Motor stator construction and manufacturing method thereof

A technology for motor stators and manufacturing methods, which is applied in the field of motors and can solve the problems of affecting the working efficiency of the stator structure, the inability to guarantee stable working performance, and the cumbersome assembly process of the motor stator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

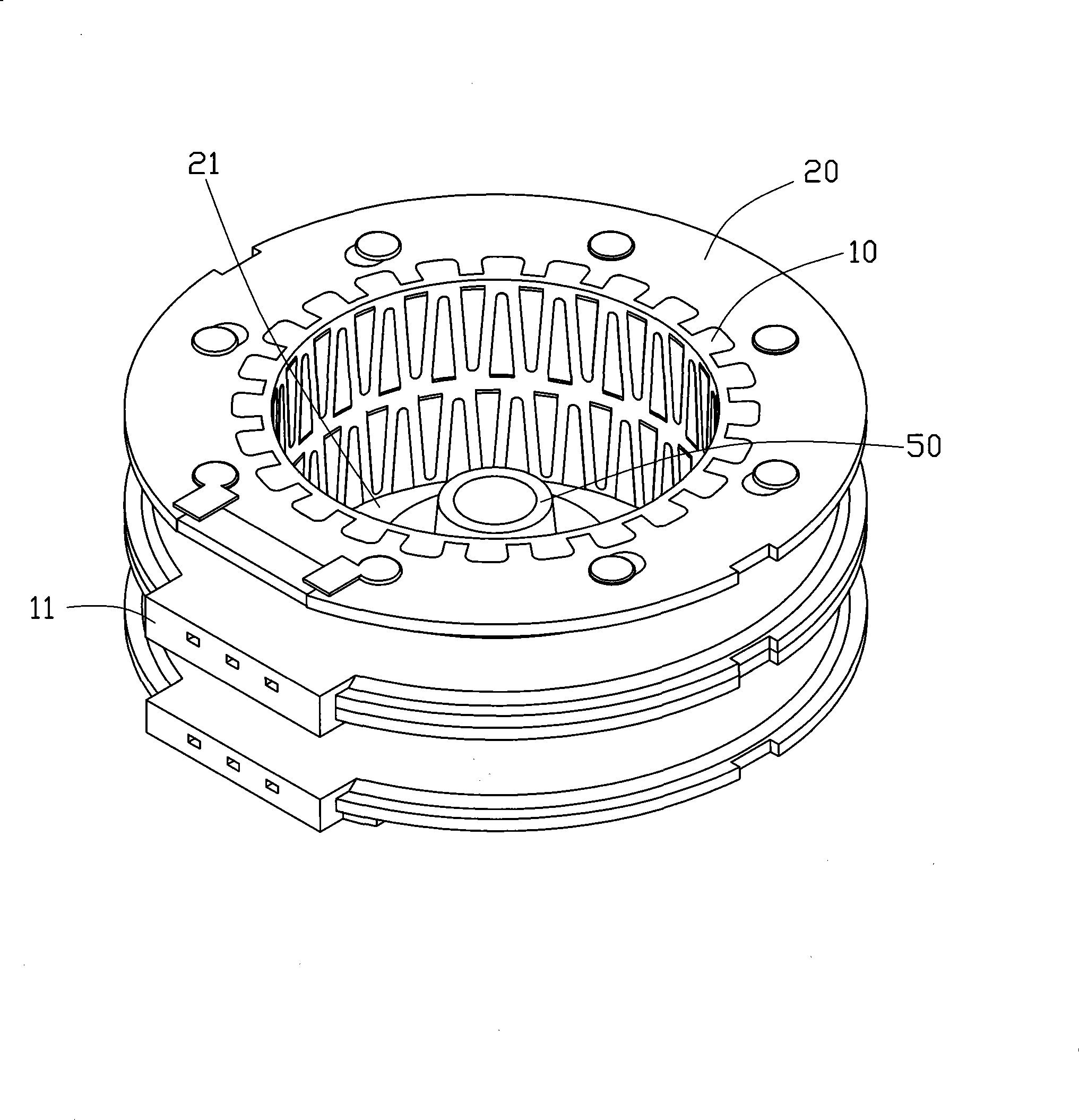

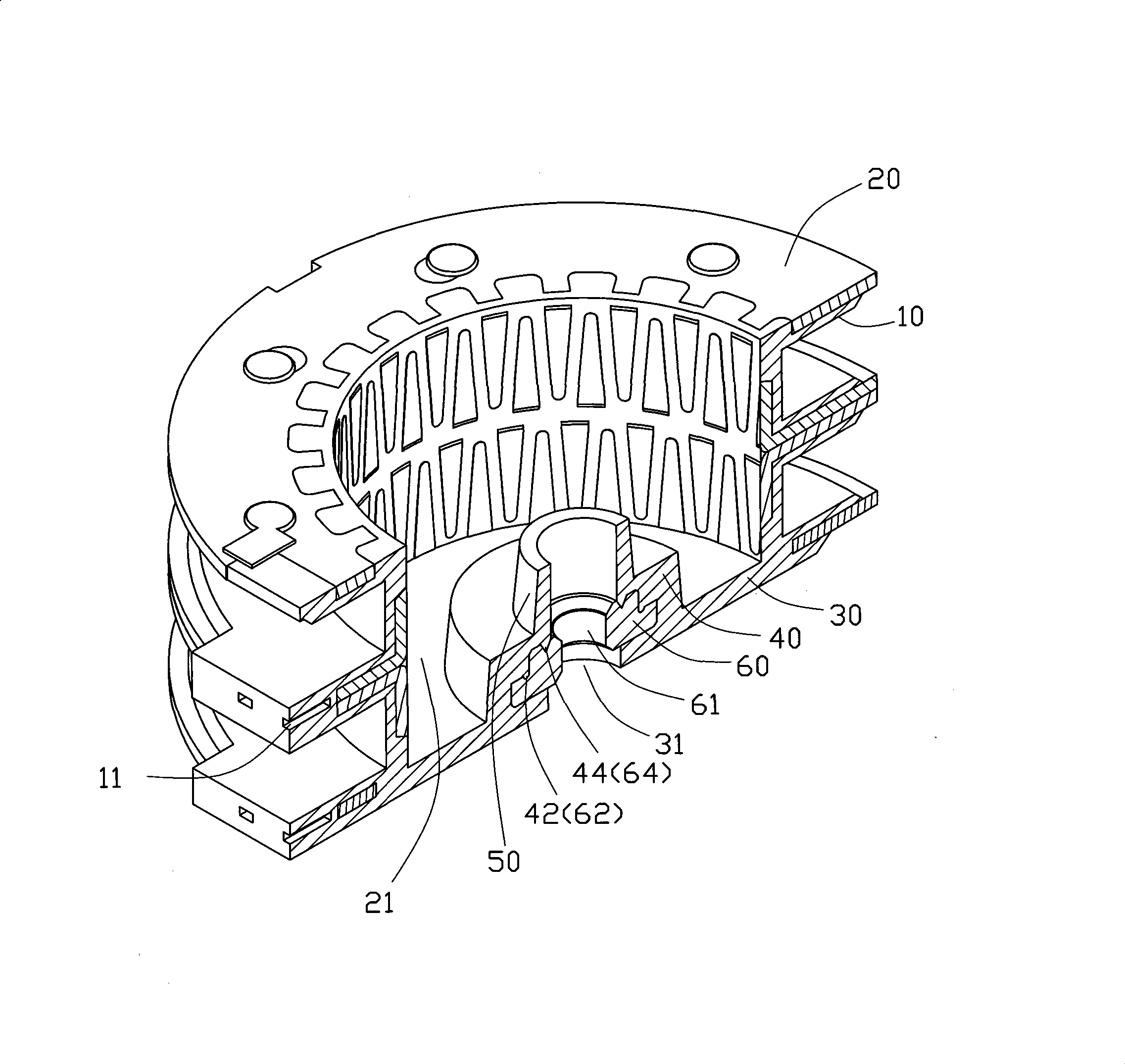

[0013] see figure 1 and figure 2 , the motor stator structure includes four pole claw elements 20 , sleeve bearings 60 and a fixing structure 10 for fixing pole claw elements 20 and sleeve bearings 60 .

