Double-channel tube electrode and electrolytic cutting method thereof

A cutting method and dual-flow technology, which are used in processing electrodes, electrode manufacturing, electric processing equipment, etc., can solve the problems of difficult electrolyte renewal and difficult discharge of electrolysis products, and achieve enhanced flow performance, reduced electrolytic processing area, and improved electrolysis. The effect of cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

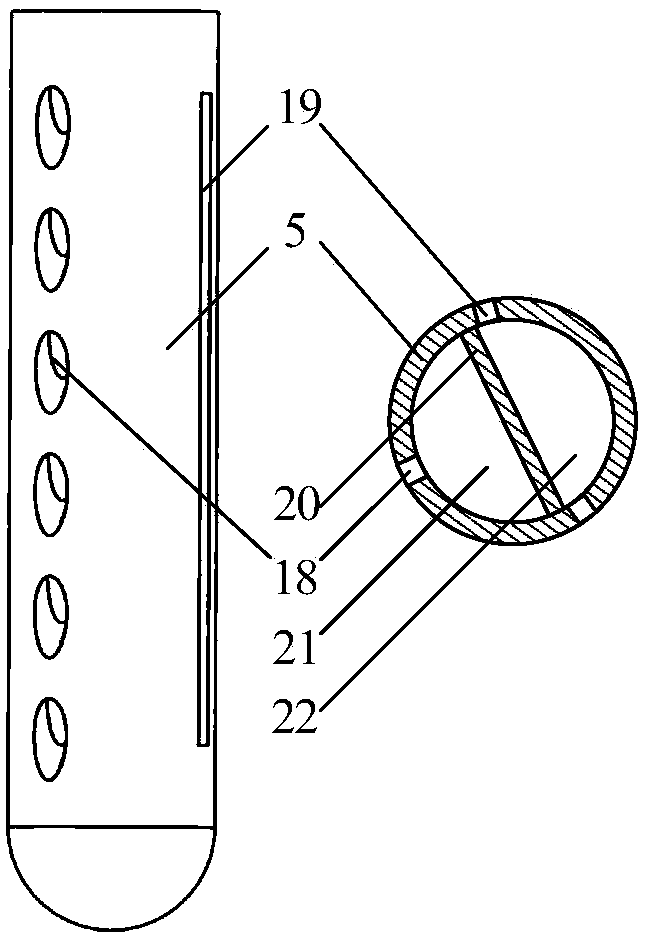

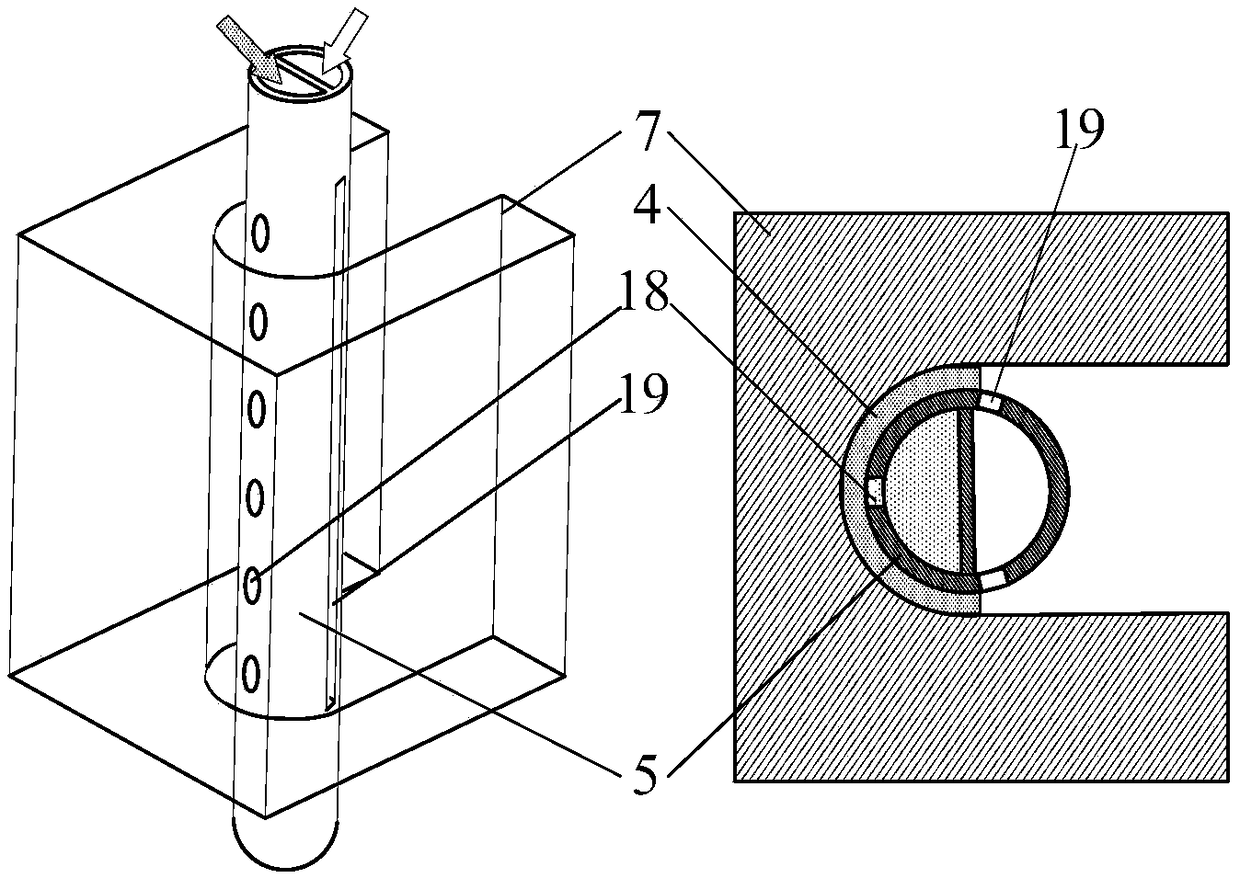

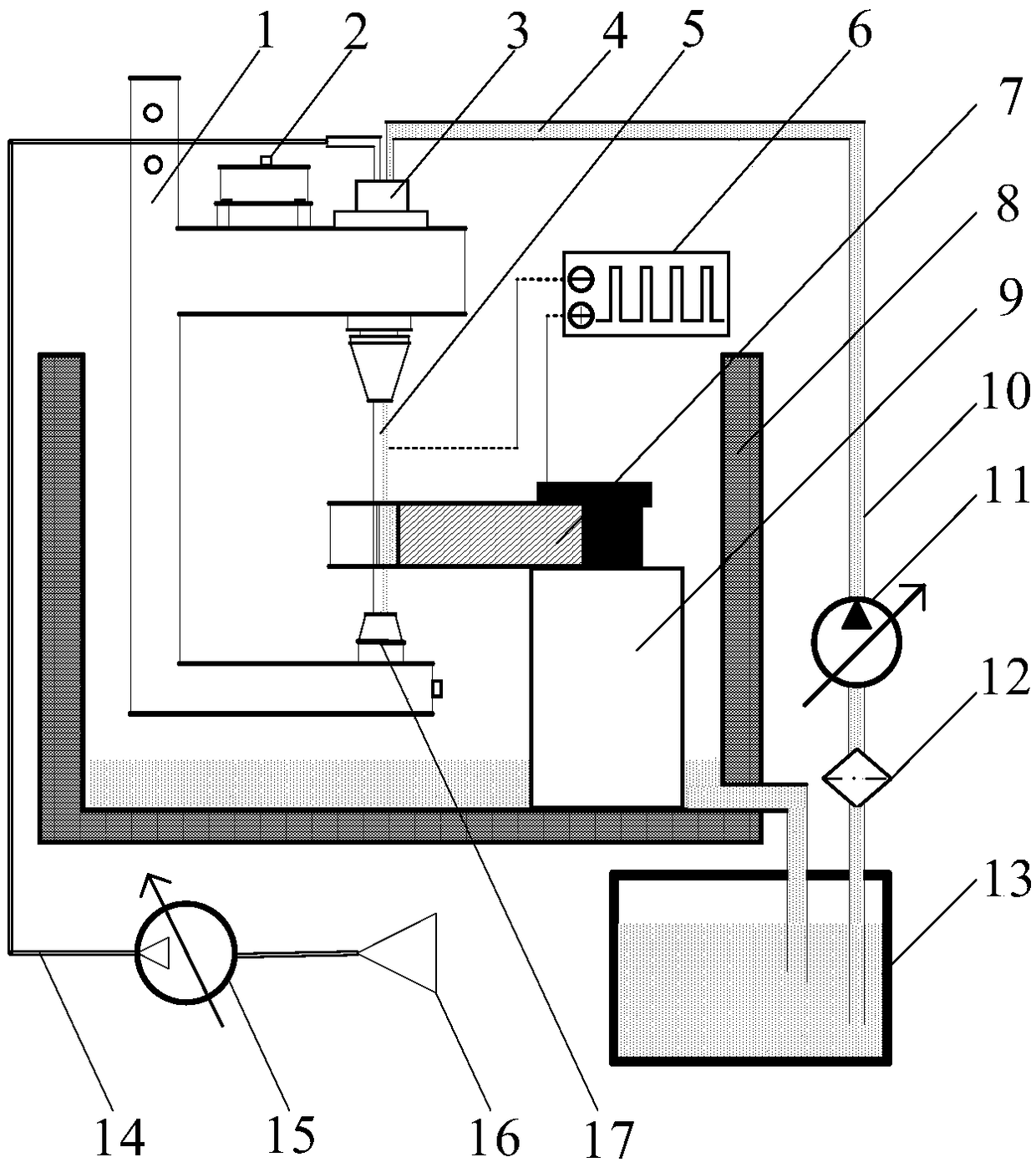

[0023] according to figure 1 As shown, a kind of double-channel tube electrode 5 proposed by the present invention is a metal circular tube with a closed lower end, and a separator 20 is arranged in the axial direction of the tube to separate the inner cavity of the circular tube into two parts: an infusion flow channel 21 and a flow channel 22; On the outer wall surface of the infusion flow channel 21, the thickness direction of the wall surface is from the inside to the outside, and an array of small holes 18 is inclined downward. In the thickness direction of the workpiece 7, the distribution range of the array small holes 18 is not less than the processing gap range; Two rows of micro-long slits 19 are provided on the outer wall surface, and the two rows of micro-long slits 19 are respectively located at the edge positions close to the outer wall surface and the partition 20, and the length of the micro-long slits 19 is greater than the thickness of the workpiece 7.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com