Fiber preforming line forming clamping device and method

A technology of clamping device and preforming line, which is applied in the field of fiber preforming line forming clamping device, which can solve the problems of unable to guarantee the tension of fiber cloth, affecting production efficiency, and slow transmission efficiency, so as to avoid heat loss and optimize shaping performance and improve the surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with preferred embodiments and accompanying drawings.

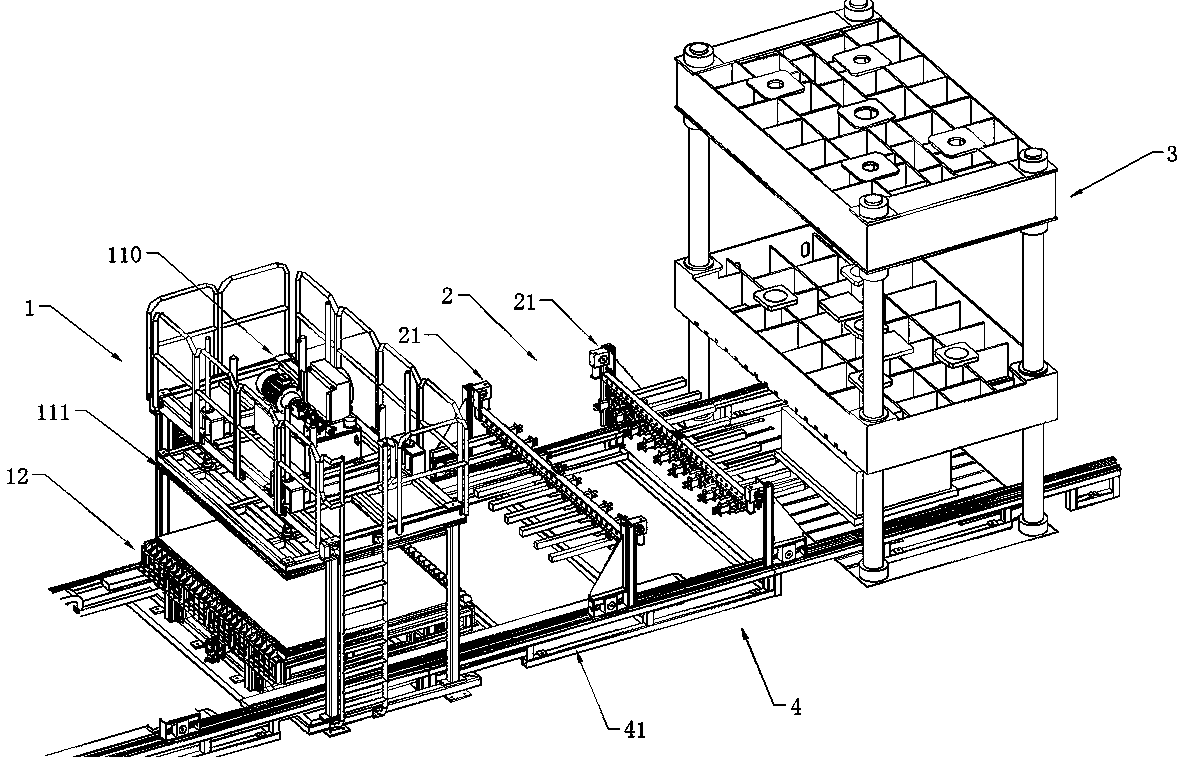

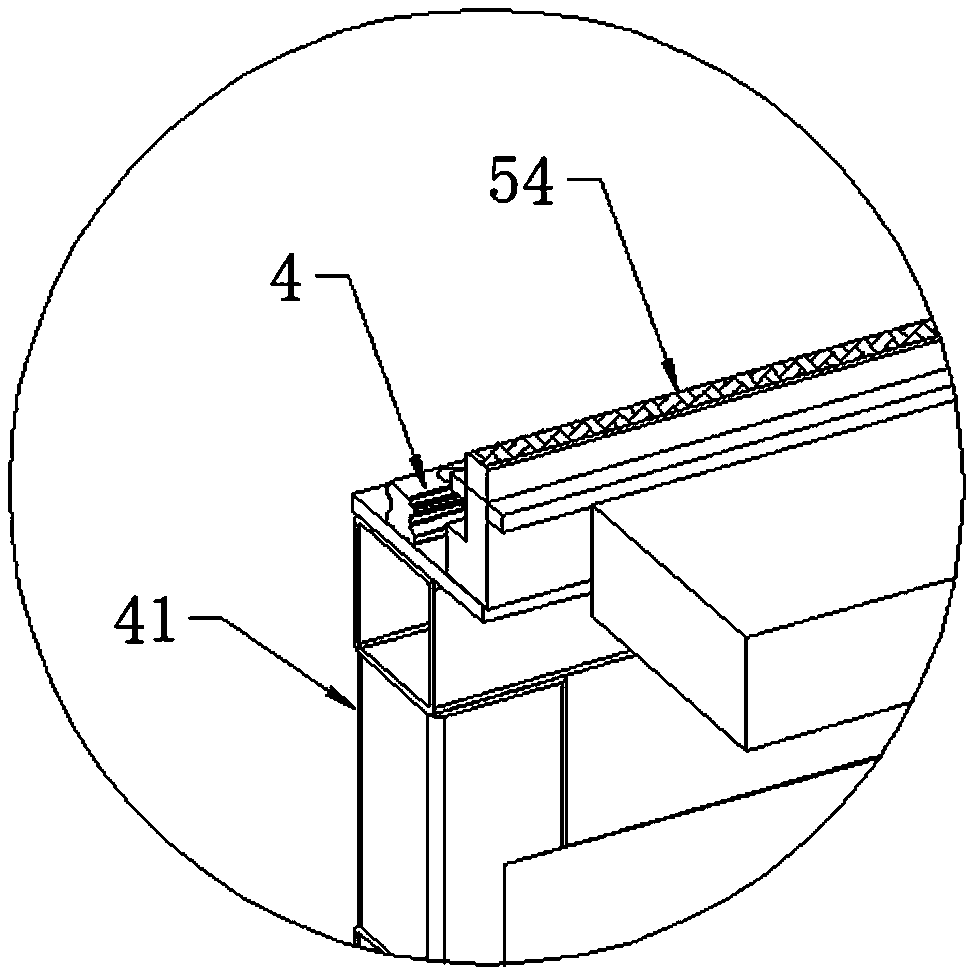

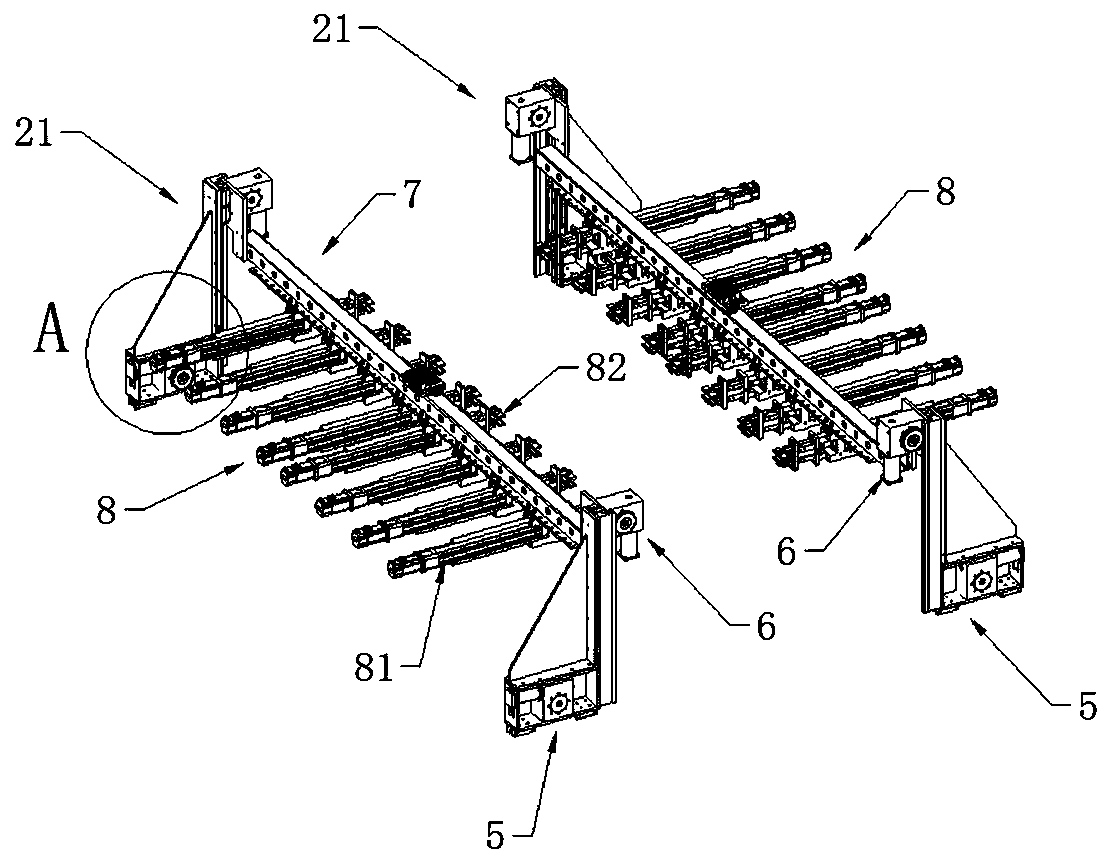

[0037] see figure 1, a fiber preforming line forming clamping device, including a heating table press 1, a clamping device 2 and a preforming press 3 arranged in sequence according to the traveling direction of the fiber to be formed; the clamping device 1 is clamped between two parallel Sliding on the hand guide rail 4, the fiber cloth heated by the heating table press 1 is transferred to the preforming press 3; the heating table press 1 spans two parallel hand holding guide rails 4 and both ends are located on the hand holding guide rails The outside of 4 is fixedly connected to the bracket 41 supporting the gripper rail 4; the preforming press 3 straddles the two parallel gripper rails 4 and the two ends are located outside the gripper rail 4 and fixed to the bracket 1 supporting the gripper rail 4 Connection; so that the heating table press 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com