Crossed slider third axis set mechanism matched with positive-axis mechanism on numerical control turn milling main shaft box moving machine

A technology of cross slider and centering machine, which is applied in the direction of metal processing machinery parts, other manufacturing equipment/tools, large fixed members, etc. It can solve the problems that complex parts cannot be realized, so as to avoid resistance, improve self-precision, and reduce heat generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

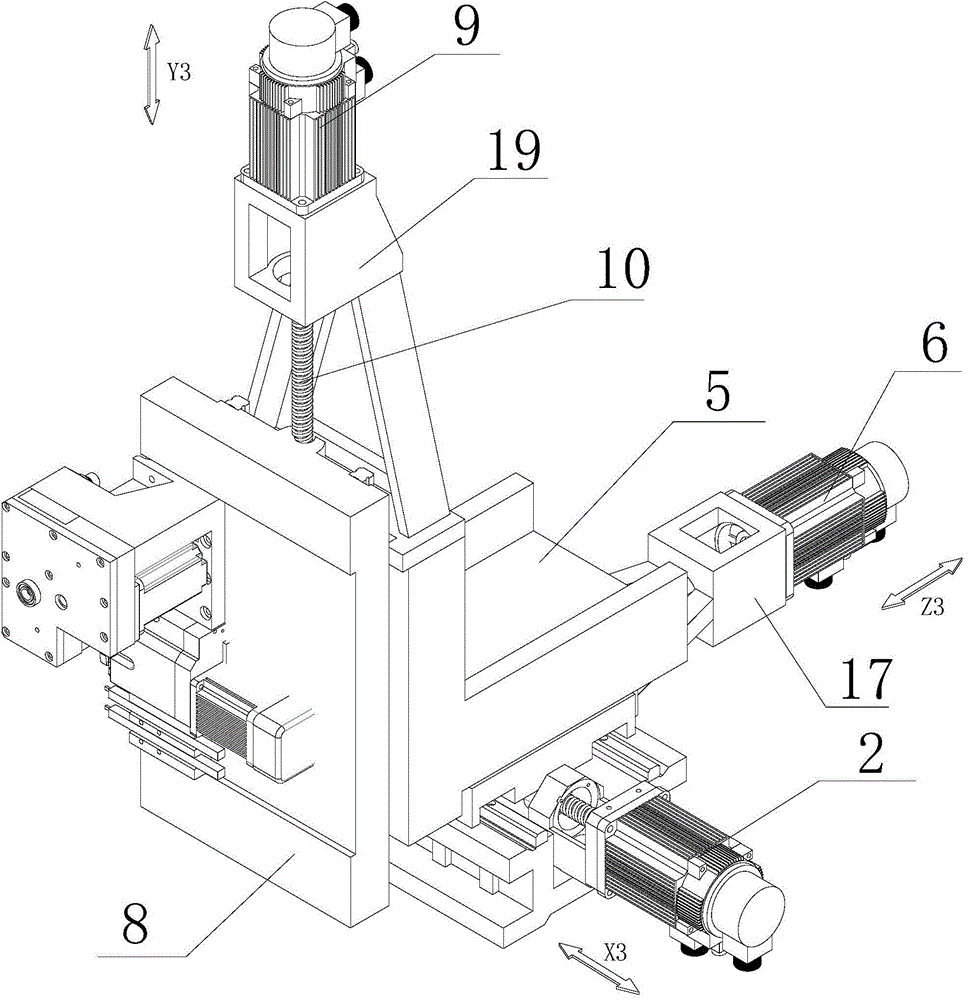

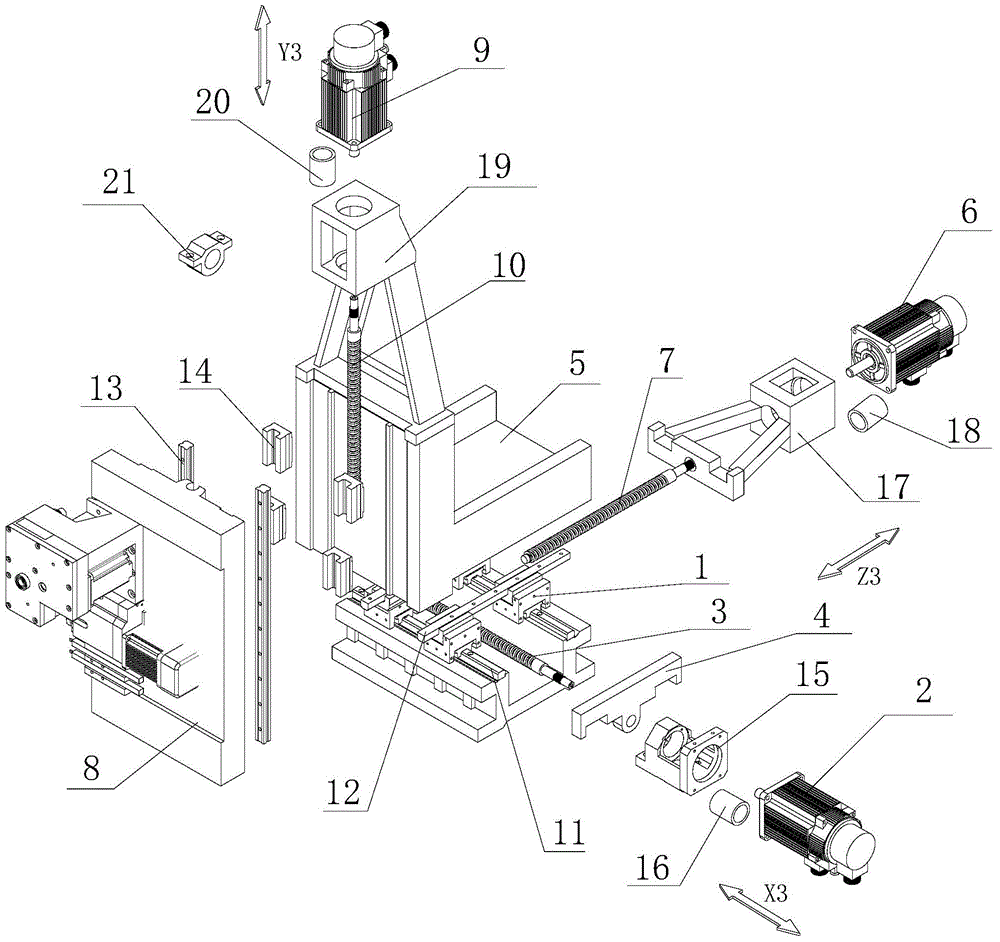

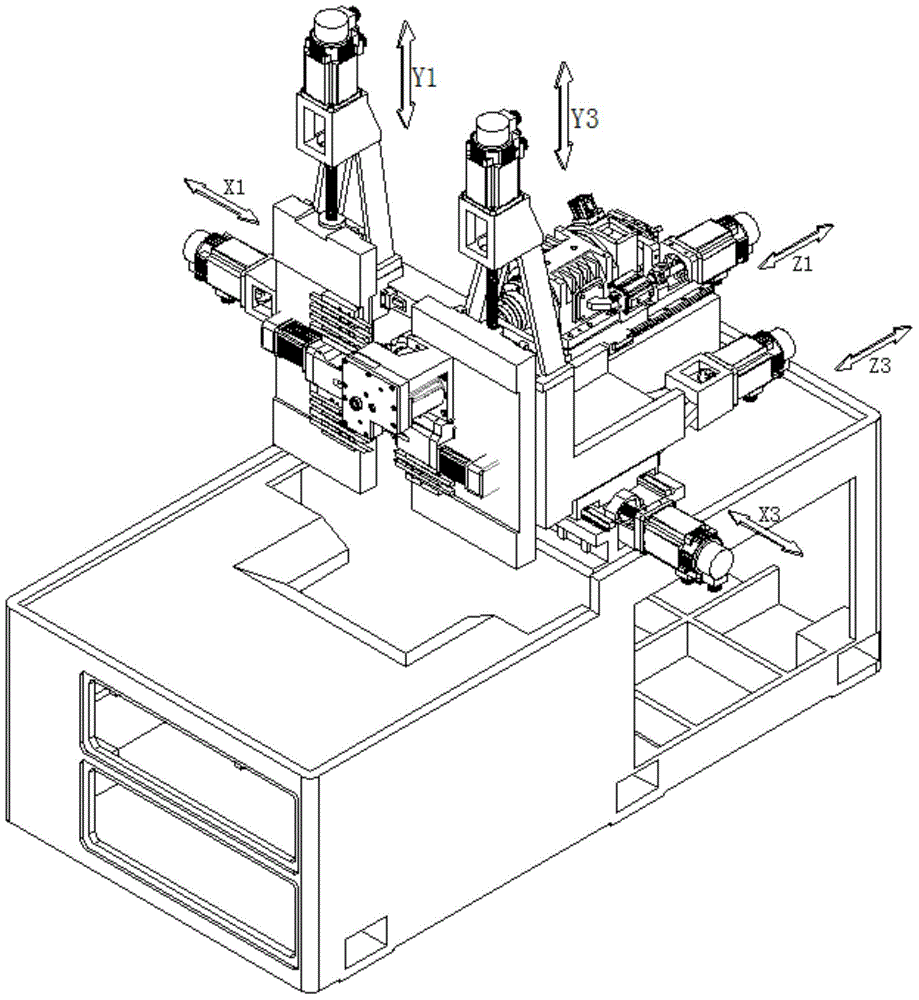

[0048] Such as Figure 1 to Figure 3 The third axis group machine for the turning-milling machine tool with cross slider includes a bed, X3 axis group, Z3 axis group and Y3 axis group arranged on the bed.

[0049] The X3 axis group includes four cross sliders 1 with an integrated structure, X3 axis motor 2, X3 axis screw rod 3, X3 axis coupling 16, two parallel X3 axis rails 11, X3 axis motor seat 15 and X3 axle seat 21. The X3 axis rail 11 is arranged on the bed, the cross slider 1 is arranged on the X3 axis rail 11, two cross sliders 1 are arranged on each X3 axis rail 11, and the