Hydraulic structure for controlling and clamping drill bit of drilling machine

A drill bit and hydraulic technology, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of not holding the drill bit too much, affecting the stability of the hydraulic cylinder, poor maintenance conditions, etc., achieving light weight, structure Simple, the effect of avoiding quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

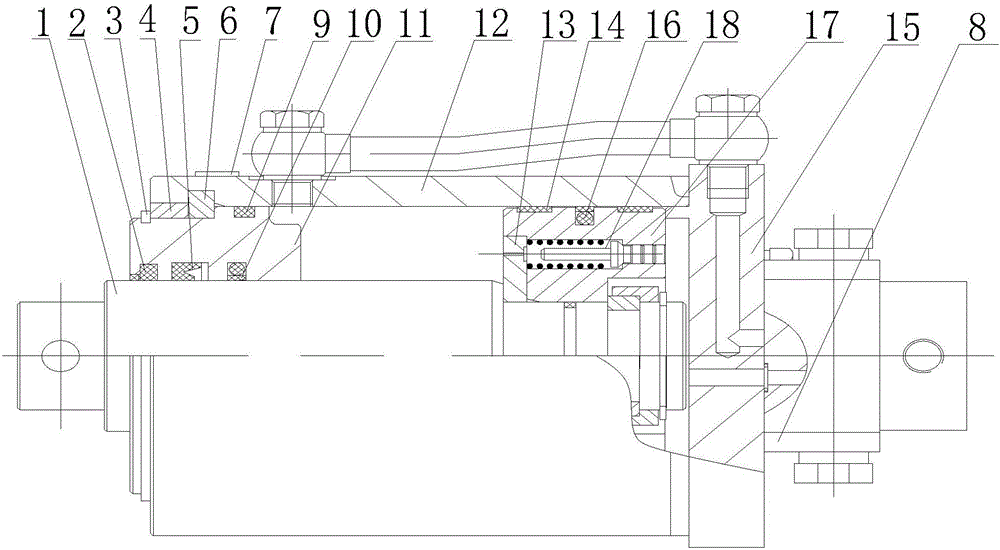

[0024] Such as figure 1 As shown, the present invention is a kind of hydraulic structure that is used for controlling the clamping drilling rig bit, comprises cylinder barrel 12, piston rod 1, piston 17 and cylinder bottom 15, and described piston rod 1 is arranged in the cylinder barrel 12, and piston rod 1 and The piston 17 is connected, and the cylinder 12 and the cylinder bottom 15 are connected by welding. The cylinder 12 and the cylinder bottom 15 form a rodless cavity. Compared with the traditional rod-type hydraulic cylinder, this method can not only Reduce the size and space required by screws and nuts, make it simple in structure, small in size and light in weight, and can also solve the aging of the seal at the end of the cylinder bottom 15, or the leakage of the cylinder bottom 15 caused by some other reasons; the outer wall of the cylinder bottom 15 is equipped with a superimposed liquid control check valve 8, the superimposed hydraulic control check valve 8 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com