Drill bushing used for high-precision drilling and convenient for chip removal

A high-precision, drill sleeve technology, which is applied in the field of process equipment and drill sleeves in the drilling process, can solve the problems of tool jamming and low tool rotation accuracy, and achieve the effects of easy chip removal, small clearance, and guaranteed straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

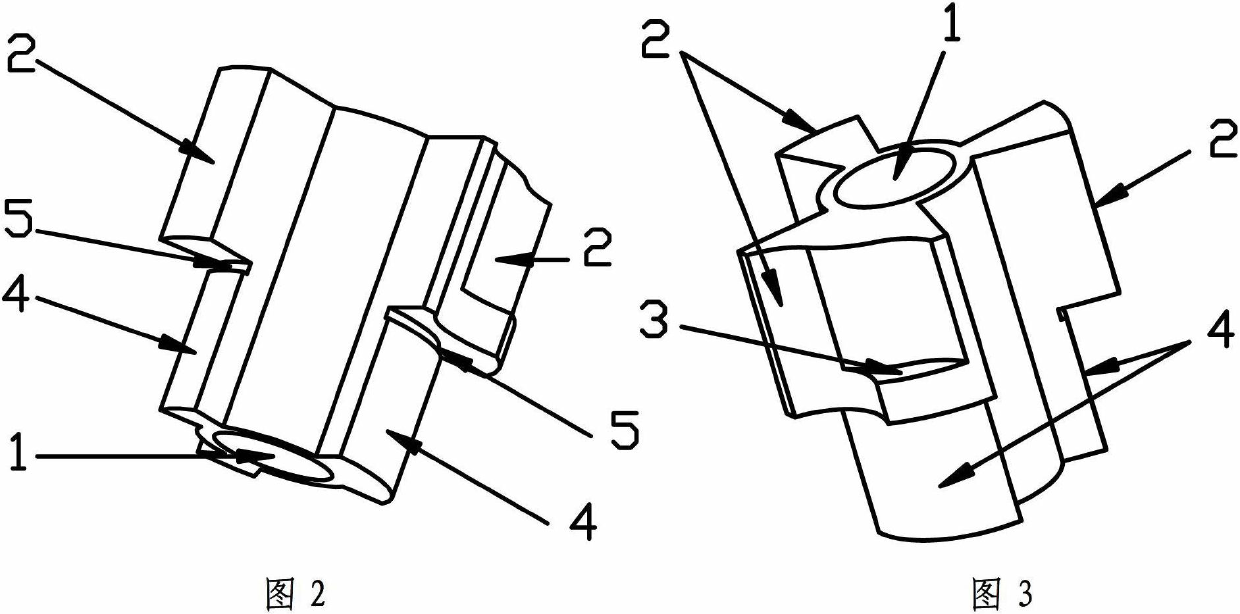

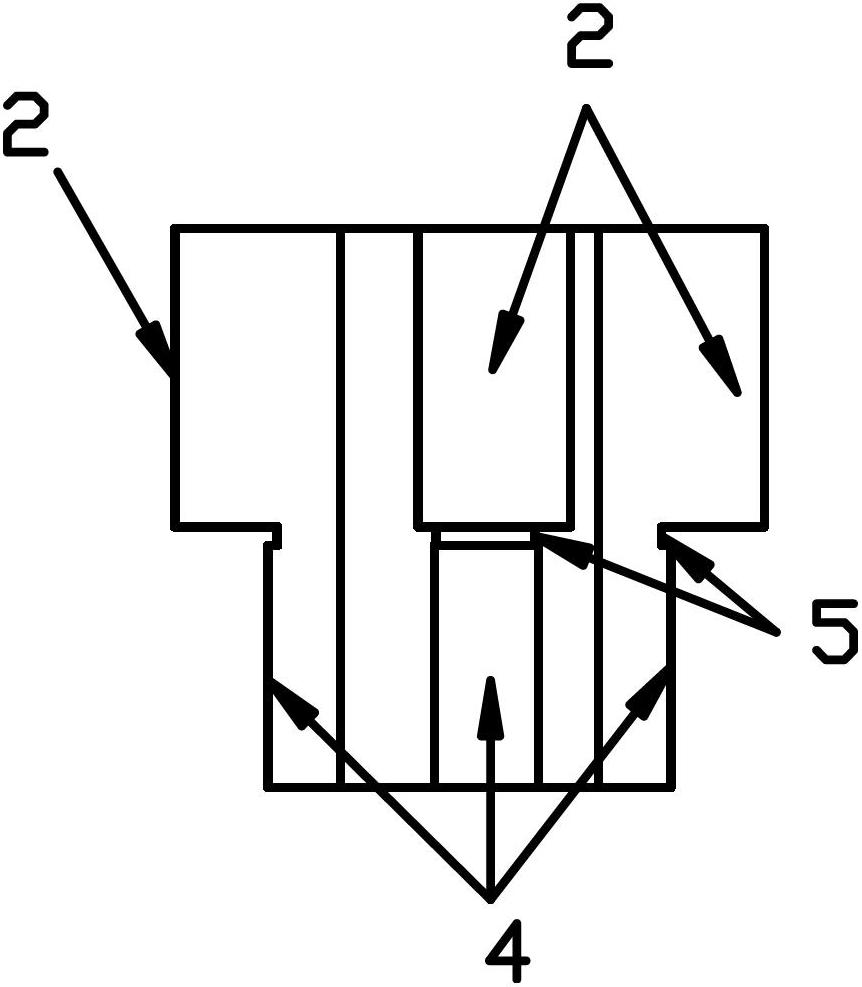

[0023] refer to figure 2 , image 3 , Figure 4 , the invention is a drill sleeve for high-precision drilling which is convenient for chip removal. It is an ordinary cylindrical piece with a drill sleeve through hole 1 in its center, and three fan-shaped grooves with different angles are cut out along the circumferential direction by processing methods, leaving one large and two small, namely three-lobed wedges. The wedge-shaped body is composed of a drill sleeve top 2 with a large rectangular cross section, a drill sleeve bottom 4 with a small rectangular cross-section and an annular groove 5 arranged between the two; at the bottom of the drill sleeve top of the large wedge-shaped body A stepped surface 3 is provided for fixing the drill sleeve. Its basic shape feature is that three fan-shaped grooves with different angles are cut by wire cutting method along the axial direction on the common drill sleeve. The specific shape feature is that a drill sleeve through hole 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com