Online potting adhesive curing device for junction box of solar photovoltaic modules

A solar photovoltaic and curing device technology, applied in electrical components, semiconductor devices, circuits, etc., to achieve the effect of simple structure, space saving, and stable placement

Inactive Publication Date: 2013-04-24

SHEN ZHEN TRONY SCI & TECH DEV CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention aims at the deficiencies of the prior art and solves technical problems such as how to solidify the potting glue in the solar photovoltaic module junction box on-line on the automatic production line, so as to improve production efficiency and reduce energy consumption

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

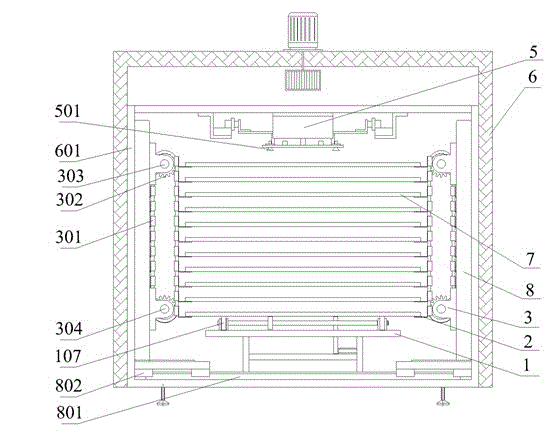

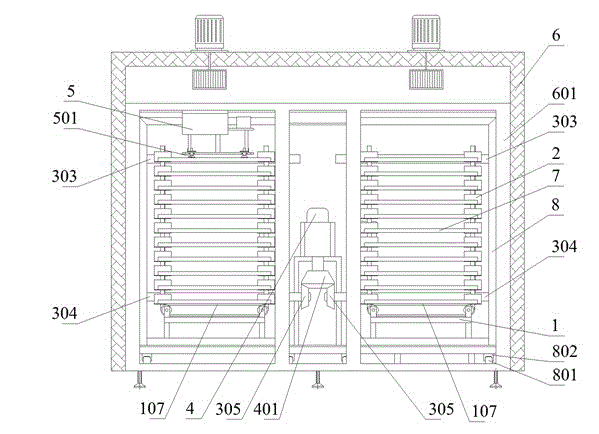

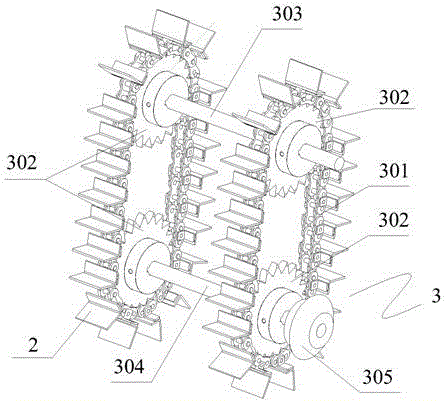

The invention discloses an online potting adhesive curing device for a junction box for solar photovoltaic modules and belongs to the technical field of solar photovoltaic equipment. For solving the technical problem of how to carry out online curing on a potting adhesive in the junction box for the solar photovoltaic modules on an automatic production line, and the like, the invention designs a curing device which is characterized in that a continuous vertical lifting mechanism is provided with a plurality of movable platforms for placing solar photovoltaic modules, a horizontal transmissionmechanism is arranged below the lifting mechanism, a sucking disc mechanism is arranged above the lifting mechanism, a photovoltaic module adhered with a junction box is transmitted to the platform of the lifting mechanism by the horizontal transmission mechanism, and then the potting adhesive in the junction box for the photovoltaic modules is subjected to online curing performed by a heating wind-blowing system. The curing device disclosed by the invention can transmit the photovoltaic modules while curing the potting adhesive in the junction box, which both ensures the curing time and saves space, thereby really realizing the continuous automatic production and improving the production efficiency.

Description

technical field [0001] The invention relates to a curing device, in particular to an on-line continuous curing device for solar photovoltaic module junction boxes after glue filling, and belongs to the technical field of solar photovoltaic equipment. Background technique [0002] In the production process of solar photovoltaic modules, in order to avoid the conductive metal components in the junction box (such as battery lead wires, metal solder joints connected to the lead wires, conductive sheets and conductive terminals, etc.) exposed to the air to produce surface oxidation and rust, which will affect the conduction Performance, generally in the solar photovoltaic module junction box will be filled with insulating gel filler (such as two-component silica gel, butyl rubber, etc.), to cover the conductive metal components in the junction box, thereby isolating these conductive metals The contact between the components and the air, most of the current glue filling devices a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L31/18

Inventor 李毅尹林东苏奇聪李伟

Owner SHEN ZHEN TRONY SCI & TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com