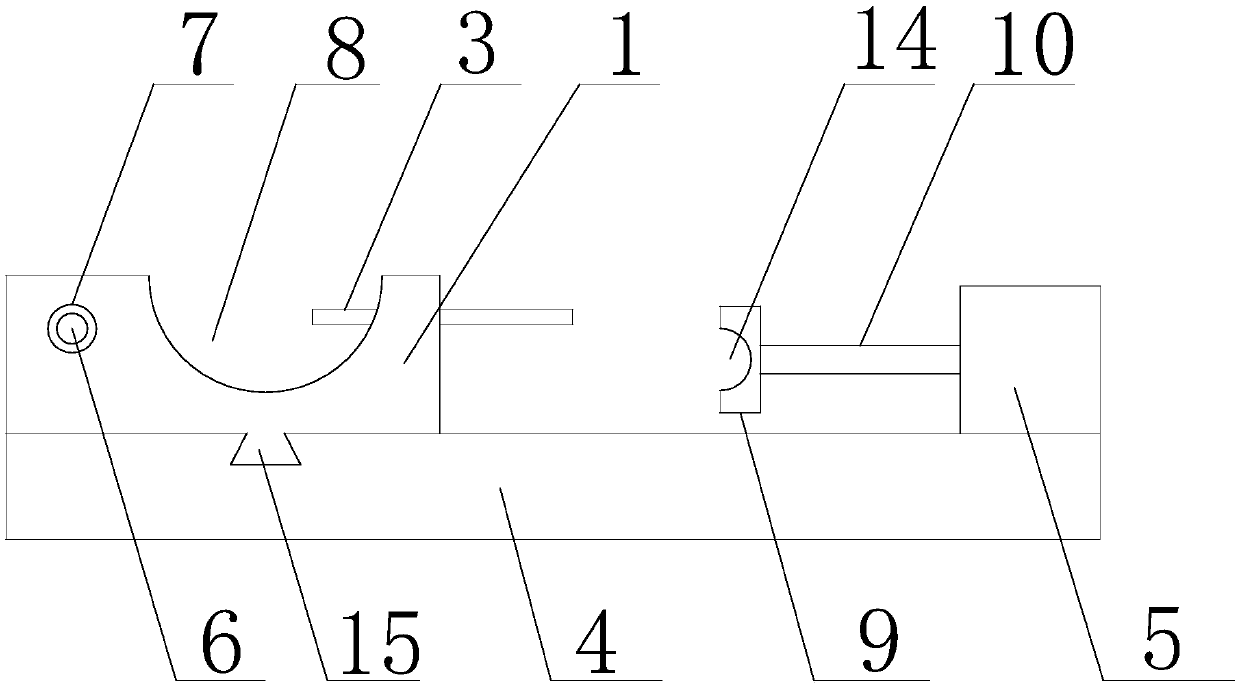

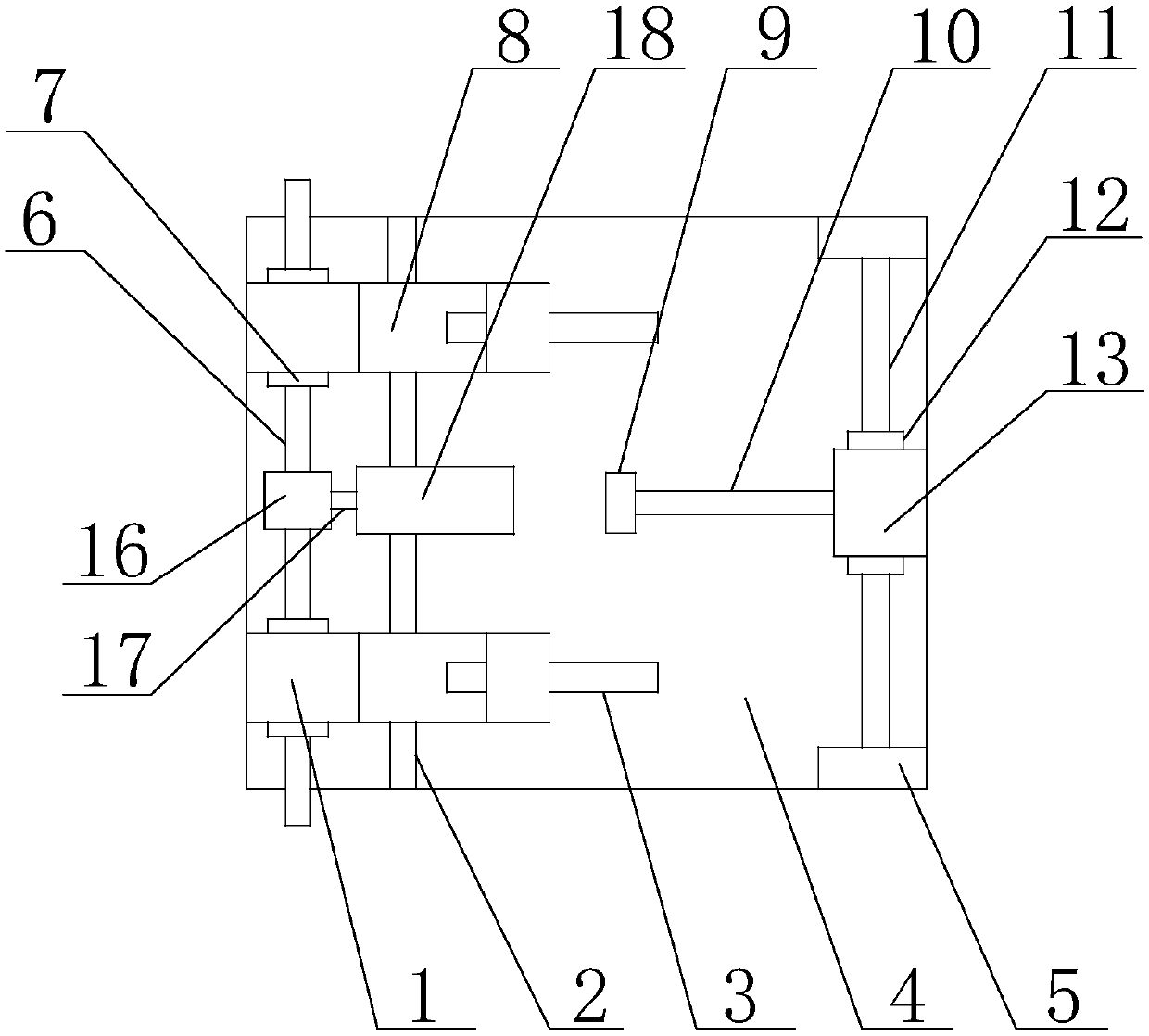

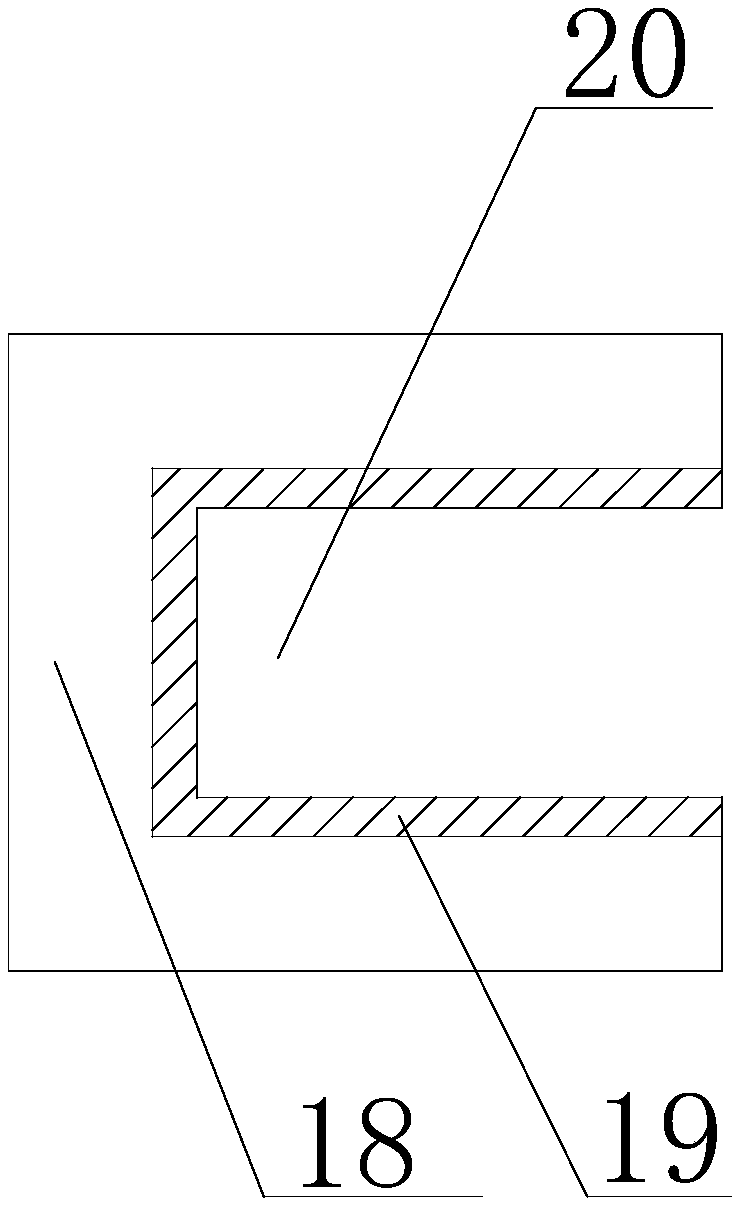

[0024] Such as Figures 1 to 3 As shown, a steel bar straightening device used in electric power construction in the present invention includes a base 4, and two support blocks 1 are arranged on the top of the base 4, and the support blocks 1 can move on the base 4, and the top of the support block 1 All are provided with arc-shaped grooves 8, and the side walls of the support block 1 are provided with movable rods 3, which are connected horizontally with the support block 1 by threads, and when the movable rods 3 are rotated, the movable rods 3 can move to the concave position. In the groove 8, the top of the base 4 is also provided with a drive mechanism 13, the drive mechanism 13 can move on the base 4, the drive mechanism 13 includes an output shaft 10, the output end of the output shaft 10 is provided with a pressing plate 9, two A movable block 18 is also provided between the two support blocks 1, and the movable block 18 can move towards the two support blocks 1 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com