Rotary body surface concave-convex array structure double-rotation-speed rotary printing electrolysis system and method

A technology with uneven surface and array structure, which is applied in the direction of electrochemical processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of long tool cathode manufacturing cycle and cumbersome manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]The specific embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

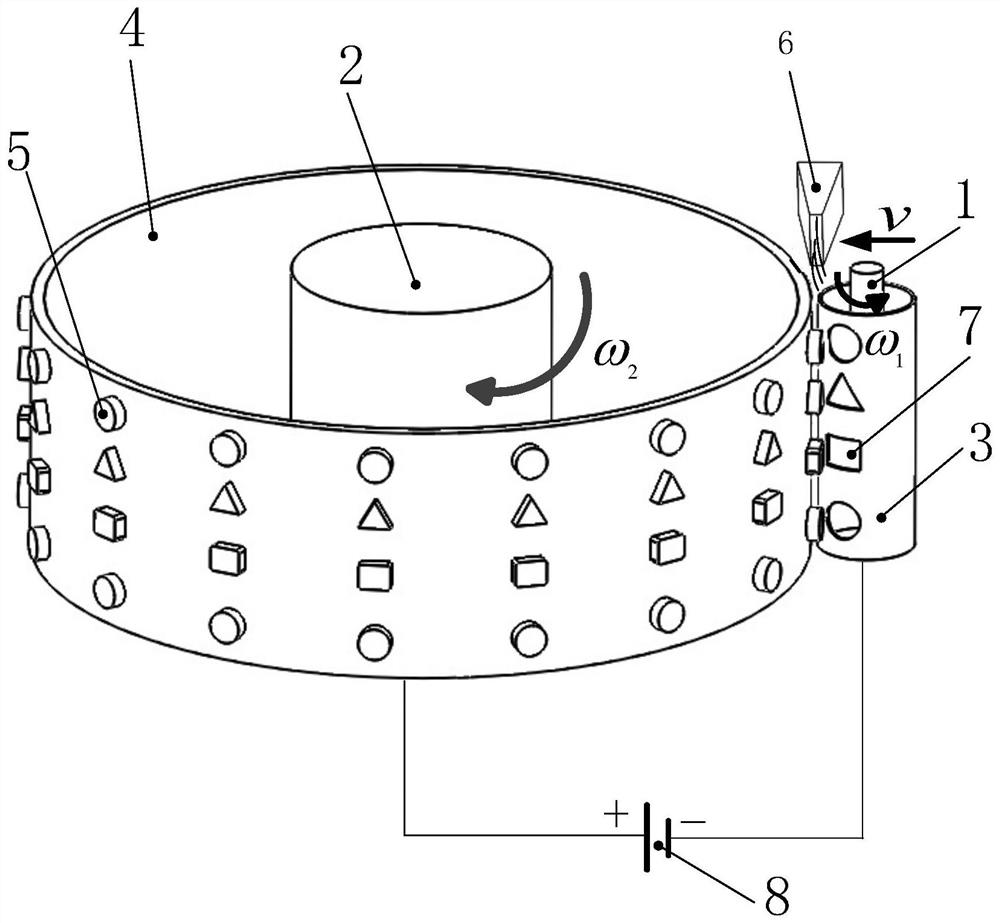

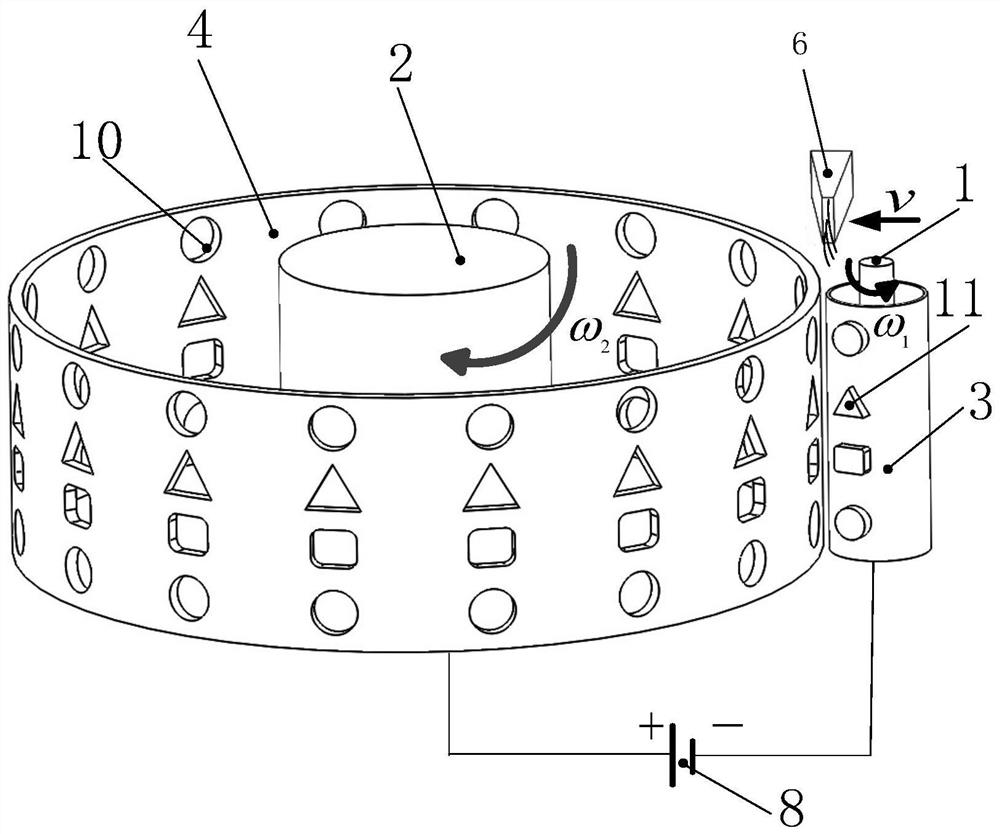

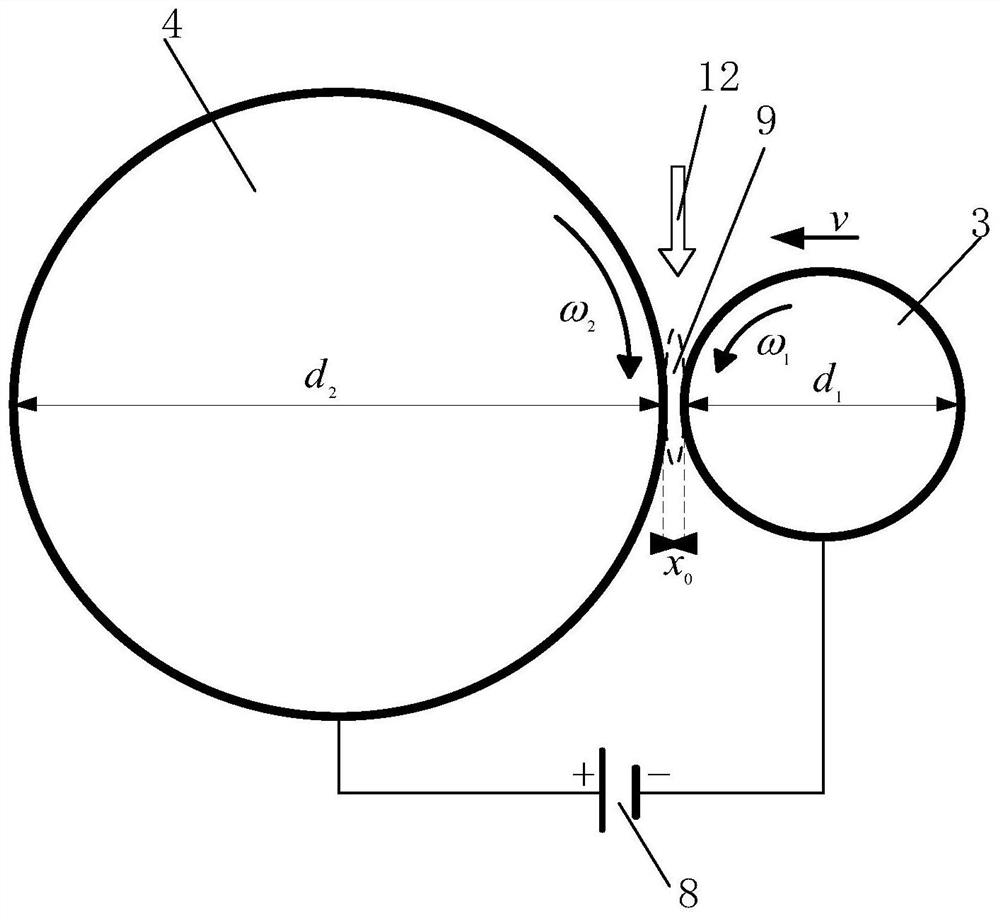

[0019]figure 1 A three-dimensional model of a multiplier rotary electrolytic processing array boss, which mainly includes: a first shaft 1 for realizing the feed electrode 3 feed and rotation, a second shaft 2 that rotates the rotation of the rotary body workpiece 4, the tool electrode 3, rotary body workpiece 4, supply liquid nozzle 6, power supply 8. The tool electrode 3 used is a rigid rotary body electrode having an electrode array recessed cavity 7. The tool electrode 3 is mounted on the first shaft 1 and rotates and feeds together; the rotary body workpiece 4 is mounted on the second shaft 2, and it is rotatable with it.

[0020]During the machining process, the rotary body workpiece 4 is powered on the power supply 8 positive electrode as the anode, and the tool electrode 3 is powered on the power supply 8 negative electrode as the cathode. The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com