The jigsaw machine with jigsaw fasteners circularly pushing the lifting mechanism

A lifting mechanism and fastener technology, which is applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve the problems of wasting human resources, increasing space occupation, unfavorable equipment installation and popularization and application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

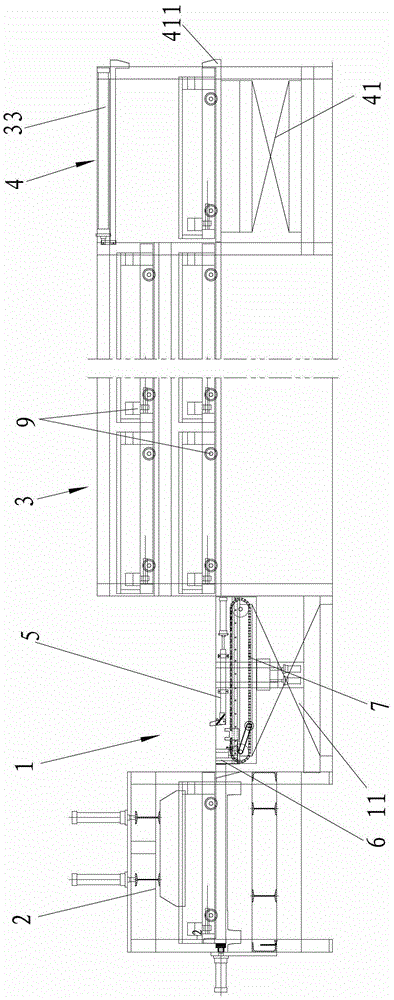

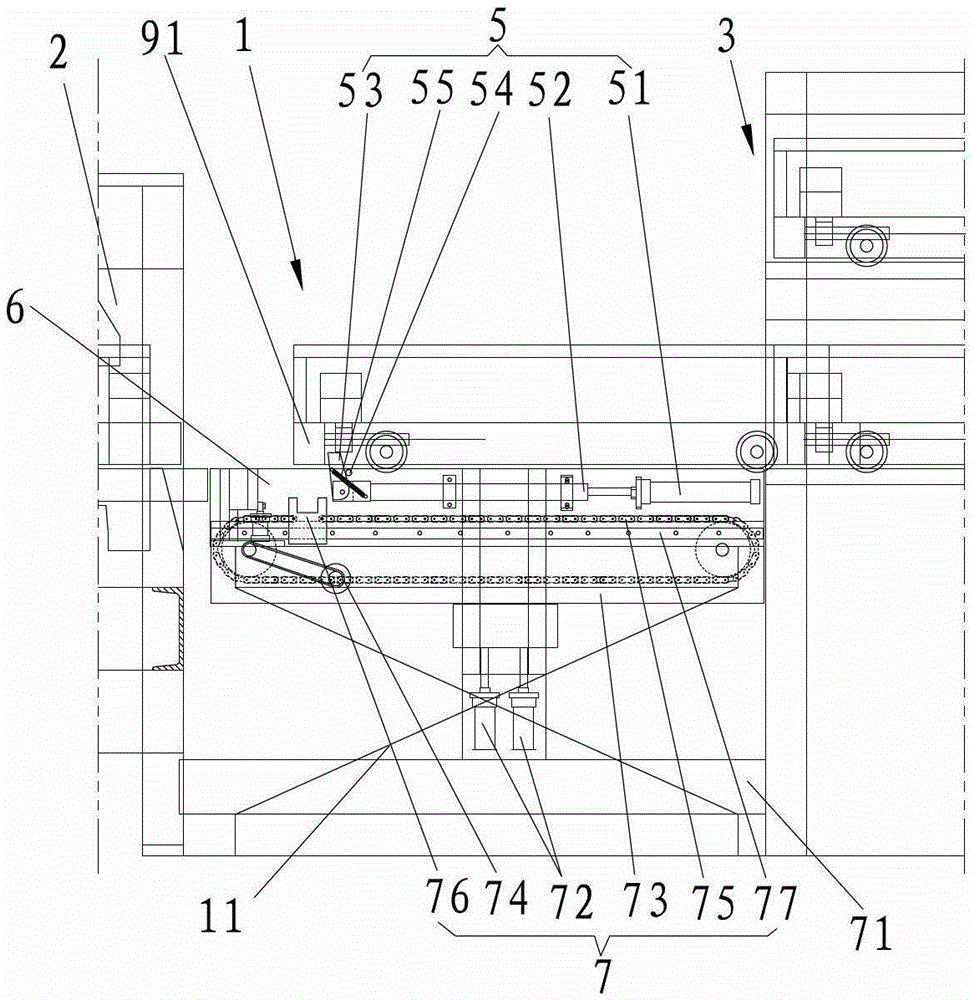

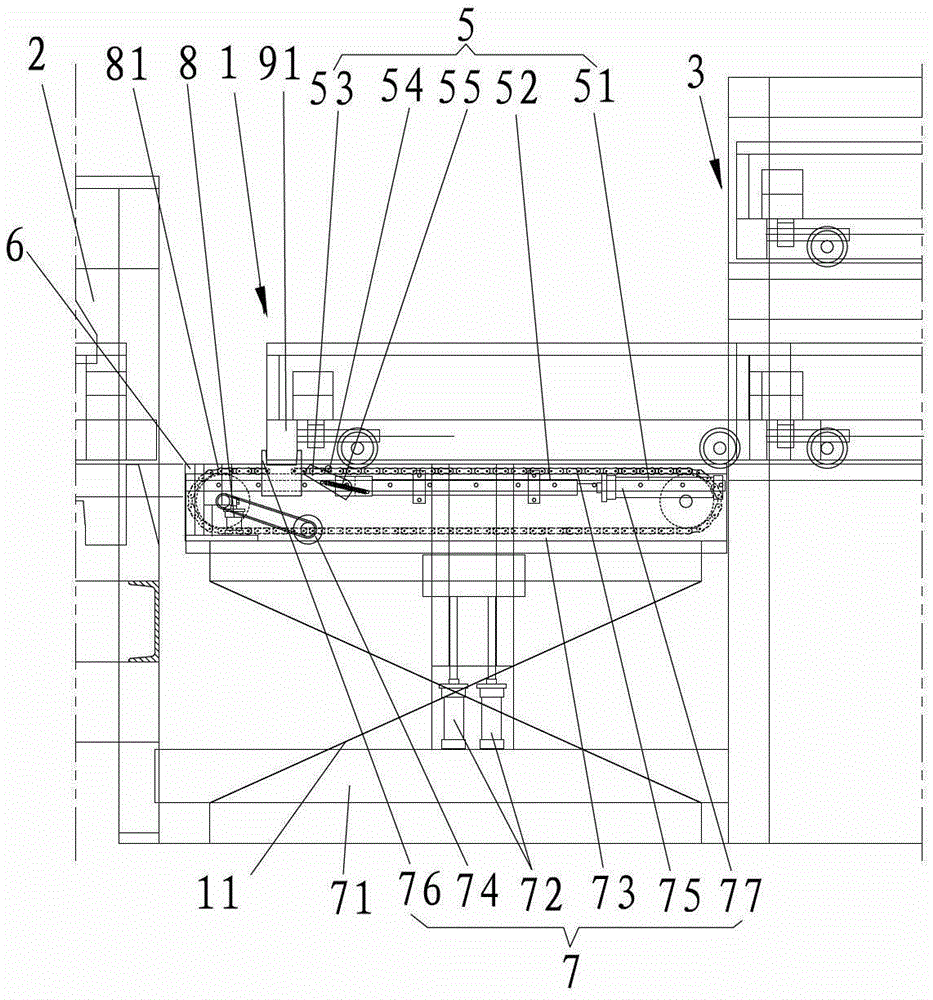

[0018] Attached below Figure 1-6 And embodiment, the present invention is further elaborated:

[0019] In the jigsaw machine provided with the jigsaw fasteners of the present invention, the lifting mechanism is cyclically pushed, and the jigsaw fastener fastening workbench 2 is set on one side of the jigsaw lifting mechanism 1, and the other side of the jigsaw lifting mechanism 1 is set on the other side. The jigsaw fastener solidifying material platform 3; the solidifying material platform 3 is a double-layer circulating material platform, and the circulation promotion lifting mechanism 1 includes a lifting material platform 11 that lifts between the two material platforms of the double-layer circulating material platform, and the lifting material platform 11 is an industrial hydraulic cylinder lifting mechanism, which is a common industrial component that is easy to purchase, and will not be elaborated too much. The end of the double-layer circulating material table is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com