bottom of the cross slider 1 is connected to the The X3 axis rail 11 constitutes a sliding pair, and the X3 axis motor base 15 is arranged on the bed (the X3 axis motor base 15 is fixed on the bed by bolts, and can also be integrally manufactured with the bed when manufacturing the bed). A sliding seat 4 is fixed on the cross slider 1 located on the same X3 axis rail 11, and the X3 axis nut is ar...

Embodiment 2

[0057] This embodiment is similar to Embodiment 1, the difference is that the tool mounting seat 8 is a turret, the tool is installed on the turret, and the tool is changed by using the 360-degree rotation of the turret. Other structures are the same as in Embodiment 1, and can be compared for specific implementation. Example 1, which will not be described too much here. At this time, the turret rotates 360°, and the tools at each station of the turret can be changed flexibly to realize the processing of the workpiece. This assembly structure not only saves space, but also can be installed on the turret. Increase the variety and quantity of cutting tools, power heads, etc. to a certain extent, and the disc design is conducive to chip removal when the tool is processing parts, and to a greater extent strengthens the rigidity of the tool when processing parts. Such a structure increases the practical operability of the machine tool and also increases the processing performance o...

Embodiment 3

[0059] Compared with Embodiment 1 in this embodiment, the tool mount 8 is composed of a Y3-axis slide plate and a turret mounted on the Y3-axis slide plate, and the Y3-axis slide plate is slidably mounted on the second Z3-axis slide plate. The Y3-axis screw rod 10 is threadedly connected with the Y3-axis slide plate. Compared with Embodiment 1, this embodiment is that a turret is installed on the Y3-axis slide plate, and a tool is installed on the turret. The rest of the structure is the same as Embodiment 1, and will not be repeated here. At this time, the turret rotates 360°, and the tools at each station of the turret can be changed flexibly to realize the processing of the workpiece. This assembly structure saves space. Not only can various original standard tools be installed on the turret, but Increase the variety and quantity of cutting tools, power heads, etc. to a certain extent, and the disc design is conducive to chip removal when the tool is processing parts, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com