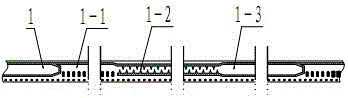

A continuous strip type drip irrigation head pressure injection molding mold

A technology of injection molding and drip irrigation head, which is applied in the field of injection molding molds, can solve the problems of easy fouling and clogging of drip irrigation heads, achieve the effect of simple structure, meet the requirements of manufacturing precision, and ensure product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

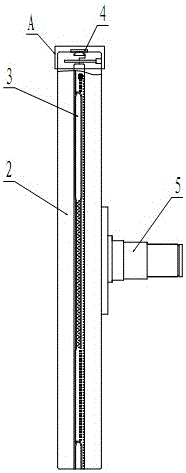

[0021] See Figure 2, image 3 , the present invention includes a rotating disk assembly 2, a mosaic annular die 3, a pressing plate 4 and a rotating shaft 5, the rotating disk assembly 2 is fixedly connected to the rotating shaft 5, and an inlay is fitted on the outer cylindrical surface of the rotating disk assembly 2 The ring-shaped die 3 is engraved with patterns matching the periodic channel structure of the continuous stick-type drip irrigation head. The curved surface is located on the outer side of the rotating disk assembly 2, and the rotating disk assembly 2, the embedded annular die 3 and the pressing plate 4 form an injection molding cavity.

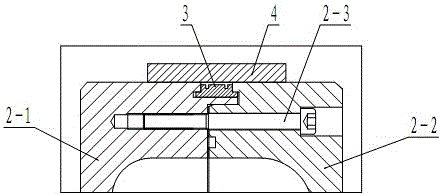

[0022] see image 3 , the rotating disk assembly 2 of the present invention includes a first rotating disk 2-1 and a second rotating disk 2-2 connected by bolts 2-3, and the first rotating disk 2-1 and the second rotating disk 2-2 are engaged An inserting structure is provided at the position, and an annular groove is formed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com