Third axis set mechanism matched with positive shaft of numerical control center-passing type lathe

A shaft group, positive shaft technology, applied in metal processing machinery parts, other manufacturing equipment/tools, large fixed members, etc., can solve the problem of inability to realize complex parts, achieve high production efficiency, realize processing and forming, and easy to install. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

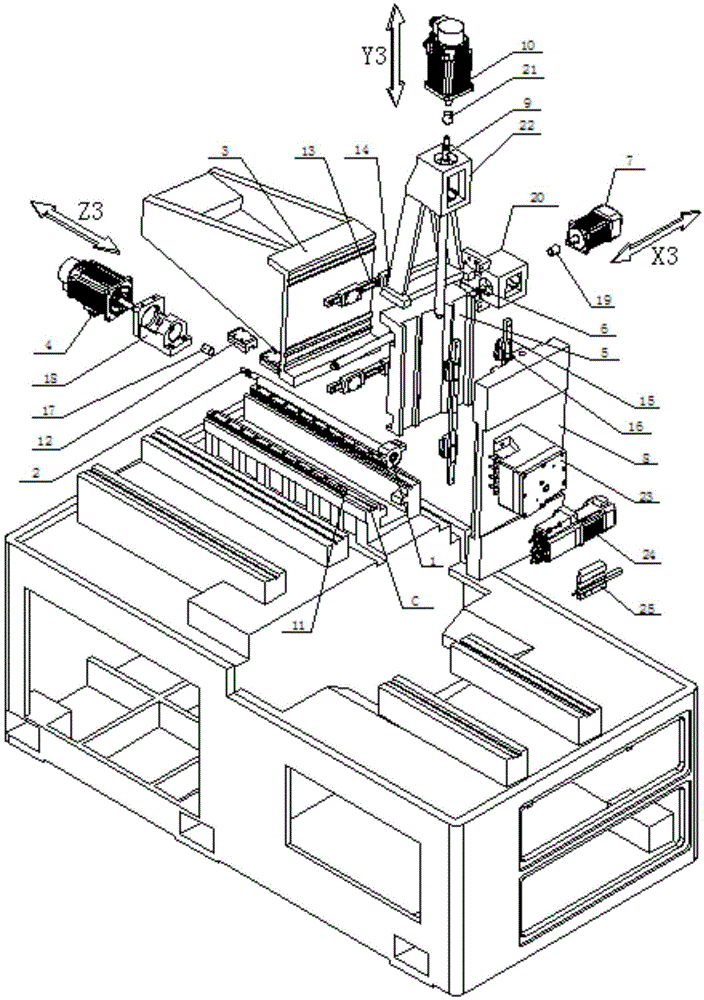

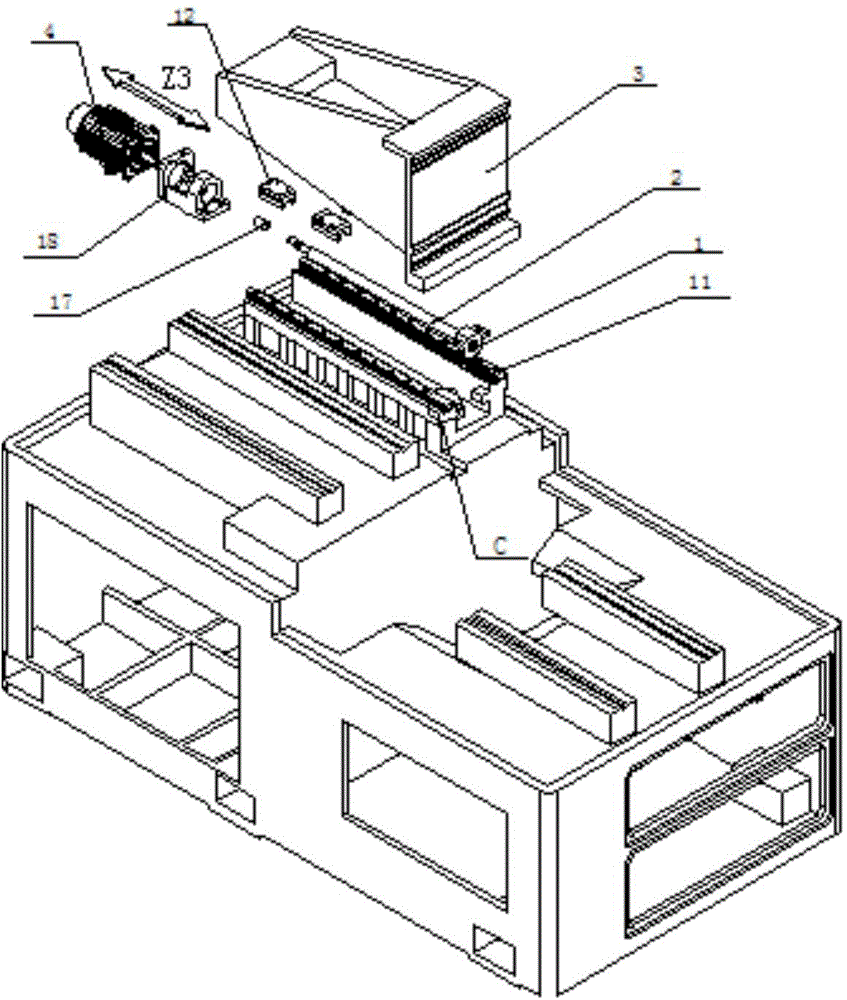

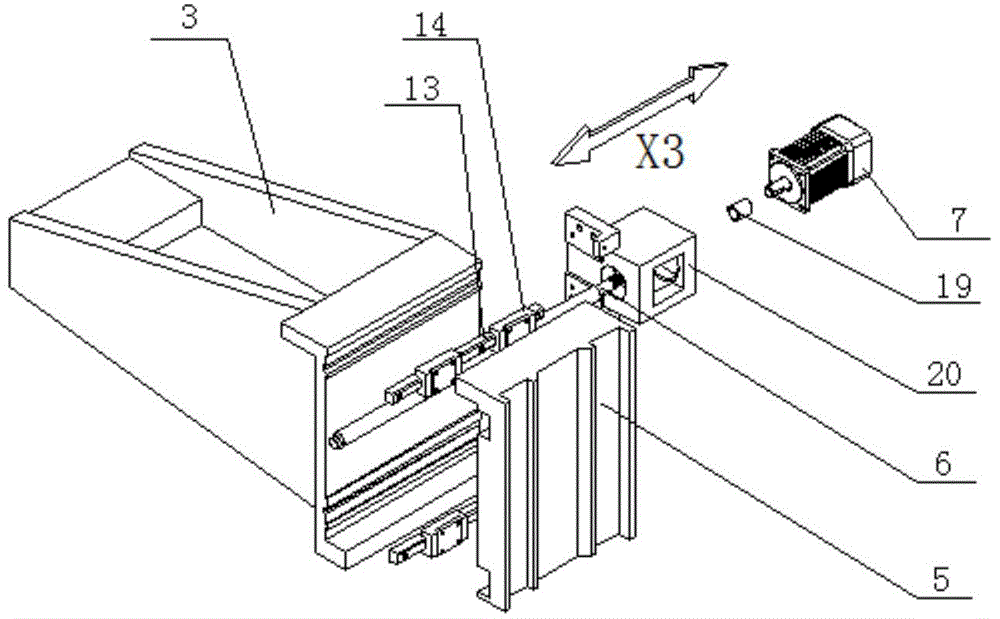

[0035] see Figure 1 to Figure 4 , The third shaft group mechanism of the present invention is composed of three major parts: Z3 shaft group, Y3 shaft group, and X3 shaft group.

[0036] The Z3-axis group includes a Z3-axis rail, a Z3-axis slider, a Z3-axis seat, a Z3-axis slide plate, a Z3-axis servo motor, a Z3-axis motor seat, and a Z3-axis coupling. The Z3 axis rail is used to be installed at C of the machine bed, and the Z3 axis slider matched with the Z3 axis rail is installed at the bottom of the Z3 axis slide plate, and the Z3 axis slide plate is slidably installed on the on the machine tool. On the bed of the machine tool where the Z3 shaft seat is fixed, bearings are installed in it, nuts are installed at the bottom of the Z3 axis slide plate, and the Z3 axis motor seat is also fixed on the machine bed for installing the Z3 axis servo motor, which also has bearings inside. The Z3 axis screw rod passes through the nut, one end is installed in the bearing located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com