Automatic type concrete test block vibrator

A concrete test block and vibrator technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as operator numbness, bubbles that cannot be removed quickly and timely, and influence of test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

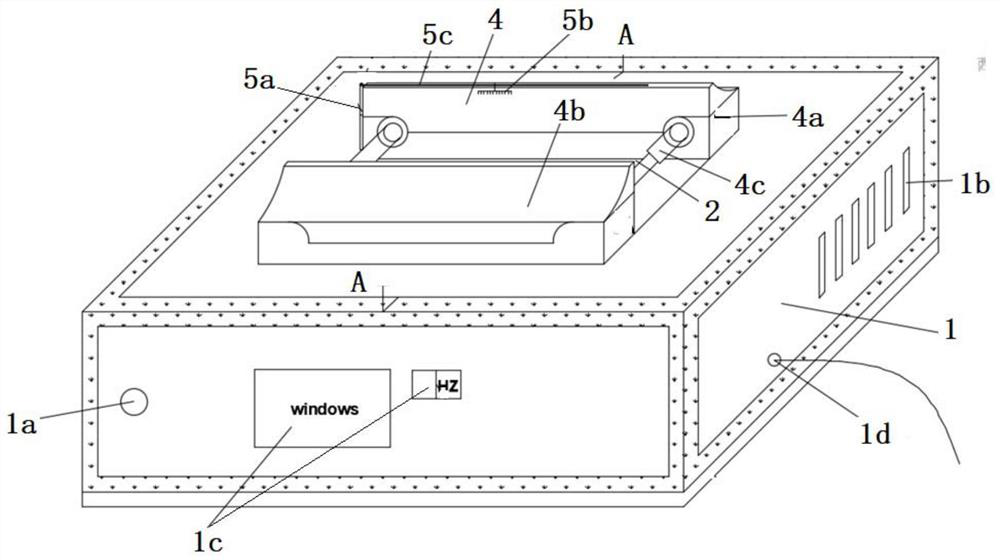

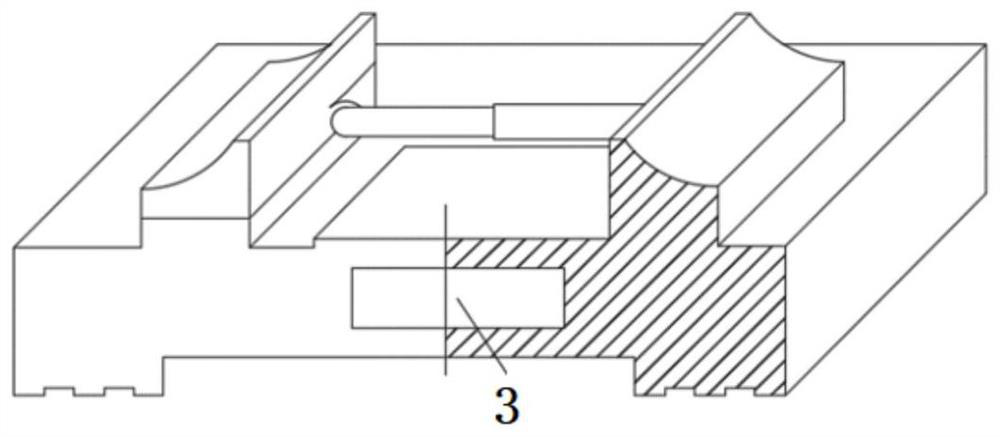

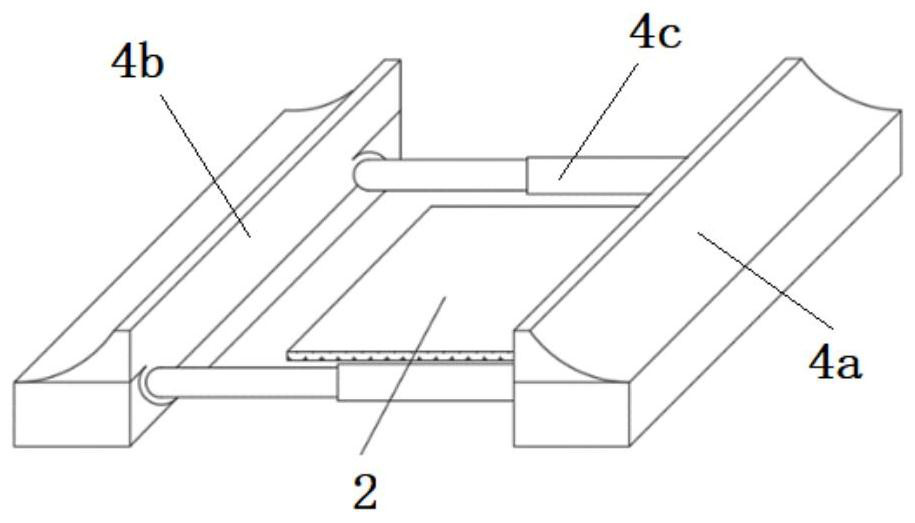

[0020] Such as figure 1 — Figure 5 As shown, an automatic concrete test block vibration instrument is mainly composed of a box body 1, a vibration panel 2, a vibration motor 3, a mold clamp assembly 4 and an air bubble elimination mechanism 5.

[0021] The vibration motor 3 is installed in the box body 1, and the box body 1 adopts a square box body, and the height is 1 / 4-1 / 3 of the length and width. The built-in vibrating motor 3 is adopted, and the overall size of the box body 1 is optimized, so that the box body can be placed on the platform conveniently, and the occupied space in terms of height is small, small and compact.

[0022] The vibrating panel 2 is placed on the box body 1 and is driven by a vibrating motor 3 to vibrate. The vibrating motor 3 is located directly below the vibrating panel 2 .

[0023] A mold clamp assembly 4 is also arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com