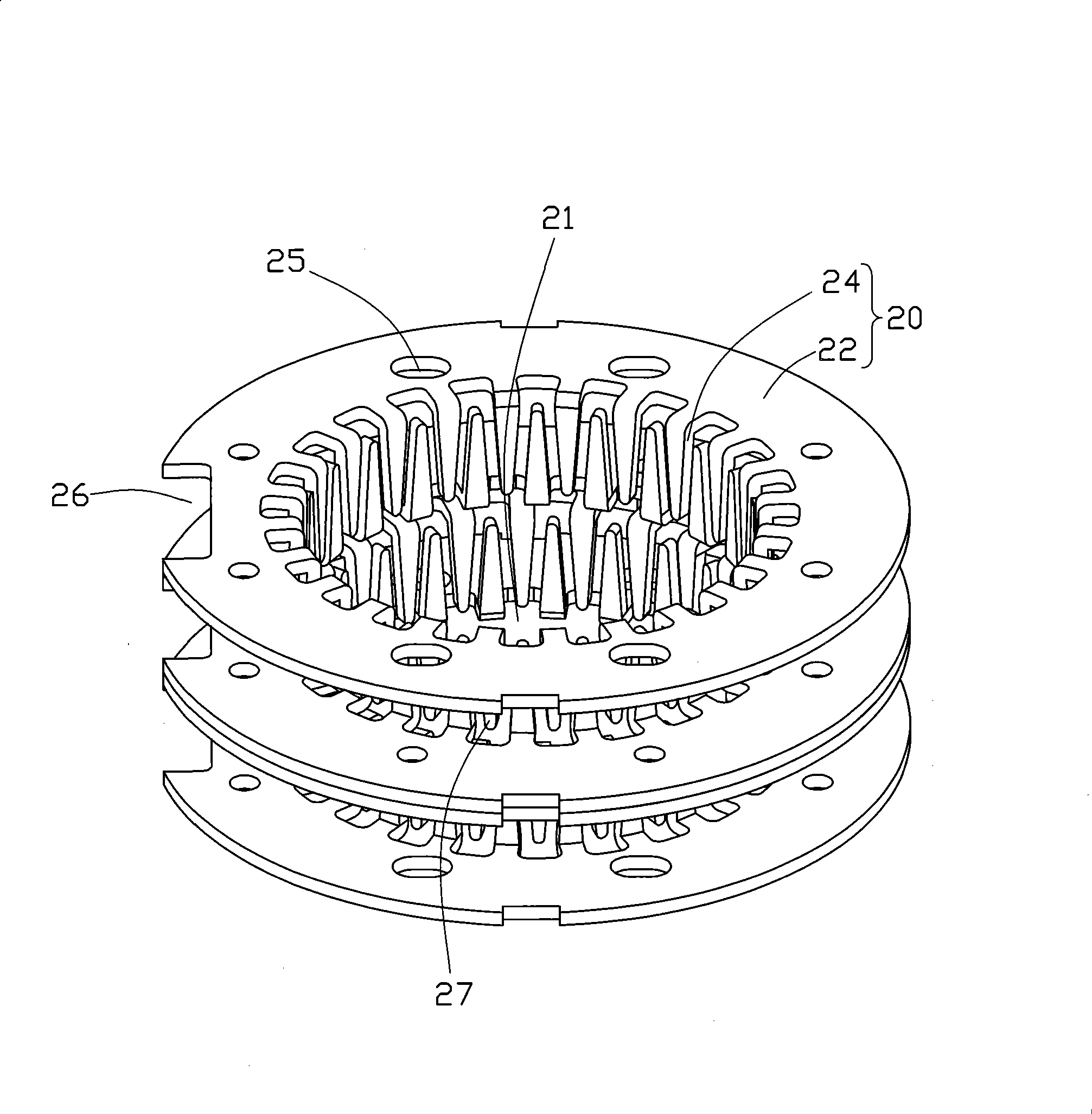

[0014] Please also refer to image 3 , the structure of the four pole claw elements 20 is the same, all including an annular sheet 22, a circular hole (not marked) is formed in the center of the annular sheet 22, extending perpendicular to the annular sheet 22 from the inner circumference of the annular sheet 22 Several pole claws 24 are formed, and these pole claws 24 are spaced from each other and arranged equidistantly. A plurality of small through holes 25 of different sizes are also provided on the annular sheet 22 , and a square notch 26 is provided at the outer circumference of the annular sheet 22 .

[0015] Every two pole claw elements 20 constitute a group of pole claw elements, and the two pole claw elements 20 of each group of pole claw elements are all arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com