Buddha-bead forming drilling machine

A drilling machine and Buddha beads technology, applied in the field of machine tools, can solve the problems of difficult and complicated drilling operations, and achieve the effect of simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

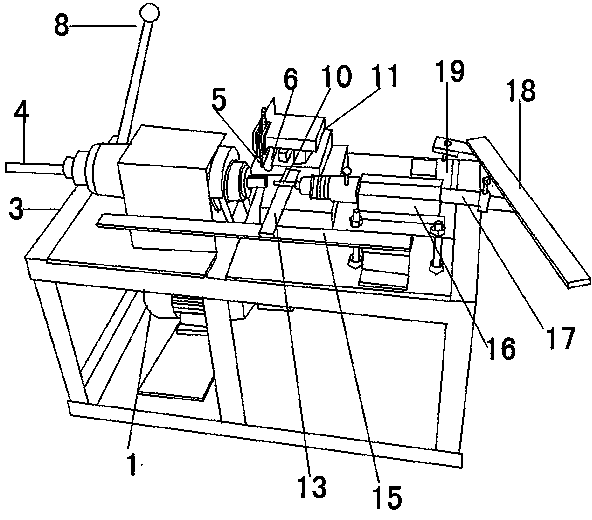

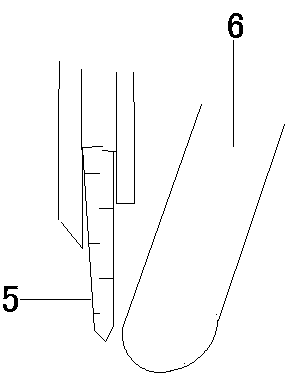

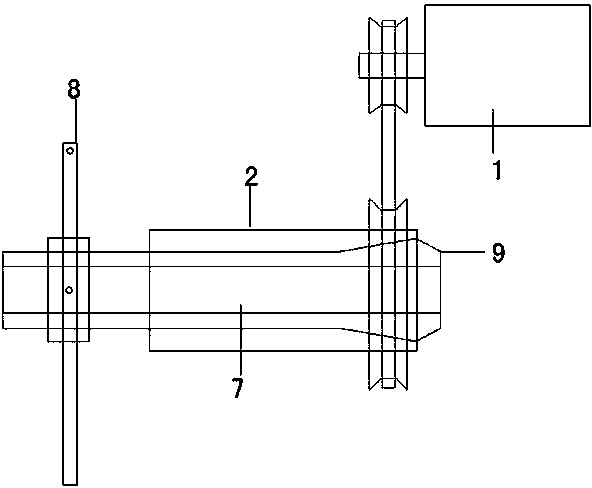

[0016] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a motor 1, the motor 1 is connected to the clutch structure on the frame 3, the wood 4 passes through the clutch structure, and the frame 3 is also respectively equipped with a drilling device for drilling the wood 4 and a cutting machine that can move back and forth. Knife 5 and forming knife 6. The clutch structure includes a power shaft 2, the motor 1 drives the power shaft 2 through a belt, the power shaft 2 is placed on the frame 3, a locking device 7 is installed inside the power shaft 2, and a handle A8 is installed on the left side of the locking device 7 , there is a perforation through which the wood material 4 passes inside, the right end is connected with the chuck 9, and the right side of the power shaft 2 is a tapered structure suitable for the chuck 9. The drill bit 10 of the drilling device is at the center of the wood material 4, the cutting knife 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com