Five-shaft structural turn milling machine tool

A shaft structure and machine tool technology, which is applied in the direction of metal processing machinery parts, other manufacturing equipment/tools, large fixed members, etc., can solve the problems that affect the forming efficiency of workpieces, and the forming time of tools and workpieces is not well optimized, so as to achieve forming Effects of time optimization, resistance avoidance, and self-improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

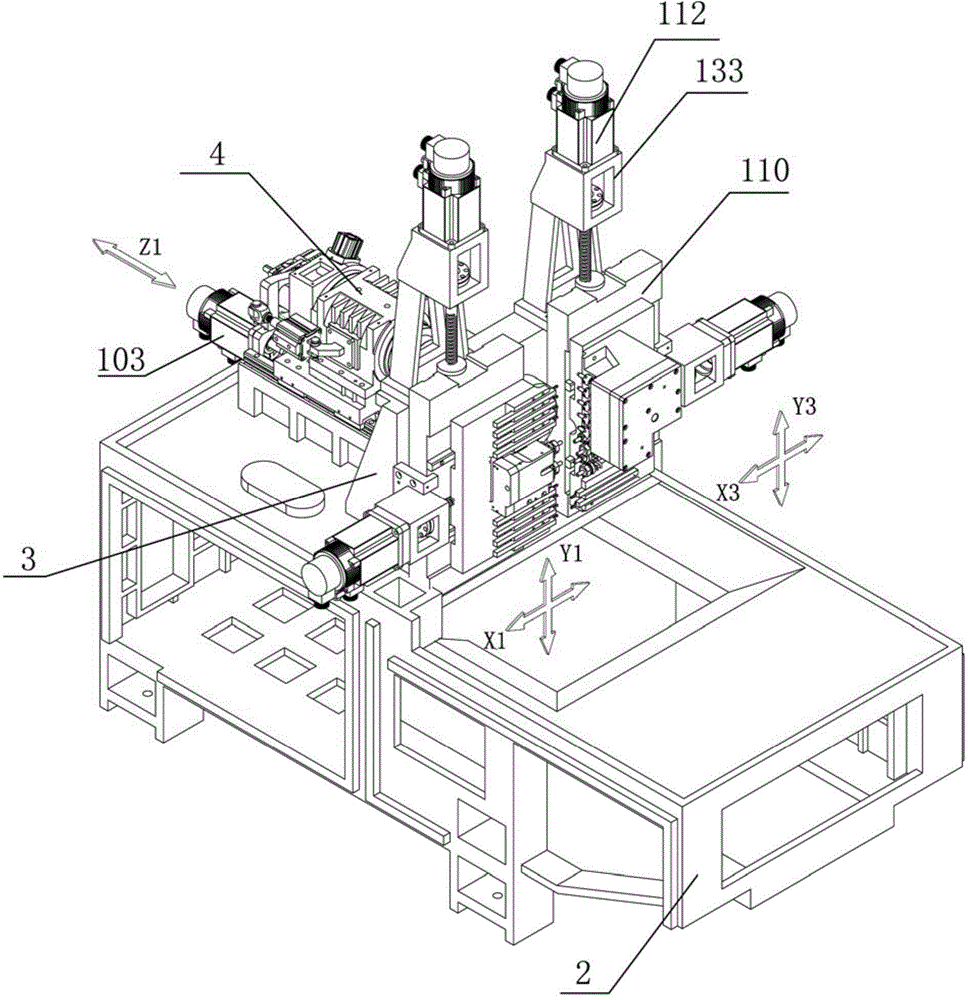

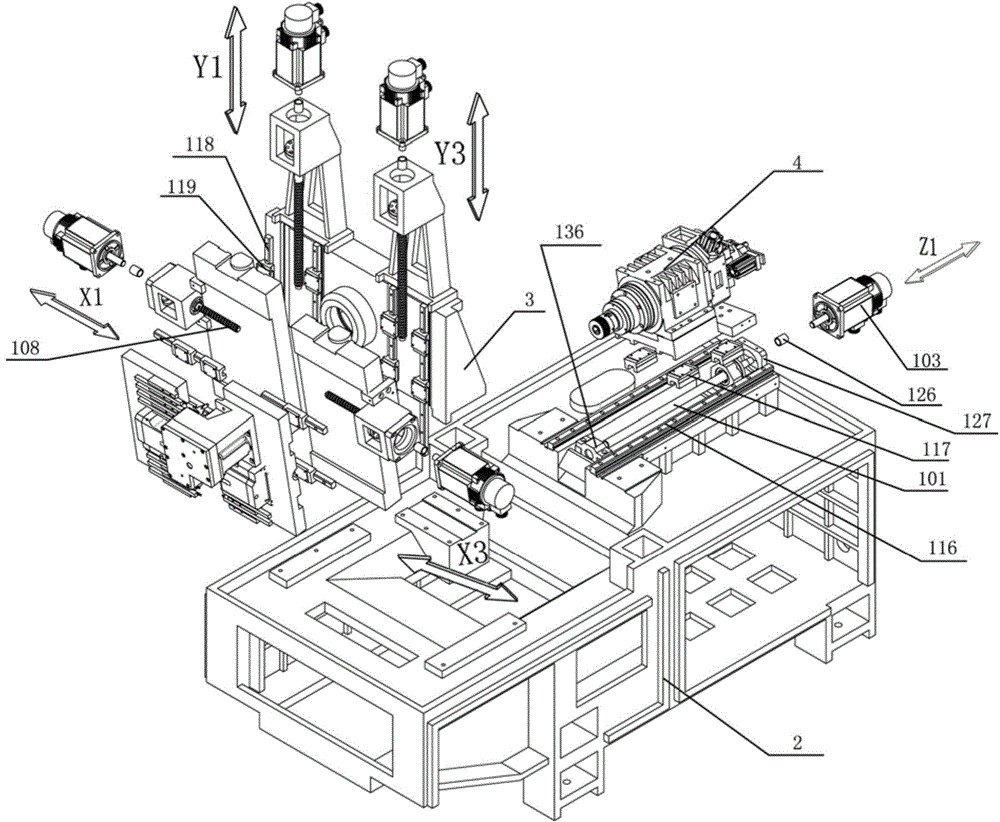

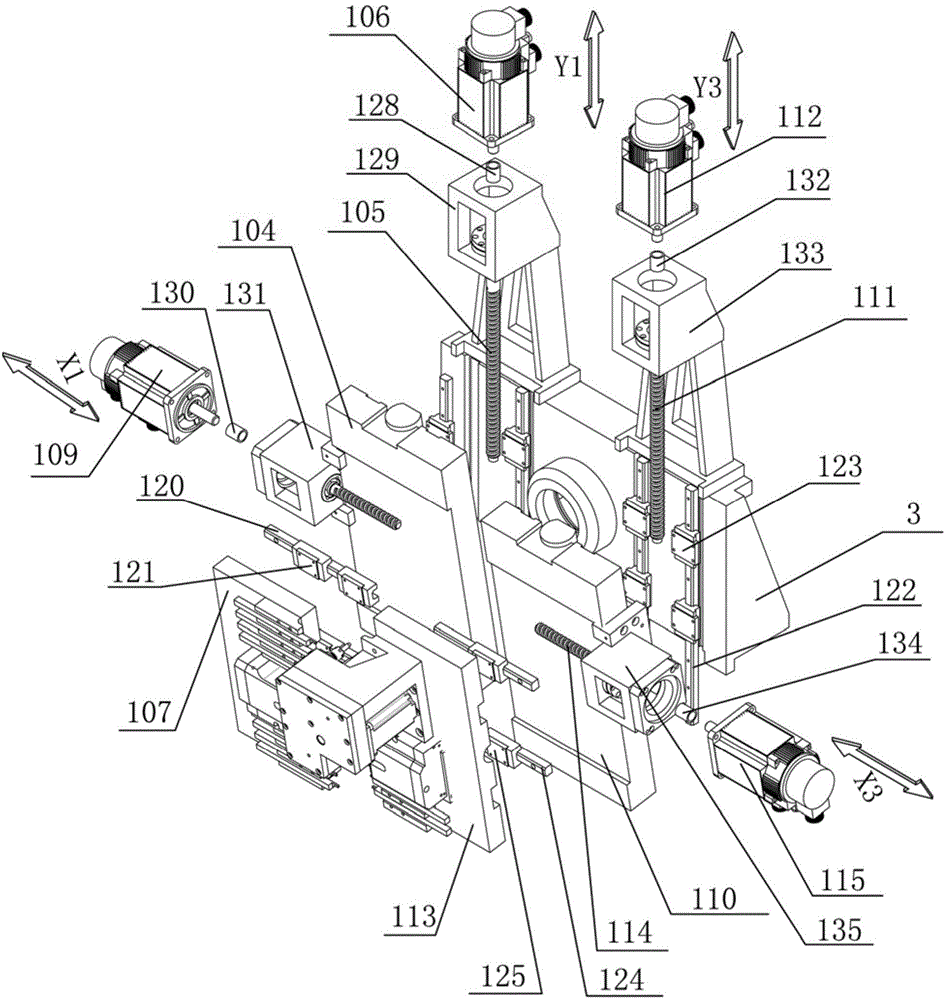

[0050] Such as Figure 1 to Figure 3 The center turning and milling machine tool shown has a five-axis structure on the positive axis, including a bed 2 and a column 3 set on the bed 2, which consists of an X1 axis group, a Y1 axis group, a Z1 axis group, a Y3 axis group, and an X3 axis group. Positive axis group of axis groups. There is a through hole on the column, and a guide sleeve structure or no guide sleeve structure is set in the through hole. The guide sleeve structure and the no guide sleeve structure in this application are both prior art, and are commonly used parts in this field. , not detailed here. The central column of the present invention can be fixed on the bed with bolts, and can also be integrally cast with the bed when casting the bed.

[0051] The Z1-axis group includes a Z1-axis slide plate 102 arranged on the bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com