Fixture device for rolling-sliding mixed friction test, and use method of fixture device

A fixture device and mixed friction technology, which is applied in the field of material friction, can solve the problems of single size of auxiliary fixture and can not meet the clamping of ceramic balls, etc., and achieve the effect of compact structure, wide application range and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

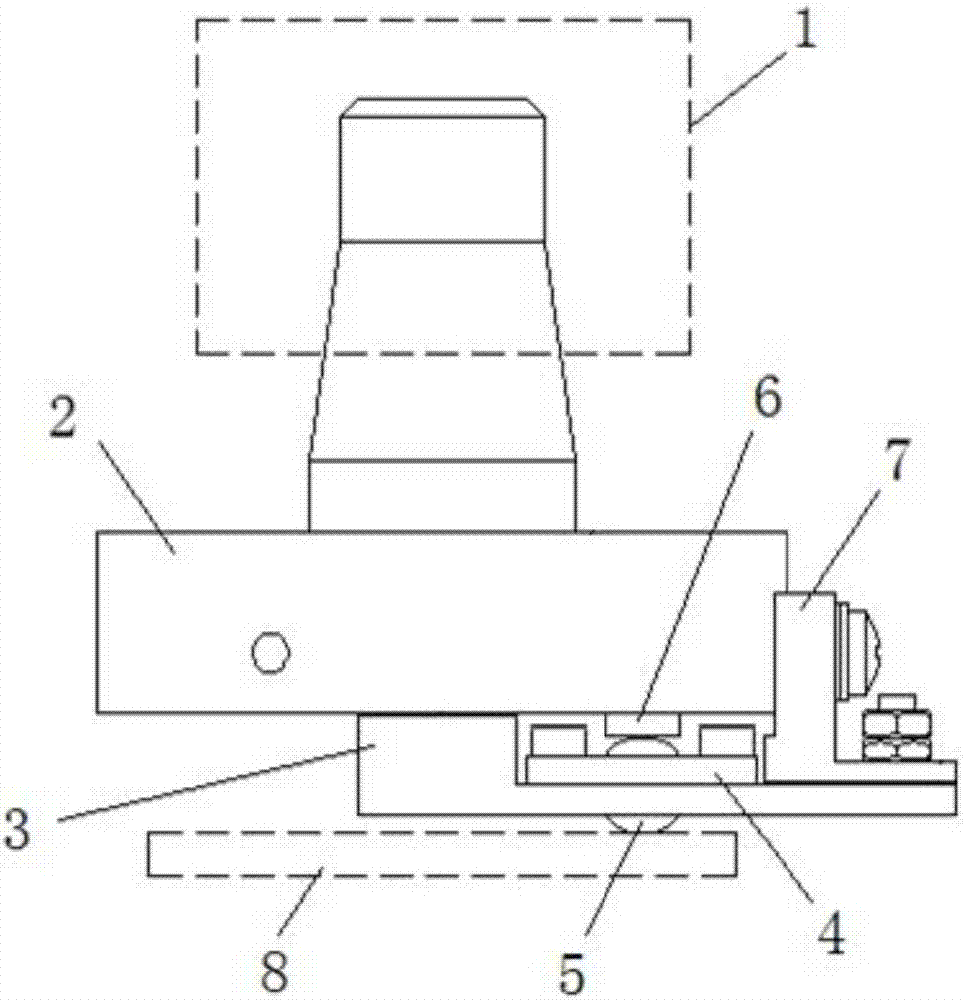

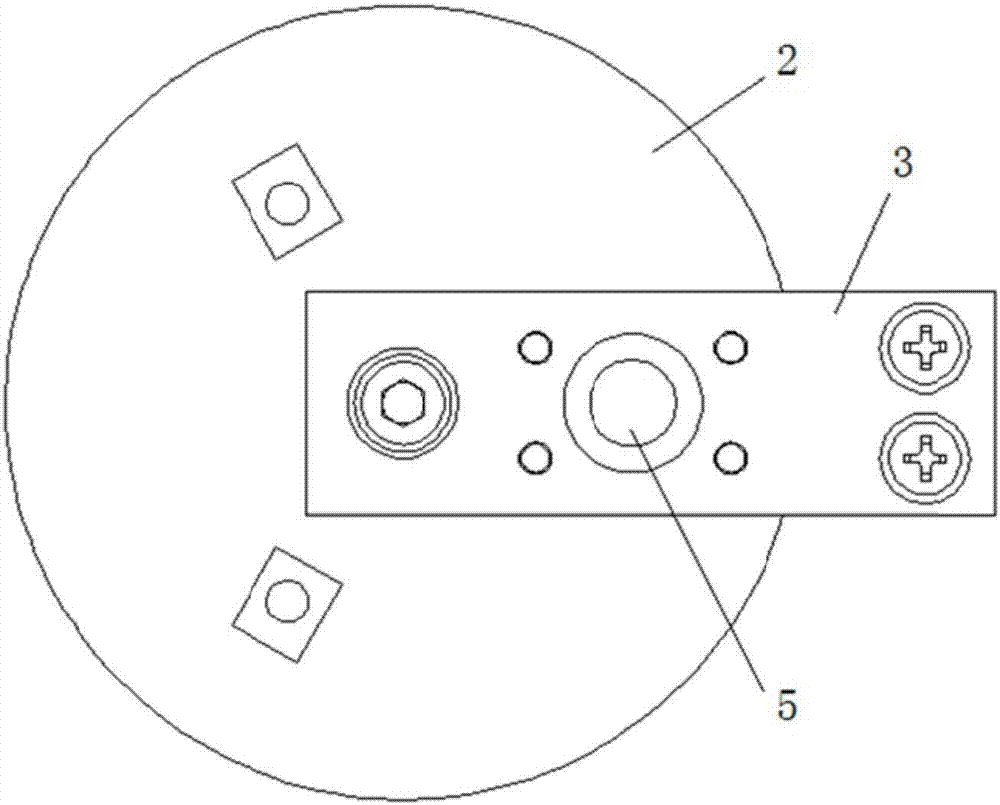

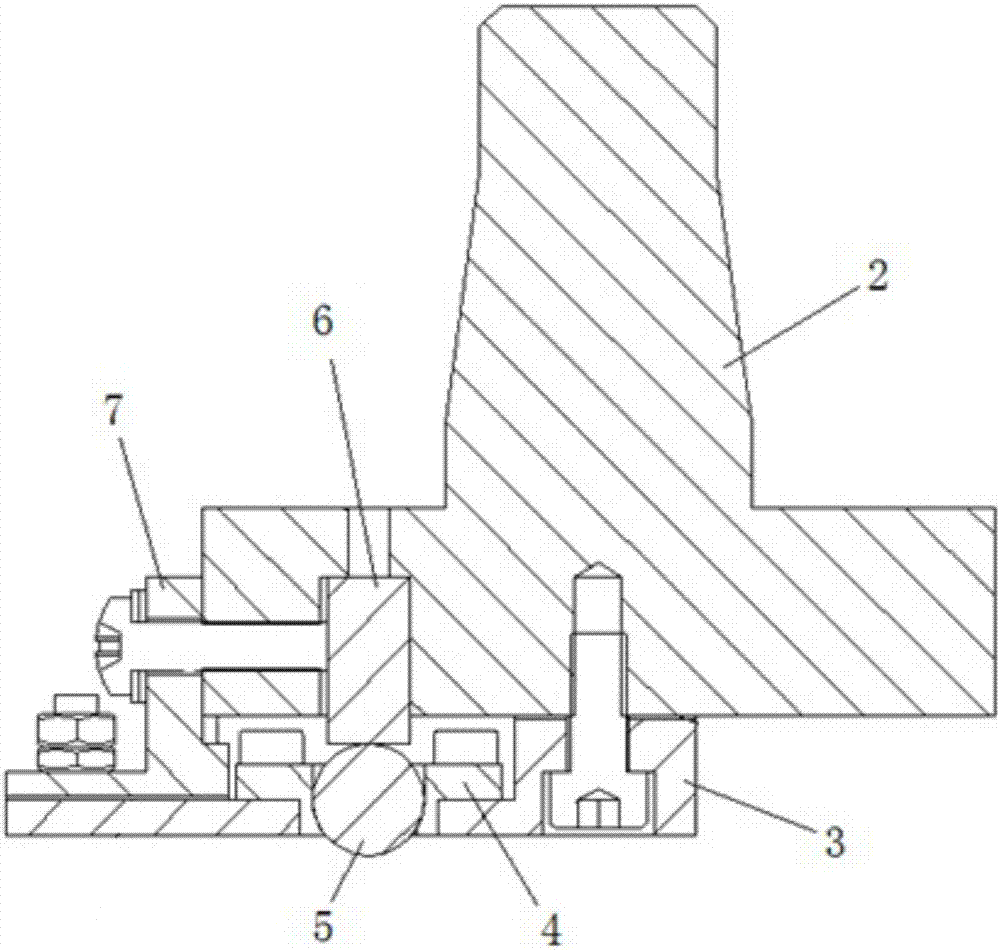

[0032] see Figure 1 to Figure 3 , a kind of fixture device that is used for rolling-sliding mixed friction test provided by the present invention, comprises fixture head 2, and described fixture head 2 is connected on the main shaft system 1 of friction testing machine, and at the same time, described fixture head 2 comprises connecting part , the lower end of the connecting part is connected with a clamping part, the connecting part of the fixture head 2 adopts a conical structure, which can be automatically centered with the spindle system 1, the connection is reliable and the precision is high, and the spindle system 1 drives the fixture head 2 to rotate sports.

[0033] The holding part is a cylindrical structure, and a support seat 3 is installed at the center of the lower surface of the cylindrical structure. The support seat 3 is an L-shaped structure, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com